Variable valve lift follower for vehicle

A valve lift, variable technology, applied in the direction of engine components, engine control, machine/engine, etc., can solve the problems of increasing the inertial mass of valve movement and affecting the dynamic performance of valve mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Next, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

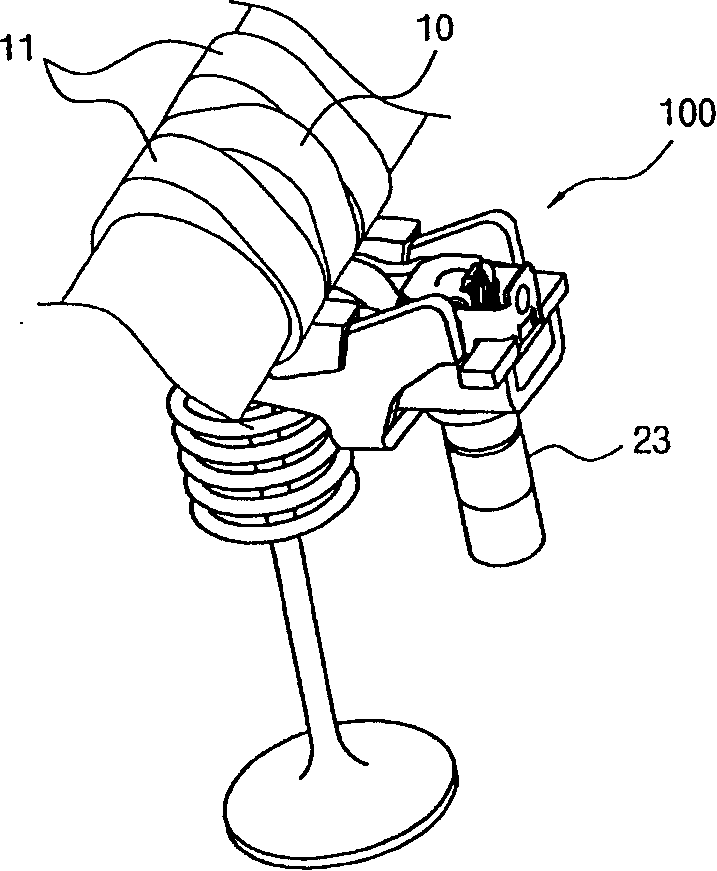

[0020] In some embodiments, the variable valve lift follower includes three cams for each valve, and the opening amount of the valve is controlled by the rotational force of the cam device according to the engine state. A middle-low lift cam 10 and two high-lift cams 11 are arranged in a row.

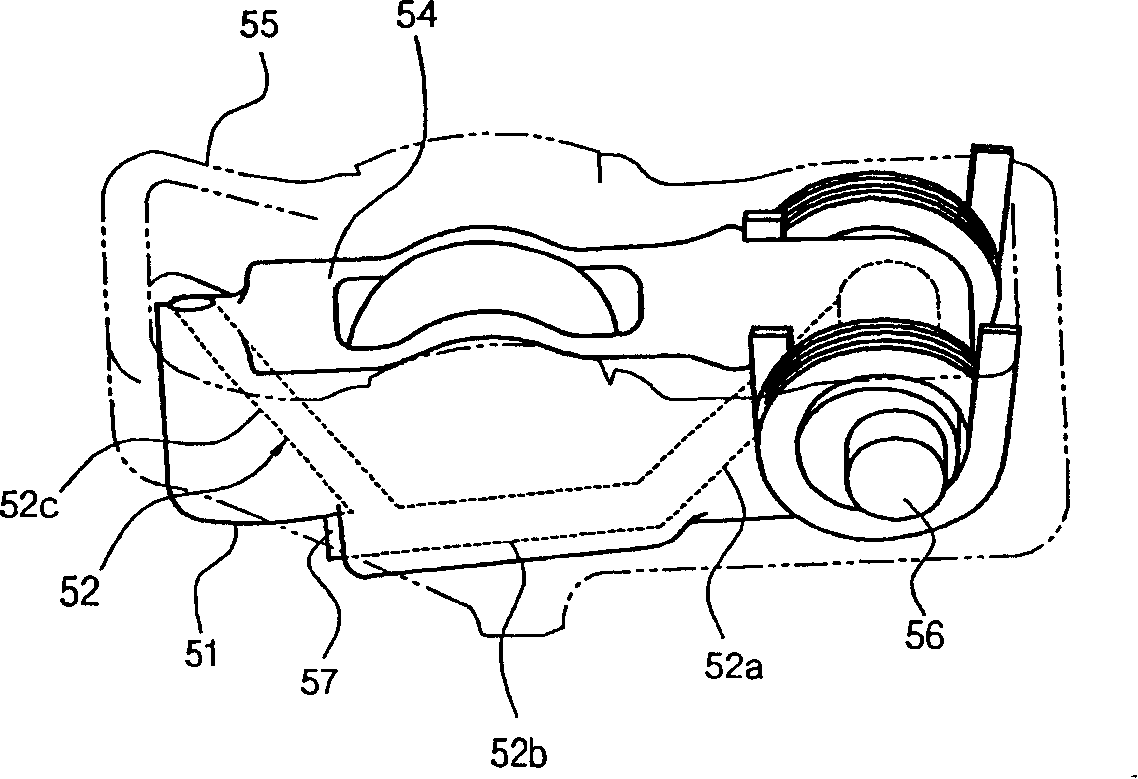

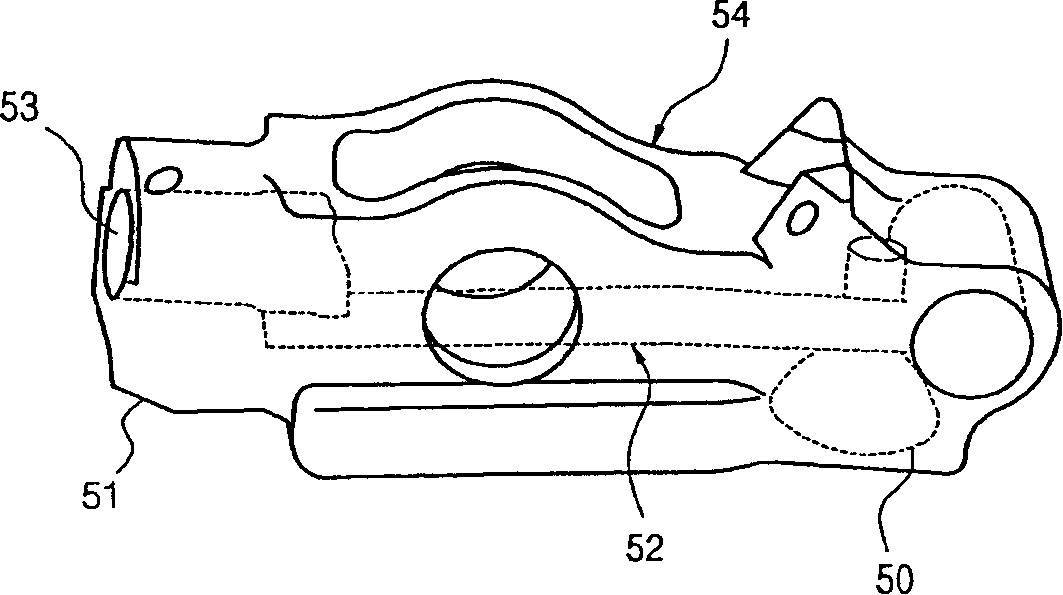

[0021] The ejector pin formed on the top of the valve contact portion 51 arranged opposite to the HLA 23 moves in the longitudinal direction to connect the inner body 54 and the outer body 55 to each other, thereby generating a high lift there.

[0022] The HLA contact portion 50 for supplying oil to the inner body 54 is arranged at the bottom of one side of the inner body 54 , the valve contact portion 51 is arranged at the bottom of the other side of the inner body 54 , and the ejector pin is arranged at the top of the valve contact portion 51 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com