Patents

Literature

140 results about "Hydraulic clearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydraulic clearance. Flow in narrow clearances are of vital importance in hydraulic system component design. The flow in a narrow circular clearance of a spool valve can be calculated according to the formula below if the height is negligible compared to the width of the clearance, such as most of the clearances in hydraulic pumps, hydraulic motors, and spool valves. Flow is considered to be laminar. The formula below is valid for a spool valve when the spool is steady.

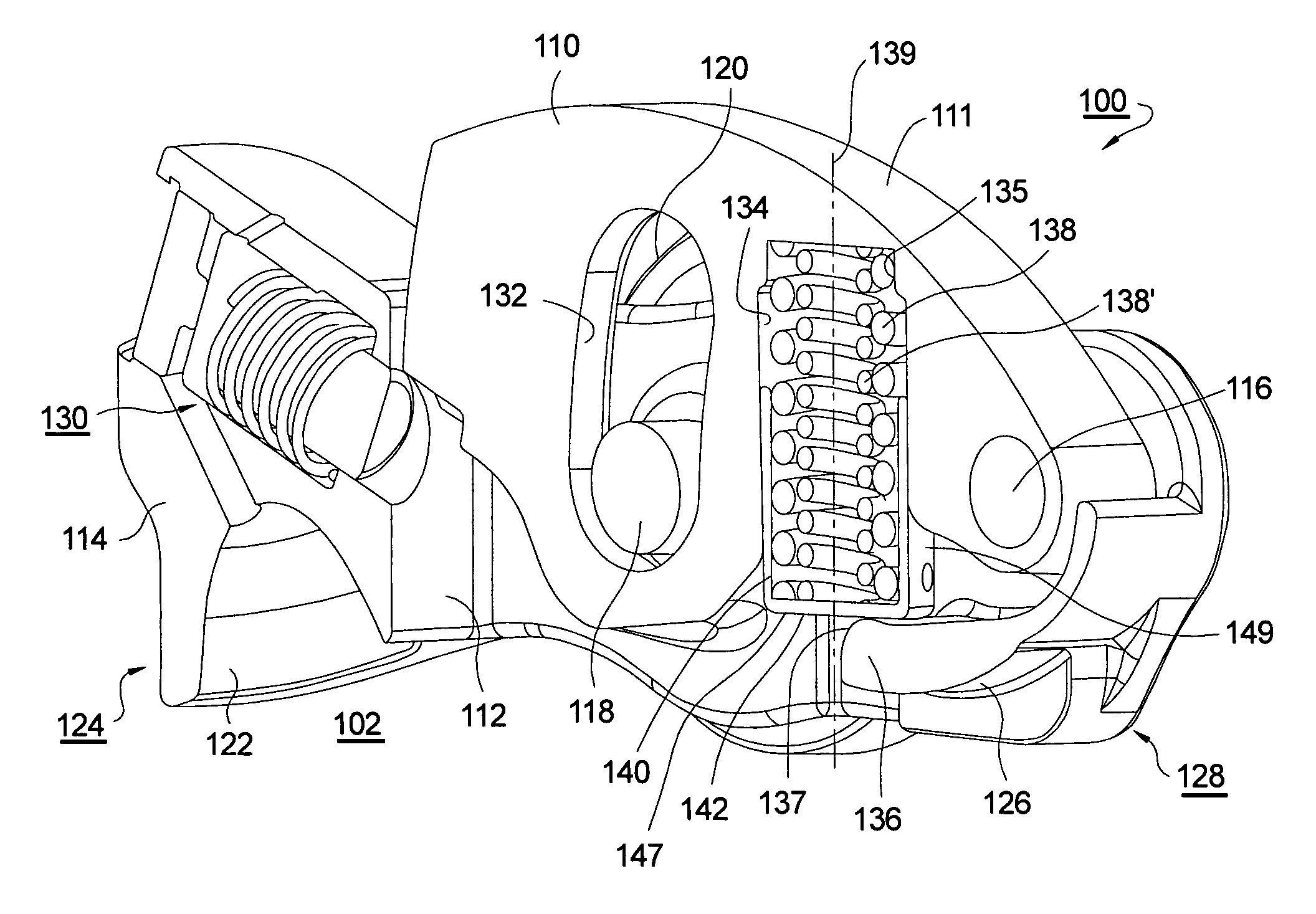

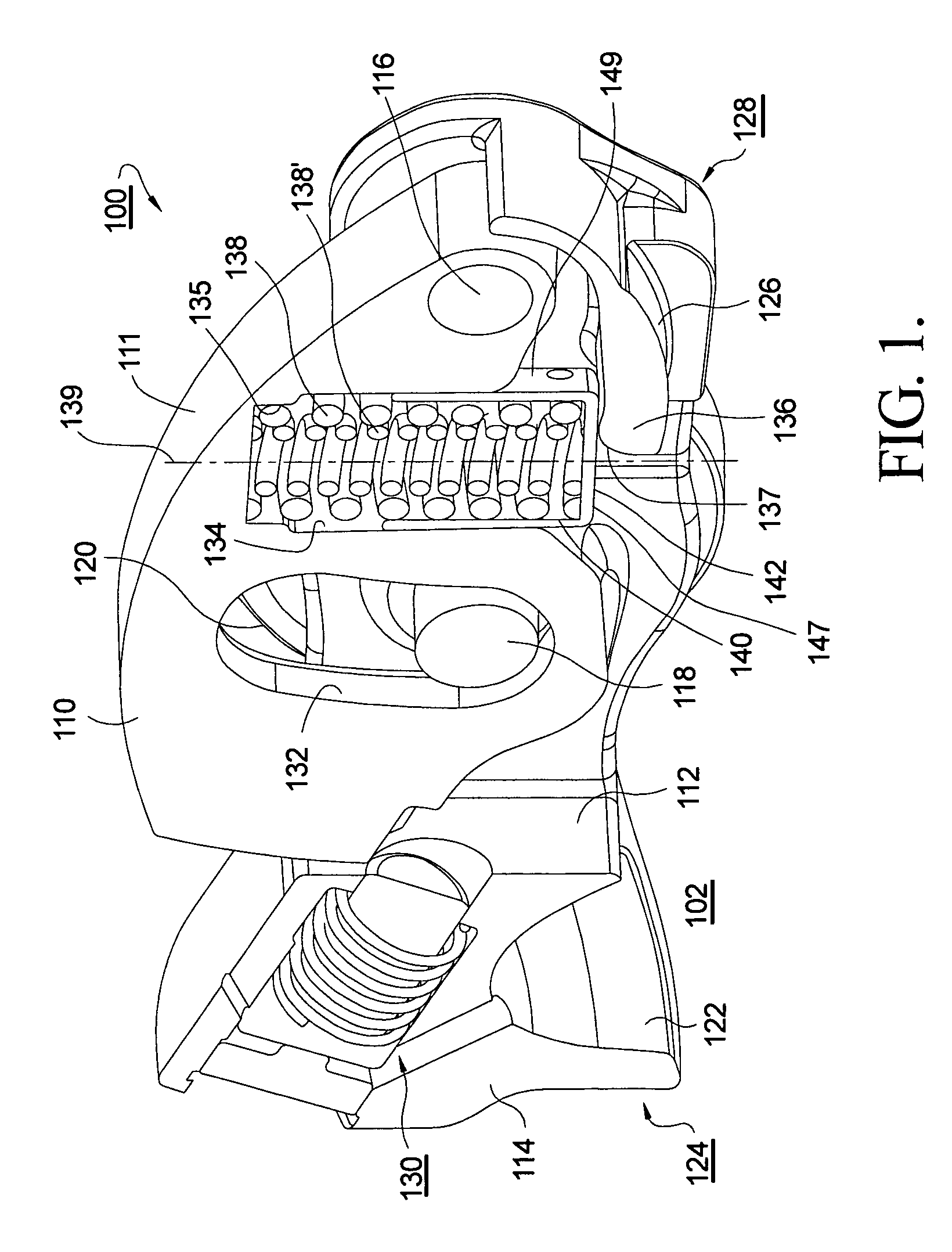

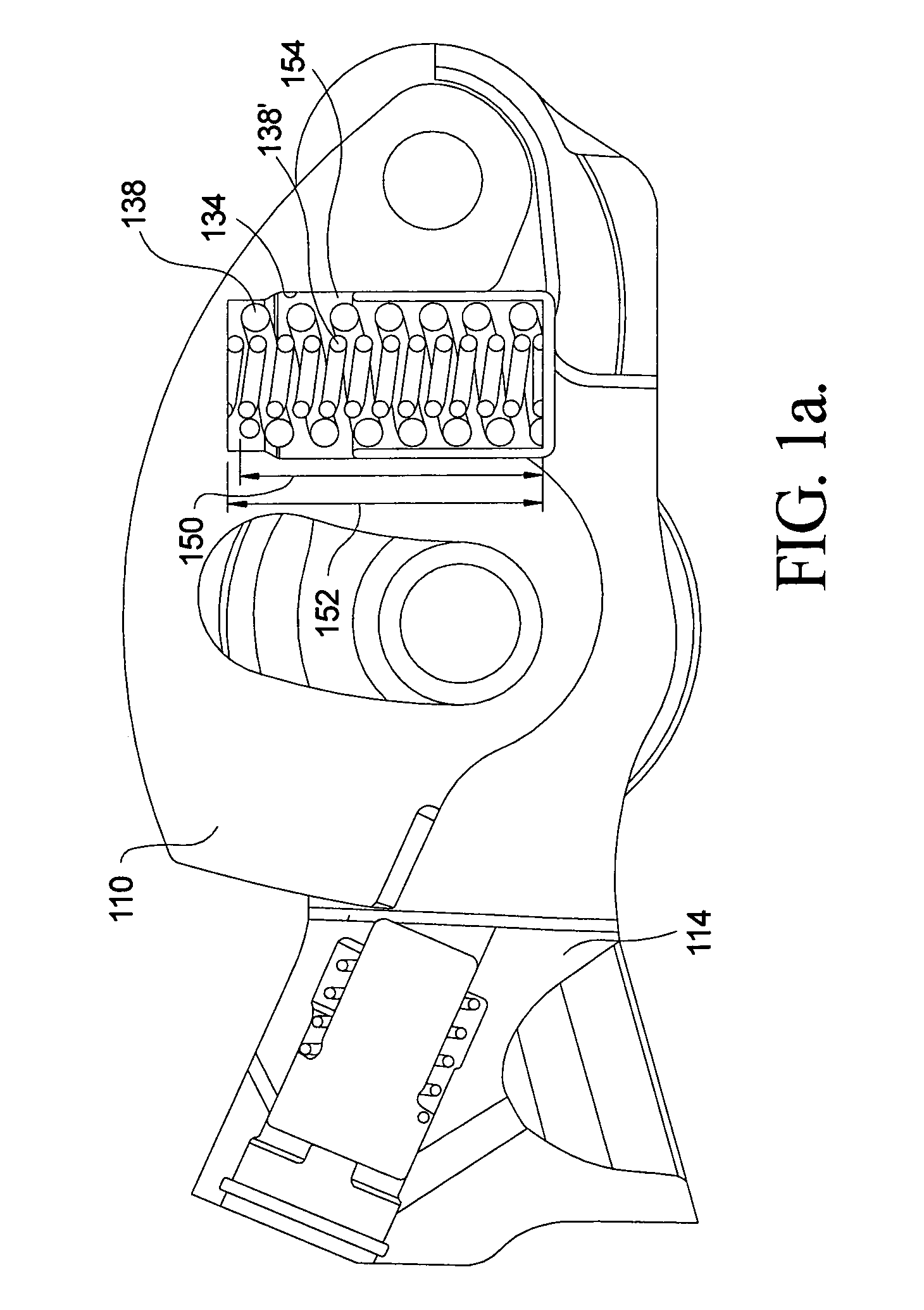

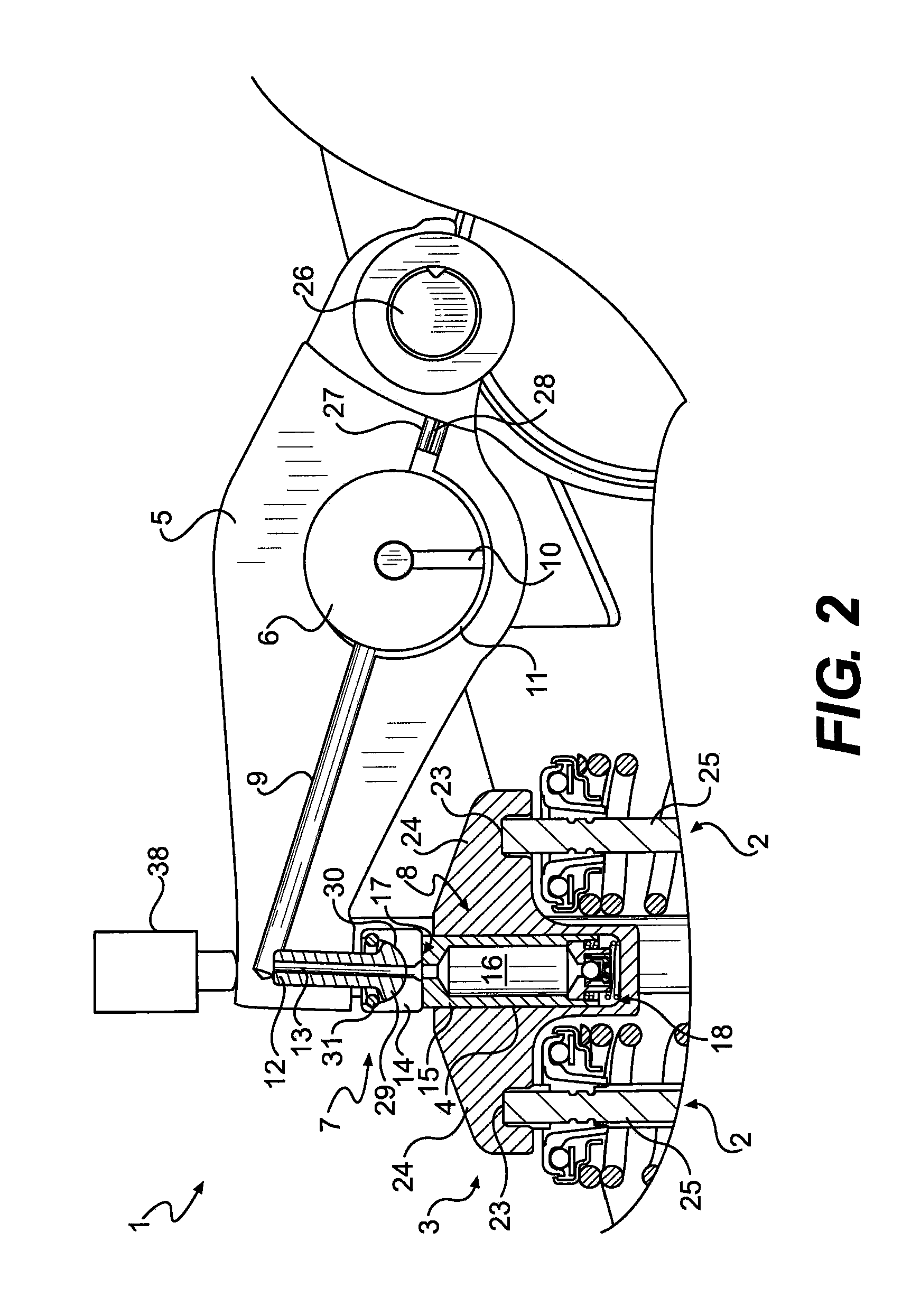

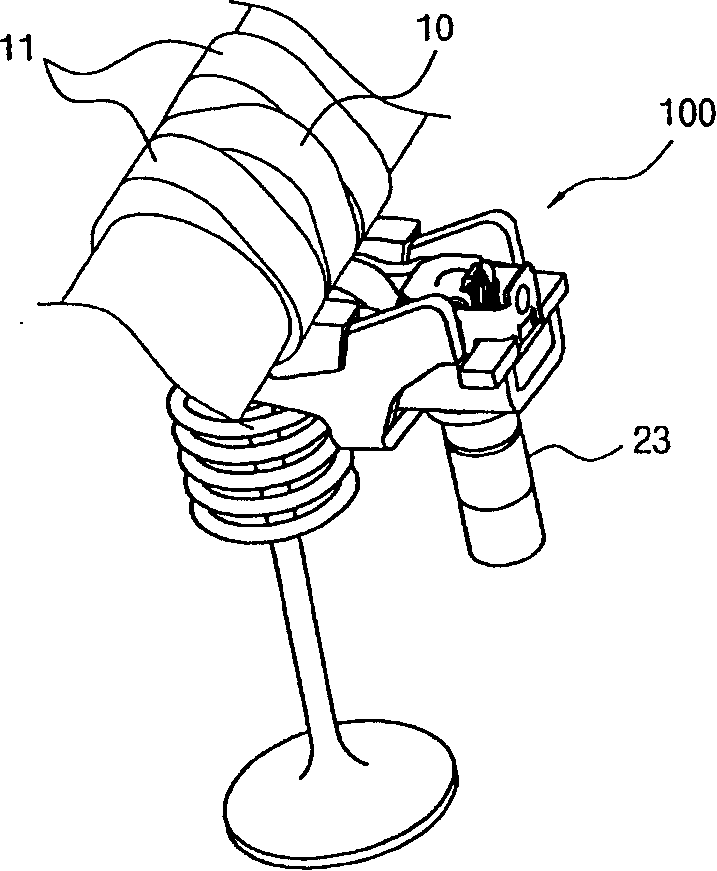

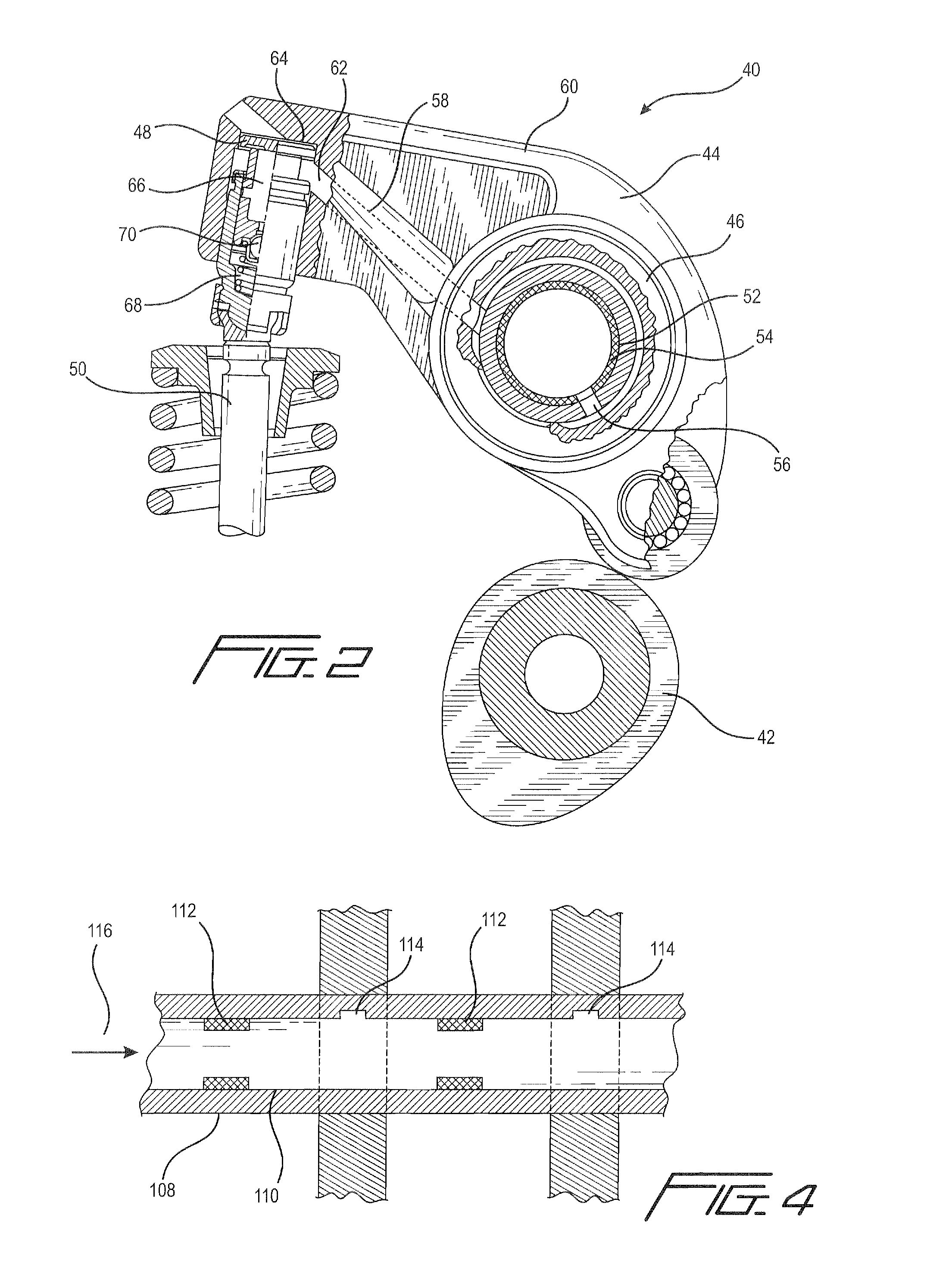

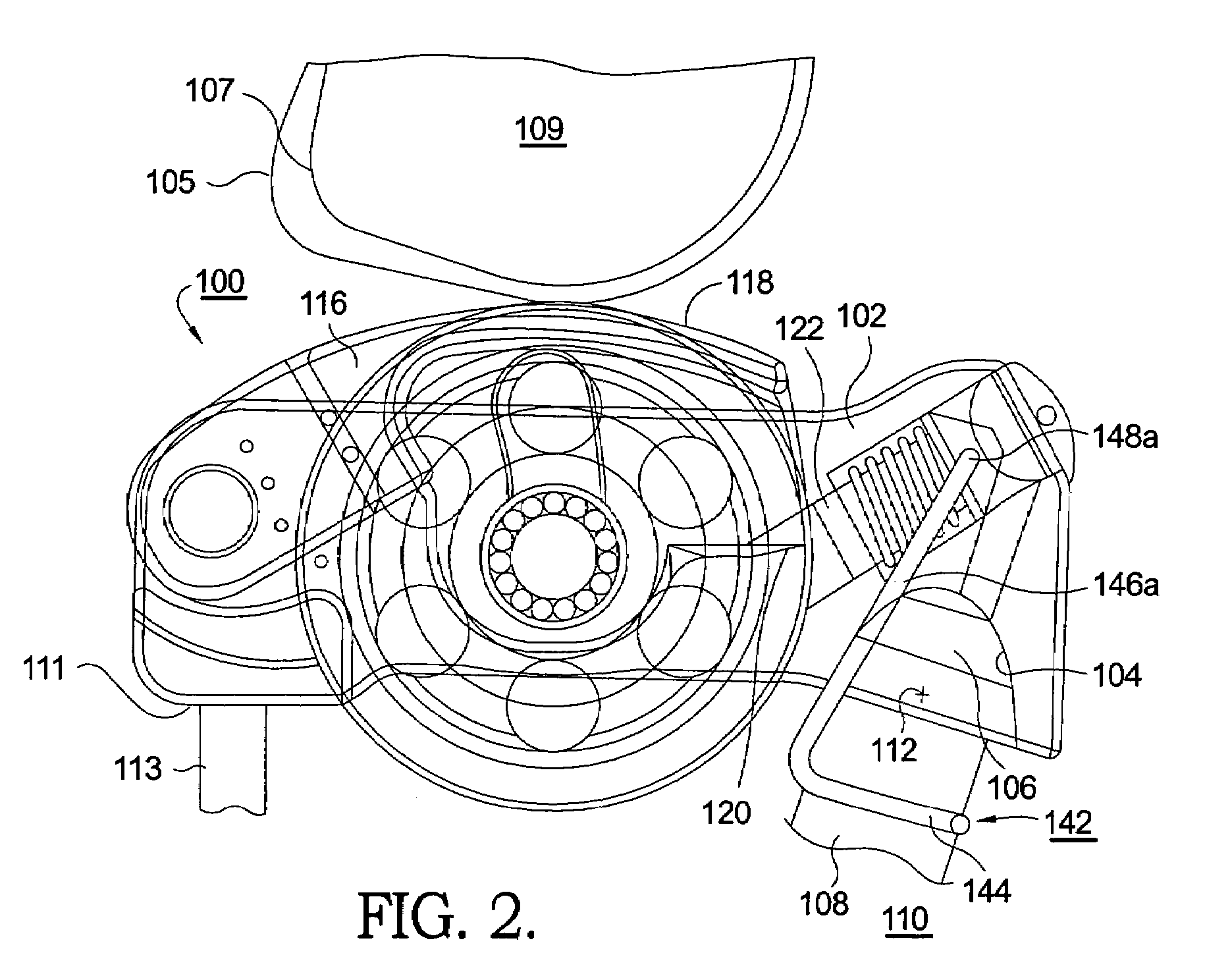

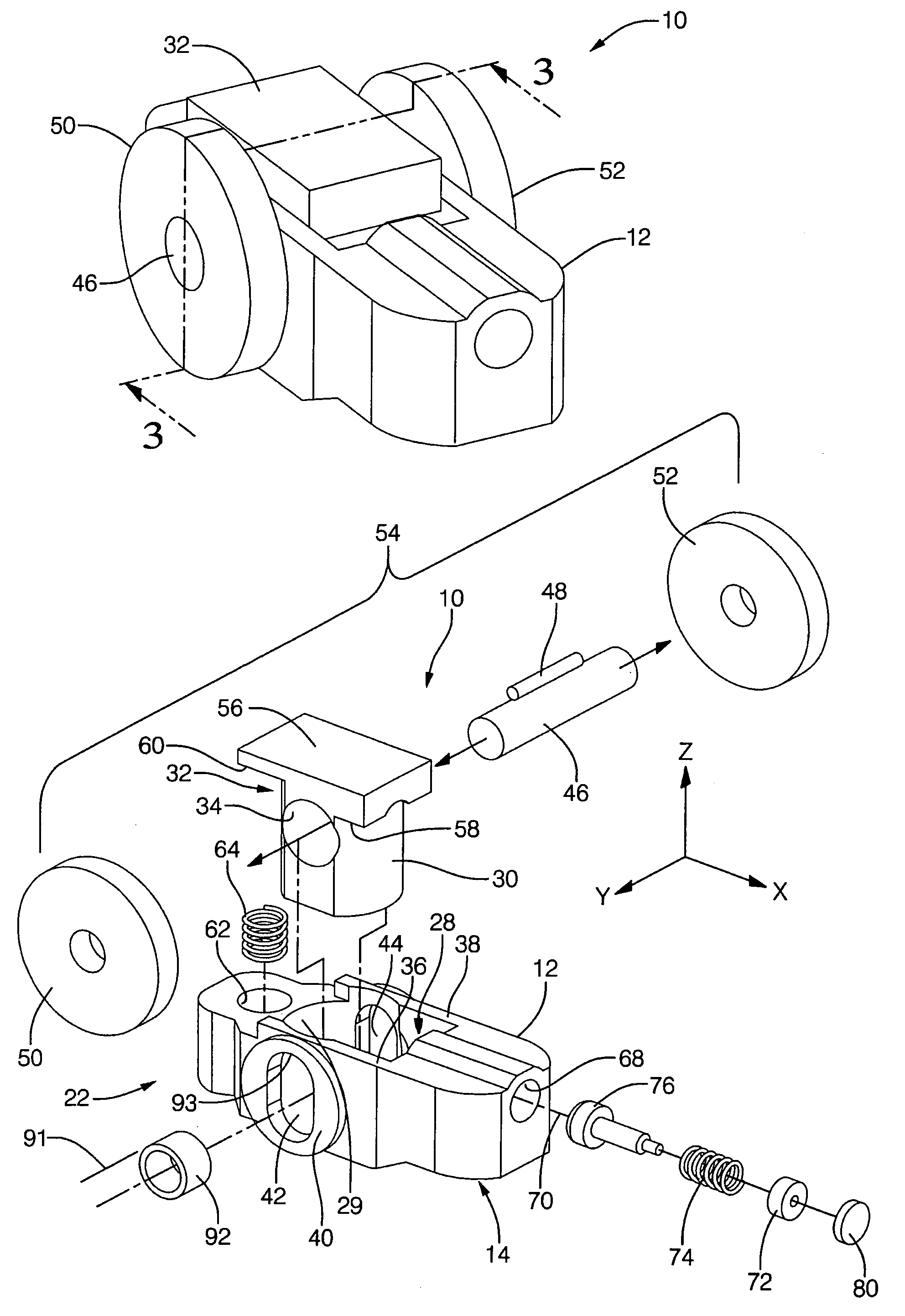

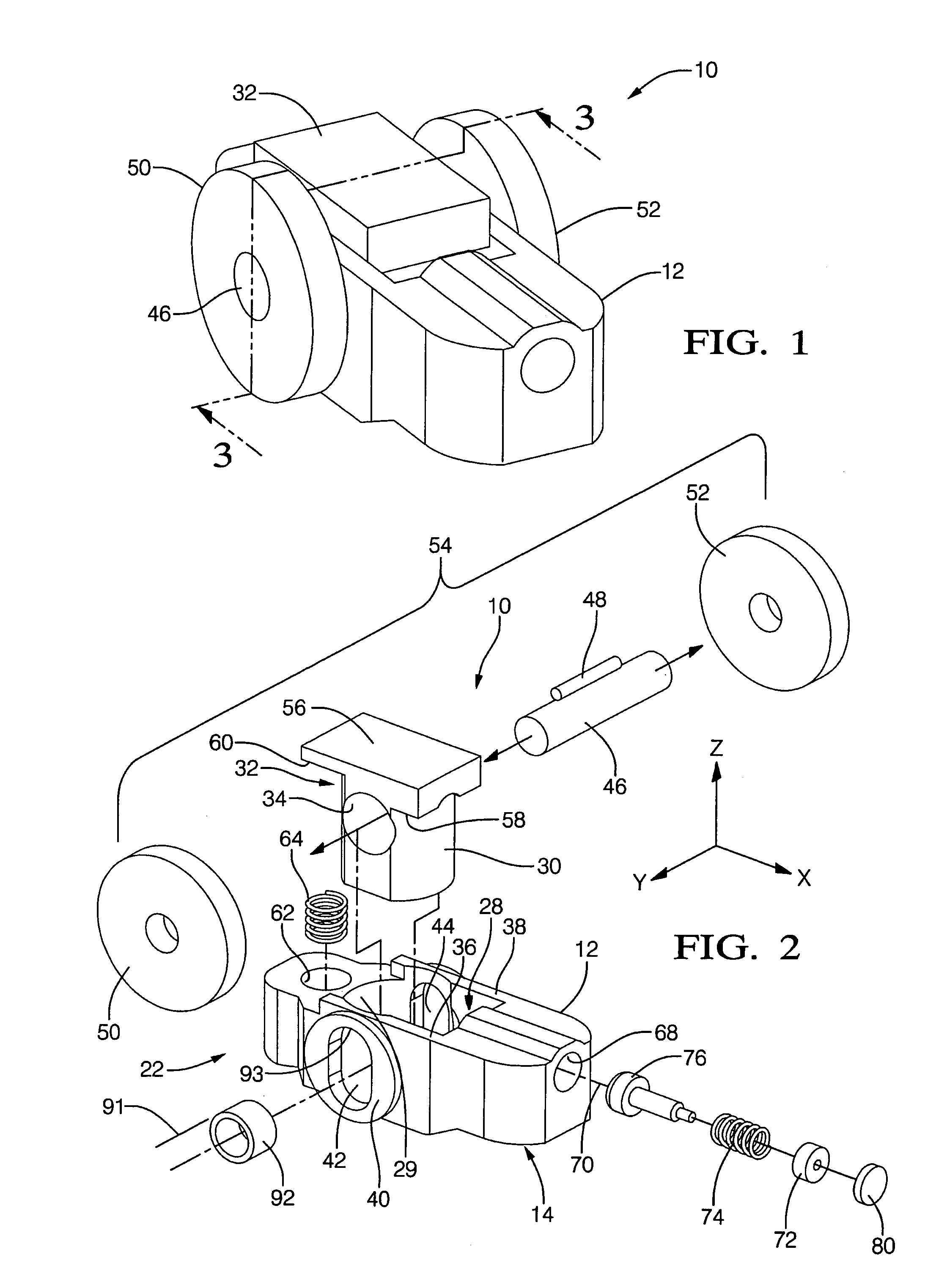

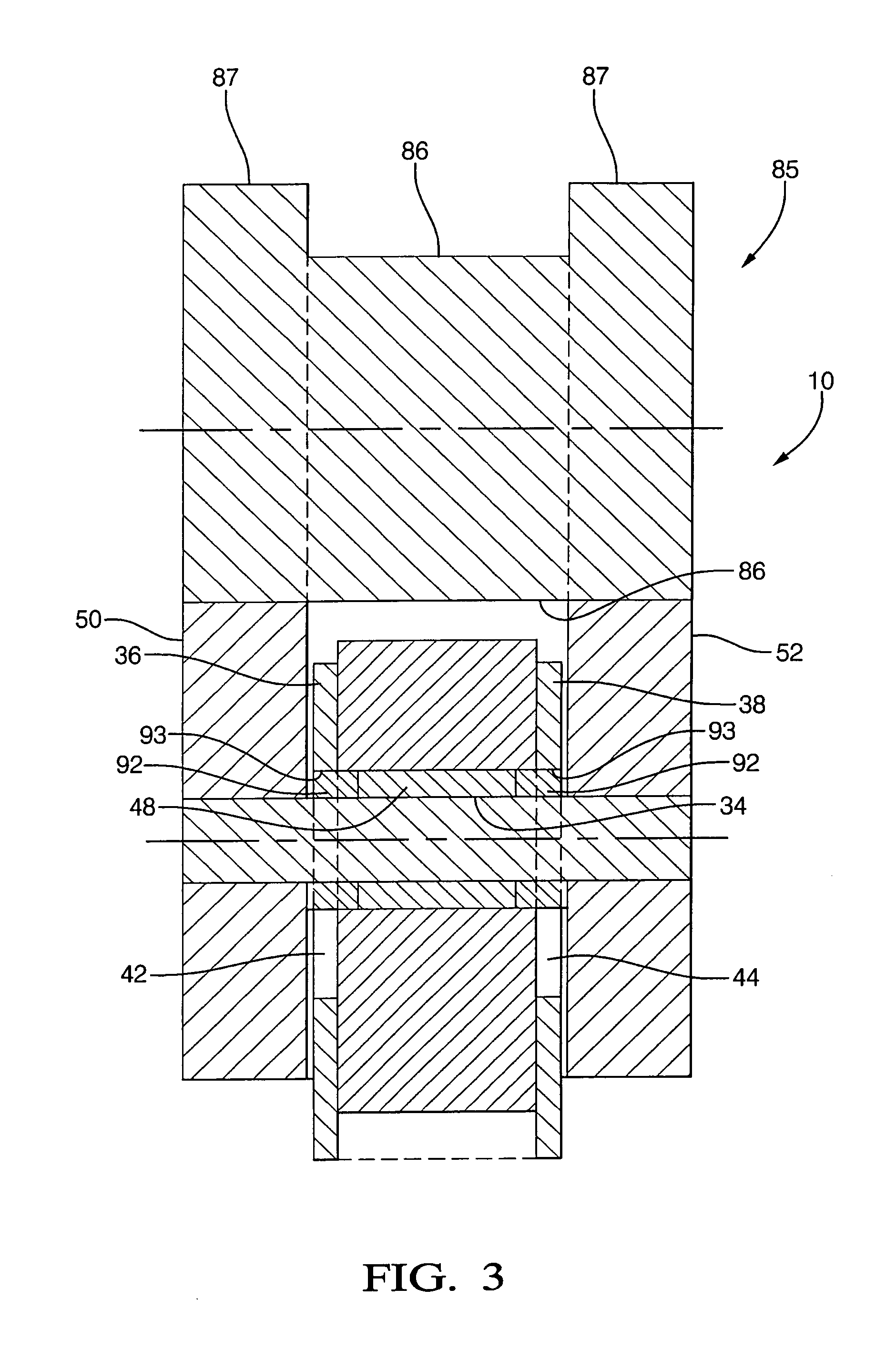

Two-step roller finger follower

A two-step roller finger follower having a high-lift follower portion that rotates relative to a low-lift follower portion about a pivot shaft, including a lost-motion compression spring disposed in a linear bore formed in the high-lift portion to exert force against an curved pad on the back side of the valve pallet of the low-lift portion. The spring is retained and guided in its bore by a spring retainer having a planar bottom for engaging the curved pad. Preferably the retainer is a cup positioned in the spring bore such that the stroke of the cup is limited, to prevent leak-down of the associated hydraulic lash adjuster. Driving the spring by a linear-acting retainer in a linear bore causes the spring to be compressed linearly, resulting in a highly stable and predictable spring rate.

Owner:DELPHI TECH IP LTD

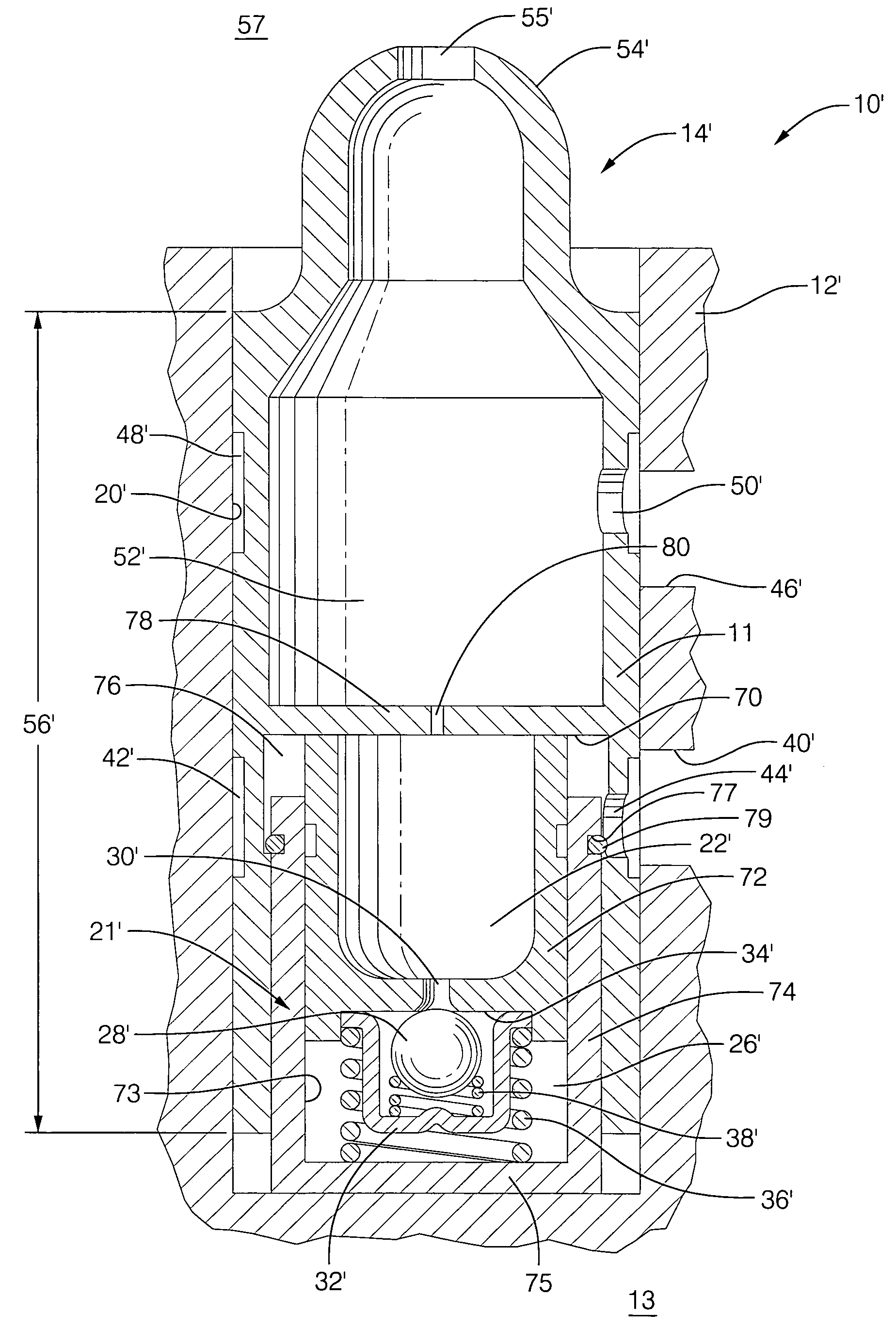

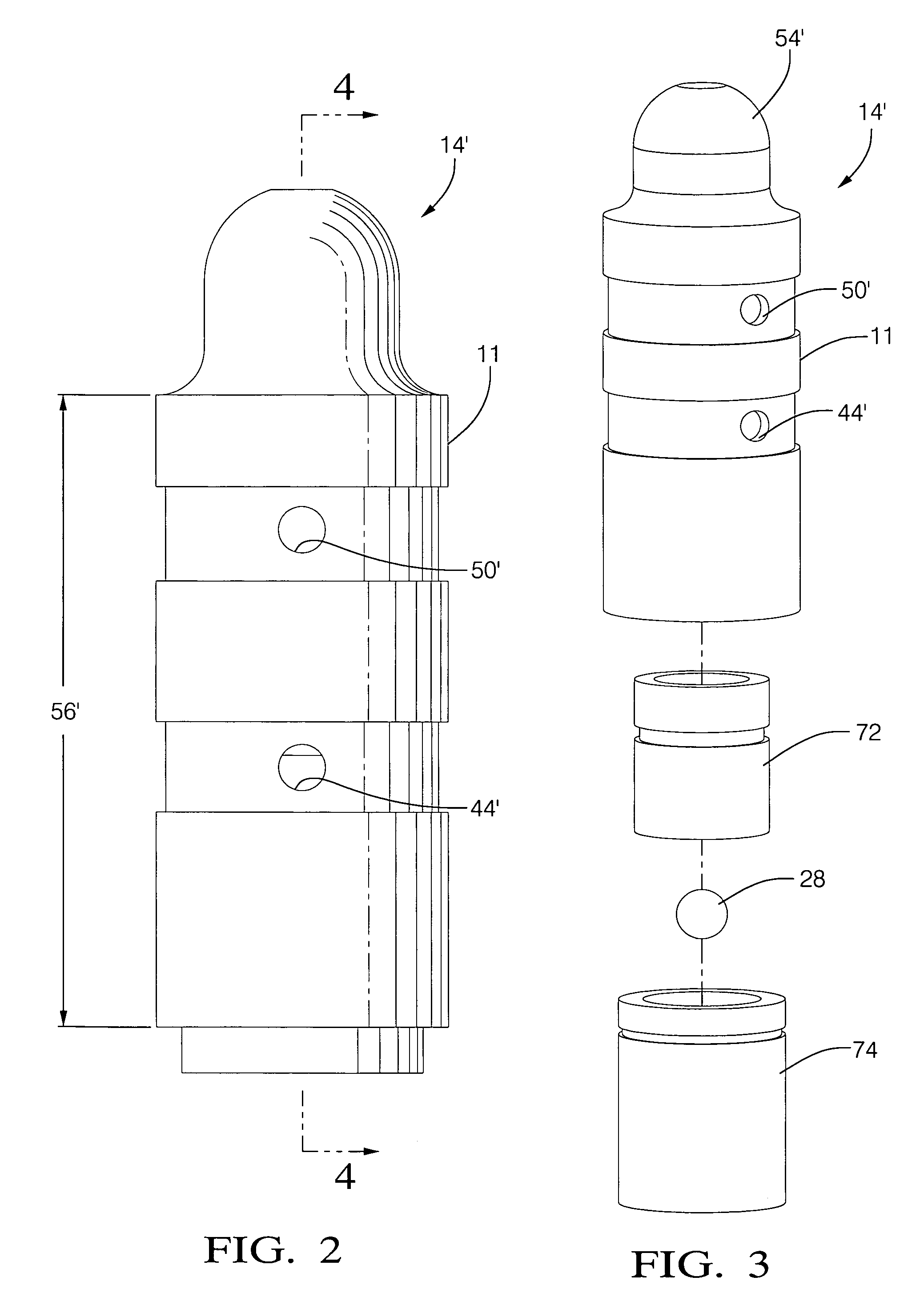

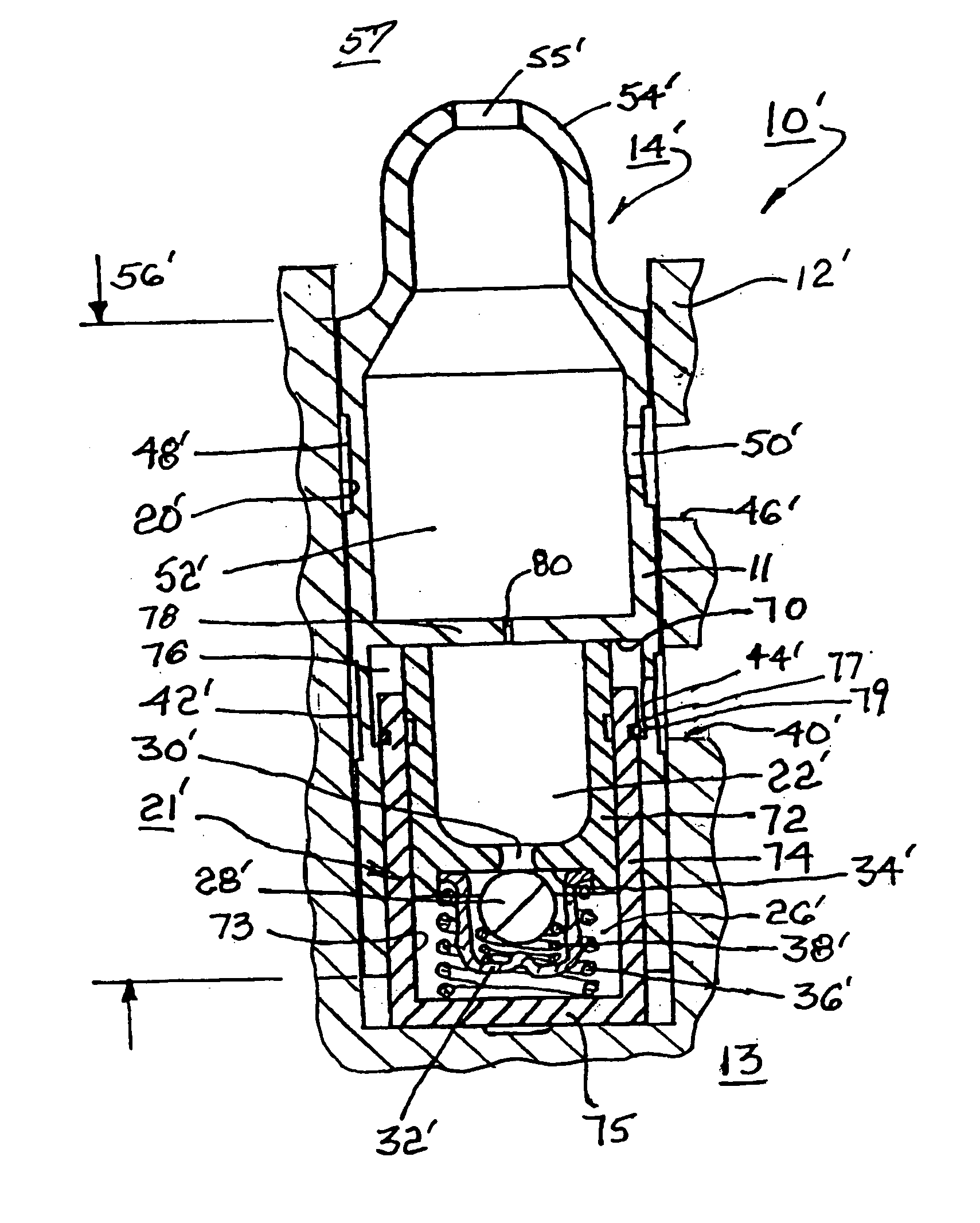

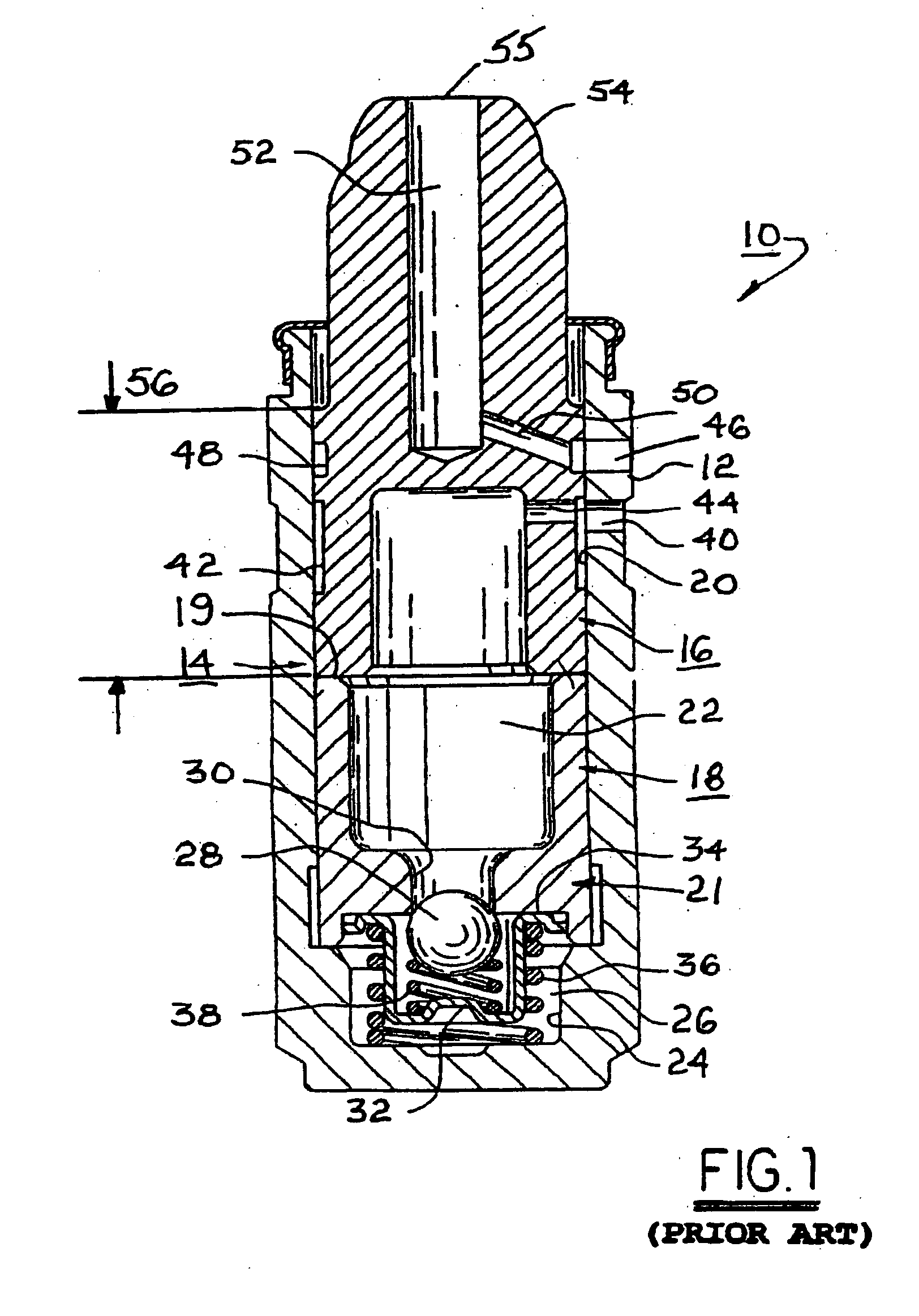

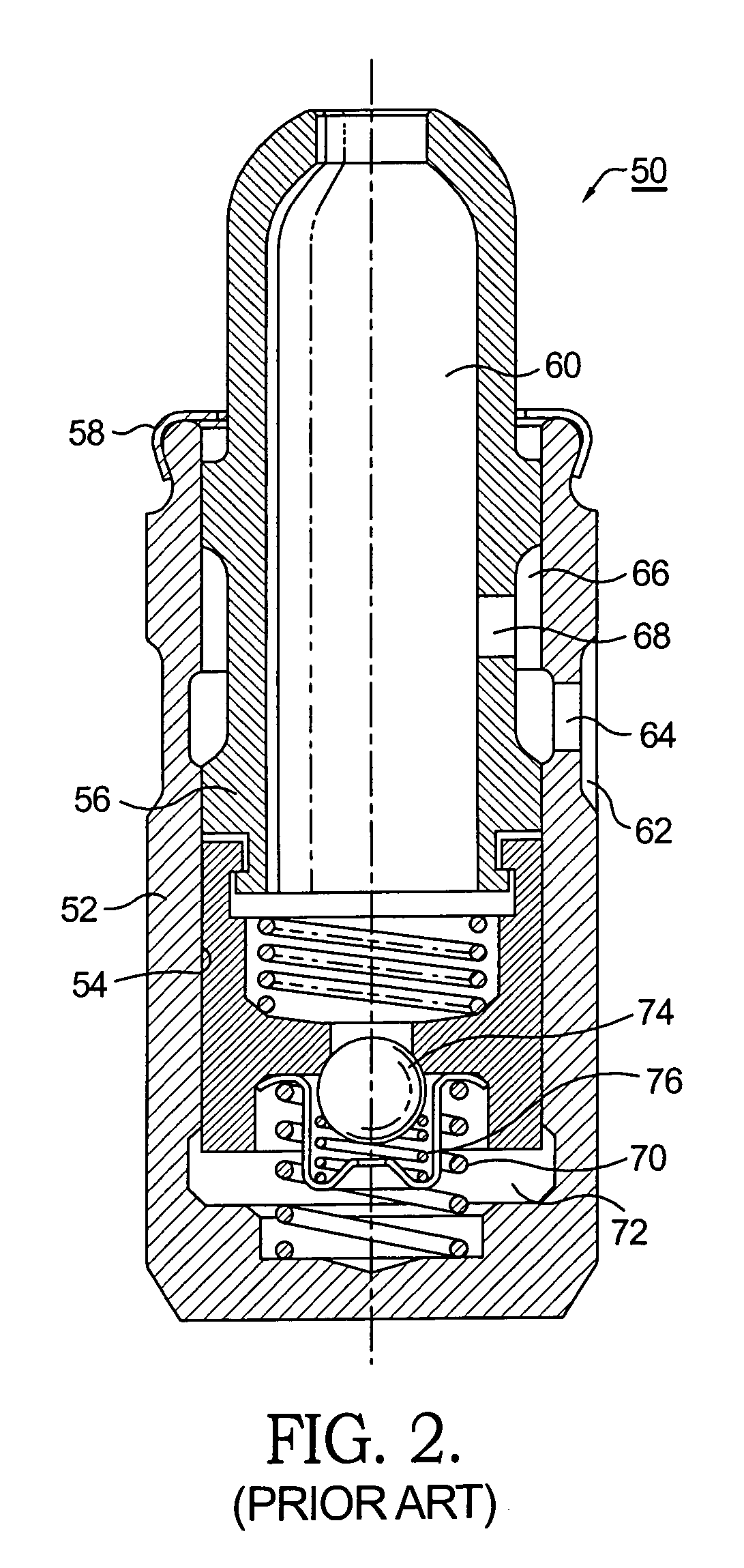

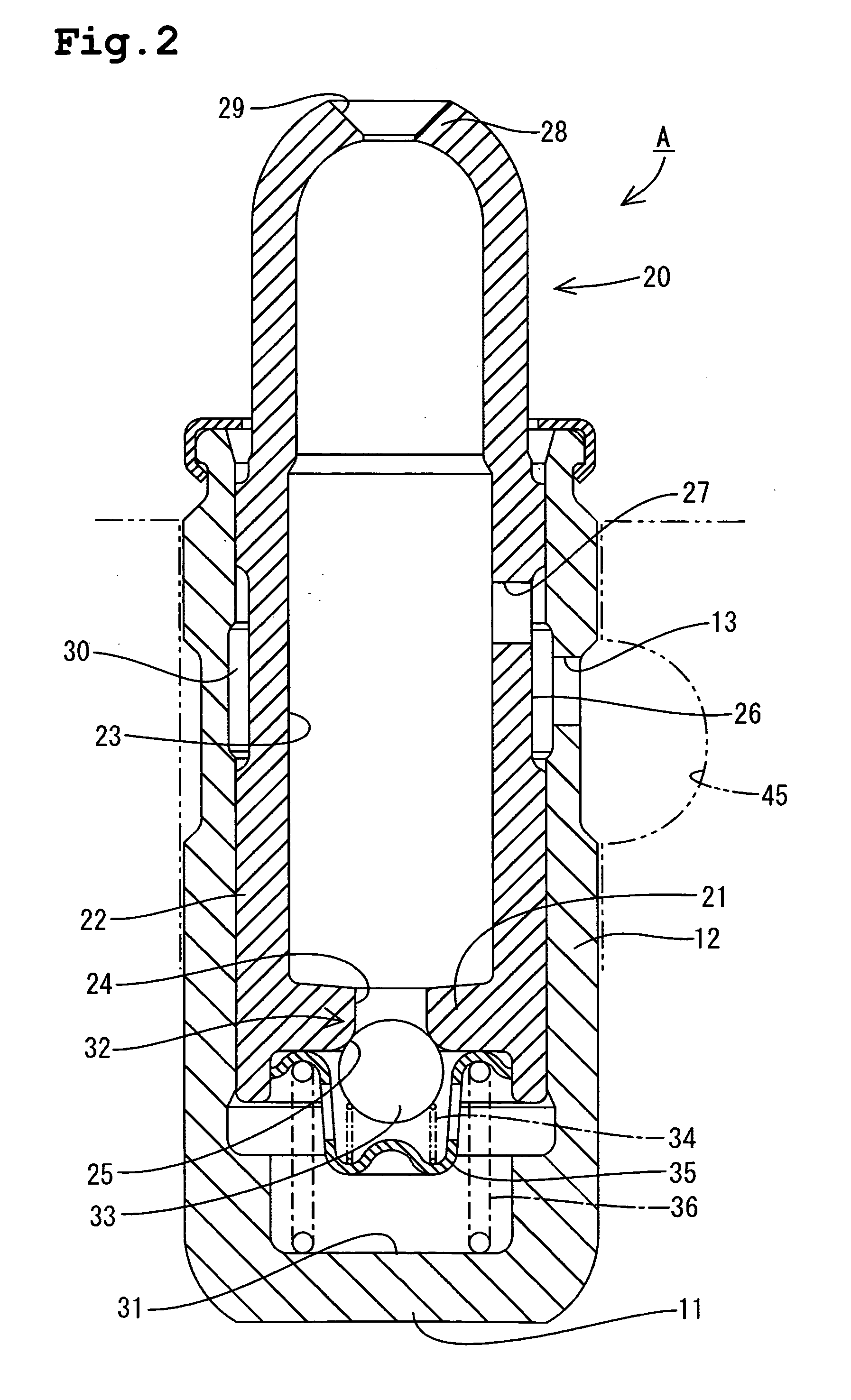

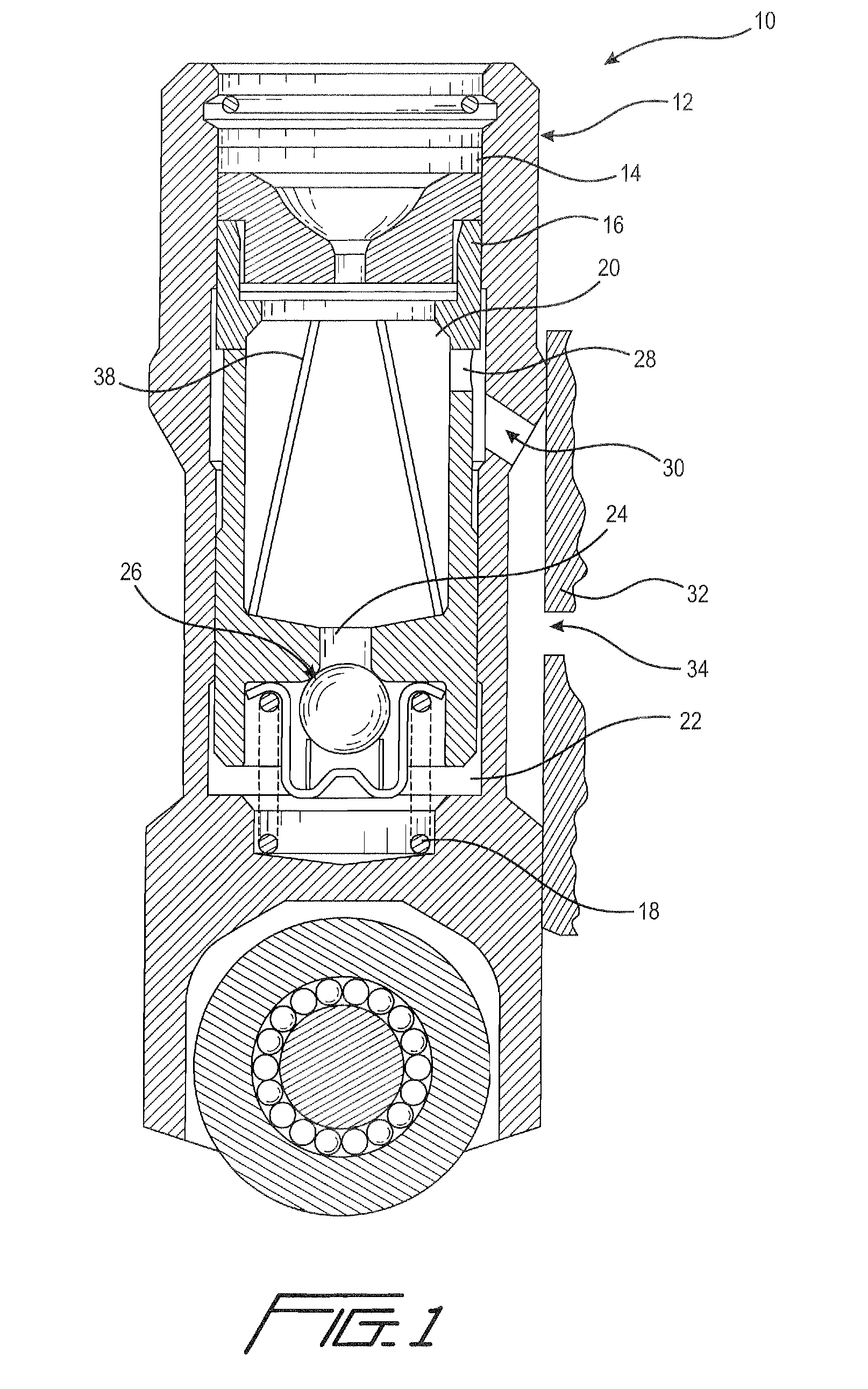

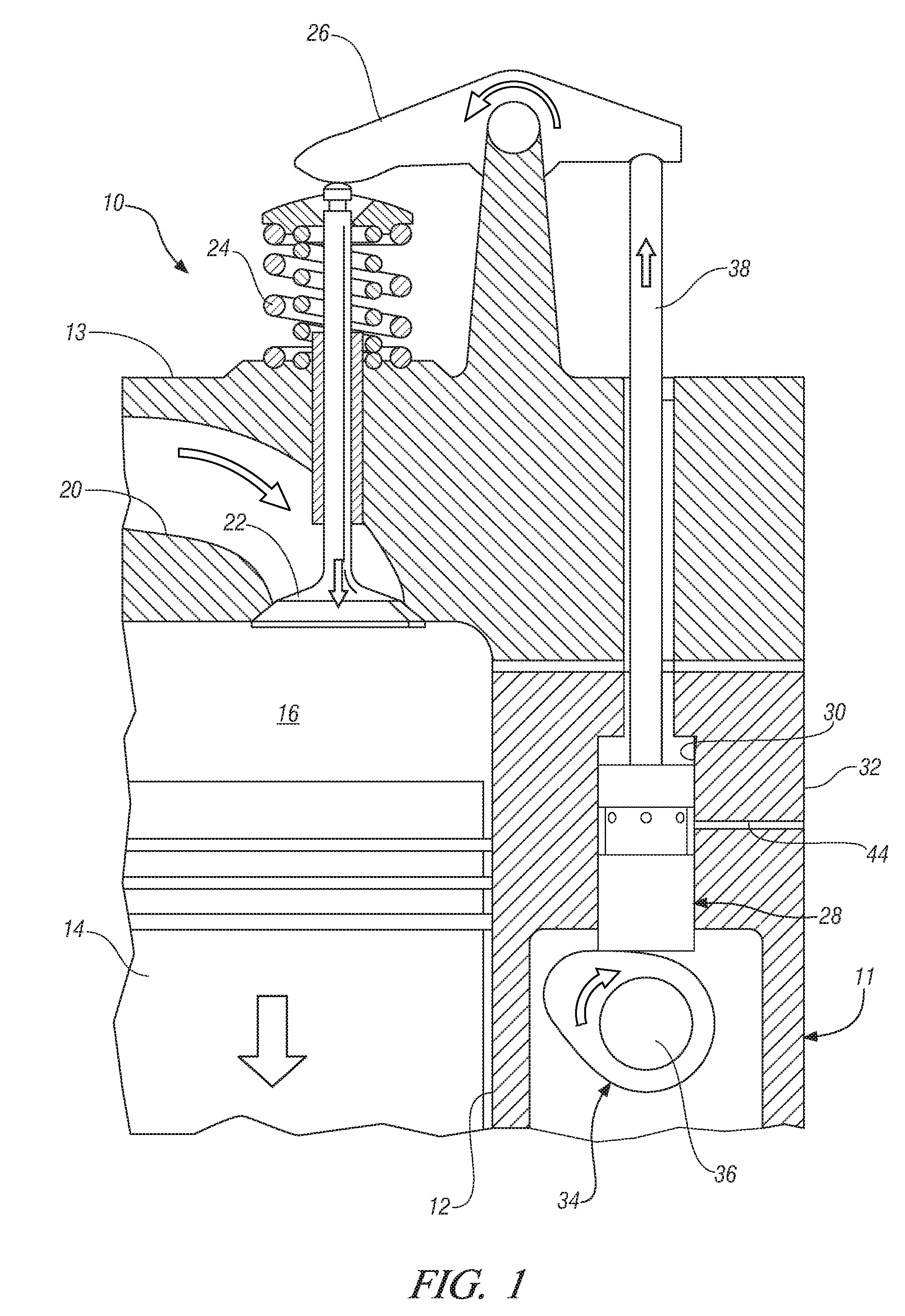

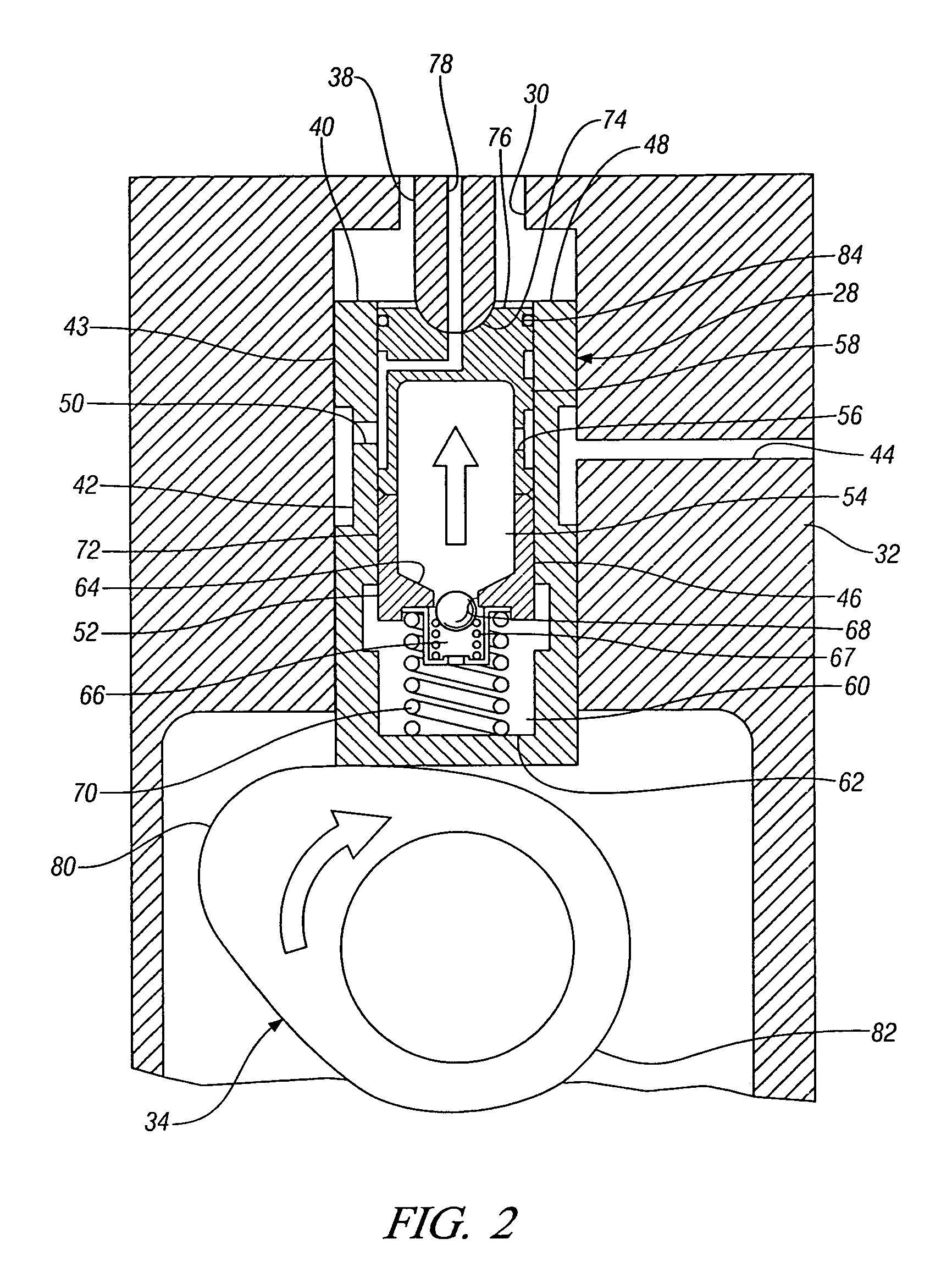

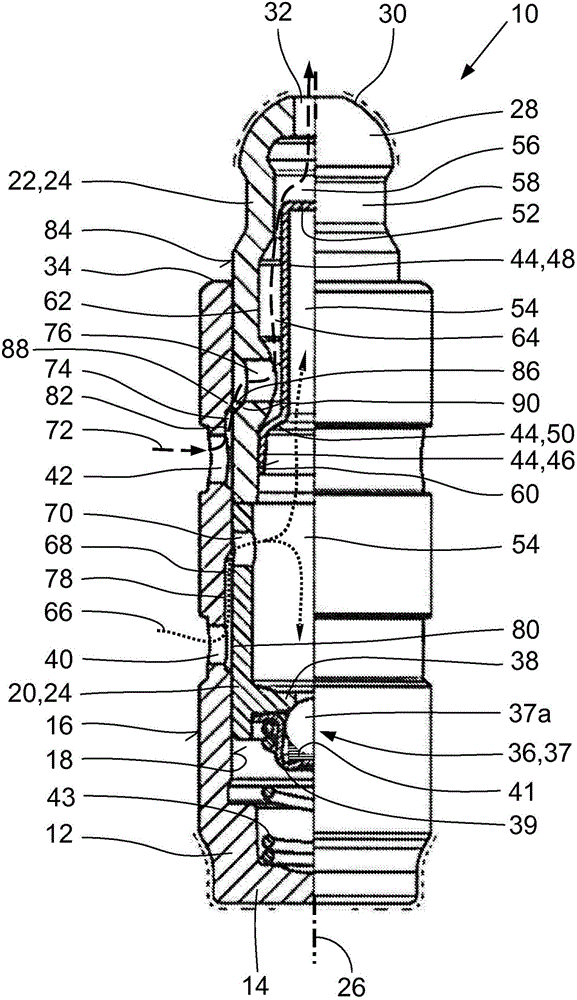

Dual feed hydraulic lash adjuster

InactiveUS7047925B2Increase resistanceValve arrangementsMachines/enginesExternal combustion engineInternal combustion engine

An improved dual feed hydraulic lash adjuster (HLA), for use in an internal combustion engine, comprising a hollow body and a plunger assembly disposed in a bore of the engine. A one-piece plunger body includes a first chamber for forming a low-pressure oil reservoir and receiving a lash adjustment mechanism, and a second chamber open at one end and partially closed hemispherically for supporting a rocker arm and providing valve deactivating oil thereto for an auxiliary valve actuation system. The first and second chambers are separated by a transverse web, optionally having a small-diameter passage therethrough for air evacuation. The one-piece plunger body provides a high degree of resistance to side loads which may be imposed on the HLA in use.

Owner:DELPHI TECH IP LTD

Valve bridge having a centrally positioned hydraulic lash adjuster

Owner:CATERPILLAR INC

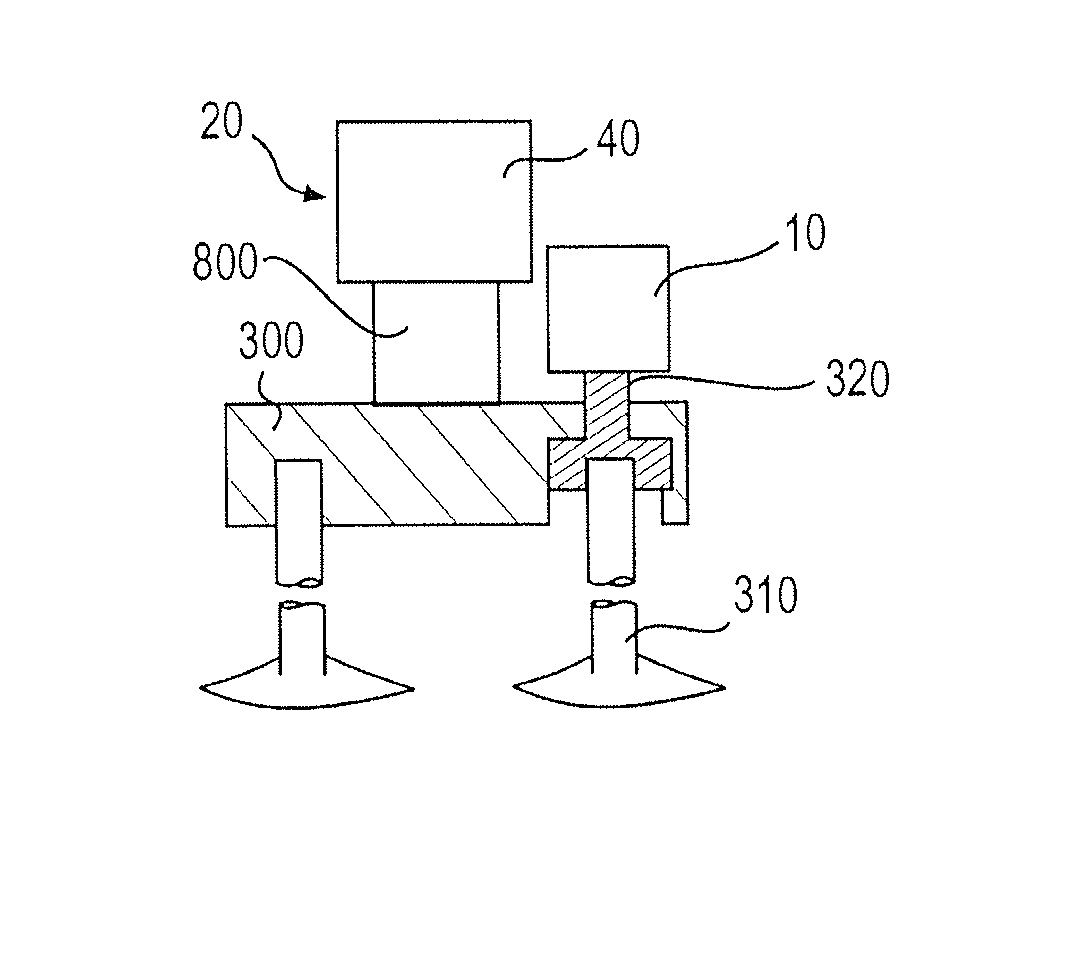

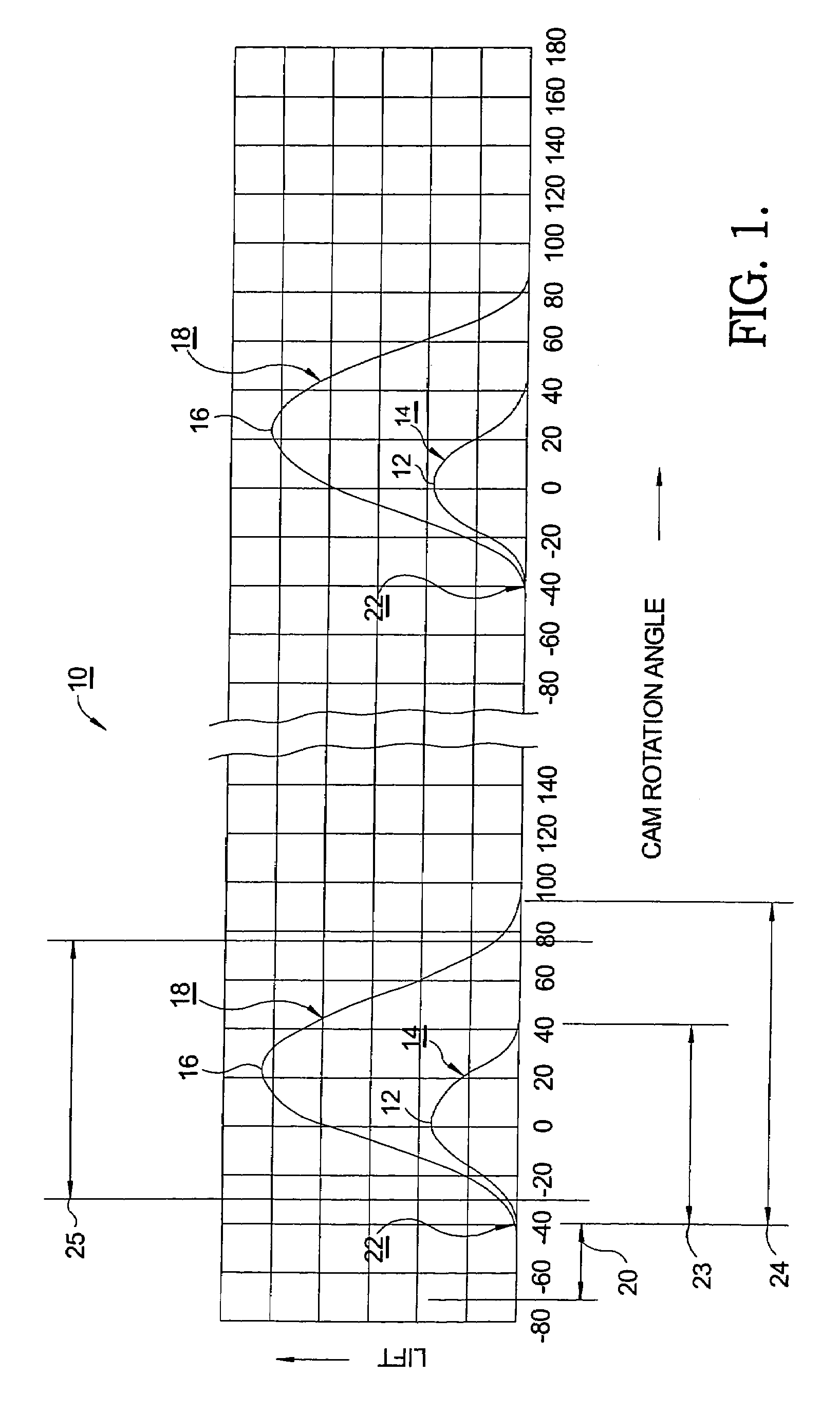

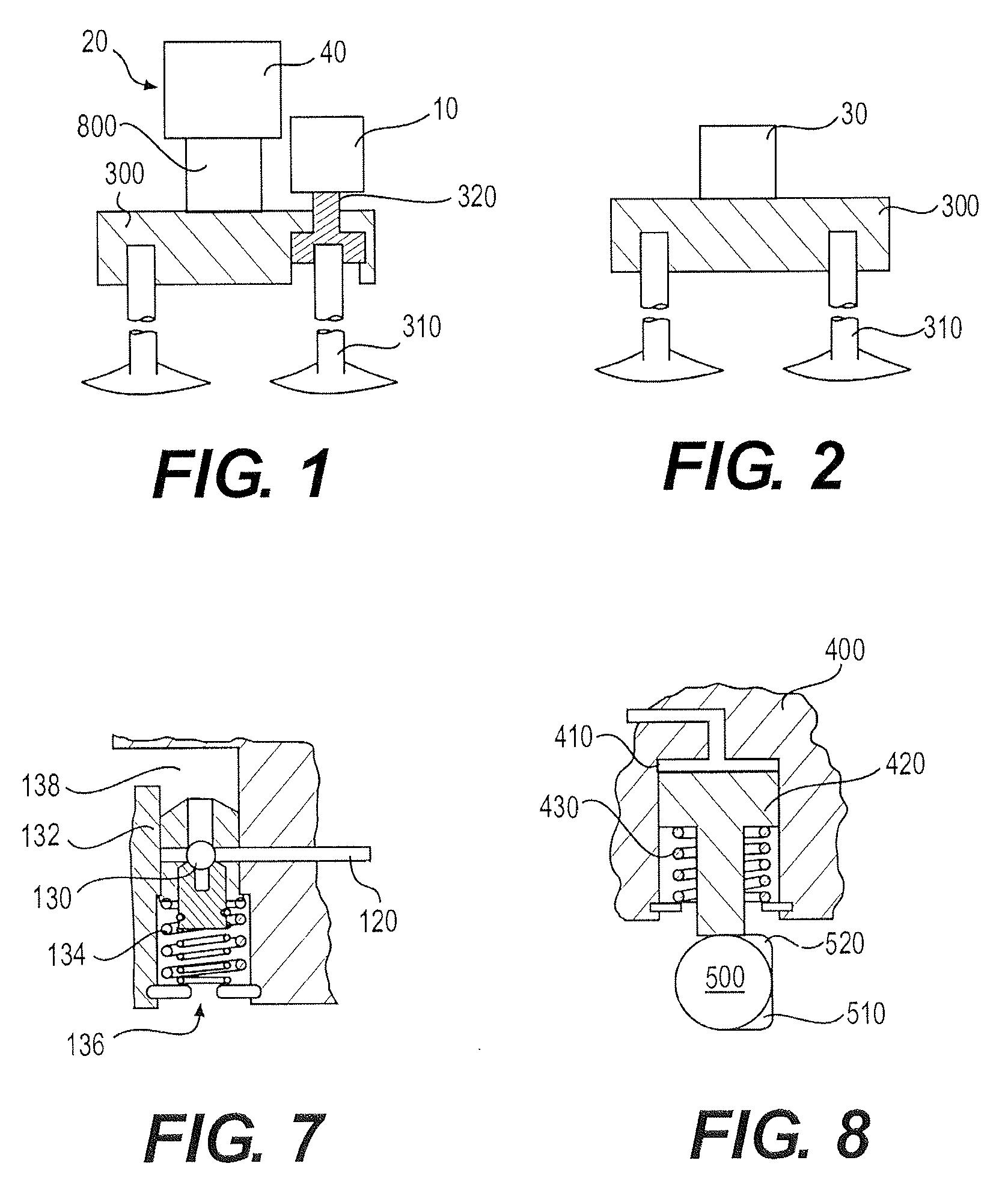

Systems and methods for hydraulic lash adjustment in an internal combustion engine

Systems and methods for actuating engine valves for positive power and engine braking operation are disclosed. The systems may include a self-lashing hydraulic piston slidably disposed in a fixed or rocker arm housing. The hydraulic piston may have an internal cavity in which a motion absorbing piston is disposed. A hydraulic fluid source may communicate with the hydraulic piston bore. A check valve which may be incorporated in a control valve may controls hydraulic fluid supply from the hydraulic fluid source to the hydraulic piston to provide self-lashing operation of the valve actuation system.

Owner:JACOBS VEHICLE SYST

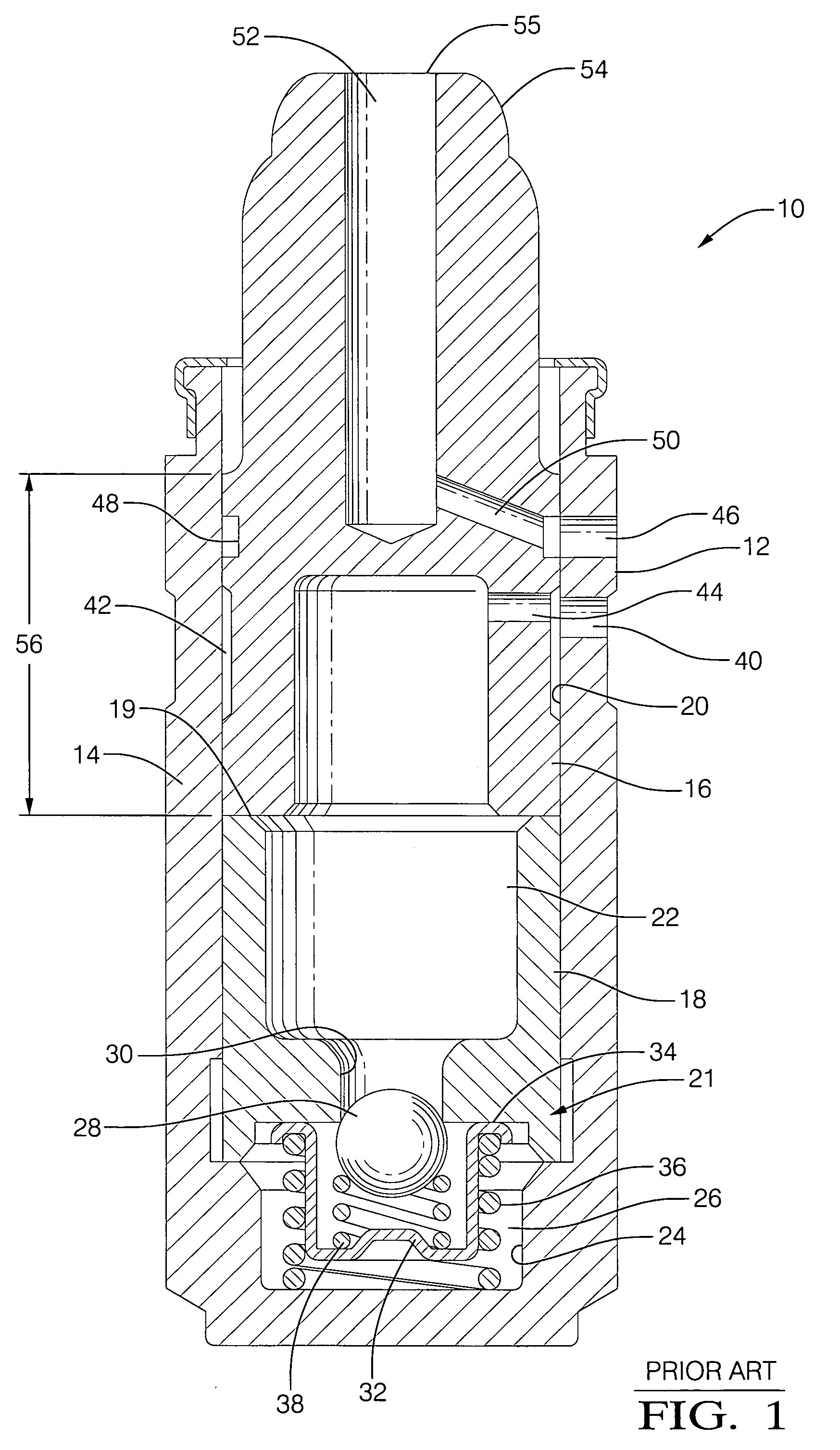

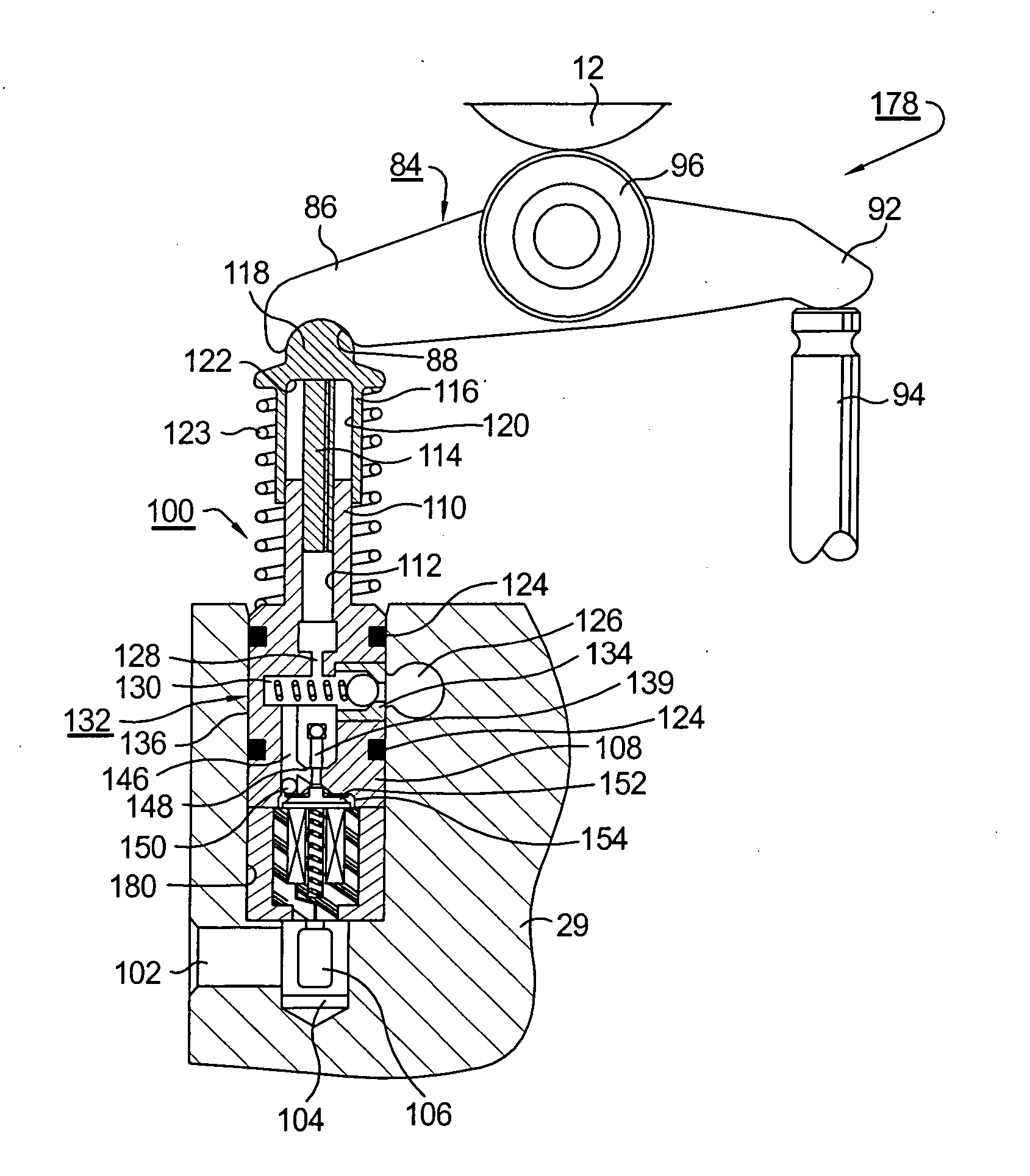

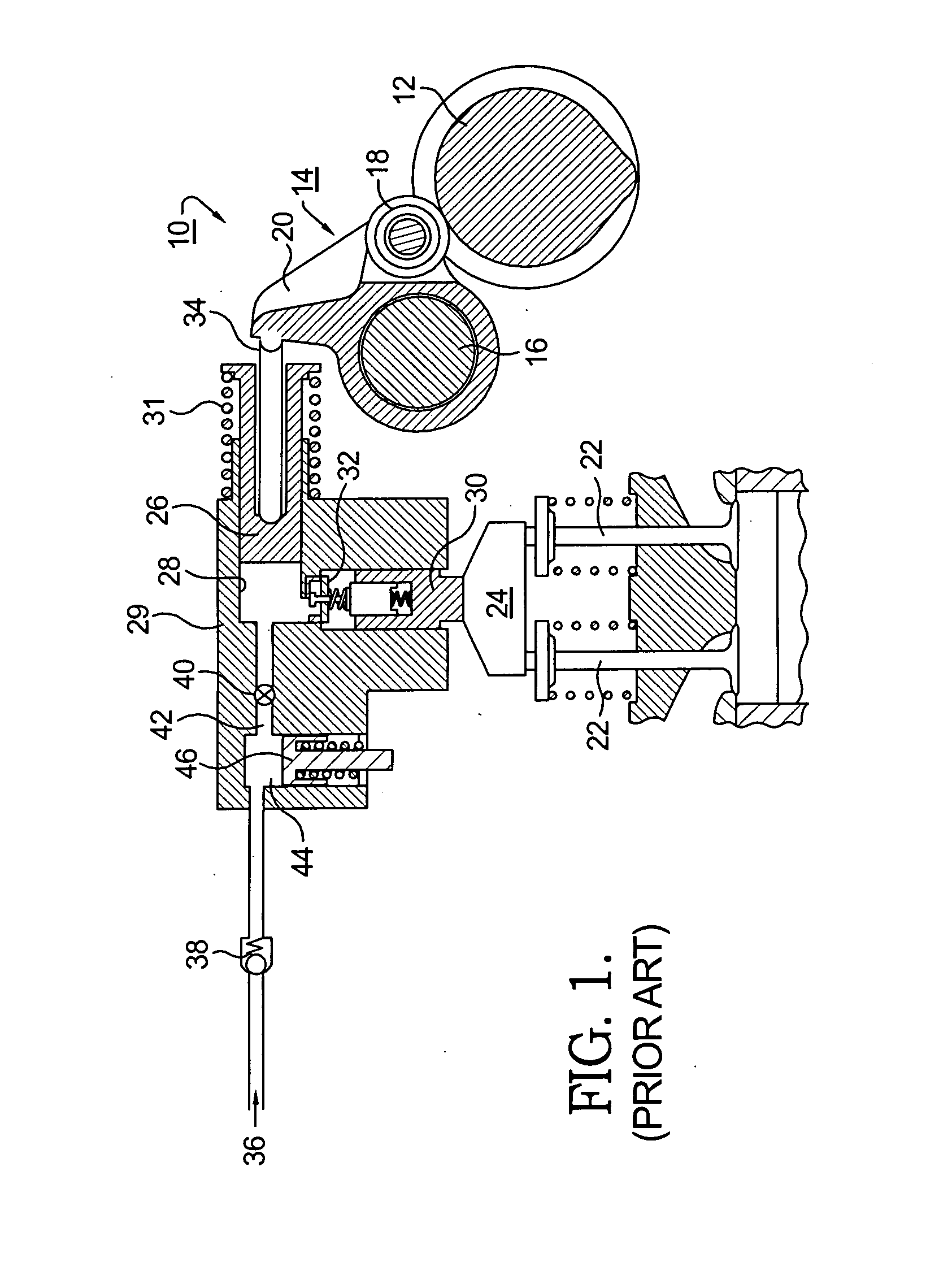

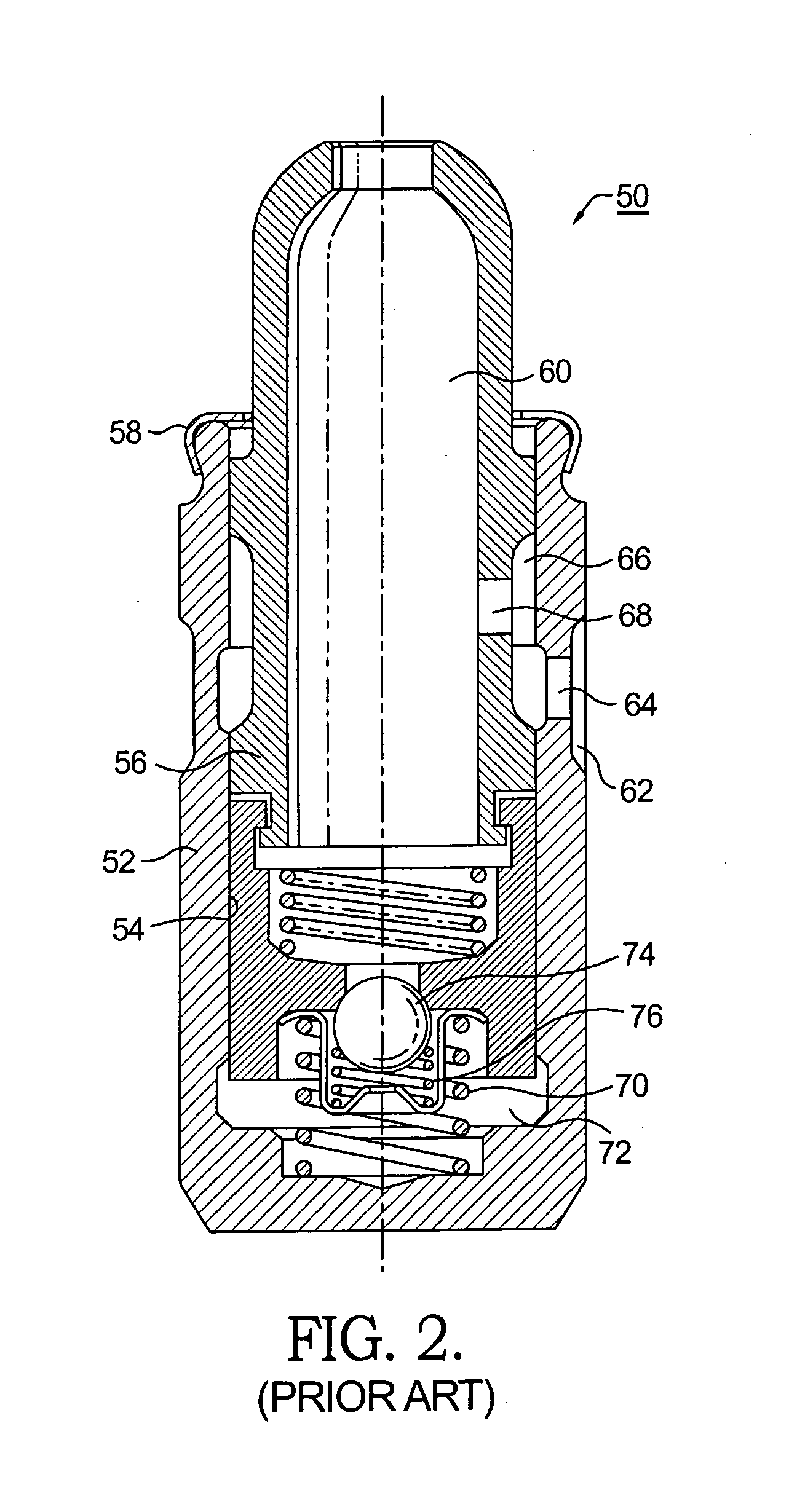

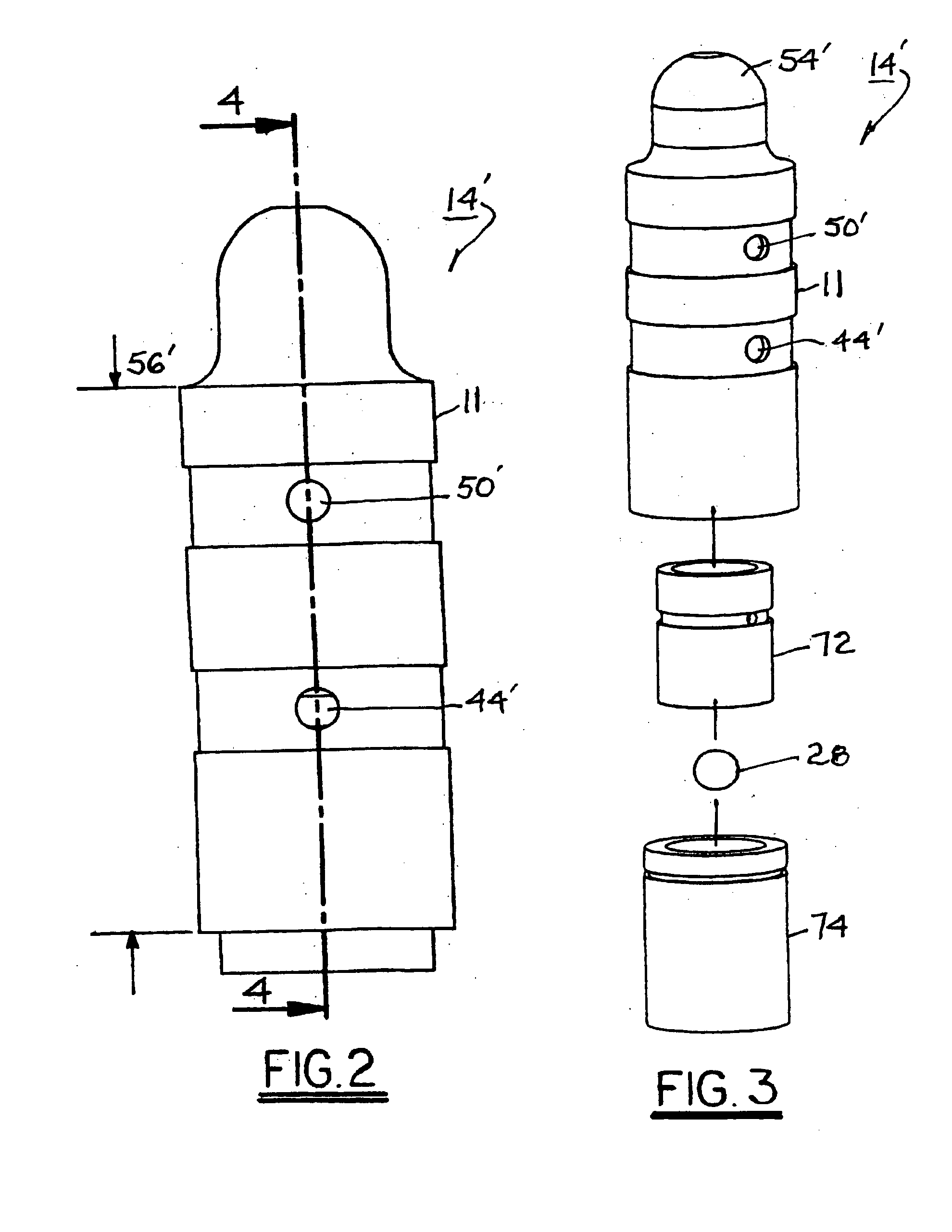

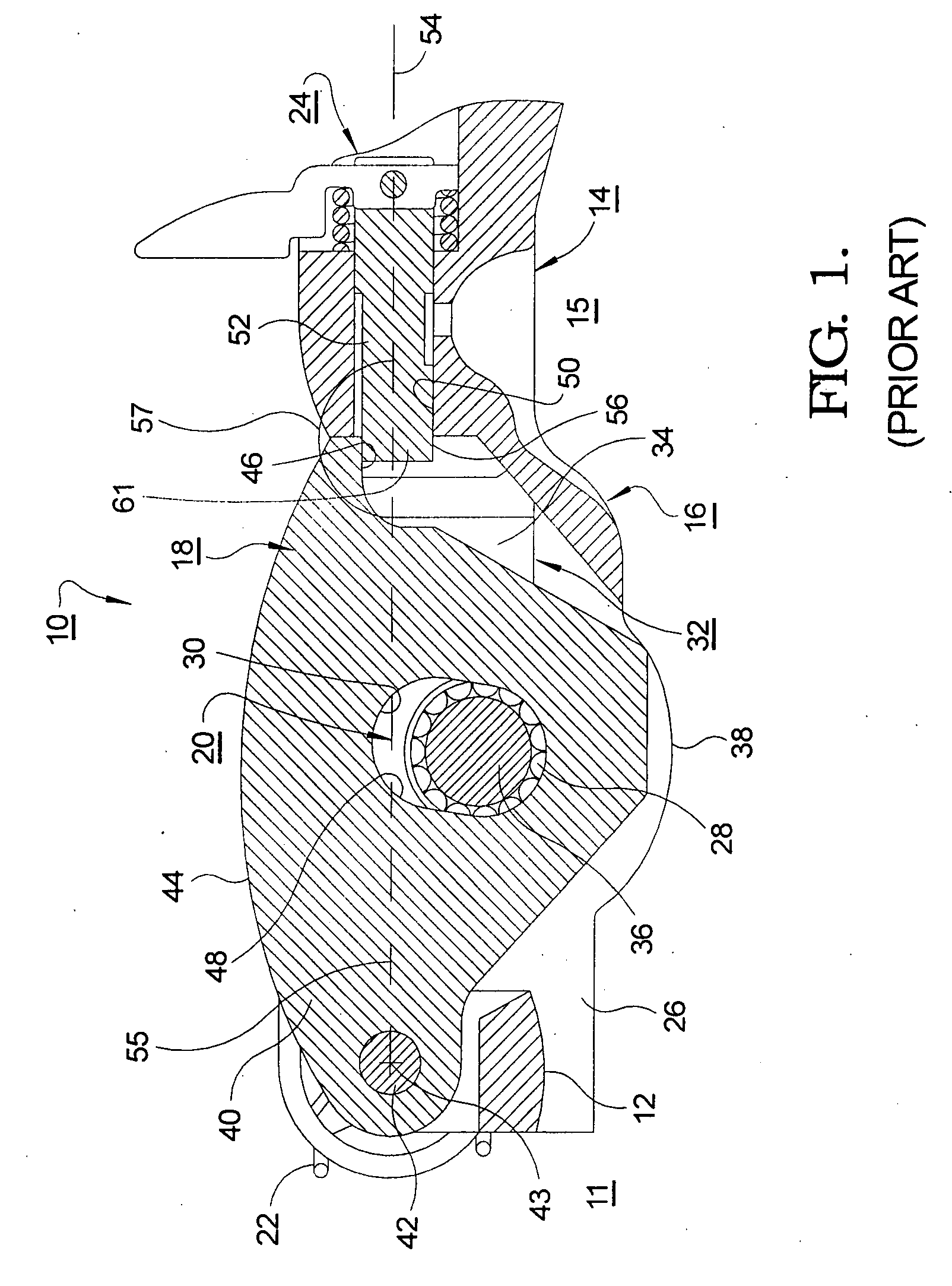

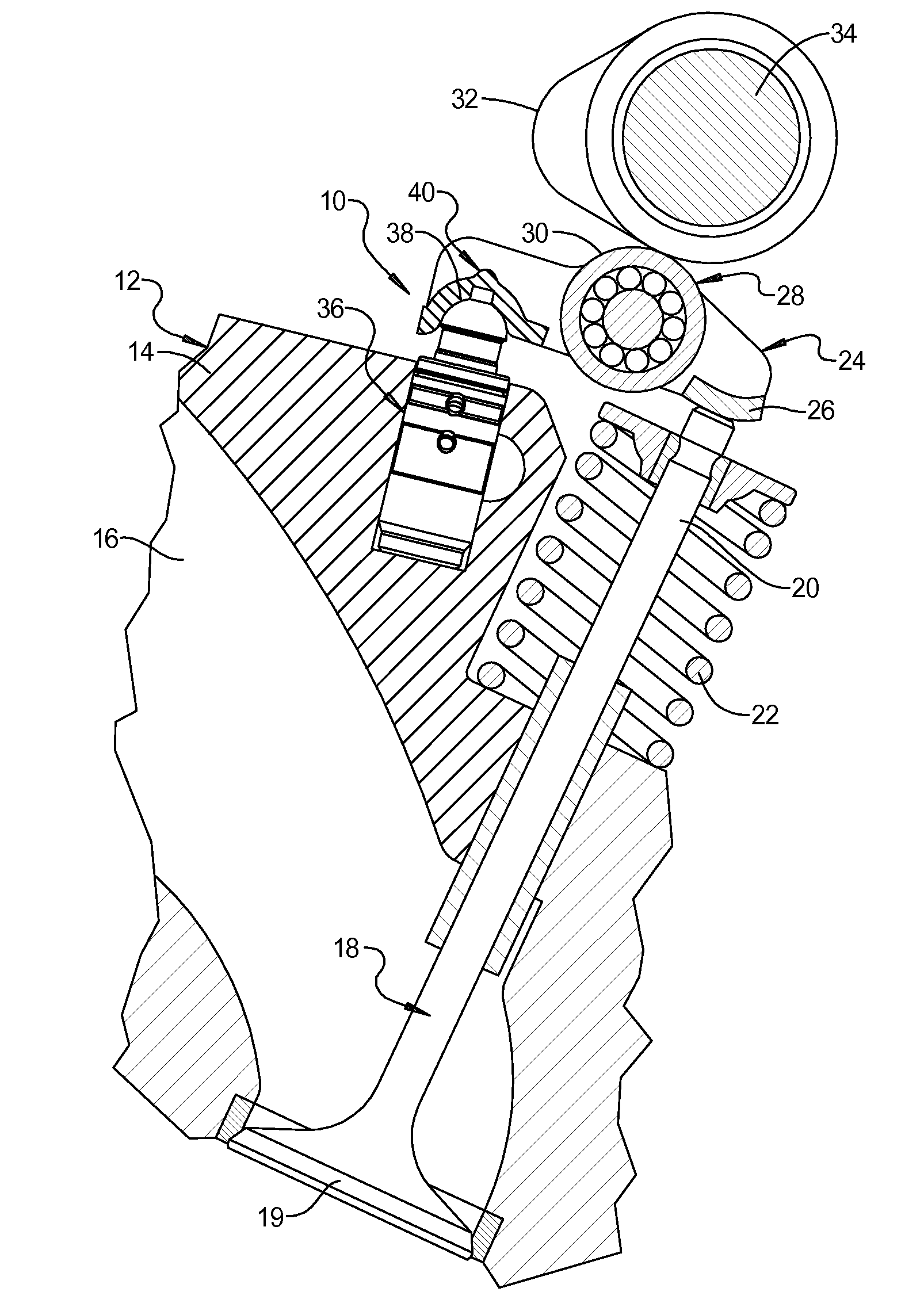

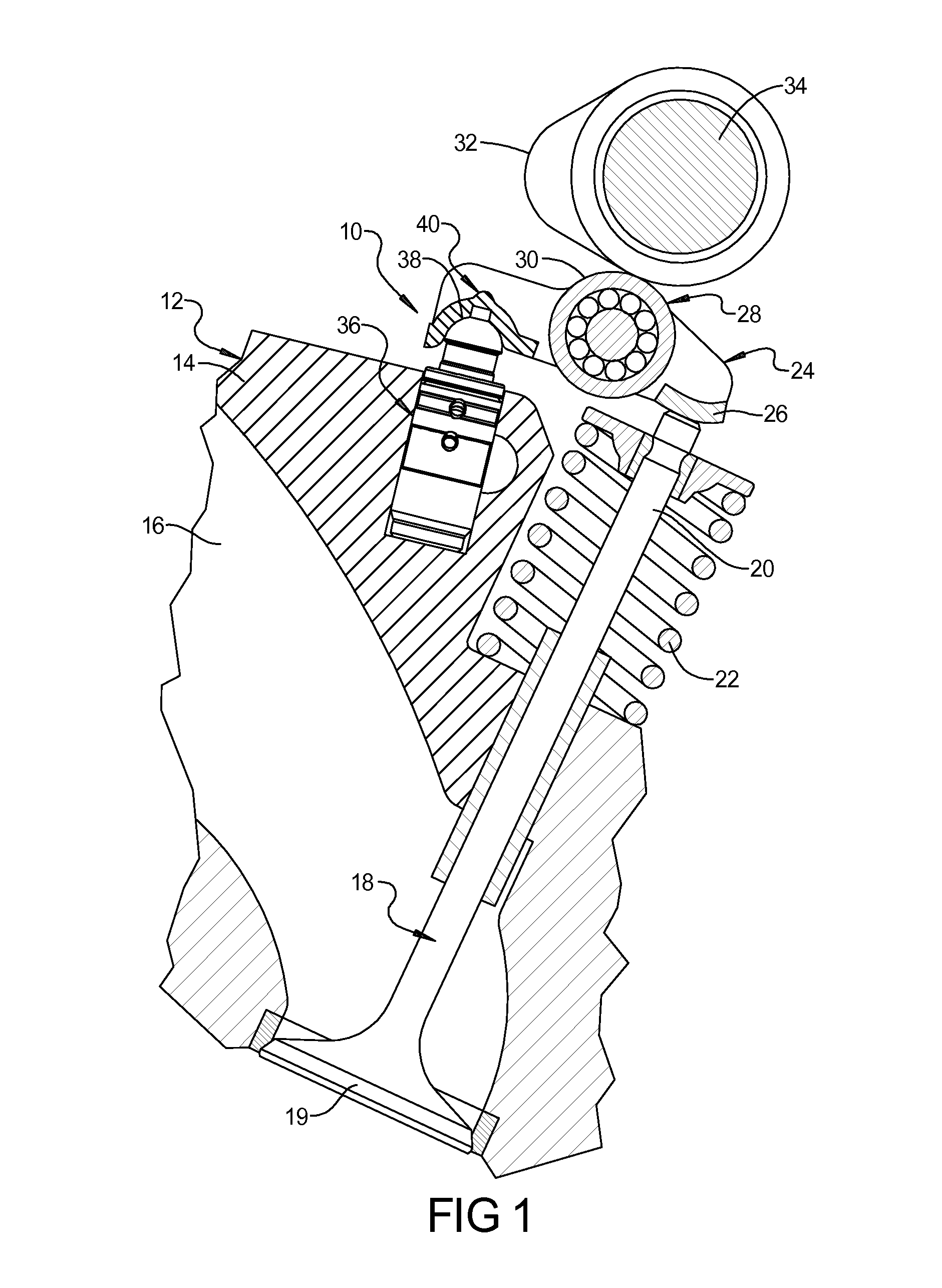

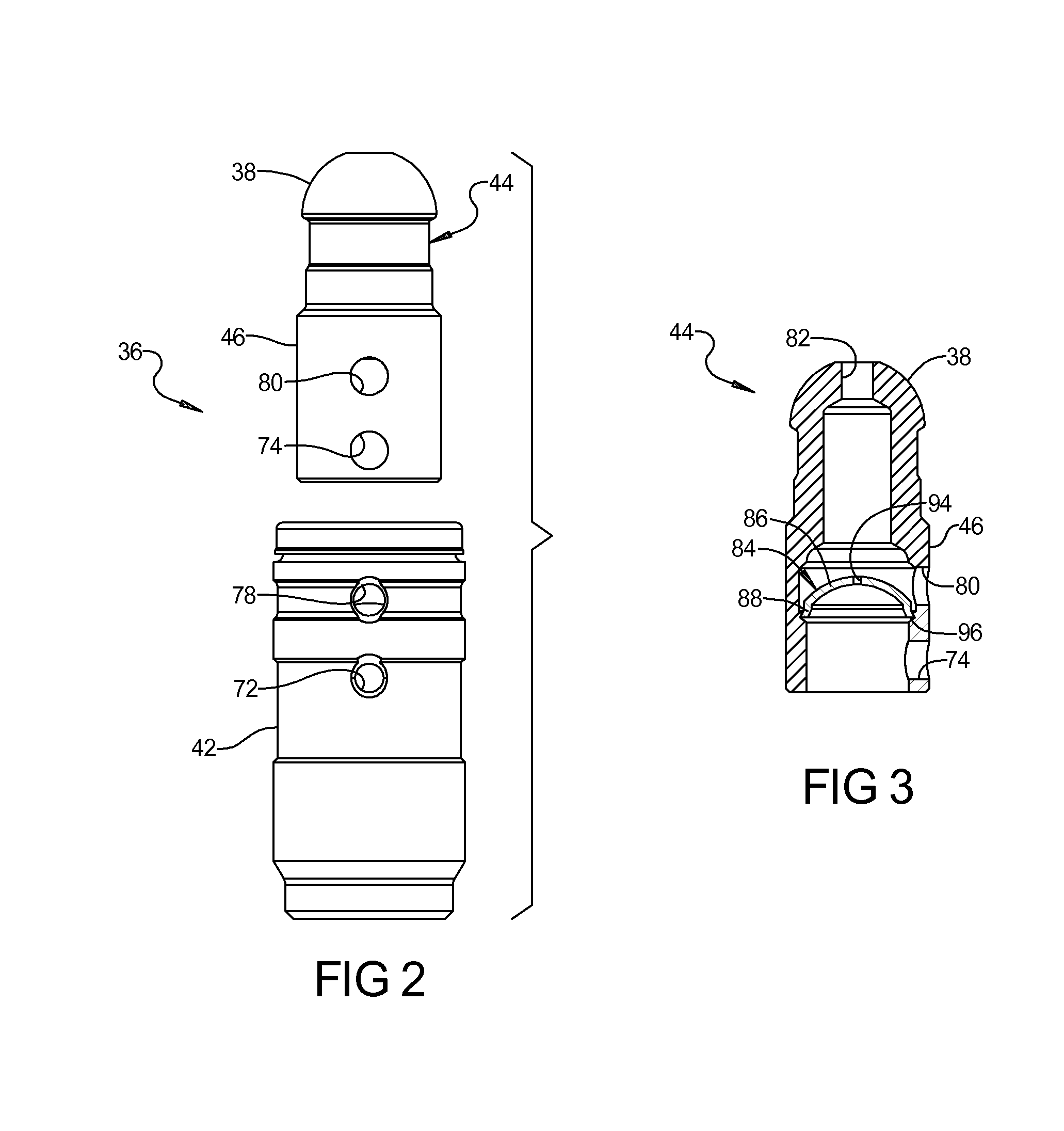

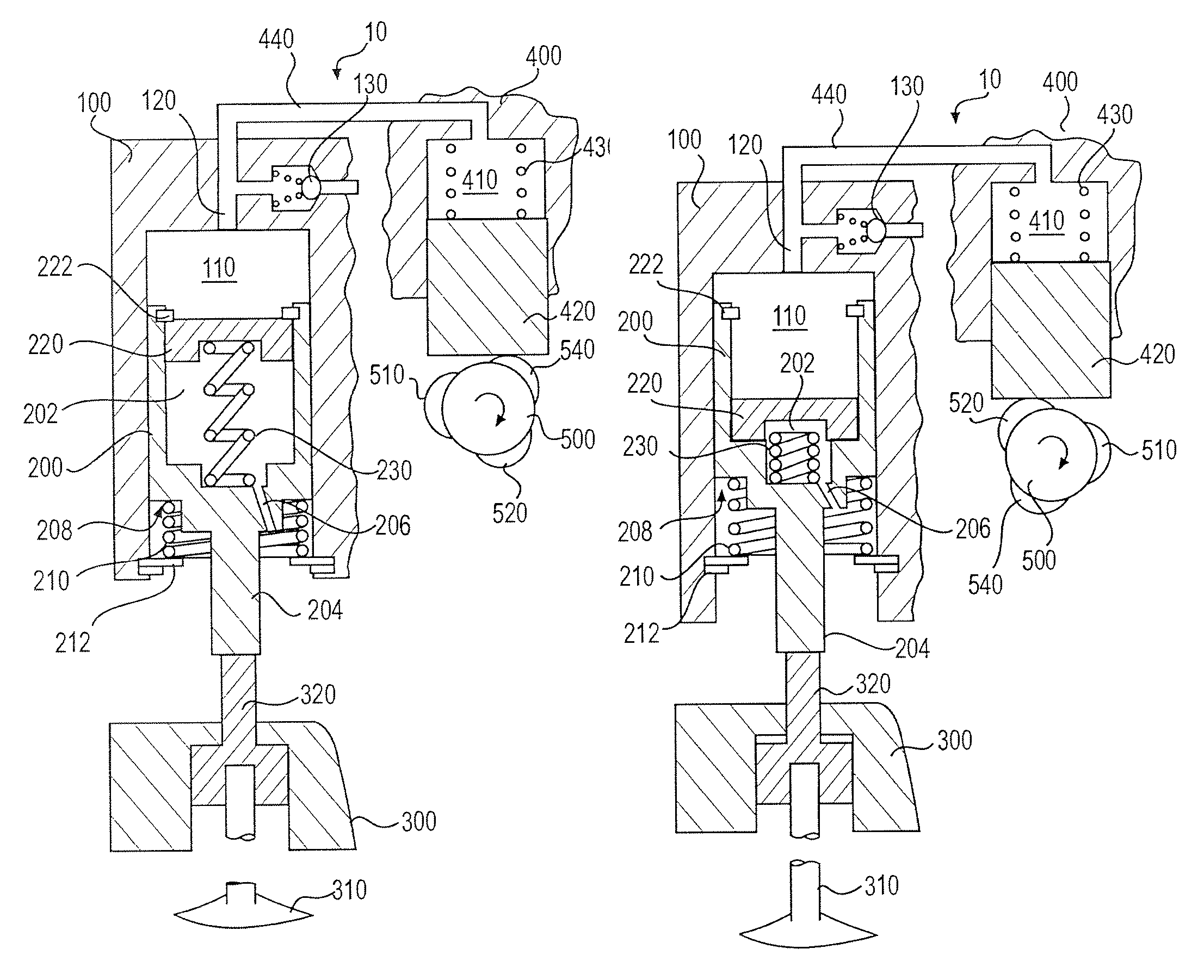

Valve lash adjuster having electro-hydraulic lost-motion capability

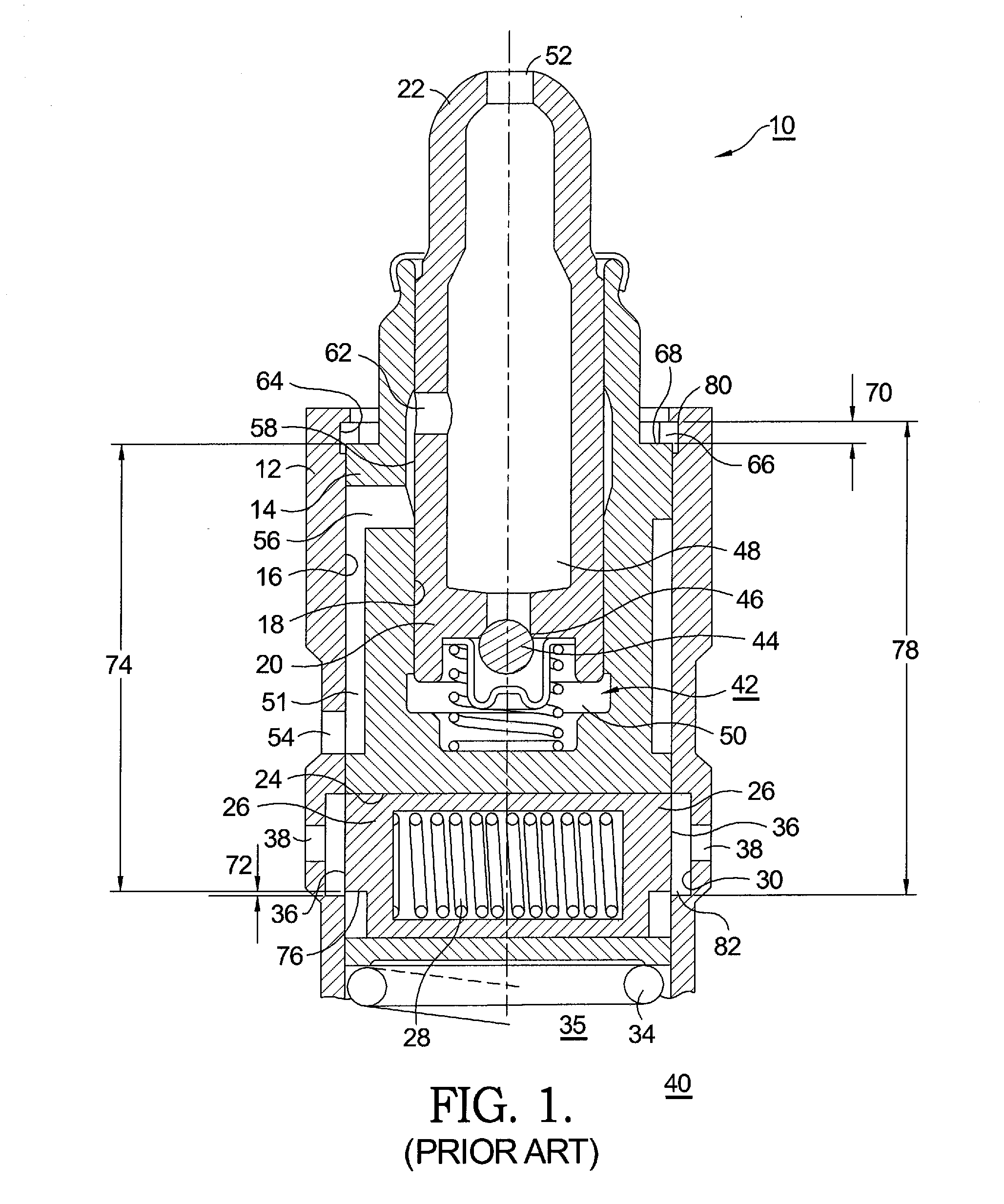

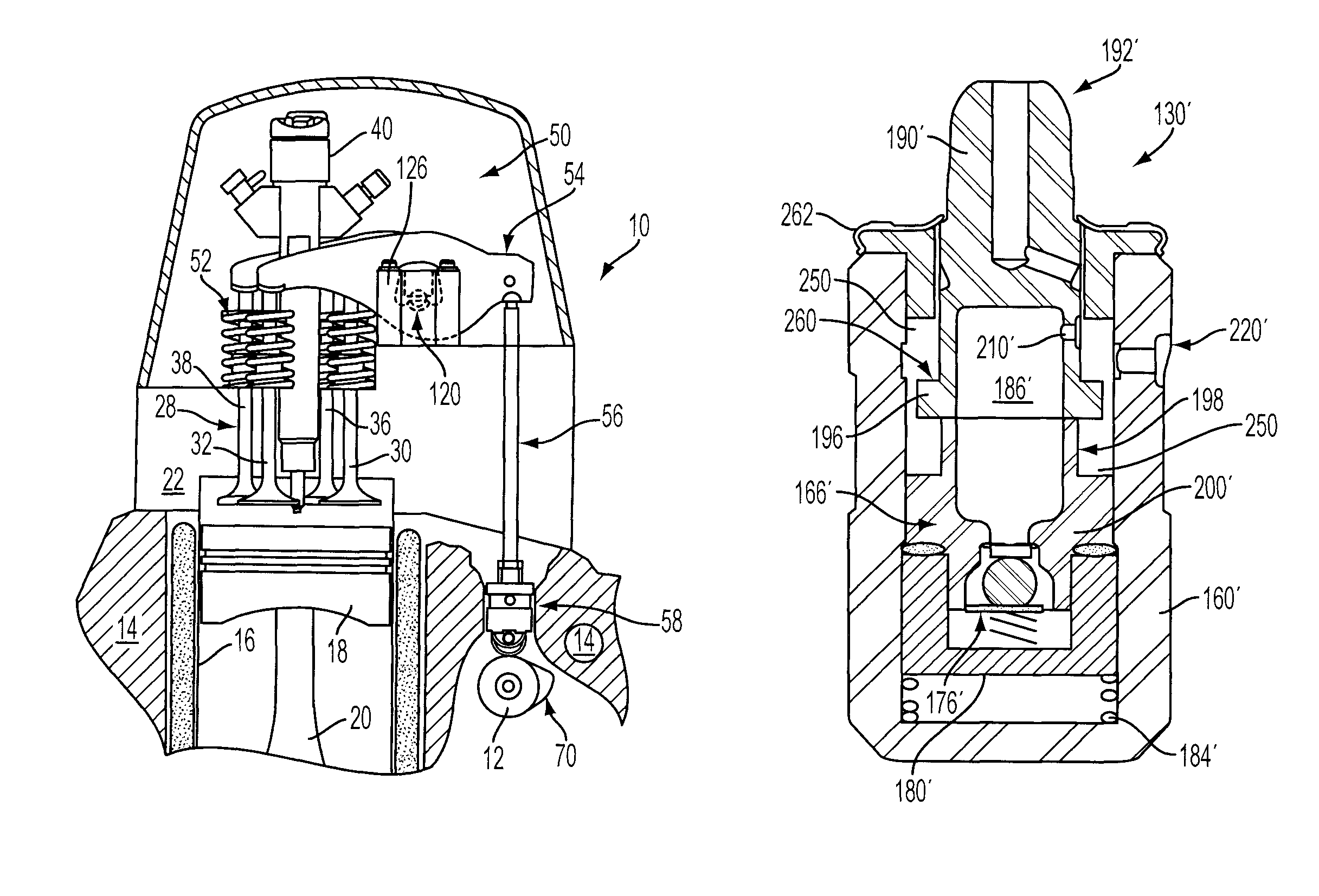

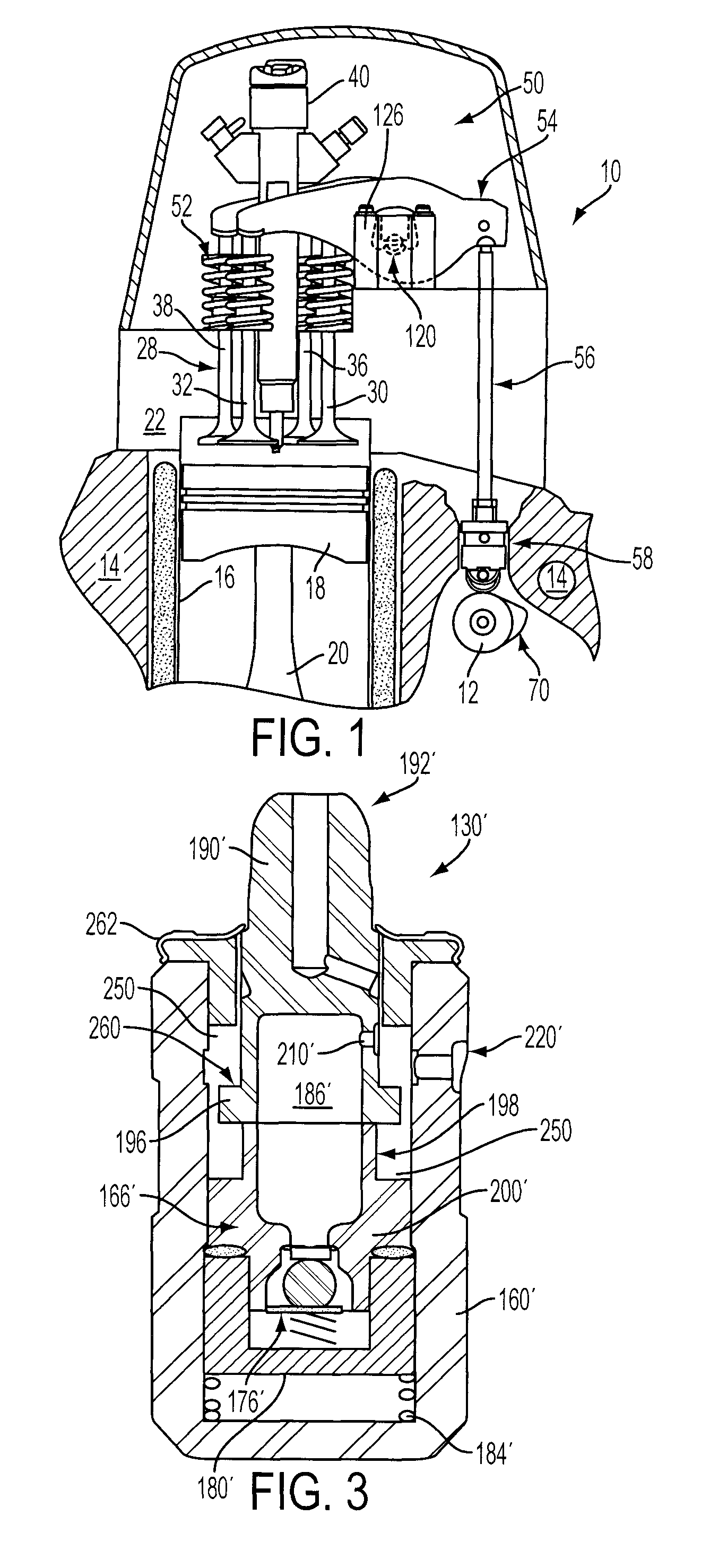

InactiveUS20070204818A1Small sizeReduced strengthValve arrangementsCam-followersSolenoid valveElectro hydraulic

In a Type 2 engine, a valve deactivation hydraulic lash adjuster (DHLA) in accordance with the invention replaces a conventional hydraulic lash adjuster in the train of a gas-exchange valve in a compression-ignited engine. In a Type 3 engine, a similar DHLA is disposed within an articulated rocker arm which is made selectively competent (valve activating) or incompetent (valve deactivating) thereby. A solenoid valve within the assembly diverts hydraulic fluid between support and non-support of a piston slidably disposed in a housing and terminating in a ball head. The valve is force-balanced. The preferred hydraulic fluid is diesel fuel, allowing for smaller diameter passages and cleaner operation than in prior art systems, eliminating the need for an accumulator chamber and accumulator piston as in the prior art. An alternate version of a type 3 engine having a DHLA, in accordance with the invention, is also shown.

Owner:DELPHI TECH INC

Dual feed hydraulic lash adjuster

An improved dual feed hydraulic lash adjuster (HLA), for use in an internal combustion engine, comprising a hollow body and a plunger assembly disposed in a bore of the engine. A one-piece plunger body includes a first chamber for forming a low-pressure oil reservoir and receiving a lash adjustment mechanism, and a second chamber open at one end and partially closed hemispherically for supporting a rocker arm and providing valve deactivating oil thereto for an auxiliary valve actuation system. The first and second chambers are separated by a transverse web, optionally having a small-diameter passage therethrough for air evacuation. The one-piece plunger body provides a high degree of resistance to side loads which may be imposed on the HLA in use.

Owner:DELPHI TECH IP LTD

Valve lash adjuster having electro-hydraulic lost-motion capability

InactiveUS7509933B2Small sizeReduced strengthValve arrangementsCam-followersSolenoid valveElectro hydraulic

In a Type 2 engine, a valve deactivation hydraulic lash adjuster (DHLA) in accordance with the invention replaces a conventional hydraulic lash adjuster in the train of a gas-exchange valve in a compression-ignited engine. In a Type 3 engine, a similar DHLA is disposed within an articulated rocker arm which is made selectively competent (valve activating) or incompetent (valve deactivating) thereby. A solenoid valve within the assembly diverts hydraulic fluid between support and non-support of a piston slidably disposed in a housing and terminating in a ball head. The valve is force-balanced. The preferred hydraulic fluid is diesel fuel, allowing for smaller diameter passages and cleaner operation than in prior art systems, eliminating the need for an accumulator chamber and accumulator piston as in the prior art. An alternate version of a type 3 engine having a DHLA, in accordance with the invention, is also shown.

Owner:DELPHI TECH INC

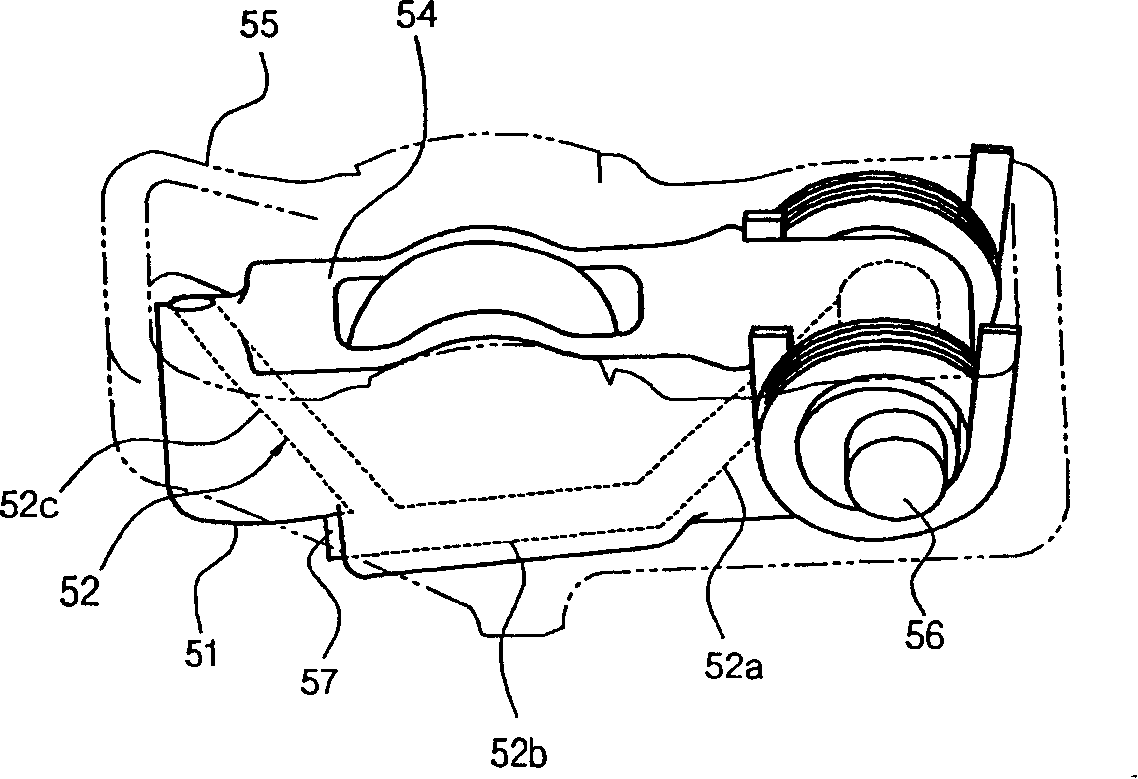

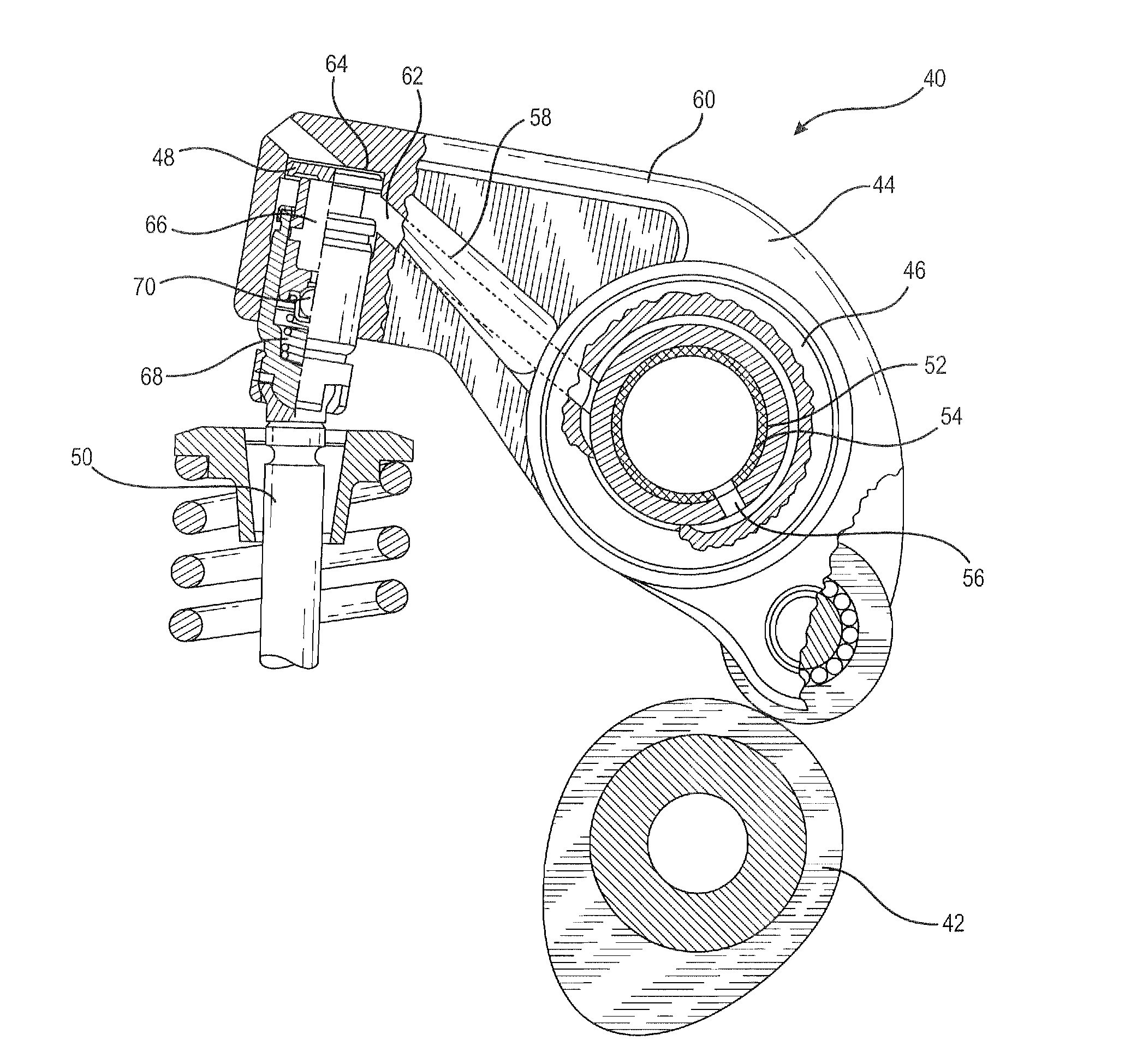

Two-step roller finger cam follower

A two-step roller finger follower assembly for shifting between high-lift and low-lift valve modes in a valve train of an internal combustion engine includes a body having side members defining coaxially disposed shaft orifices, a pallet end, a socket end, a slider arm aperture, and a latch pin channel. The socket end is mountable to a hydraulic lash adjuster, and the pallet end is matable with a valve stem. A slider arm for engaging a high-lift cam lobe is disposed in the aperture, is pivotably mounted to a rotatable cross-shaft extending through the shaft orifices, and includes a slider tip for selectively engaging a latch pin to latch or unlatch the slider arm from the body. Dual rollers on the cross-shaft follow dual low-lift cam lobes. Preferably, the slider arm has a compound radial surface to provide compound lost motion of the slider arm, thereby minimizing rotational inertia.

Owner:DELPHI TECH INC

Variable valve lift follower for vehicle

Owner:HYUNDAI MOTOR CO LTD

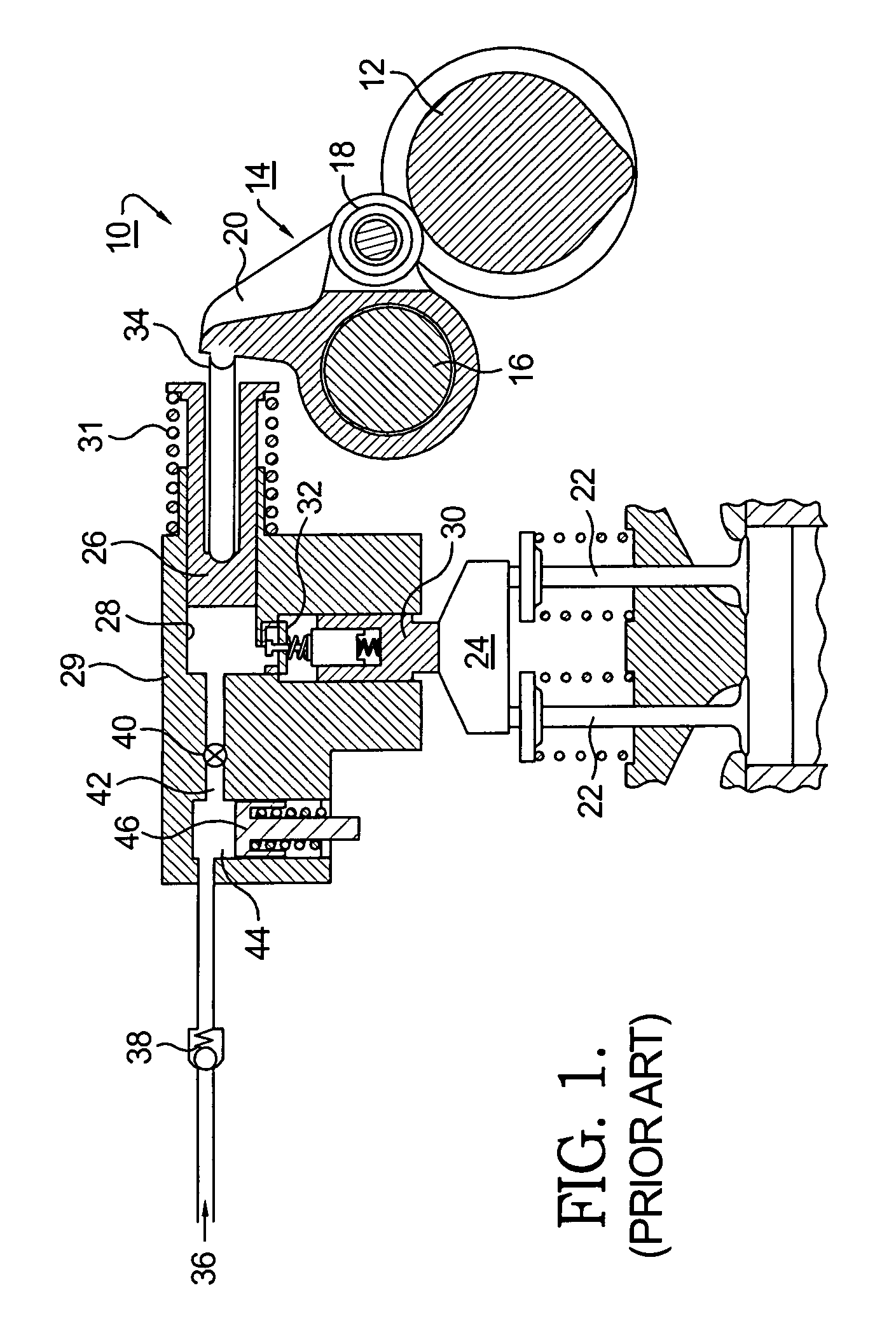

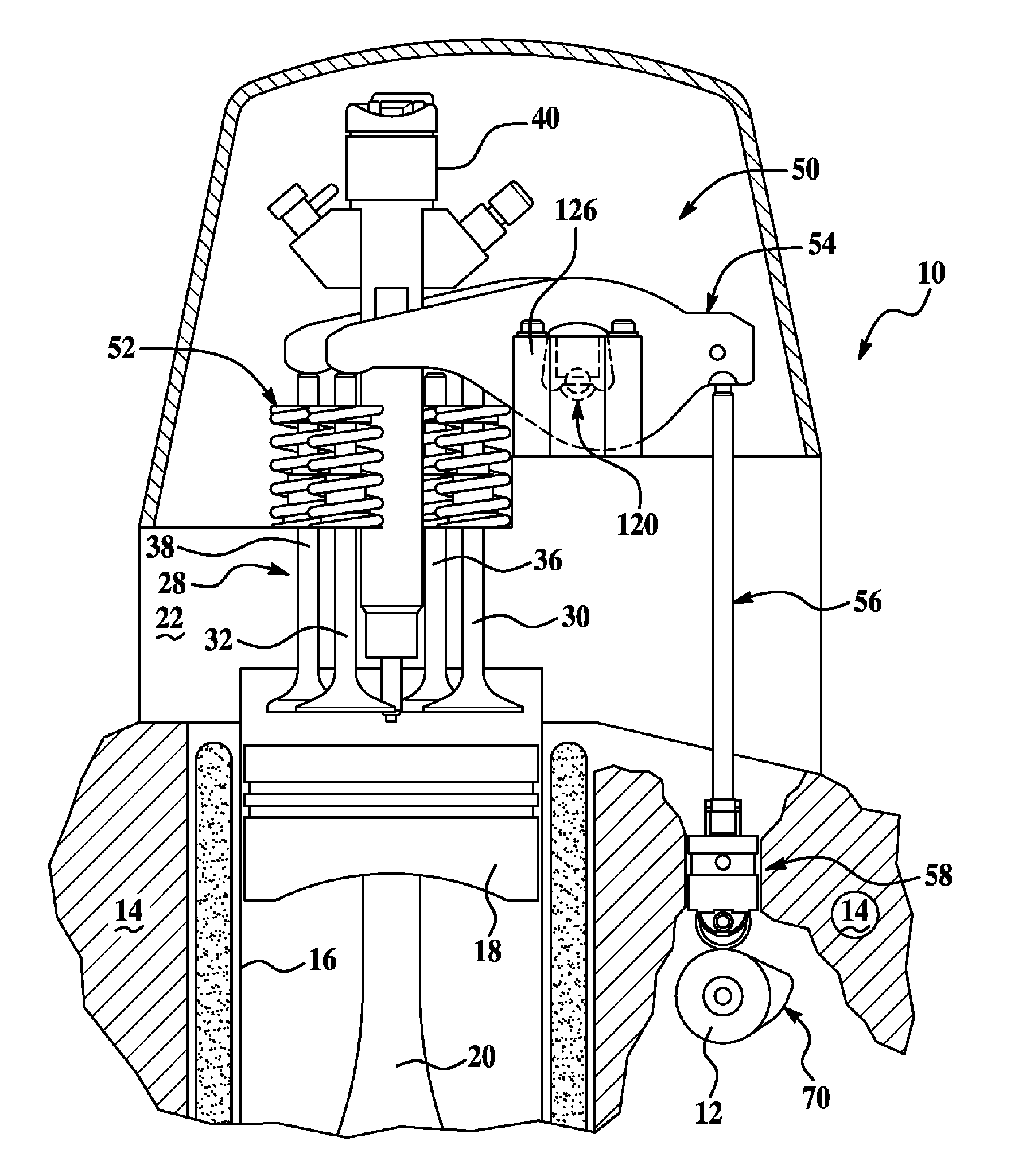

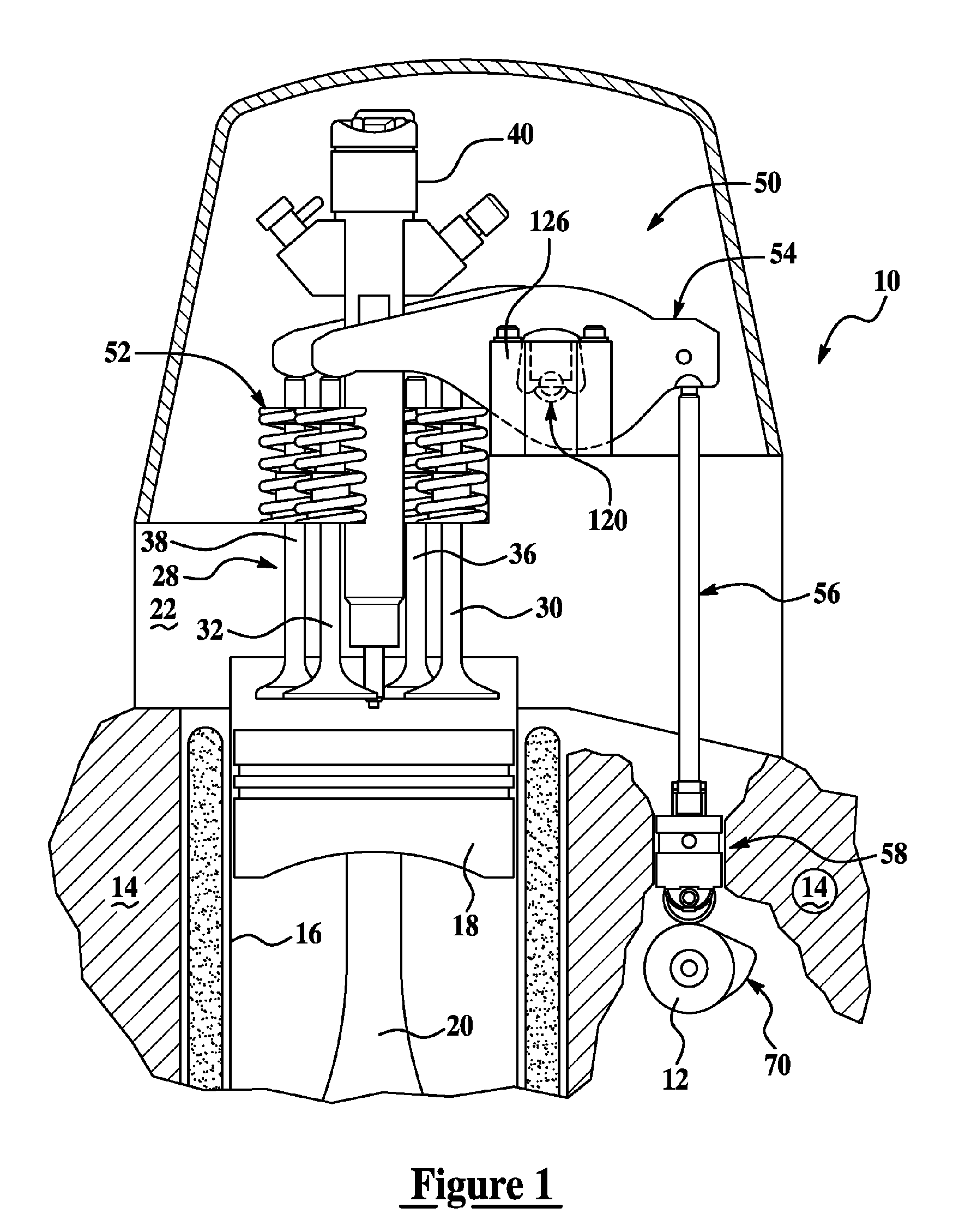

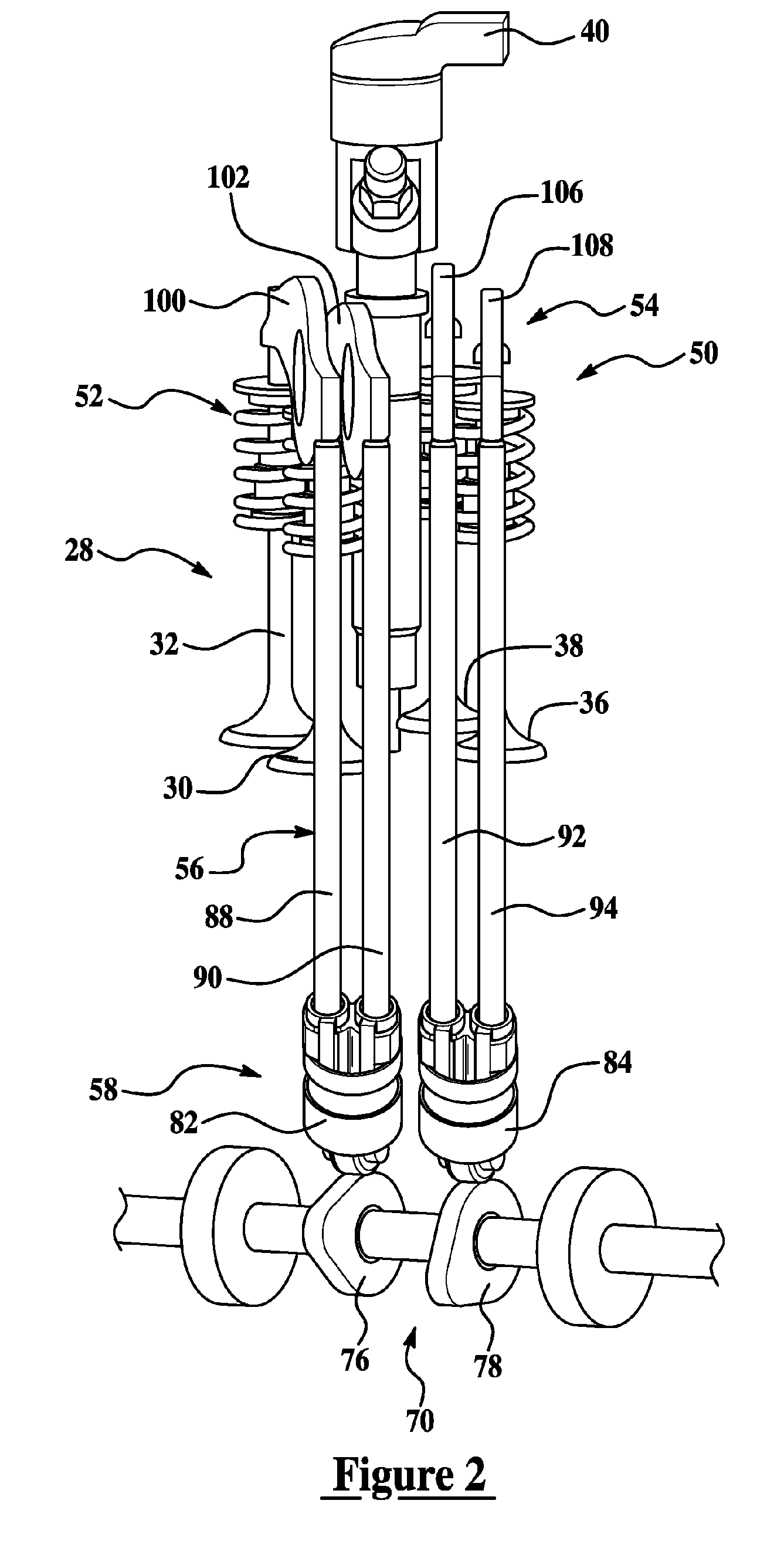

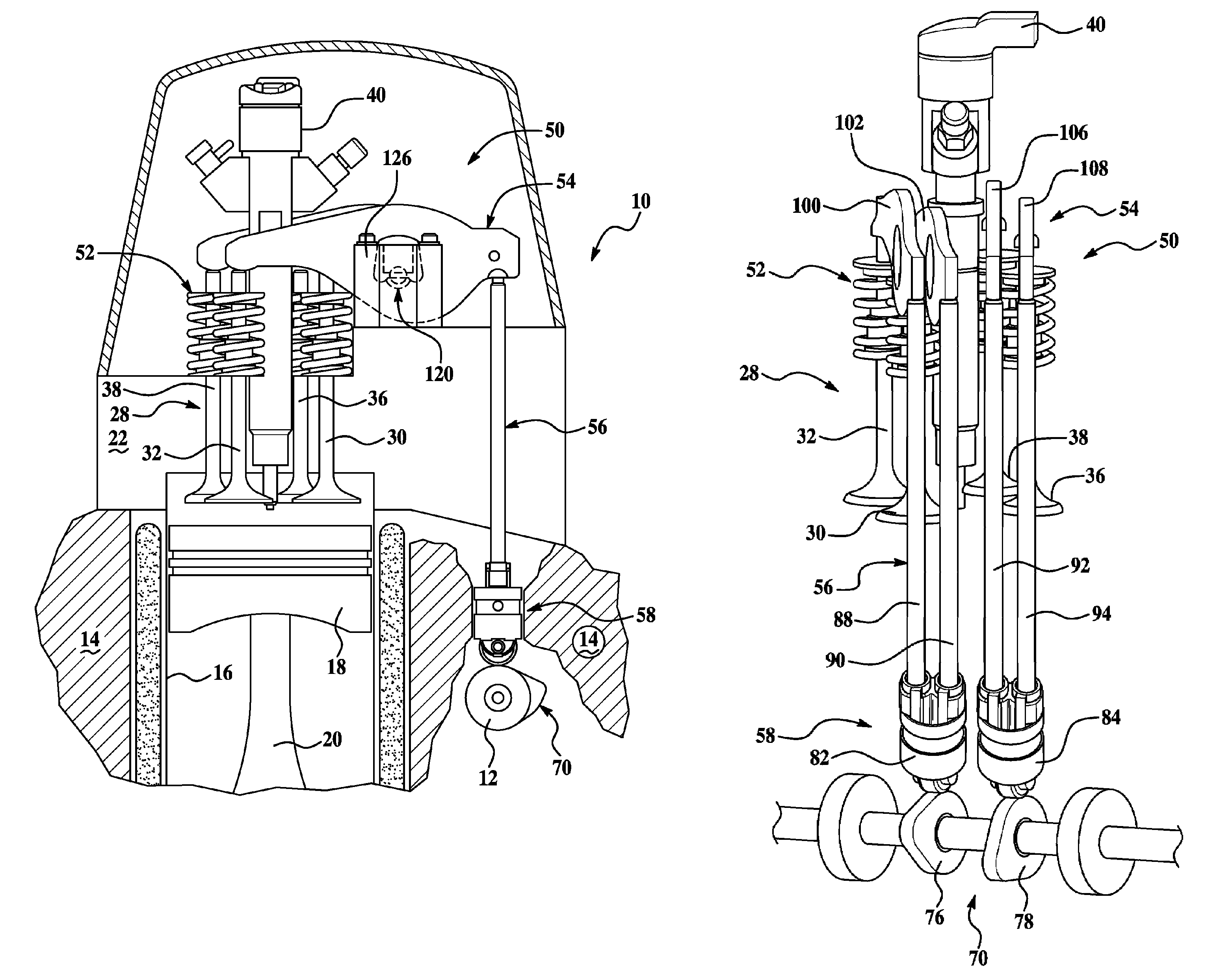

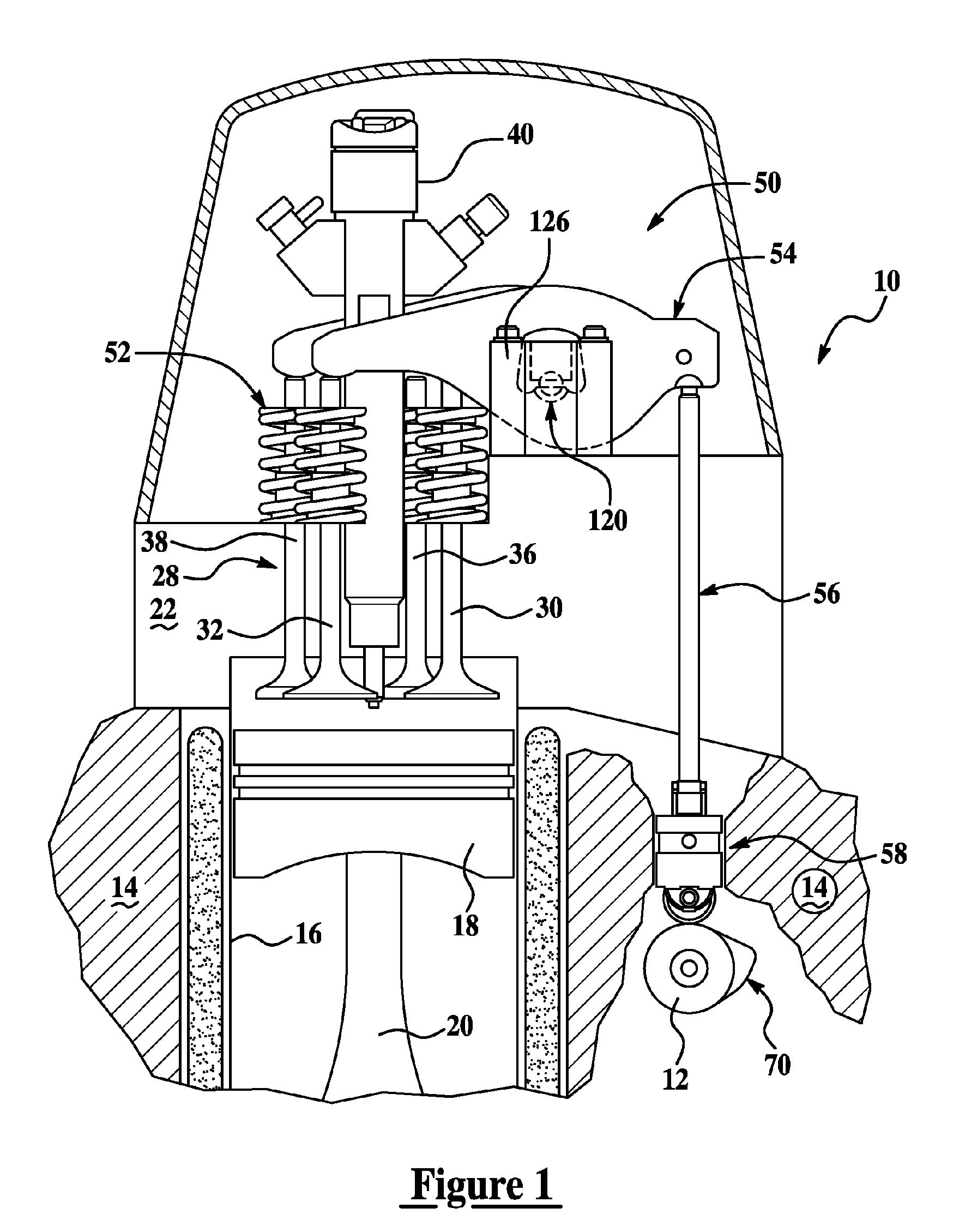

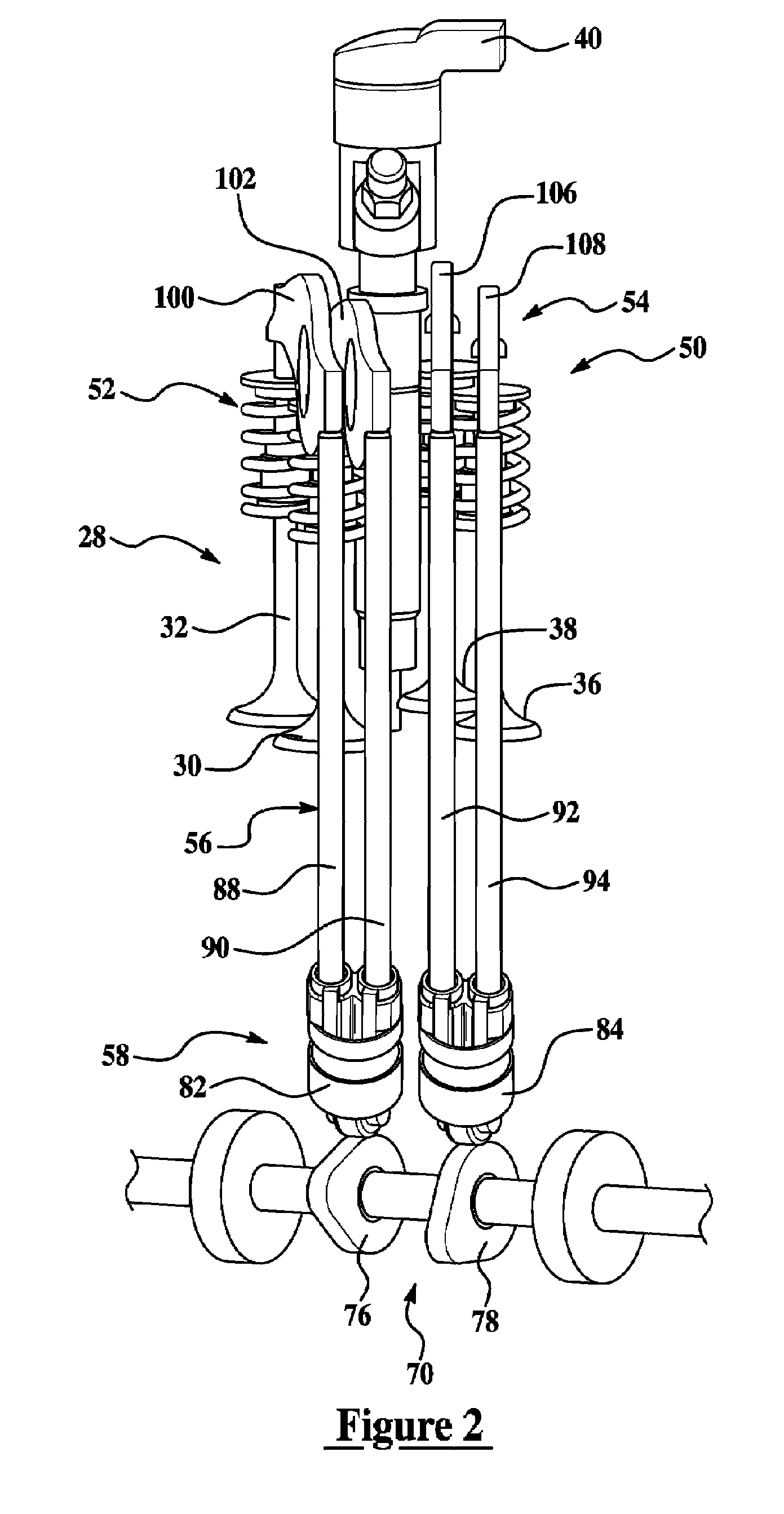

Engine and valvetrain with dual pushrod lifters and independent lash adjustment

InactiveUS20070119397A1Reduce and eliminate noiseReduce and eliminate and vibrationValve arrangementsMachines/enginesExhaust valveCylinder head

A multiple cylinder internal combustion engine having a camshaft-driven valvetrain with a camshaft disposed within an engine block includes at least two intake and / or exhaust valves with a pair of valves operated by a common camshaft lobe and a cam follower. The valvetrain may include independently operable mechanical or hydraulic lash adjusters. The cam follower contacts the common camshaft lobe and at least two pushrods with each pushrod having an associated single plane rocker arm which couples to a fulcrum mounted to the cylinder head to actuate the at least two valves.

Owner:FORD GLOBAL TECH LLC

Driving oil way of variable valve mechanism with VVT and VVL system

ActiveCN101956584AOil circuit structure is simpleEasy to control speedLubrication of auxillariesCylinder headsControl valvesCam

The invention relates to a driving oil way of a variable valve mechanism with VVT and VVL system. The driving oil way comprises a VVT oil way, a cam shaft journal lubricating oil way, a hydraulic clearance adjuster oil way, a VVL system control oil way and one-way valves (6), wherein the VVT oil way is arranged in the middle of a cylinder cover; the cam shaft journal lubricating oil way is arranged on the two sides of the cylinder cover; the VVL system control oil way is integrated in the hydraulic clearance adjuster oil way; and a plurality of one-way valves (6) are arranged between a VVT oil way inlet (4) on the oil way of the cylinder cover and an engine oil control valve OCV (11) of the VVT system, and opened when the VVT system works normally and closed when an engine is stopped or idles.

Owner:CHERY AUTOMOBILE CO LTD

Engine and valvetrain with dual pushrod lifters and independent lash adjustment

InactiveUS7617807B2Reduce and eliminate noiseReduce and eliminate and vibrationValve arrangementsMachines/enginesExhaust valveCylinder head

A multiple cylinder internal combustion engine having a camshaft-driven valvetrain with a camshaft disposed within an engine block includes at least two intake and / or exhaust valves with a pair of valves operated by a common camshaft lobe and a cam follower. The valvetrain may include independently operable mechanical or hydraulic lash adjusters. The cam follower contacts the common camshaft lobe and at least two pushrods with each pushrod having an associated single plane rocker arm which couples to a fulcrum mounted to the cylinder head to actuate the at least two valves.

Owner:FORD GLOBAL TECH LLC

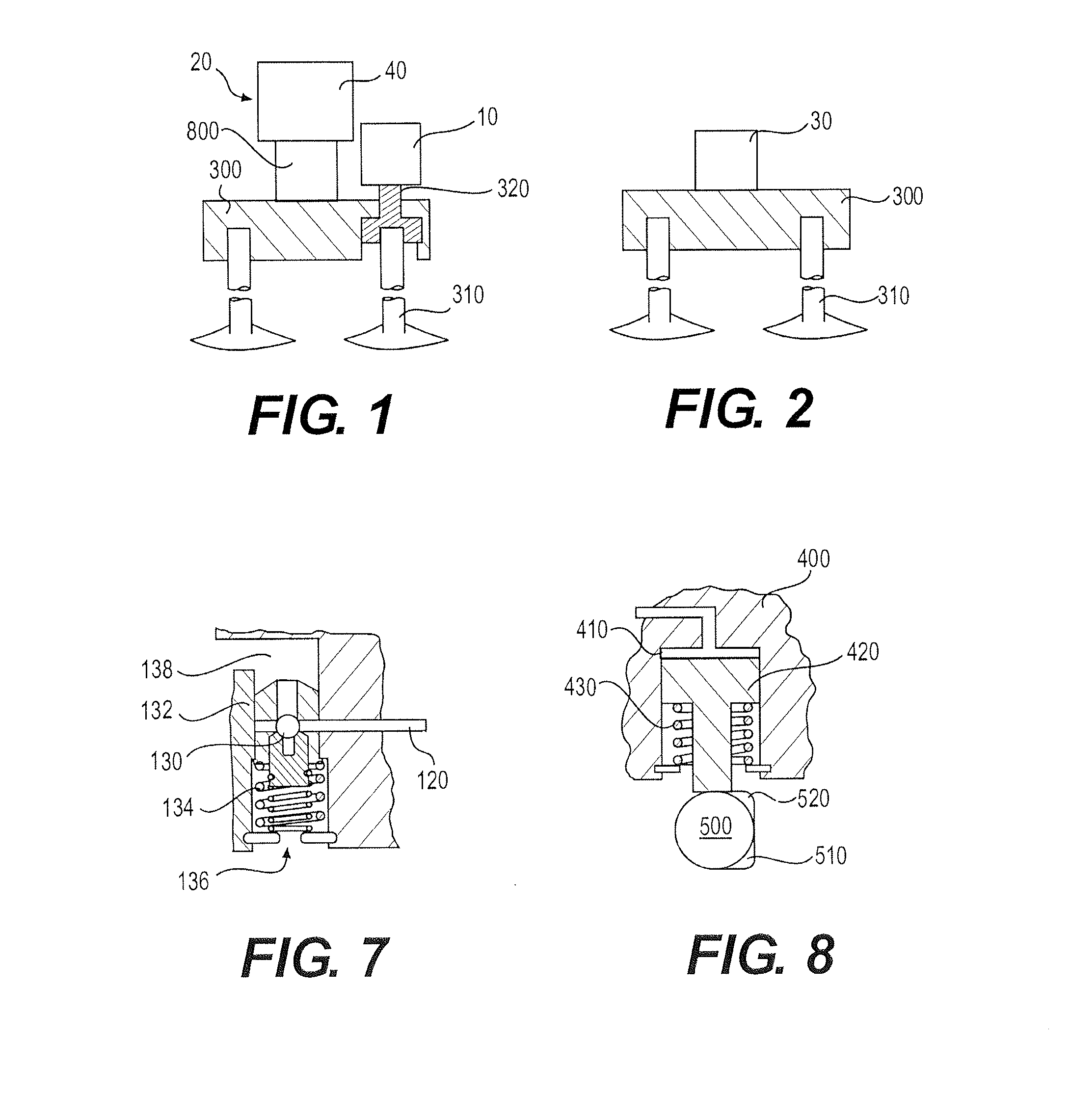

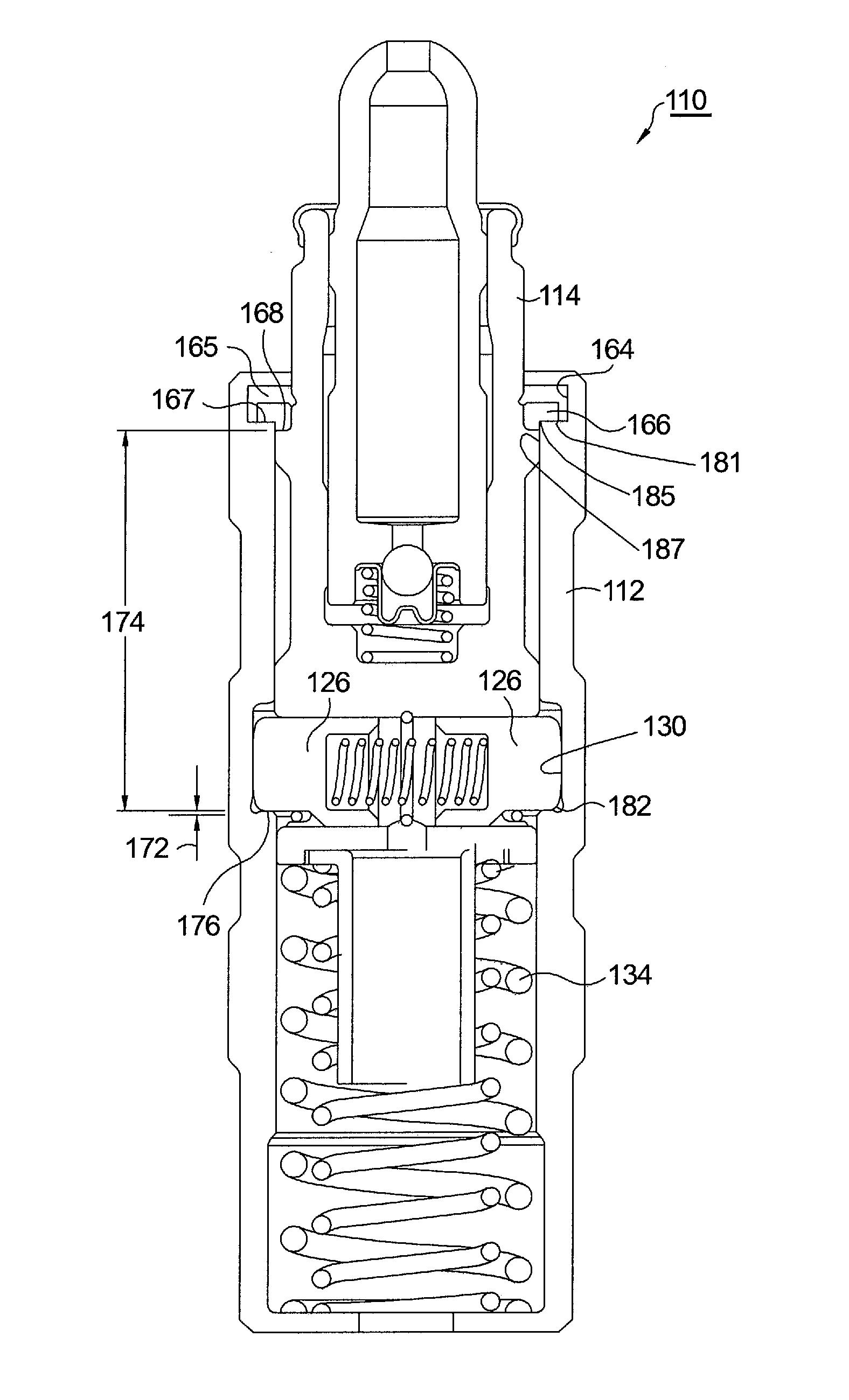

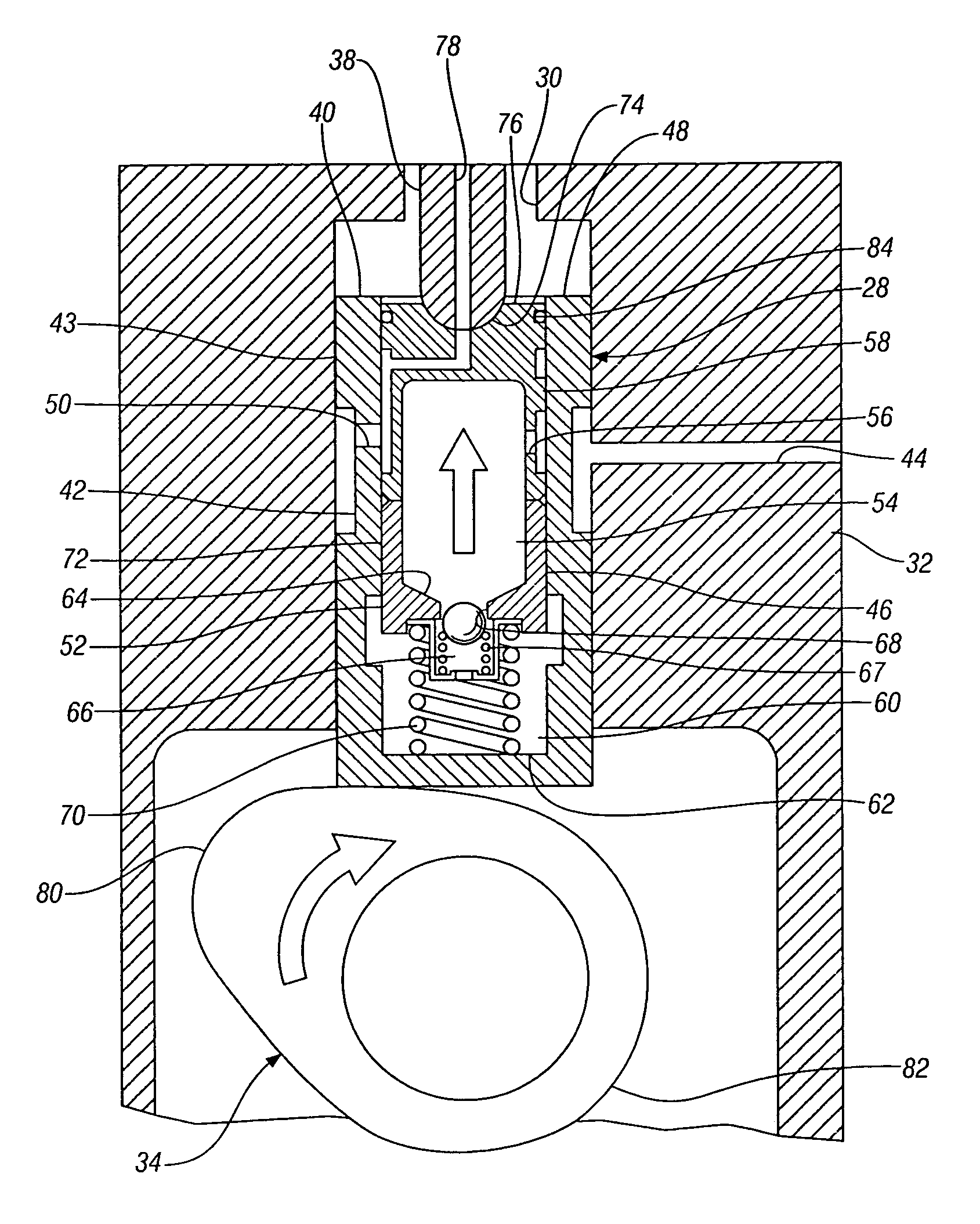

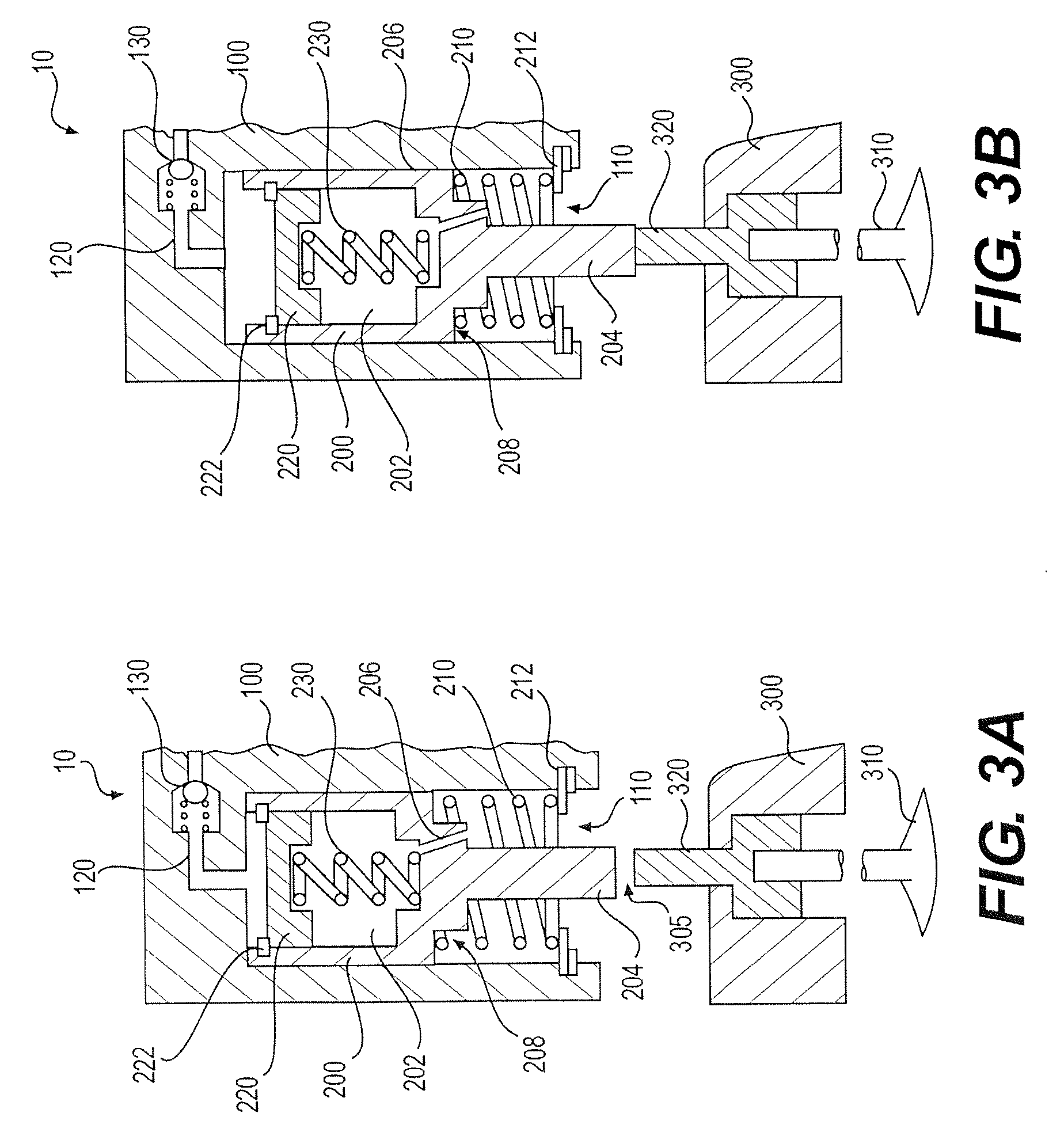

Apparatus and Method for Setting Mechanical Lash in a Valve-Deactivating Hydraulic Lash Adjuster

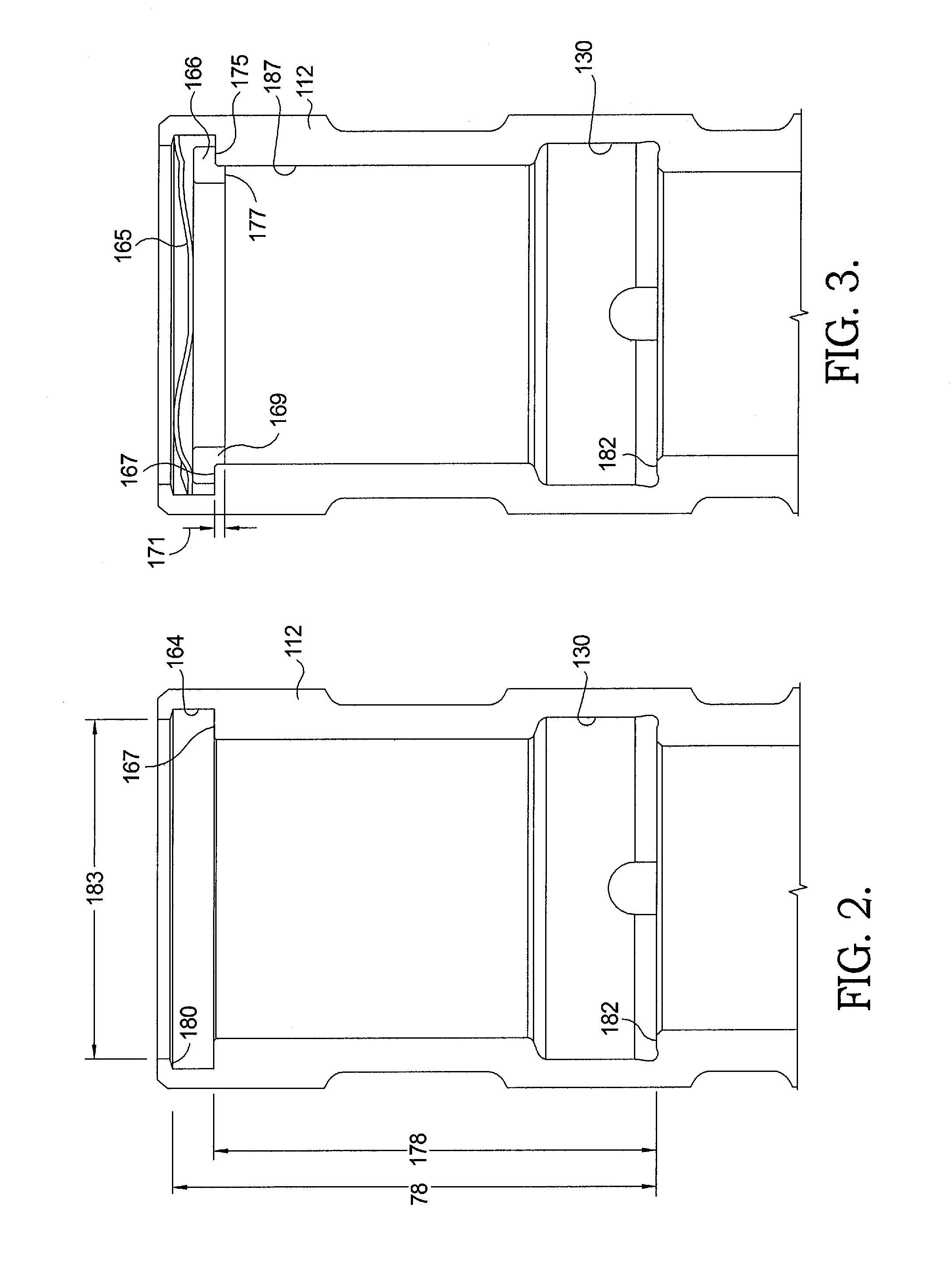

InactiveUS20110061615A1Travel can be limitedValve arrangementsMachines/enginesEngineeringManufacturing variation

A DHLA including a hydraulic lash adjustment mechanism disposed within a plunger slidably disposed within a pin housing that is slidably disposed within an axial bore in an adjuster body. A lash ring disposed in a groove near the outer end of the DHLA body includes a portion extending into the bore to limit travel of the pin housing and thereby set the internal mechanical lash in the DHLA. The lash ring has a thickness selected to provided a predetermined amount of mechanical lash in the assembled lifter, which thickness varies from assembly to assembly to compensate for manufacturing variation in the components. A biasing means such as a wave ring, a Belleville washer or a beveled retaining ring is also installed in the annular groove to urge the lash ring against the lower surface of the groove under all DHLA operating conditions.

Owner:DELPHI TECH IP LTD

Hydraulic lash adjuster

InactiveUS20050183686A1Reduce wearSmall specific gravityValve arrangementsSolid-state devicesInternal combustion engineHydraulic fluid

A hydraulic lash adjuster for an internal combustion engine is disclosed. The hydraulic lash adjuster includes a low-pressure chamber defined in the plunger and filled with a hydraulic fluid and a high-pressure chamber filled with hydraulic fluid defined in a lower interior of the cylinder and partitioned by the bottom wall of the plunger from the low-pressure chamber. A valve port is formed through the bottom wall of the plunger so as to communicate with both the low-pressure and high-pressure chambers. The valve port has at the high-pressure chamber side an opening edge formed with a valve seat face. A valve element is provided in the high-pressure chamber so as to abut and depart from the valve seat face, thereby closing and opening the valve port. The valve element is made of a material having a specific gravity smaller than steel.

Owner:OTICS CORP

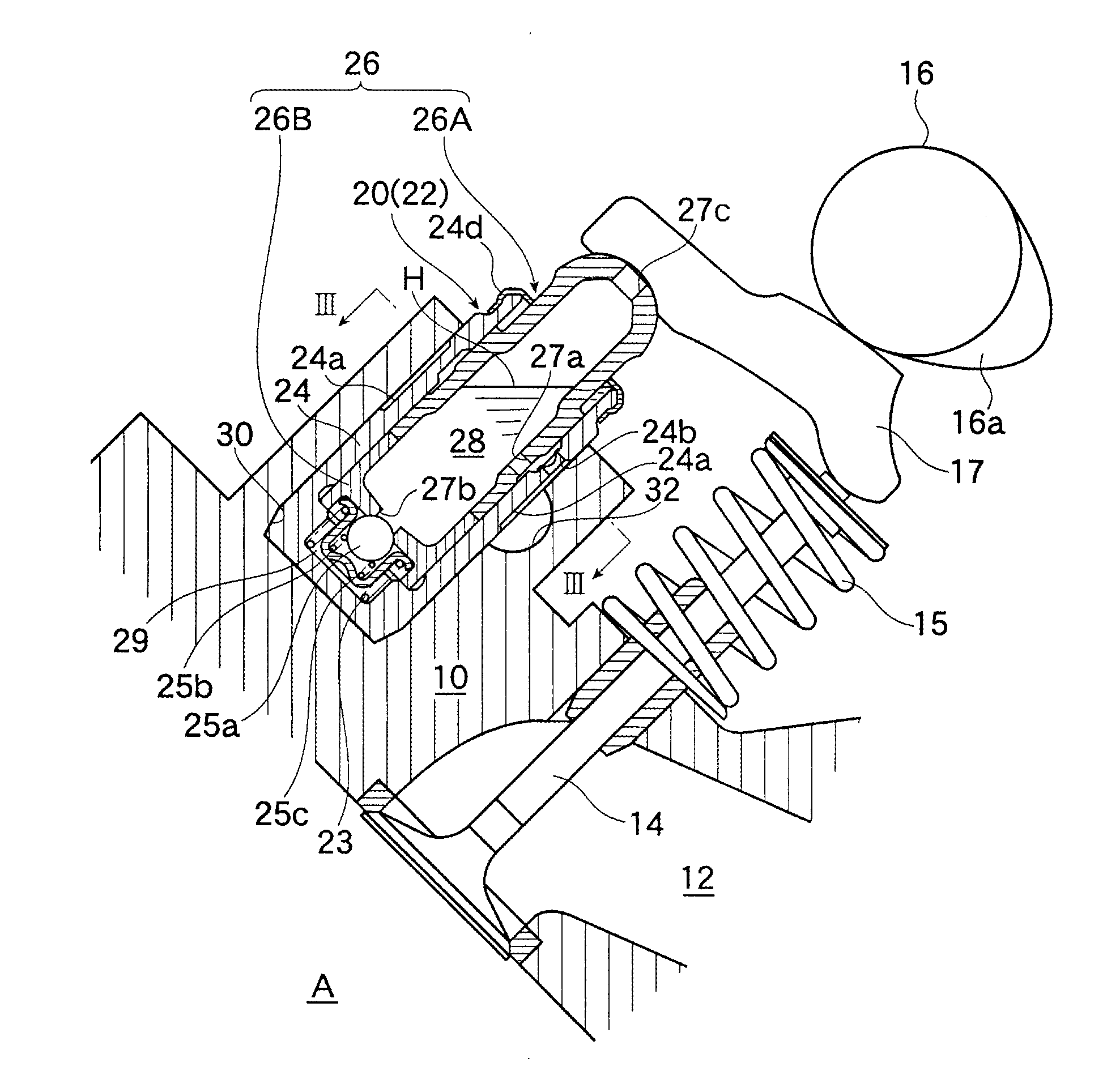

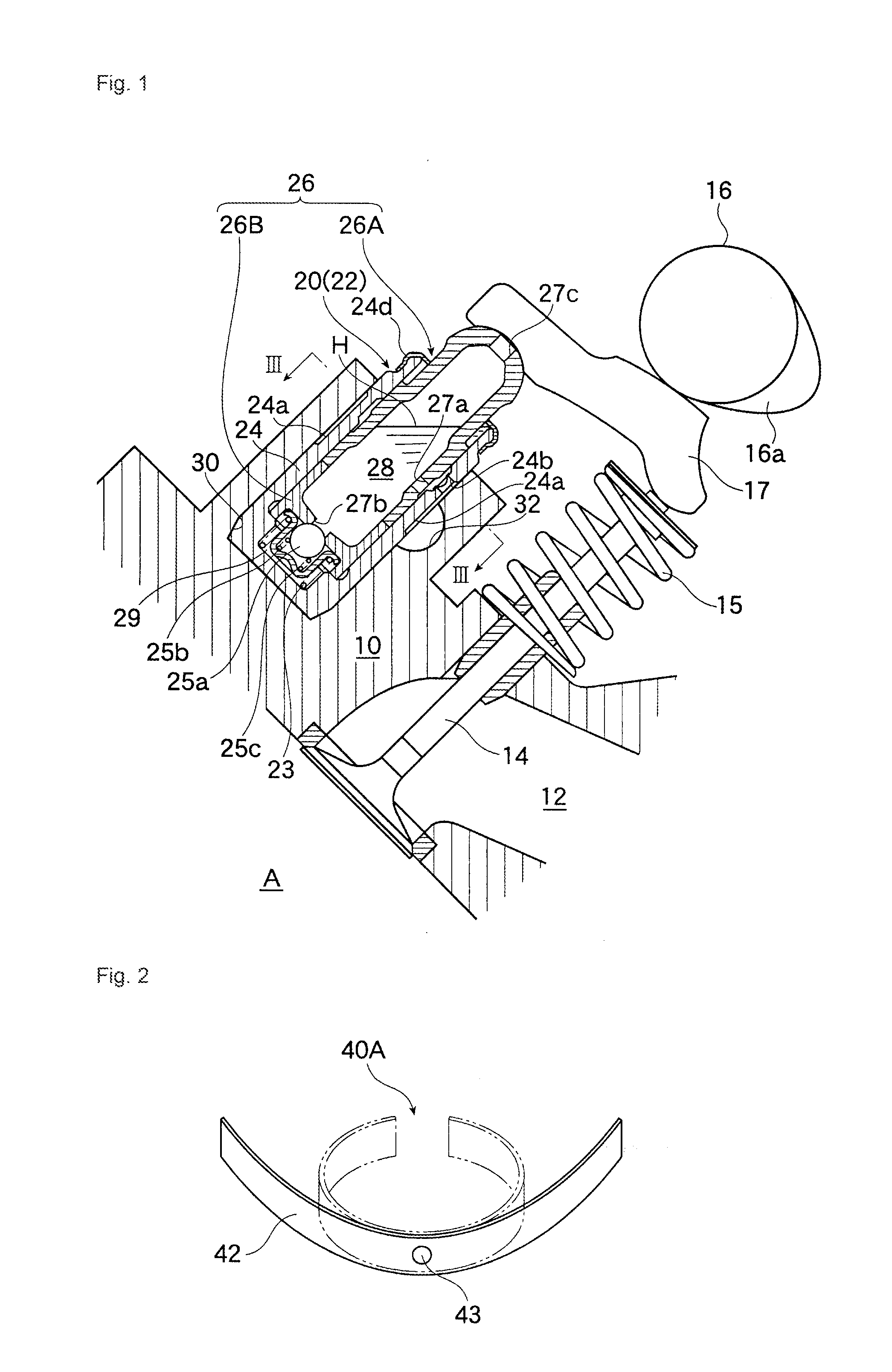

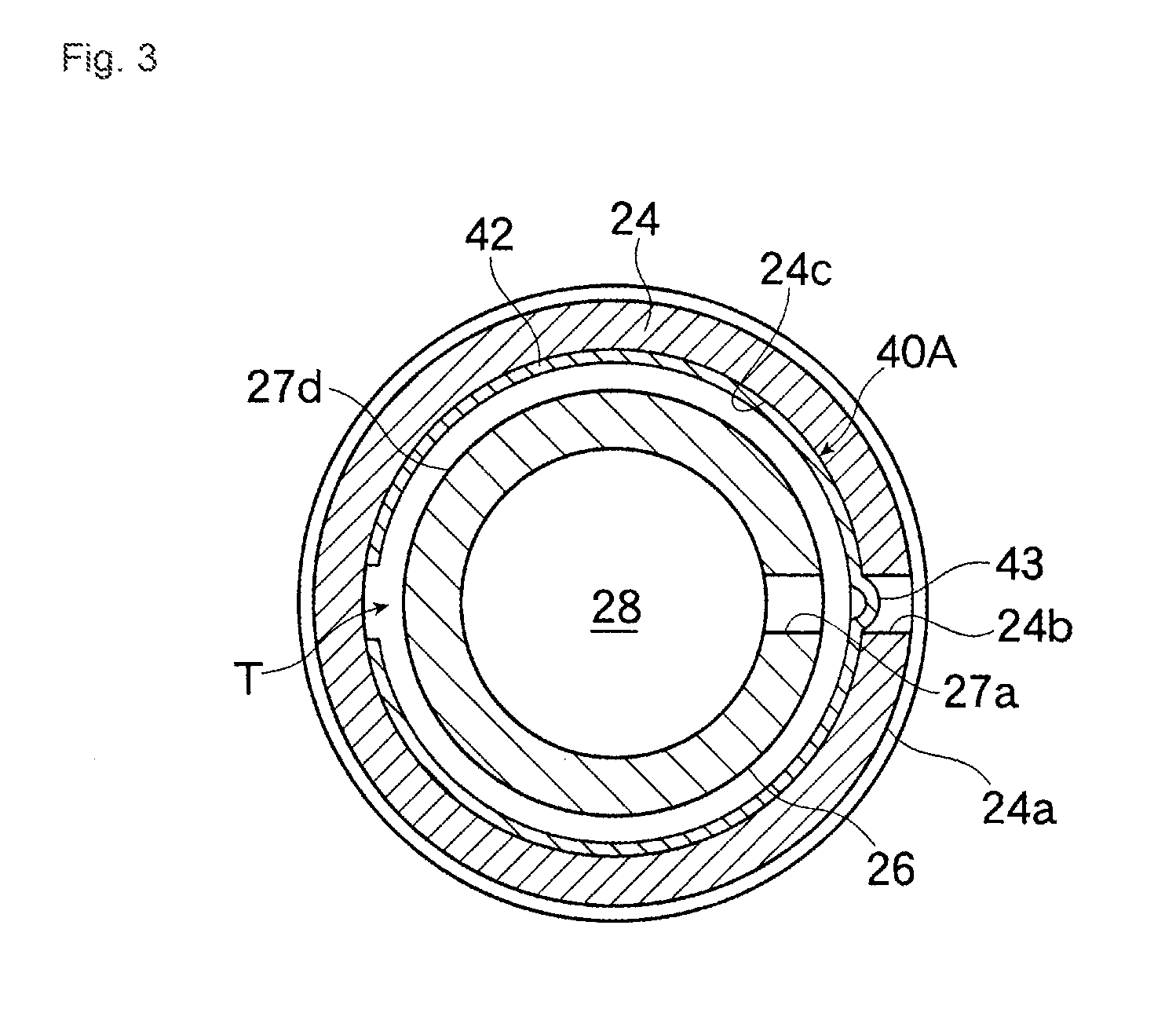

Hydraulic lash adjuster for internal combustion engine

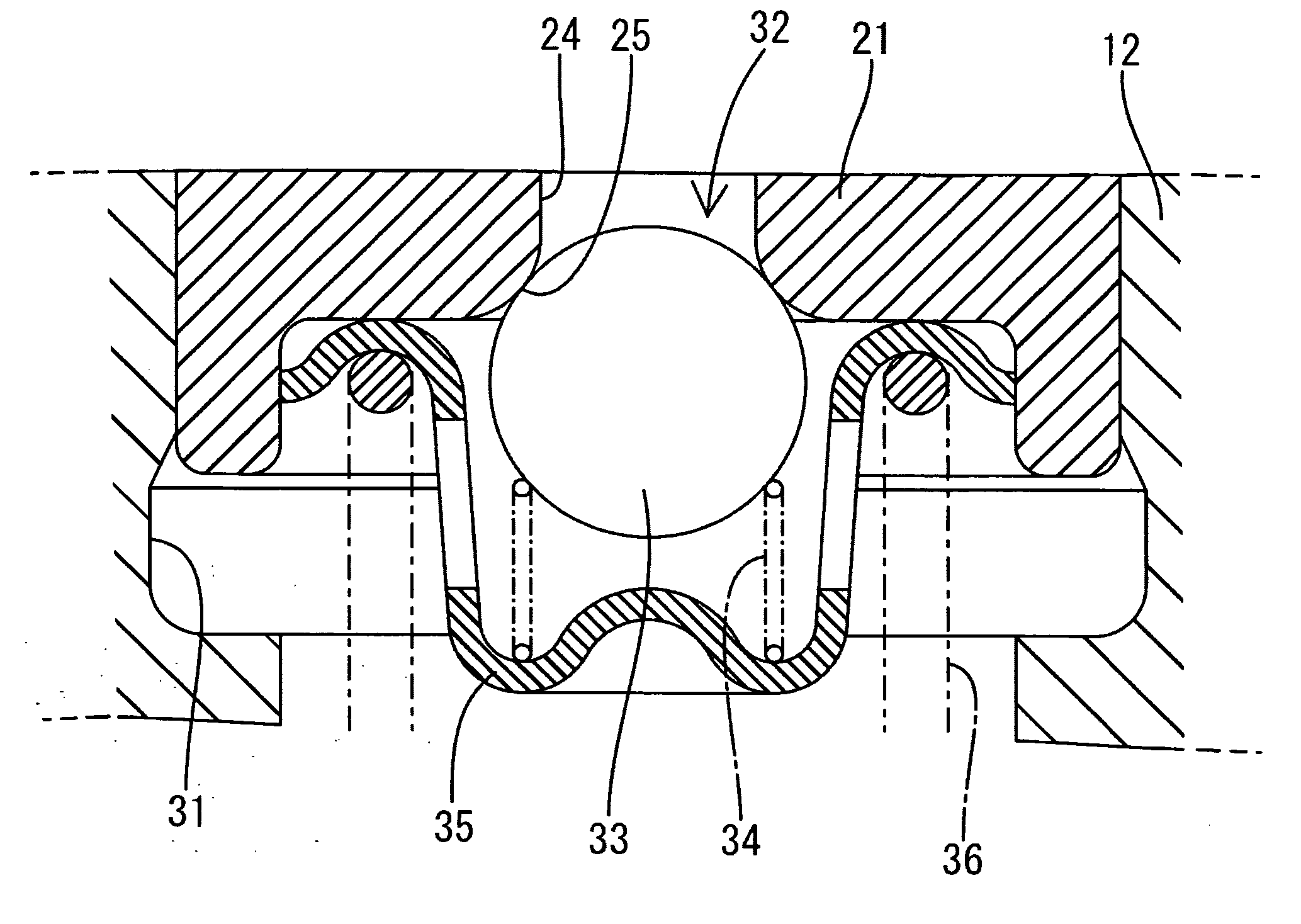

ActiveUS20120042843A1Improve securityLess amountCam-followersCheck valvesInternal combustion engineHigh pressure chamber

OBJECTTo provide a hydraulic lash adjuster capable of retaining a large amount of hydraulic oil, in a reservoir communicated with a high-pressure chamber when the engine is stopped.MEANS FOR SOLVING THE PROBLEMA hydraulic lash adjuster including: a cylindrical body (24) having an upper open end, a closed bottom, and a second oil supply hole (27a) formed in the sidewall of the cylindrical body; and a plunger having a top end serving as a plunging end, a sidewall, a bottom end, a high pressure chamber (29) at the lower bottom, and a first oil supply hole (24b) formed in the sidewall, the plunger being slidable on the inner wall of the body. The plunger has a reservoir (28) that communicates with an external oil supply line (32) via the first oil supply hole (24b) and the second oil supply hole (27a). The lash adjuster is provided with a check valve (40a) for opening the oil supply hole (24b) by the oil pressure led from an external oil passage (32) to the oil supply hole (24b). The check valve (40a) is arranged in an annular communication passage (T) formed between the sidewalls of the plunger (26) and the body (24) for communicating the oil supply hole (27a) with the oil supply hole (24b). Leak-down oil is recycled while the engine is in operation. When the engine is stopped, the check valve (40A) closes the oil supply hole (24b). Accordingly, a large amount of hydraulic oil is stored in the reservoir (28) communicated with the high pressure chamber (29), with the oil level H in the reservoir (28) never being lower than the open end of the body (24).

Owner:NITTAN VALVE CO LTD

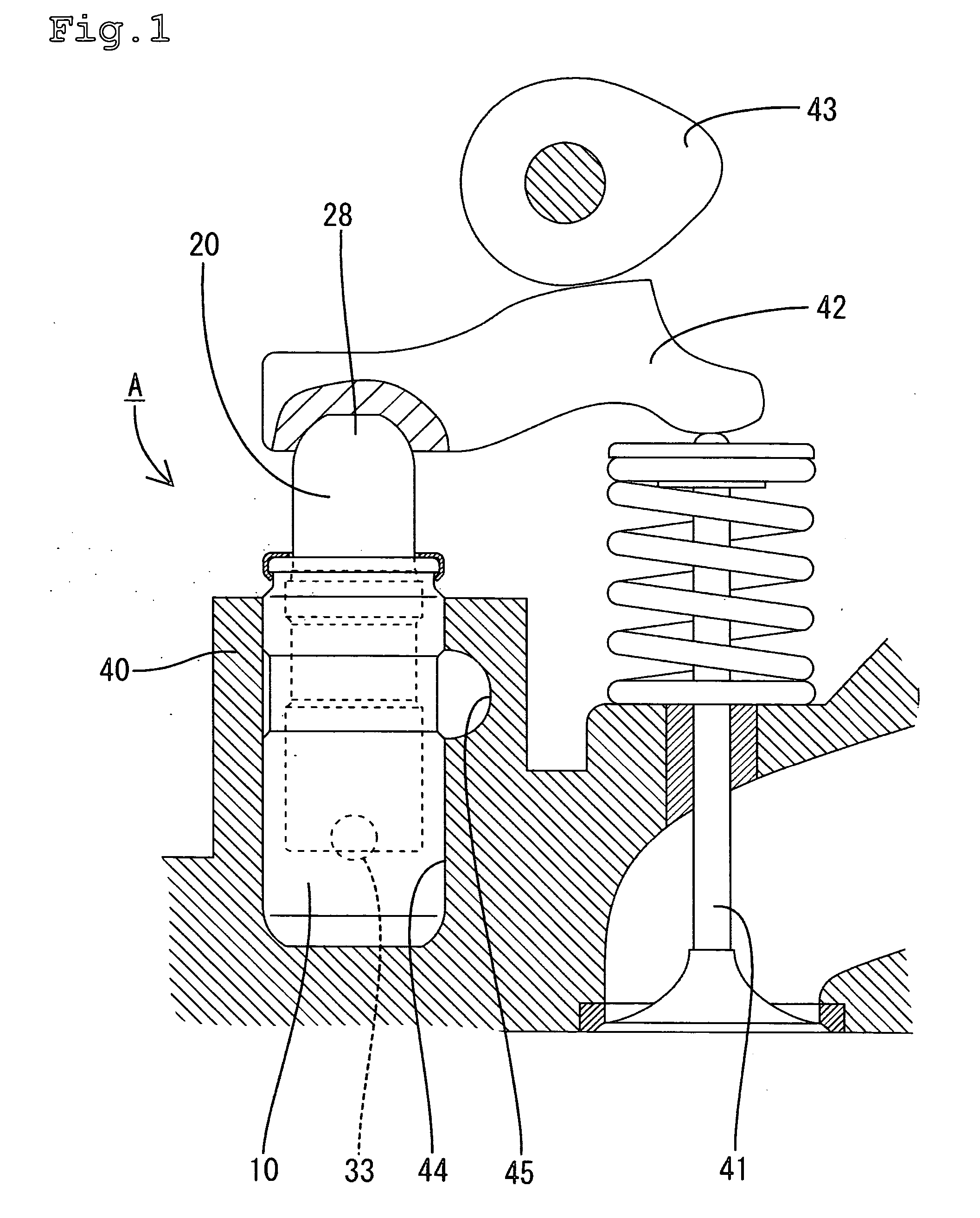

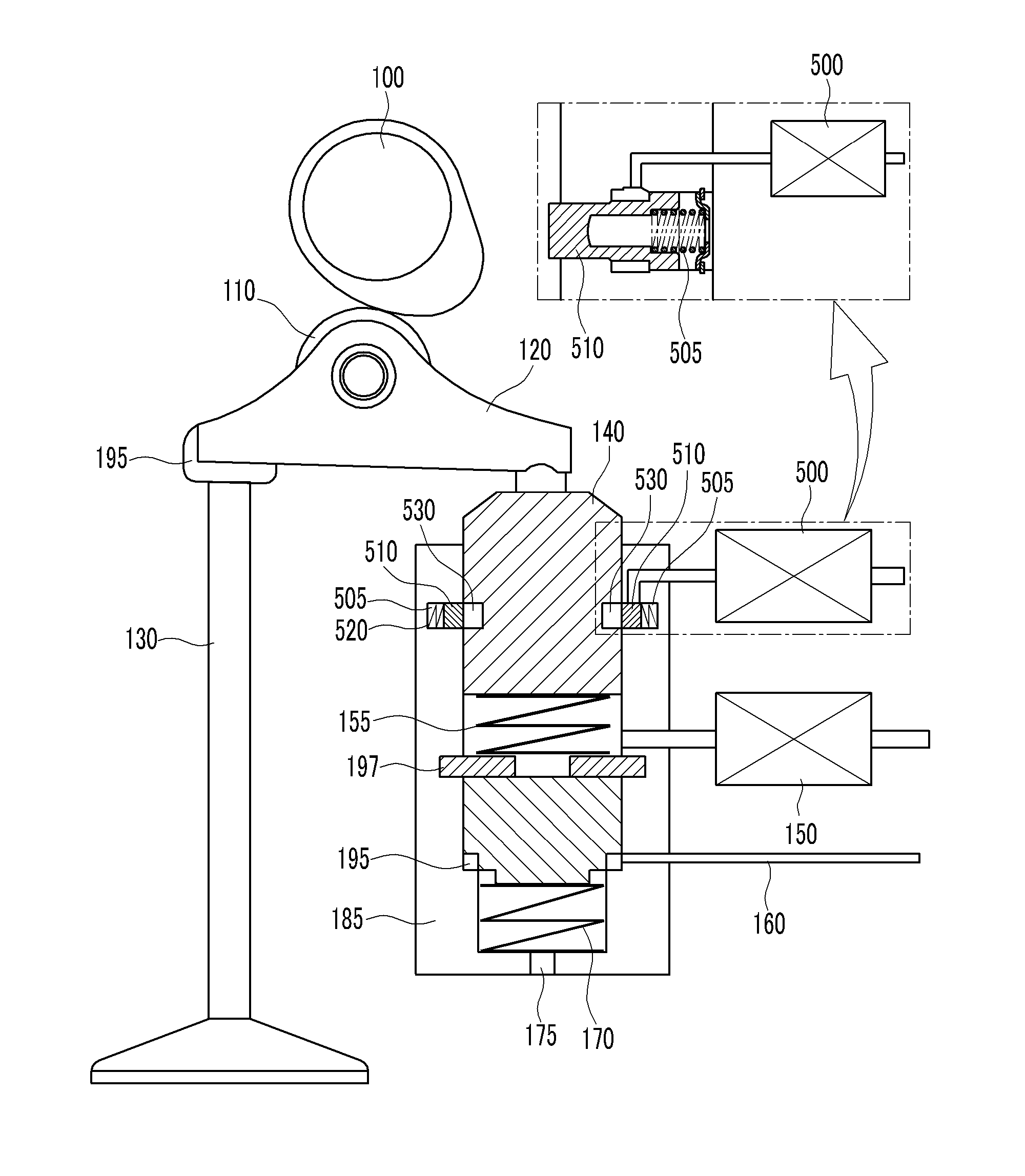

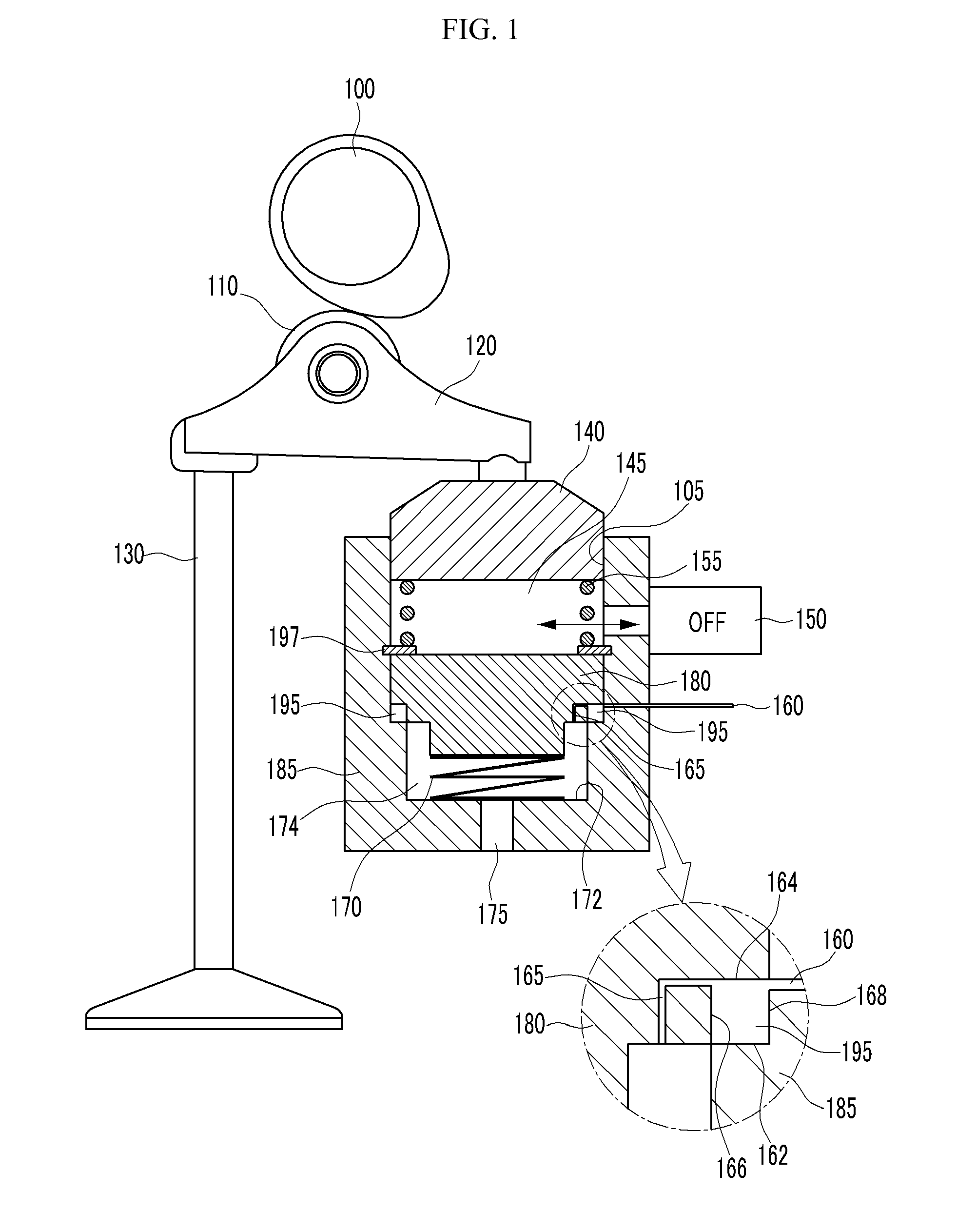

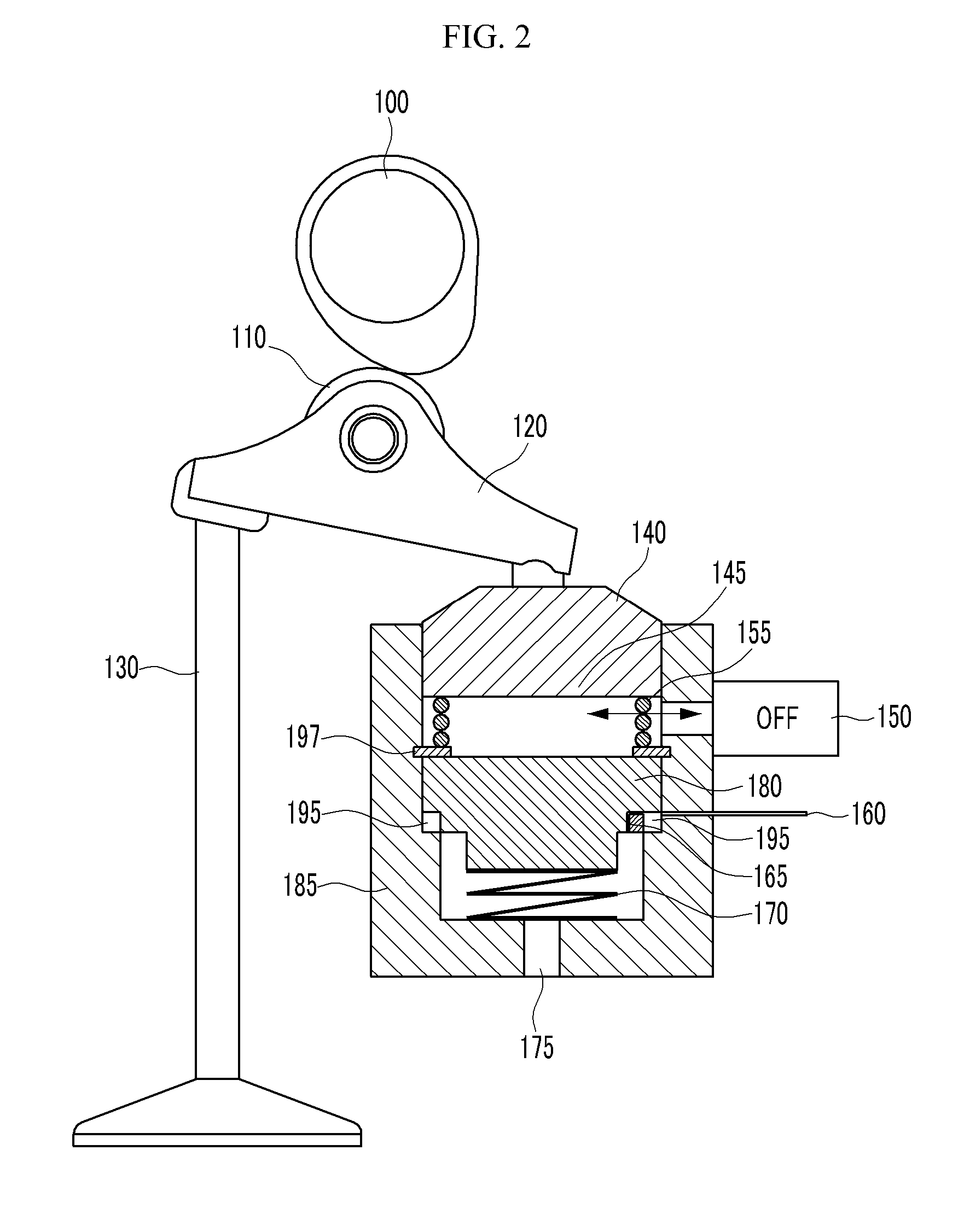

Engine that is Equipped with Variable Valve Device

InactiveUS20120067312A1Small structureReduce component weightValve arrangementsMachines/enginesEngineeringMechanical engineering

An engine includes a hydraulic pressure lash adjuster (HLA) pivotally supporting an end of a swing arm and having a valve supporting the other end of the swing arm, wherein the hydraulic pressure lash adjuster includes a housing, a plunger of which one end portion thereof may be slidably inserted into the inside of the housing, the other end portion of which extends outwards and supports the end of the swing arm by selectively moving upwards or downwards in a length direction of the housing, a stopper pin slidably mounted in a chamber of the plunger so as to selectively lock the plunger to the housing such that the plunger cannot move in the housing, and a hydraulic pressure supply portion that selectively supplies one side of the stopper pin with a hydraulic pressure in the chamber of the plunger to move the stopper pin toward the housing.

Owner:HYUNDAI MOTOR CO LTD

Valve train assembly with magnet

InactiveUS20080190391A1Avoid failureAvoid cloggingValve arrangementsMachines/enginesEngineeringMetal particle

The valve train assembly with magnet uses the magnet to collect ferrous metal particles that are in the oil prior to their arrival at the high pressure cavity of the hydraulic lash adjuster. The magnet can be positioned in the low pressure cavity of the hydraulic lash adjuster, in the bore of the hollow rocker arm shaft or in the bore of the hollow push rod.

Owner:FCA US +1

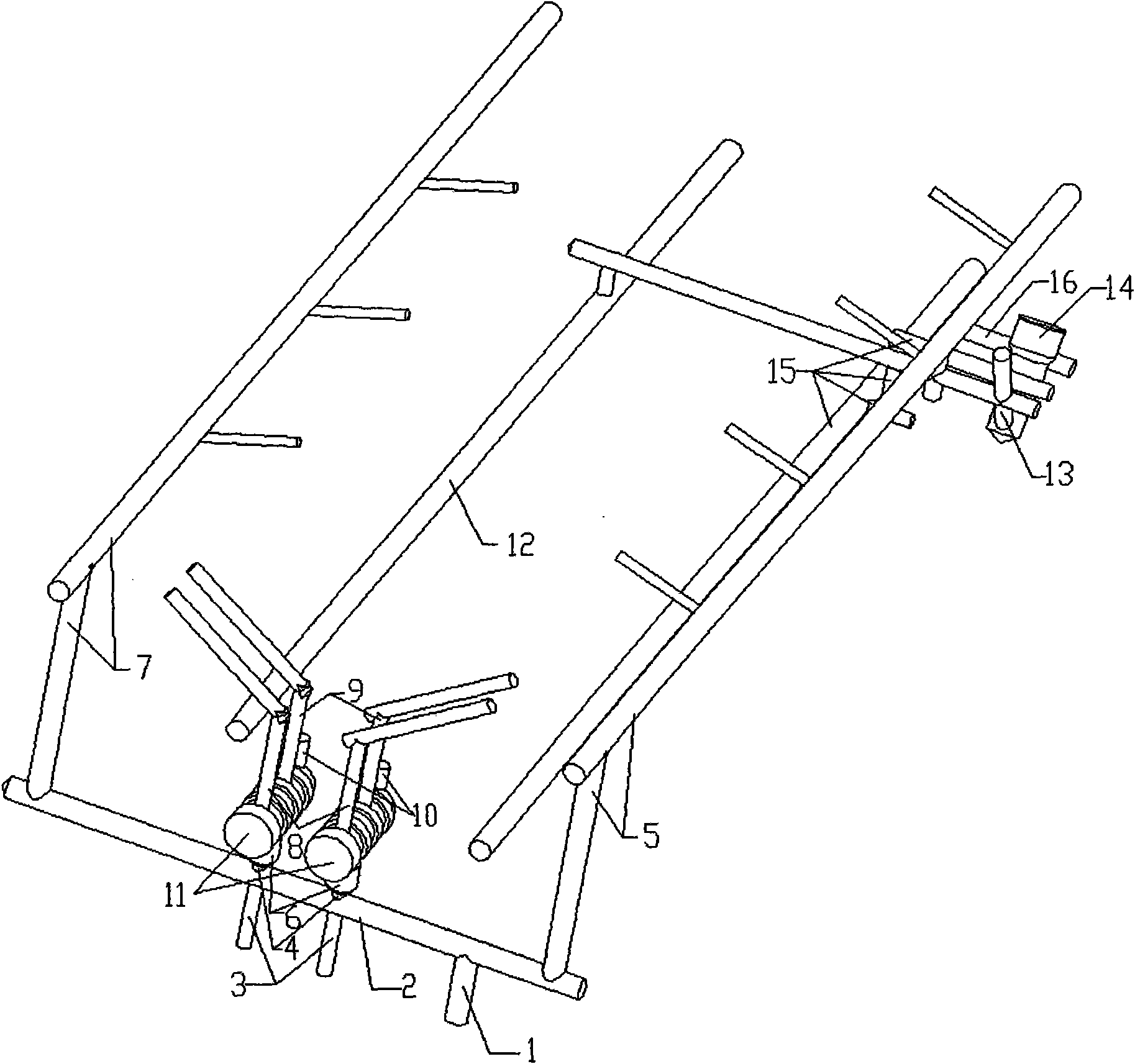

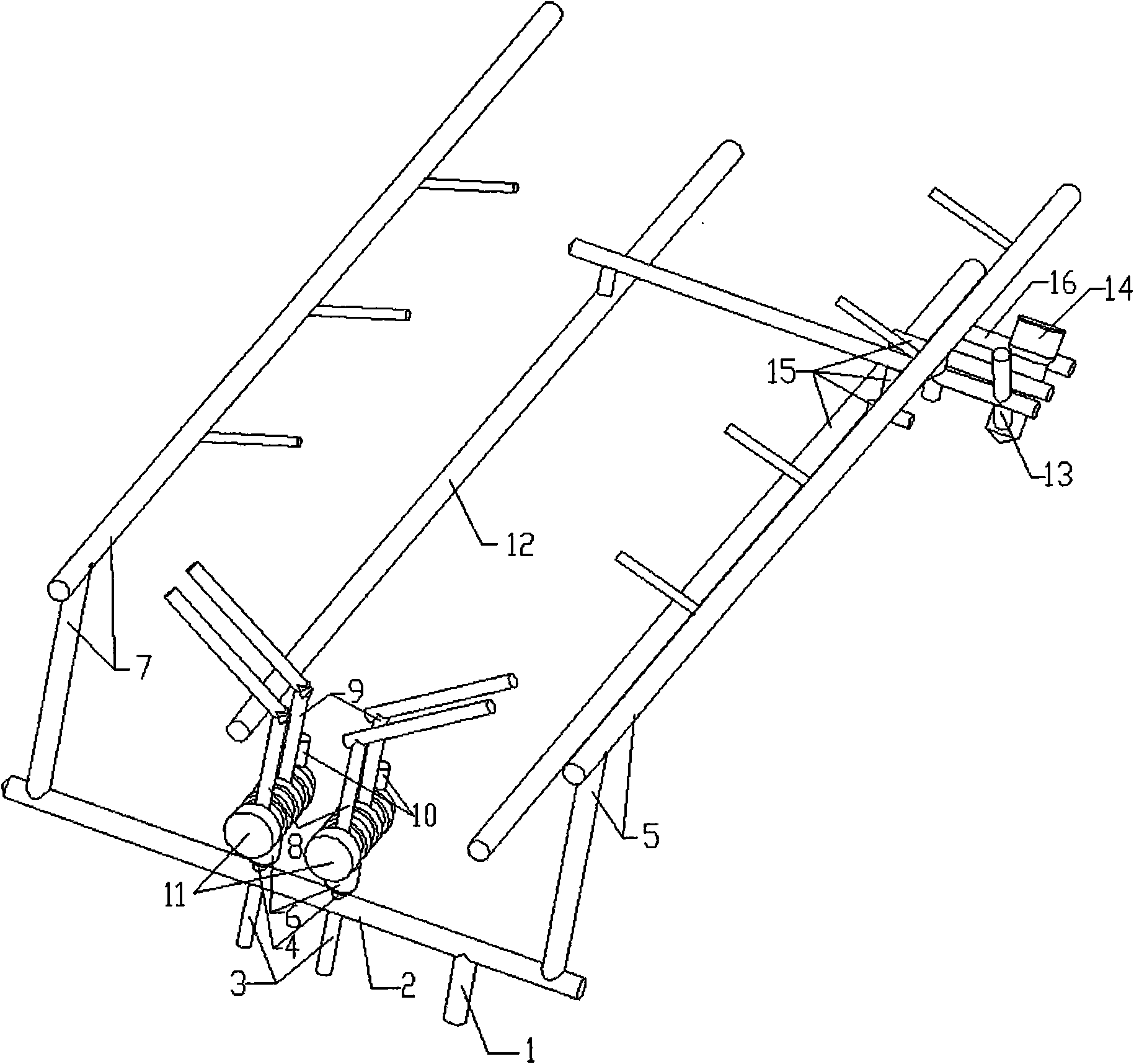

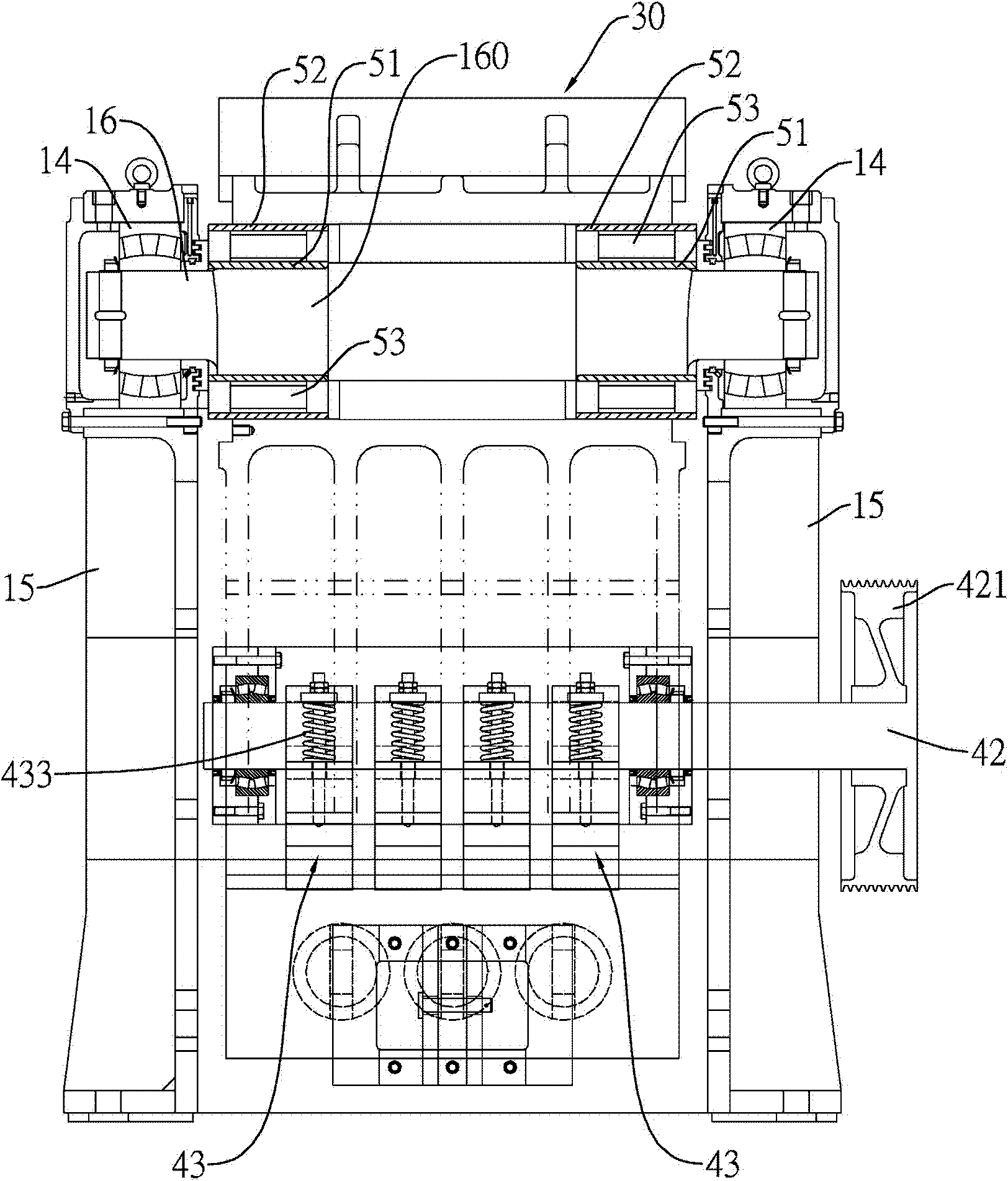

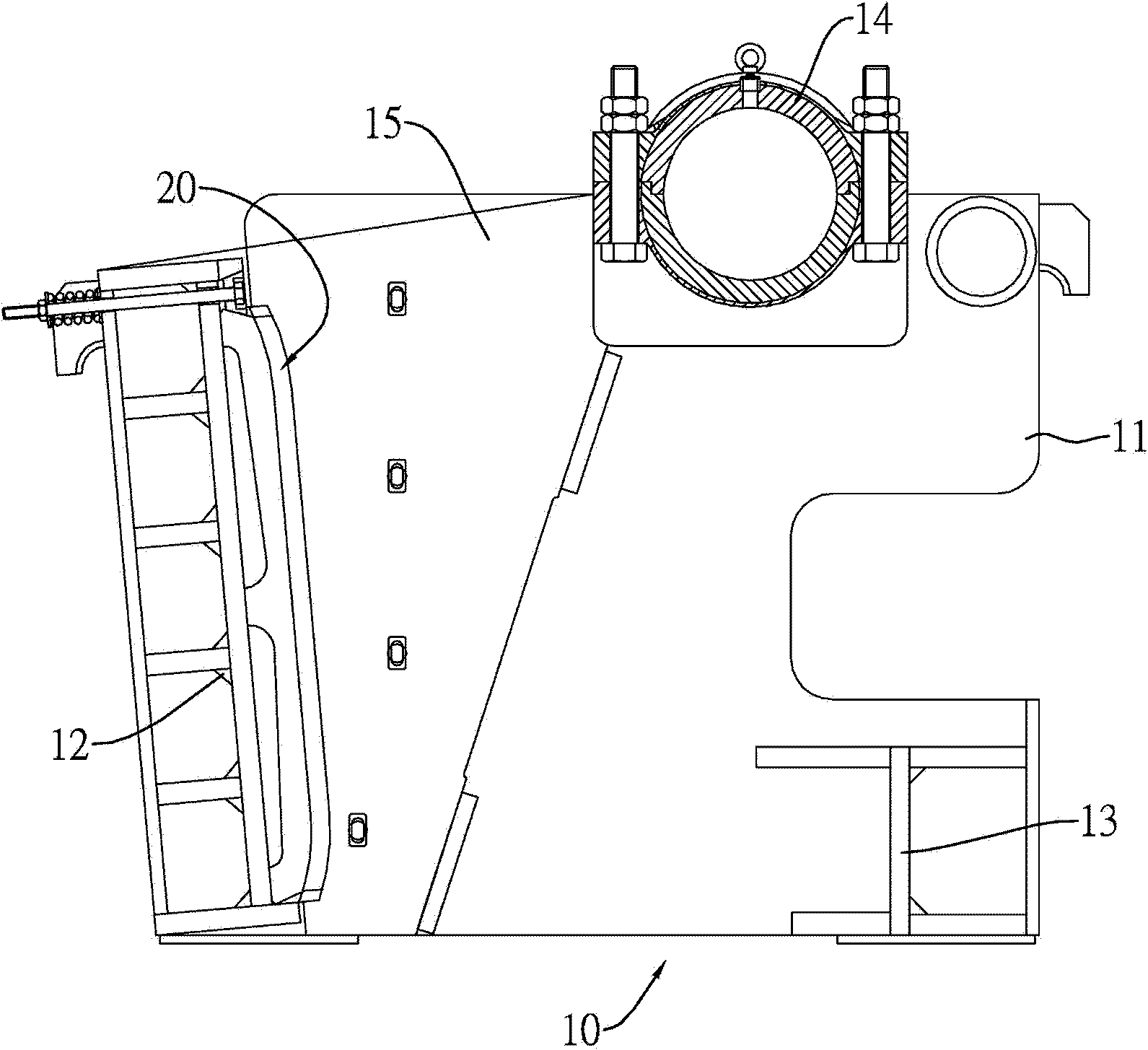

Vibration jaw crushing machine

InactiveCN103028460AIncrease production capacityReduce weightGrain treatmentsProtection mechanismEngineering

The invention relates to a vibration jaw crushing machine. The crushing machine comprises a rack body, a fixed jaw lining plate, a movable jaw assembly, a vibration exciter mechanism, a non-linear elastic supporting assembly and a hydraulic clearance adjustment protection mechanism. According to the vibration jaw crushing machine, the actuation power of the movable jaw assembly can satisfy the requirements on crushing ores through utilizing inertia vibration, the crushing ratio and yield are increased, and energy consumption is reduced; and the movement track of the movable jaw assembly varies from top to bottom, so that the ores can be crushed, chopped and milled.

Owner:范公奇

Dual feed hydraulic lash adjuster for valve actuating mechanism

Owner:GT TECH INC

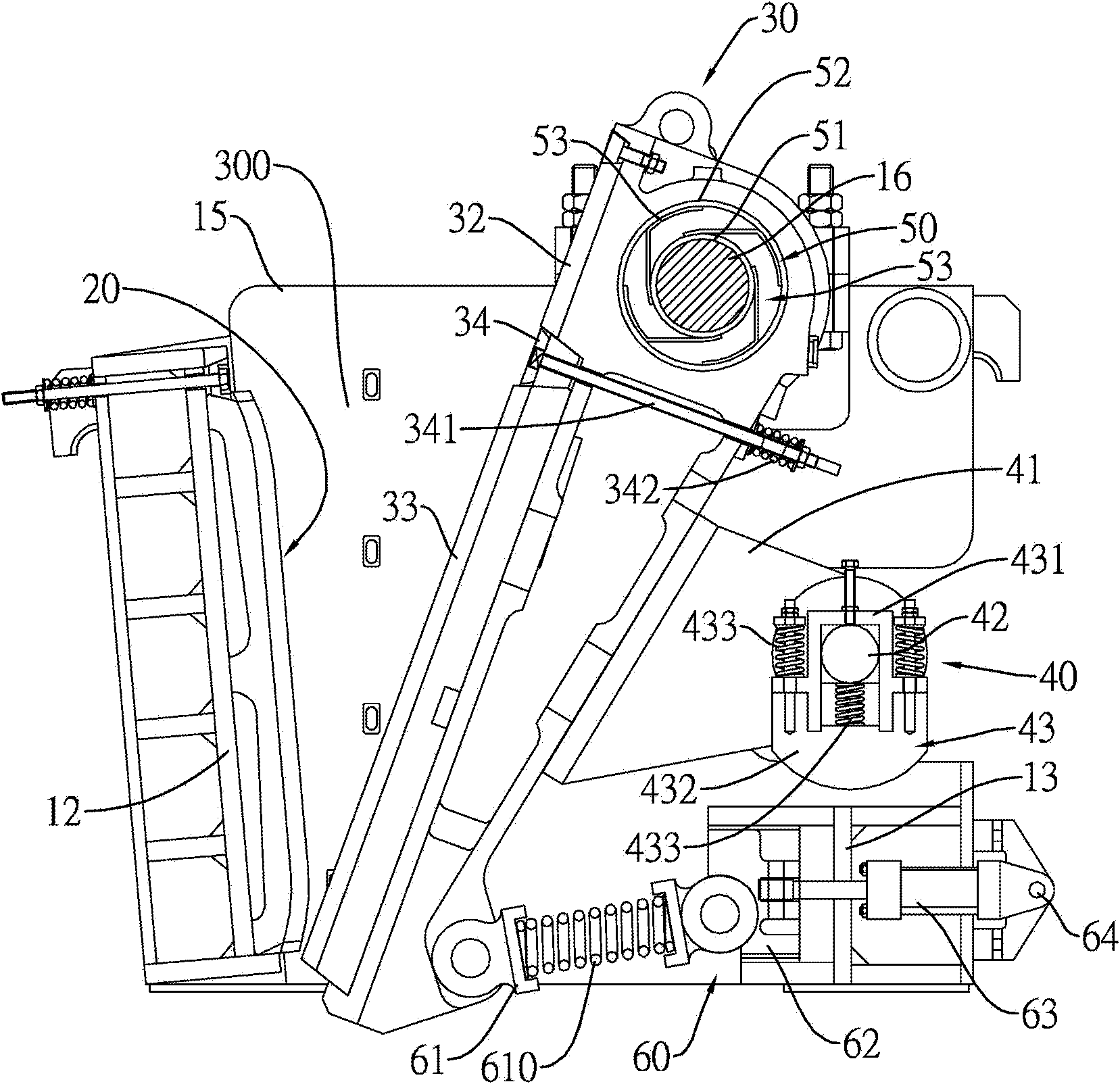

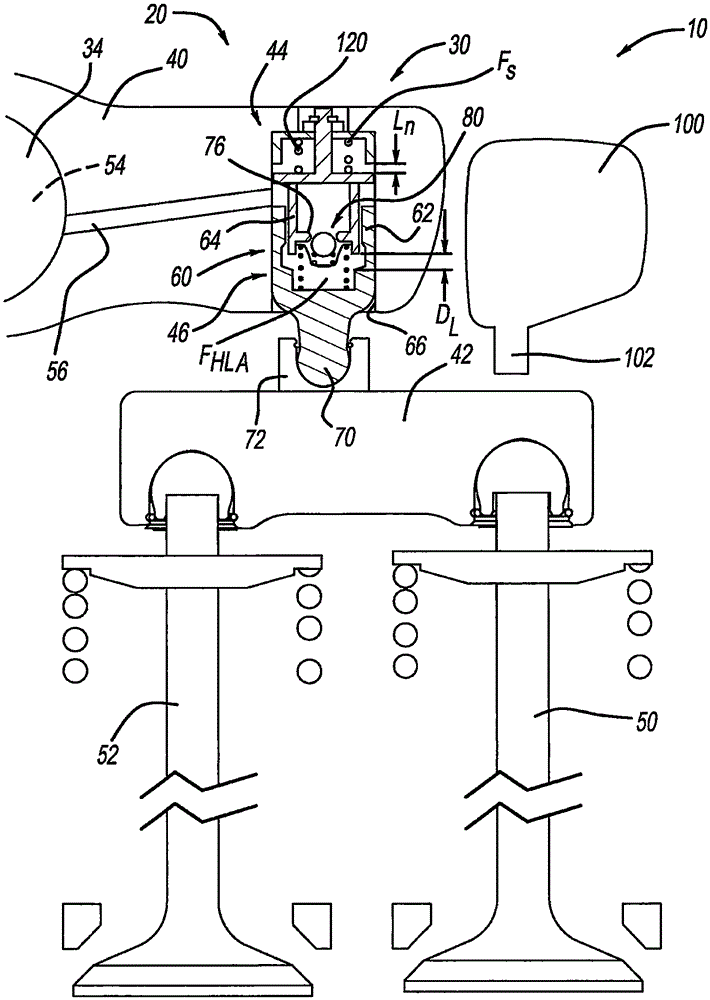

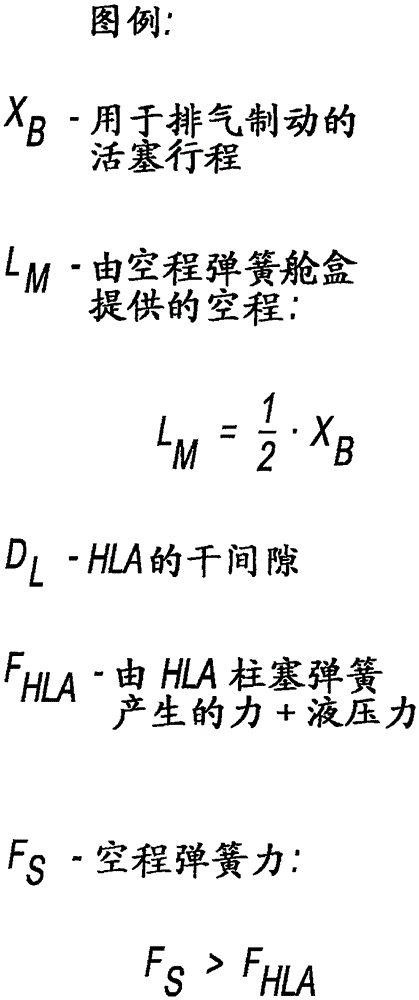

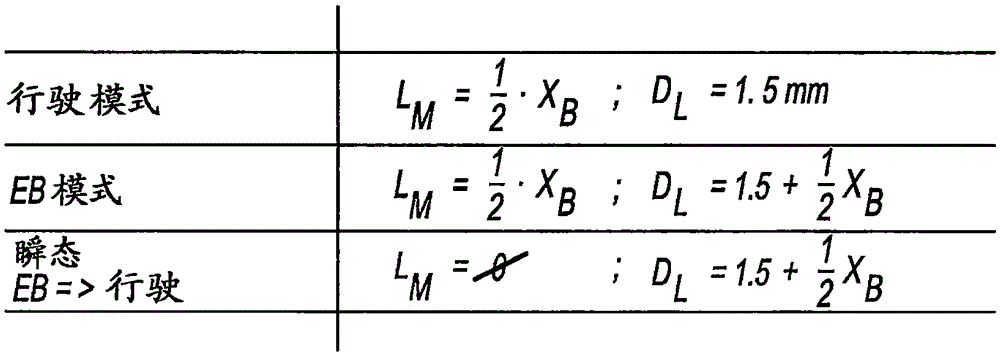

Valve mechanism system with hydraulic lash adjuster and exhaust brake

The invention relates to a valve mechanism system with a hydraulic lash adjuster and an exhaust brake. In the brake mode of an engine, an operable exhaust valve rocker arm assembly comprises a rocker arm shaft, a rocker arm, a valve cross arm, a discharge valve, a hydraulic lash adjuster and an elastic tank box. The rocker arm shaft defines a pressurized oil supply pipeline. The rocker arm receives the rocker arm shaft and is configured to rotate about the rocker arm shaft. The rocker arm is provided with an oil supply passage defined therein. The valve cross arm is engaged with a first exhaust valve and a second exhaust valve. The discharge valve is provided with a piston capable of moving between a retractable position and an extendable position. The hydraulic lash adjuster assembly is arranged on the rocker arm and comprises a first plunger that moves between a first position and a second position. At the first position, the first plunger extends rigidly to be cooperatively engaged with the valve cross arm.

Owner:EATON SRL

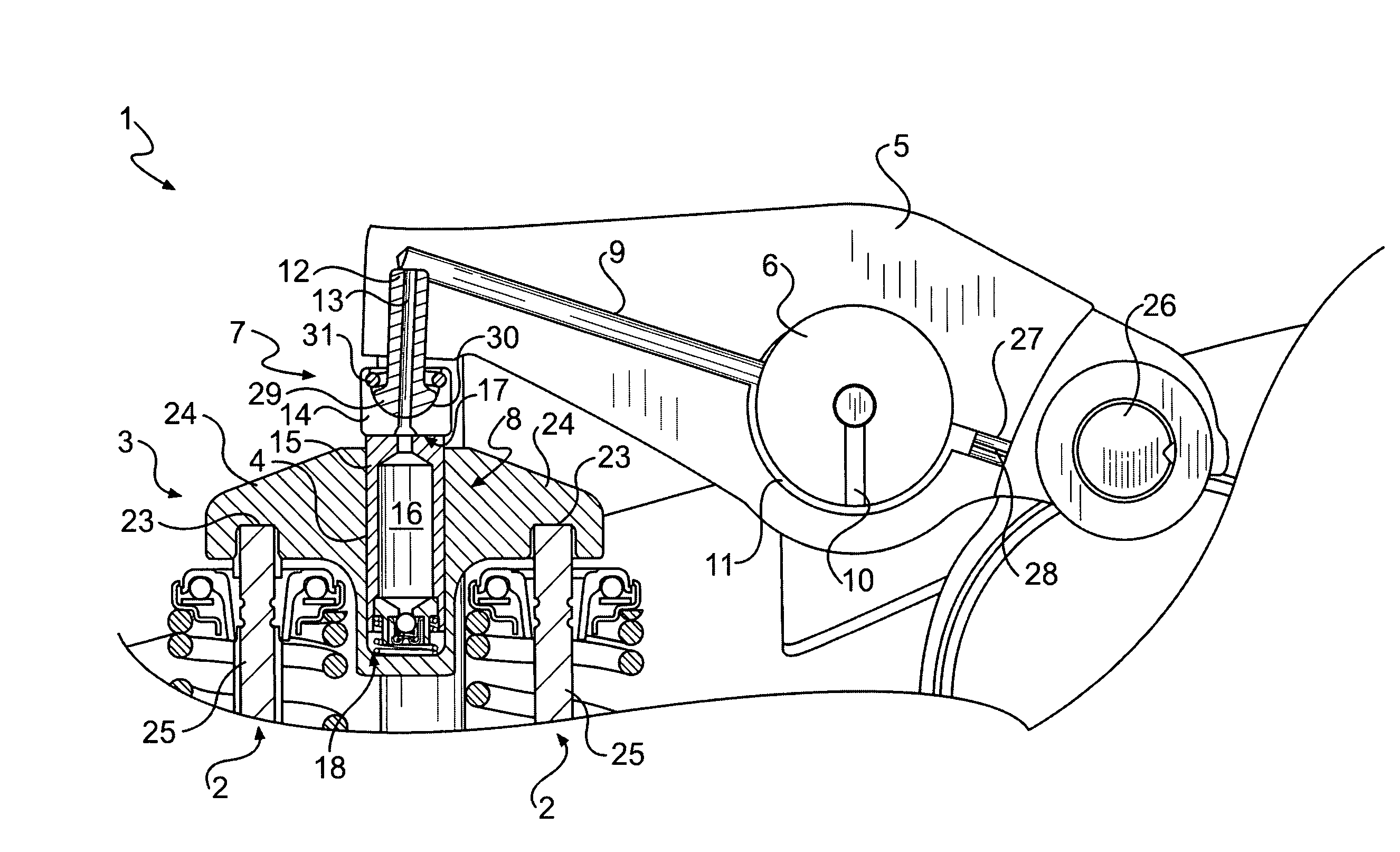

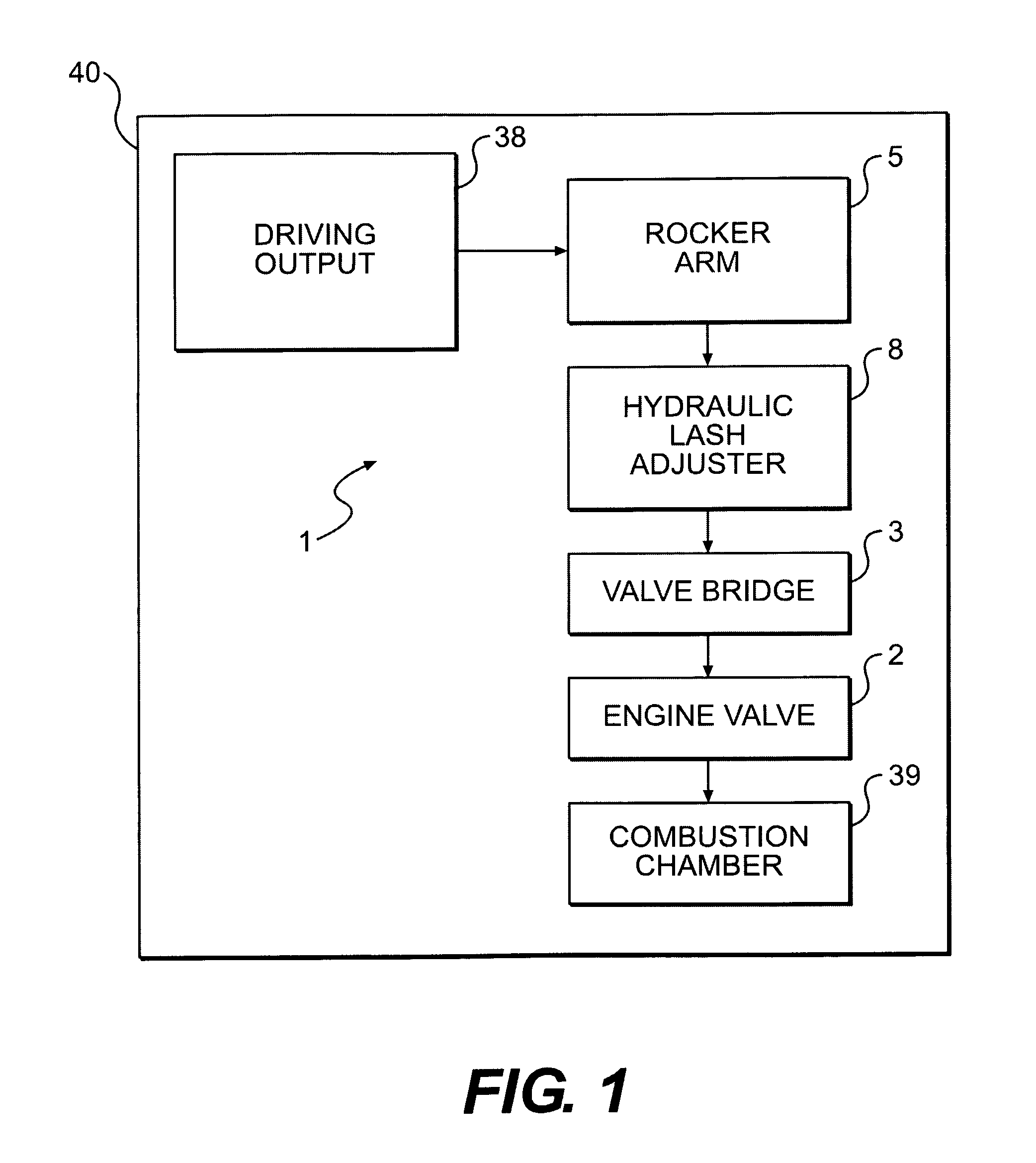

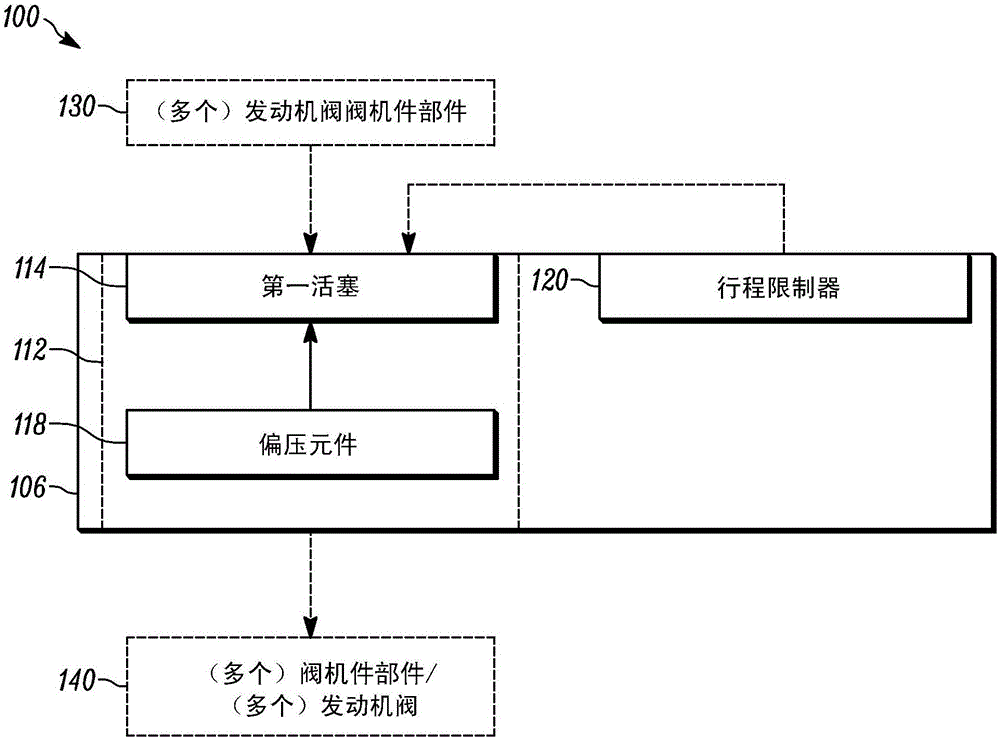

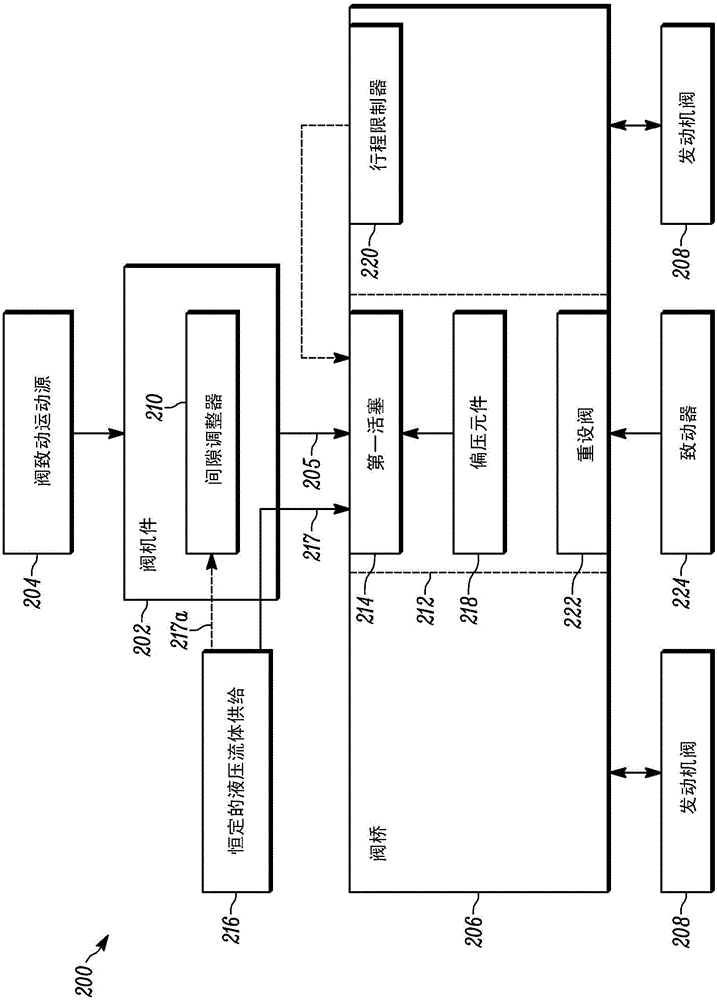

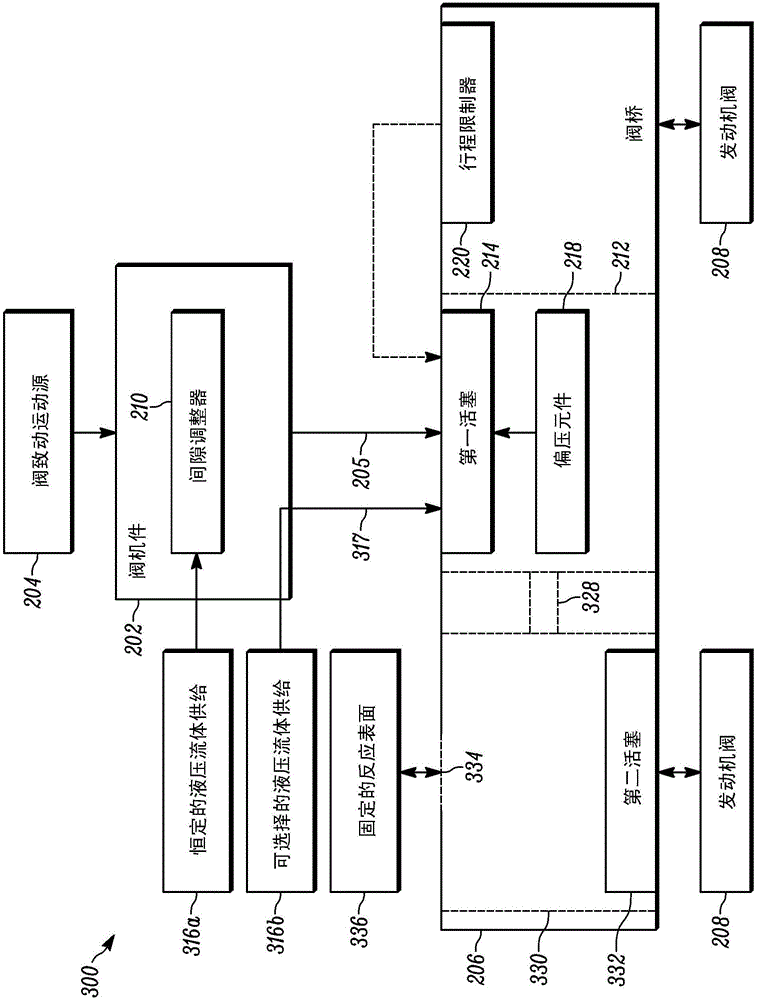

Lost motion assembly in a valve bridge for use with a valve train comprising a hydraulic lash adjuster

In an internal combustion engine comprising two or more engine valves that receive valve actuation motions from a valve actuation motion source via a valve train, which valve train comprises a hydraulic lash adjuster, an apparatus for valve actuation comprises a valve bridge and a lost motion assembly disposed therein. The lost motion assembly comprises a first piston disposed in a first piston bore formed in the valve bridge. The first piston is configured to operatively connect with a component of the valve train. A biasing element is configured to bias the first piston out of the first piston bore with a first force that is greater than a second force applied to the first piston by the hydraulic lash adjuster. A travel limiter is configured to limit travel of the first piston out of the first piston bore to be no greater than a maximum lost motion distance.

Owner:JACOBS VEHICLE SYST

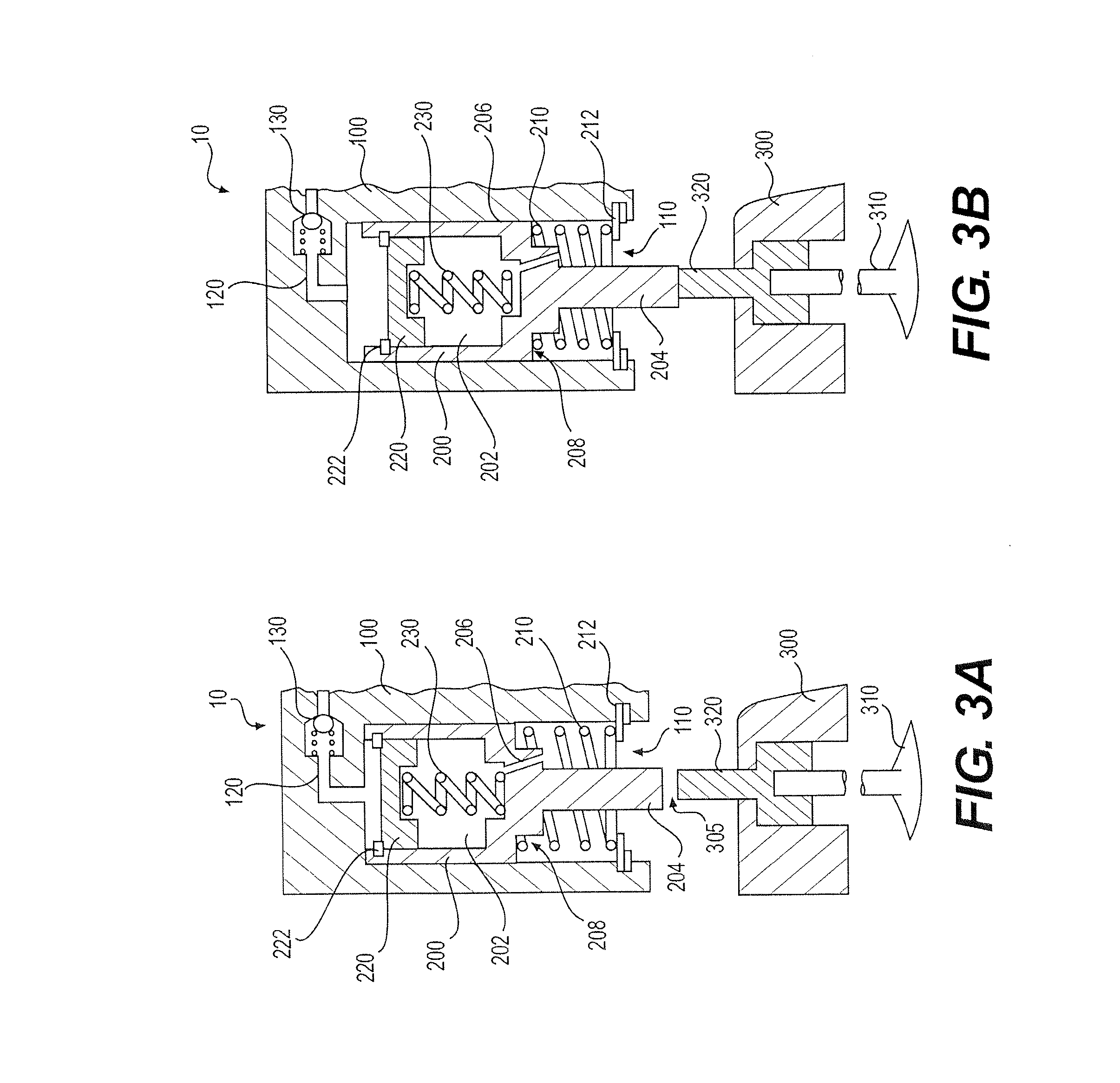

Hydraulic lash adjuster

InactiveUS7464678B2Avoid intakePrevent leakageValve arrangementsMachines/enginesReciprocating motionEngineering

A hydraulic lash adjuster includes a cylindrical body having a central cylindrical bore. A hollow plunger is reciprocable in the bore and includes a reservoir chamber therein. The plunger has a close clearance with the bore. A high pressure chamber is defined by the plunger and a closed end of the bore. An orificed wall of the plunger separates the reservoir chamber from the high pressure chamber. A check valve is disposed in the orifice for allowing one-way flow of oil from the reservoir chamber to the high pressure chamber. A plunger spring disposed in the high pressure chamber urges the plunger away from the closed end of the bore. A seat is disposed at an end of the plunger distal from the high pressure chamber. The plunger includes a circumferential groove proximate the seat for holding oil to maintain an oil seal in the clearance to limit leakage of air through the clearance.

Owner:GM GLOBAL TECH OPERATIONS LLC

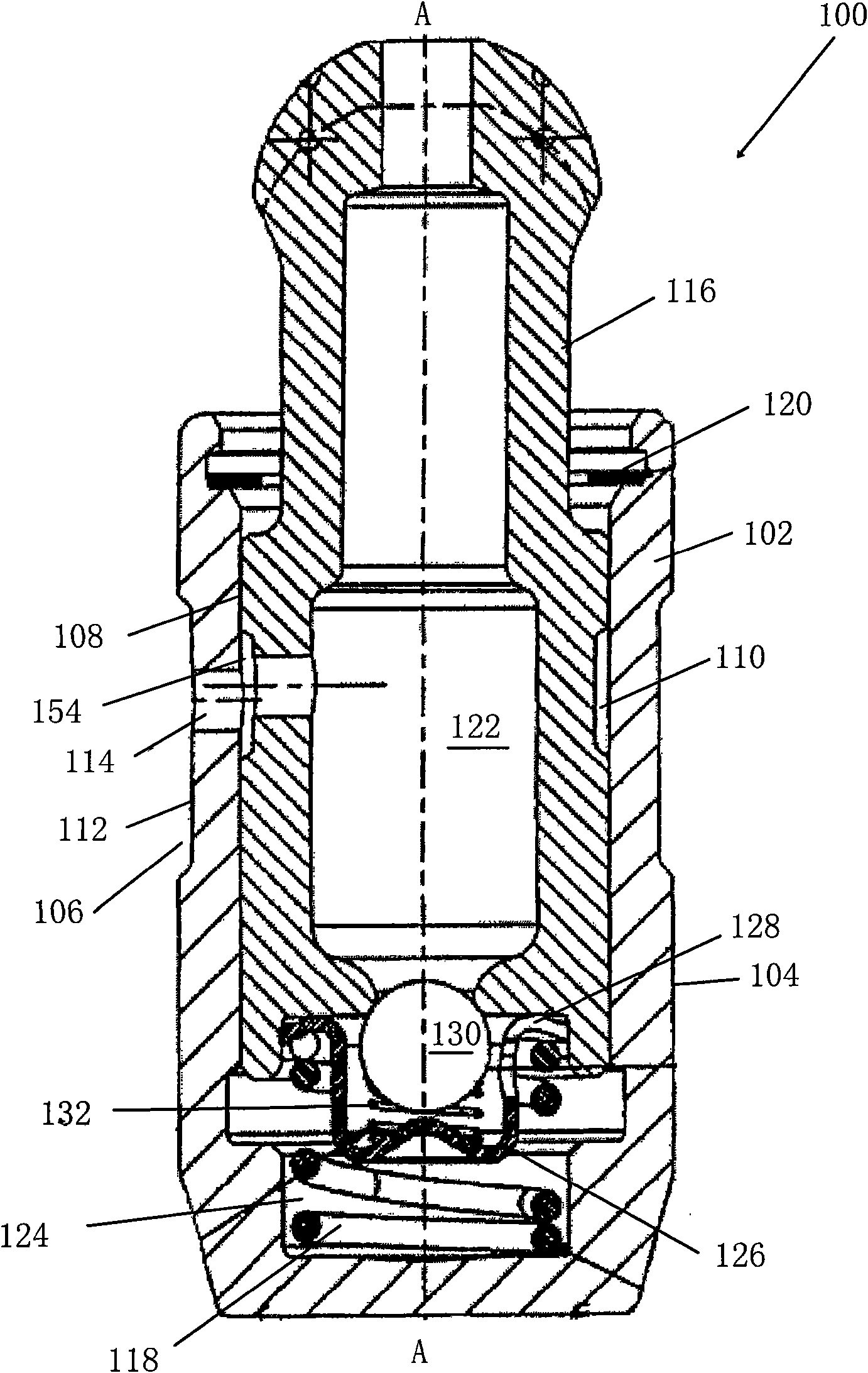

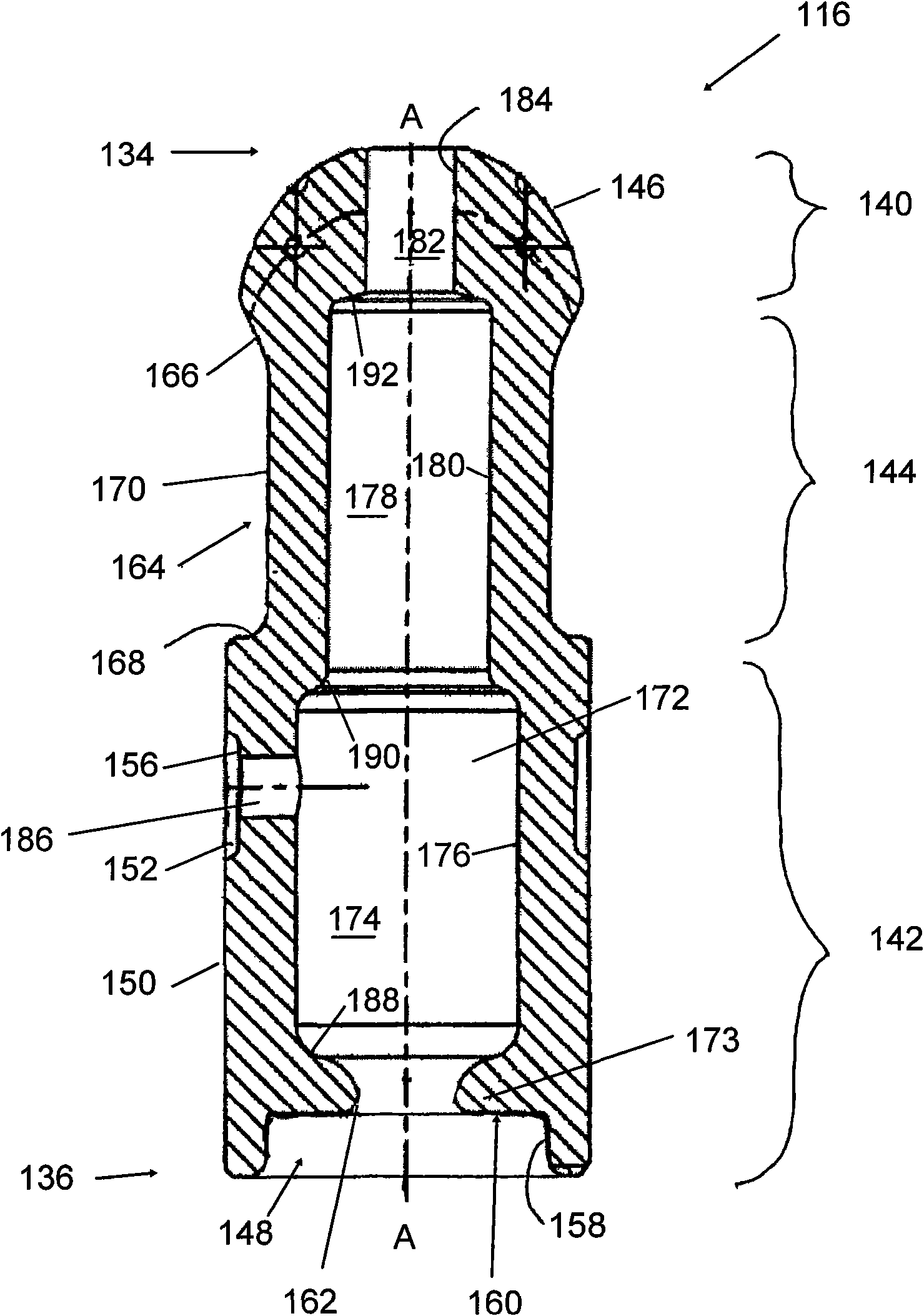

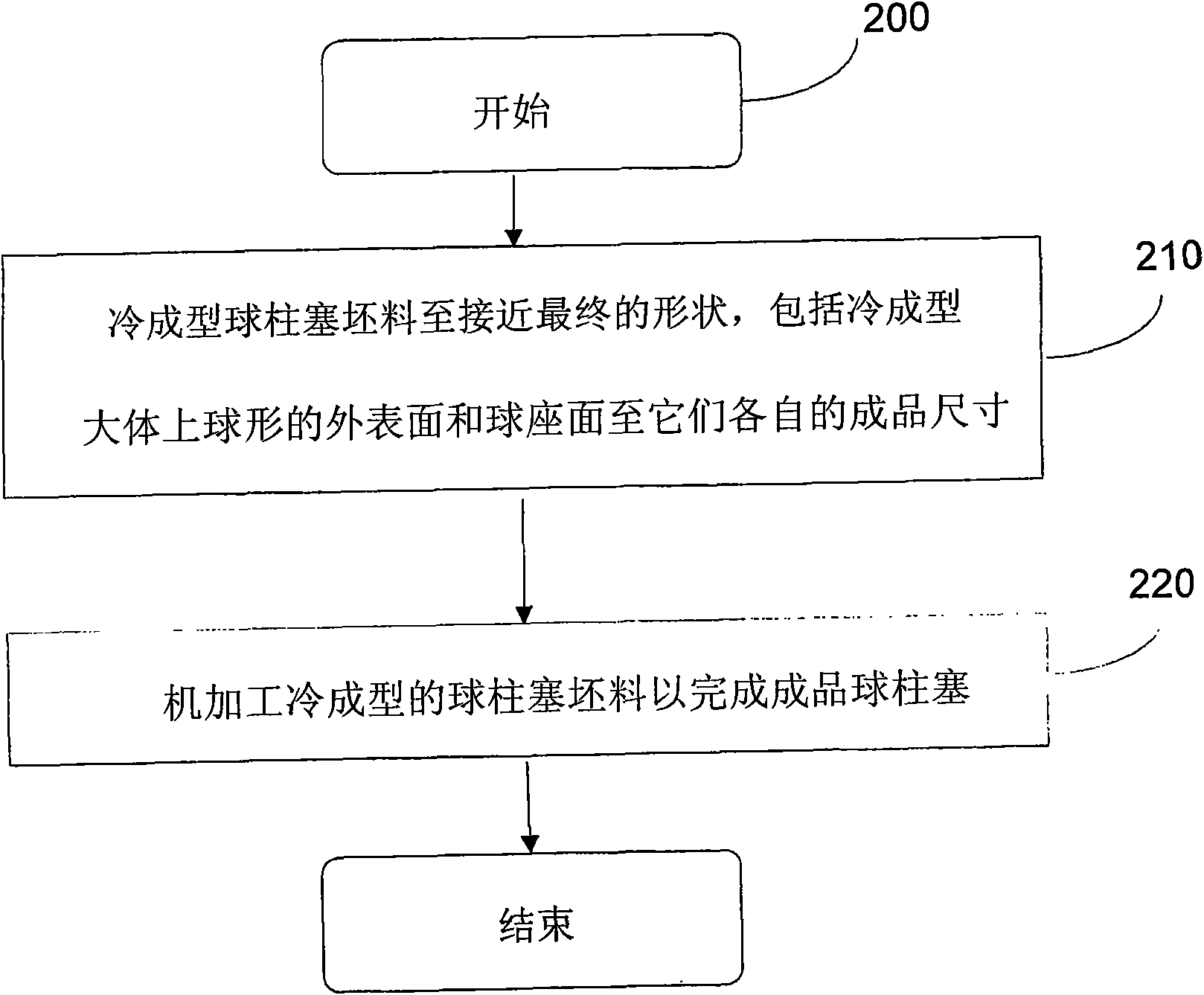

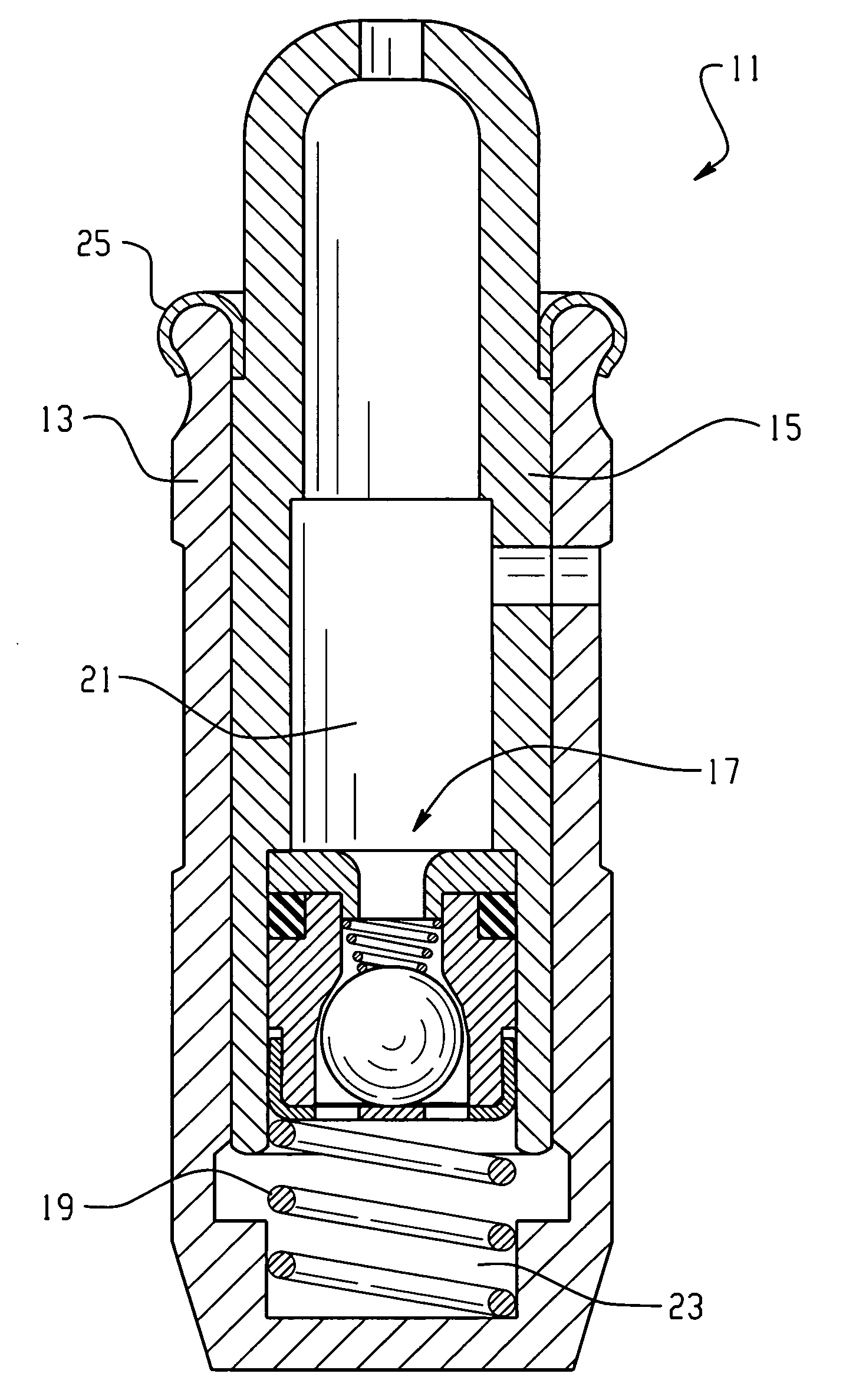

Ball plunger for use in a hydraulic lash adjuster and method of making same

A cold-formed ball plunger blank is provided for use in manufacturing a finished ball plunger used in a hydraulic lash adjuster that includes a check valve assembly having a check ball and a retainer. The ball plunger blank includes a cup-shaped member that extends from a first end to a second end along a longitudinal axis. The cup-shaped member includes a ball portion adjacent the first end of the member and a body portion adjacent the second end of the member. The body portion has a cavity disposed therein, a counterbore extending from the second end of the body towards the first end of the member, and a shoulder that separates the cavity from the counterbore and at least partially closes the cavity. The shoulder defines a ball seat surface configured to receive the check ball and a retainer receiving surface configured to receive the retainer, wherein the ball seat surface and the retainer receiving surface are to sized to the final dimensions of the finished ball plunger. The invention also relates to a method of cold-formed ball plunger blank.

Owner:EATON INTELLIGENT POWER LIMITED

Hydraulic lash adjuster with damping device

A system and method for lash adjustment in the valvetrain of an internal combustion engine include a hydraulic lash adjuster having a damping device to limit rate of movement of a plunger relative to a body to control response time of the lash adjuster reducing or eliminating over-compensation or pump-up of the lash adjuster.

Owner:FORD GLOBAL TECH LLC

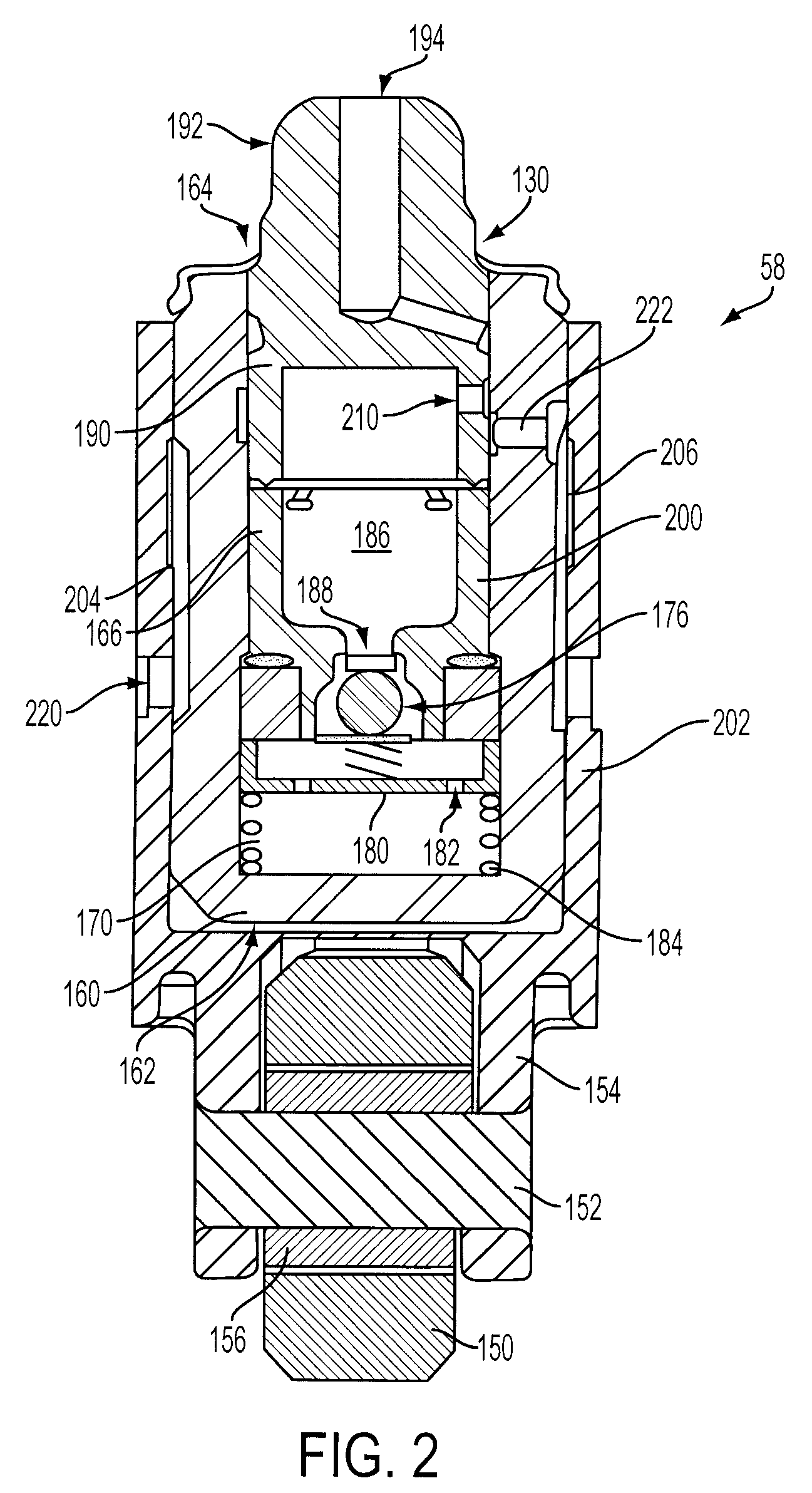

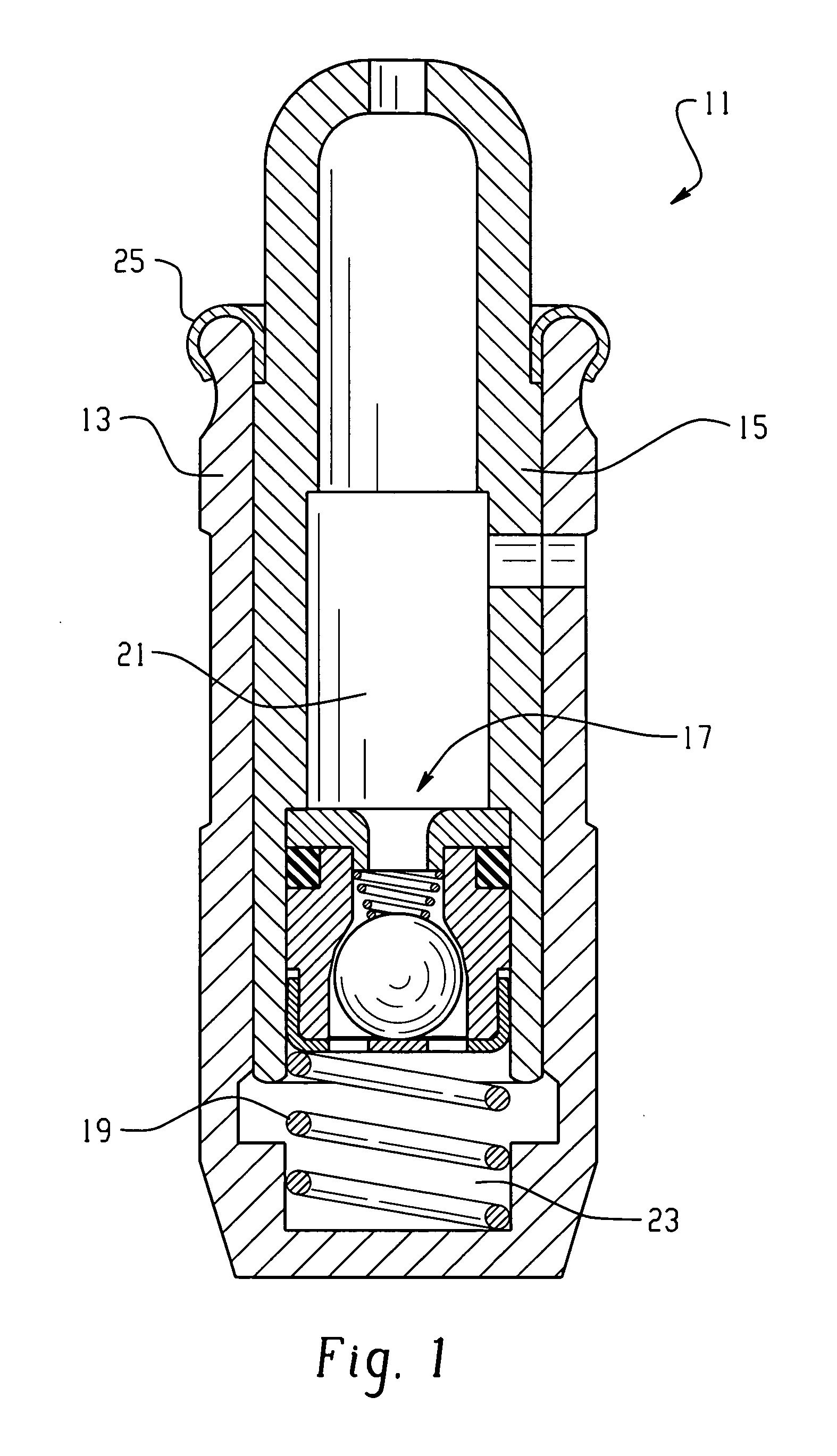

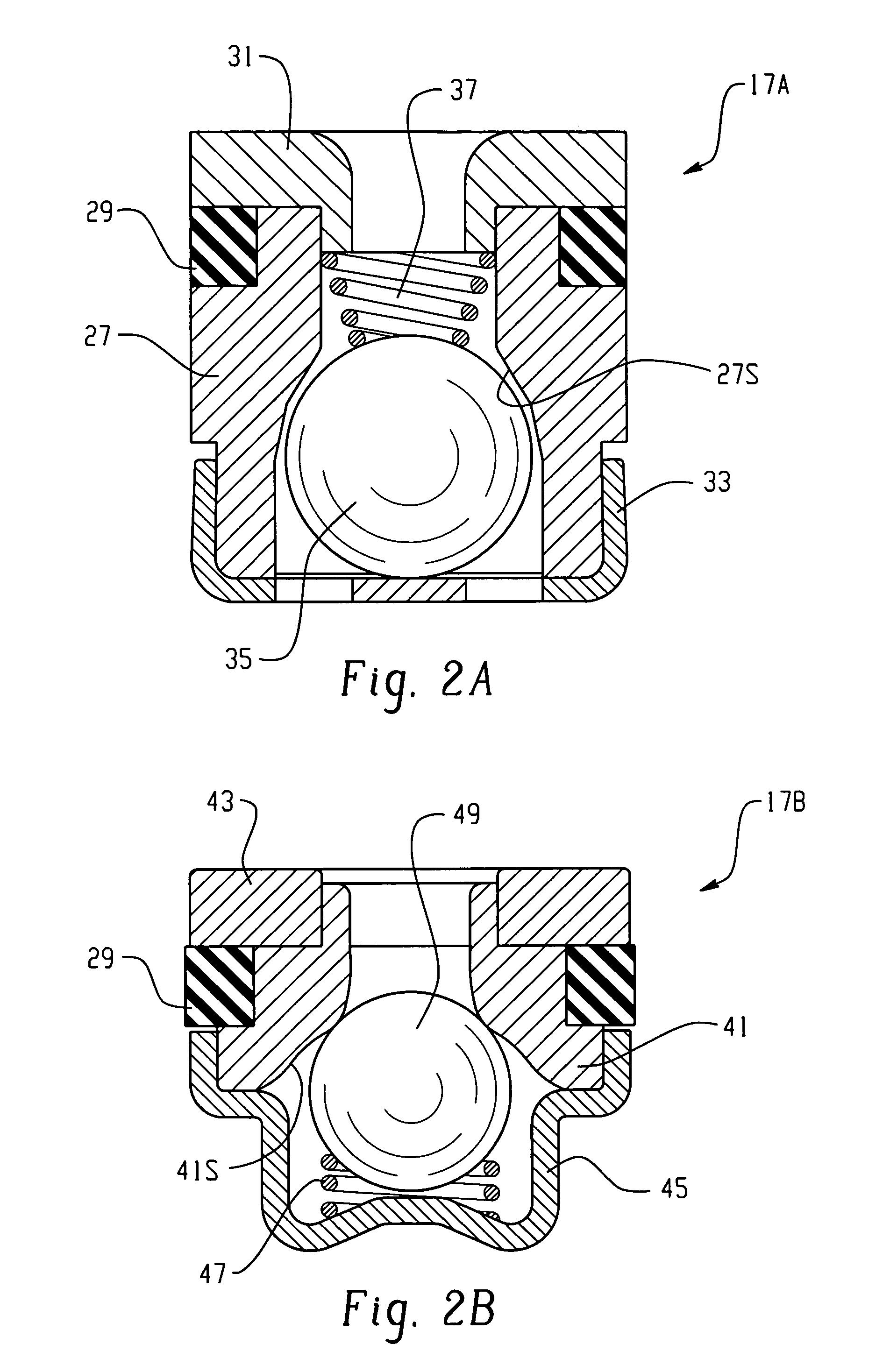

Hydraulic lash adjuster and improved method of assembly thereof

InactiveUS6941915B1Simple methodEnsure correct executionValve arrangementsMetal-working apparatusEngineeringImproved method

A hydraulic lash adjuster (11) for an internal combustion engine, and an improved method of assembly of such a lash adjuster. The lash adjuster (11) is of the type having a body (13), a plunger (15), and a check valve assembly (17). In accordance with one aspect of the invention, the check valve assembly comprises a cartridge (17A;17B) comprising a member (27;41) separate from the plunger (15) and defining a valve seat (27S;41S). The check valve cartridge is capable of being assembled and tested for compliance with a predetermined relationship of flow versus pressure differential, prior to assembly into the plunger (15). In accordance with the improved method of assembly, a plurality of different bodies (13A;13B) and plungers (15A;15B;15C;15D) is provided, as well as a plurality of different, interchangeable check valve cartridges (17A;17B), and the assembly operator selects a body, a plunger, and a cartridge to provide an assembled lash adjuster having the predetermined, desired operating parameters.

Owner:EATON CORP

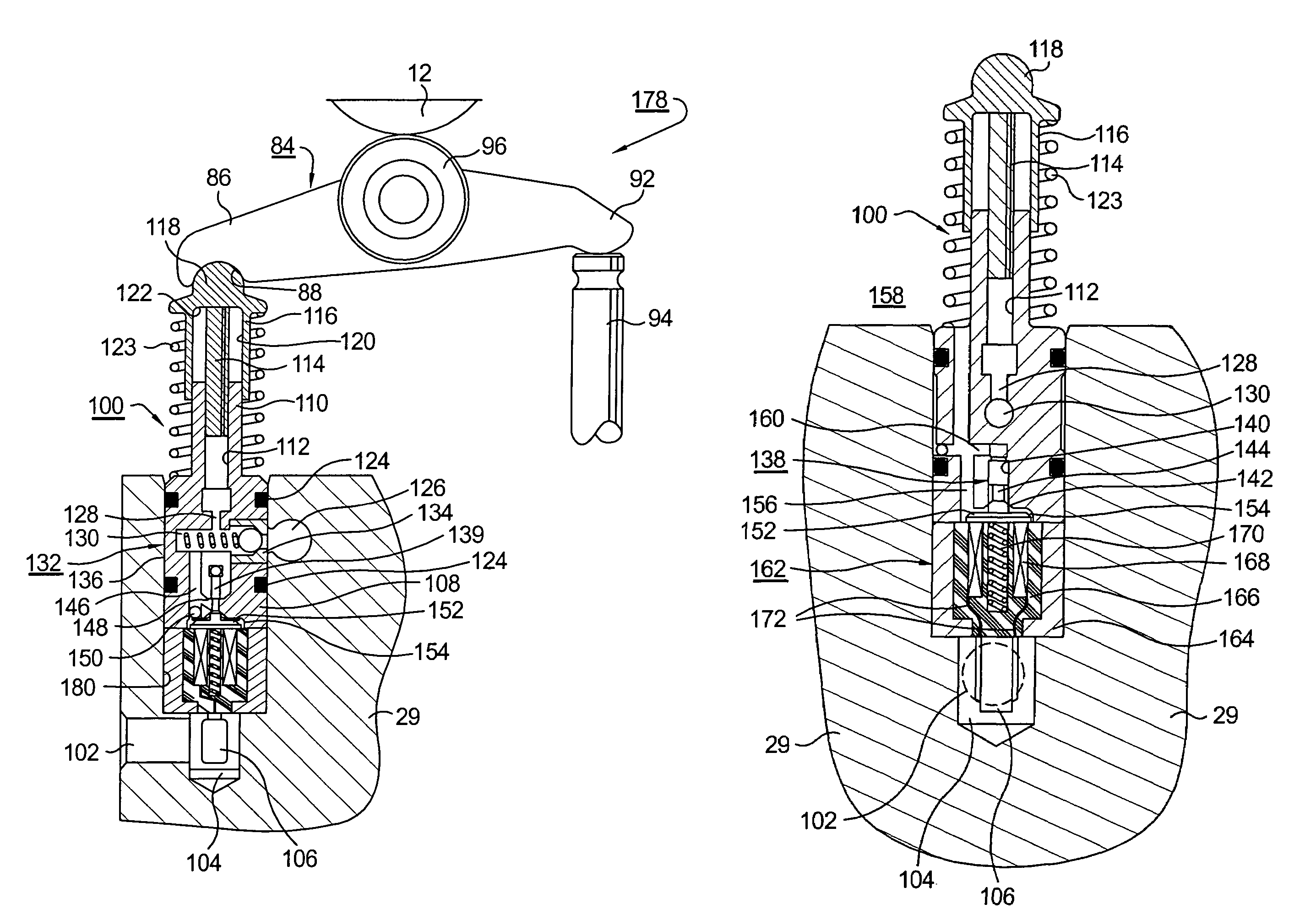

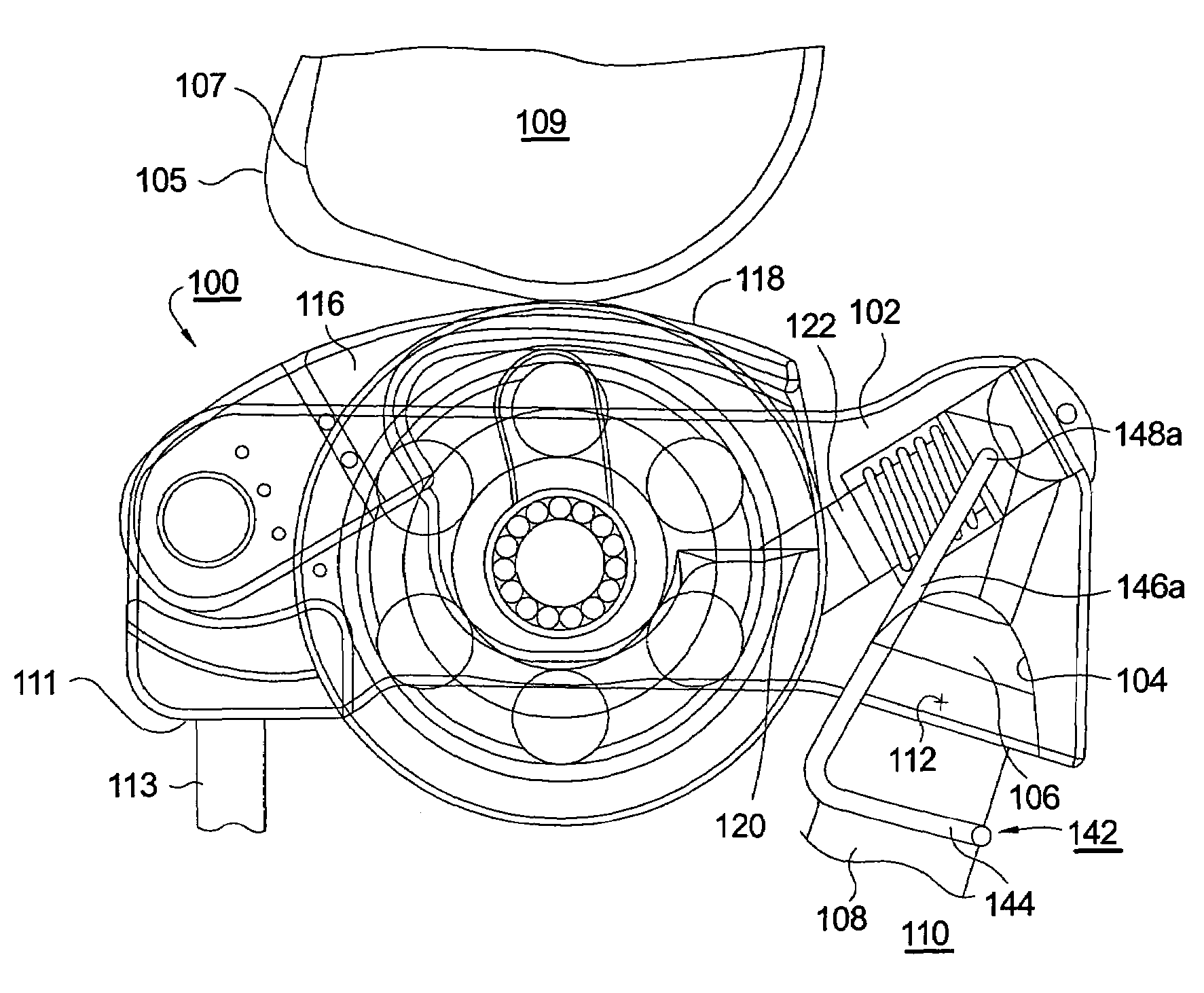

Timing mechanism for a switchable two-step roller finger follower

A two-step roller finger follower having a movable high-lift portion and a low-lift portion. A lock pin mechanism in the low-lift portion includes a lock pin that may be driven hydraulically into latched engagement with the high-lift portion. The lock pin assembly comprises a lock pin and a separable switching pin. A blocking clip mountable on the associated hydraulic lash adjuster includes first and second ends that extend into a switching pin locking groove to block axial motion thereof. A ramp on the follower body mates with a ramp on the blocking clip such that oscillatory motion of the follower engages and disengages the blocking pin from the locking groove. The clip unblocks the switching pin at only those times in the camshaft rotational cycle when complete locking and unlocking is assured, and ending well before the beginning of the next valve lift event.

Owner:DELPHI TECH IP LTD

Systems and methods for hydraulic lash adjustment in an internal combustion engine

Systems and methods for actuating engine valves for positive power and engine braking operation are disclosed. The systems may include a self-lashing hydraulic piston slidably disposed in a fixed or rocker arm housing. The hydraulic piston may have an internal cavity in which a motion absorbing piston is disposed. A hydraulic fluid source may communicate with the hydraulic piston bore. A check valve which may be incorporated in a control valve may controls hydraulic fluid supply from the hydraulic fluid source to the hydraulic piston to provide self-lashing operation of the valve actuation system.

Owner:JACOBS VEHICLE SYST

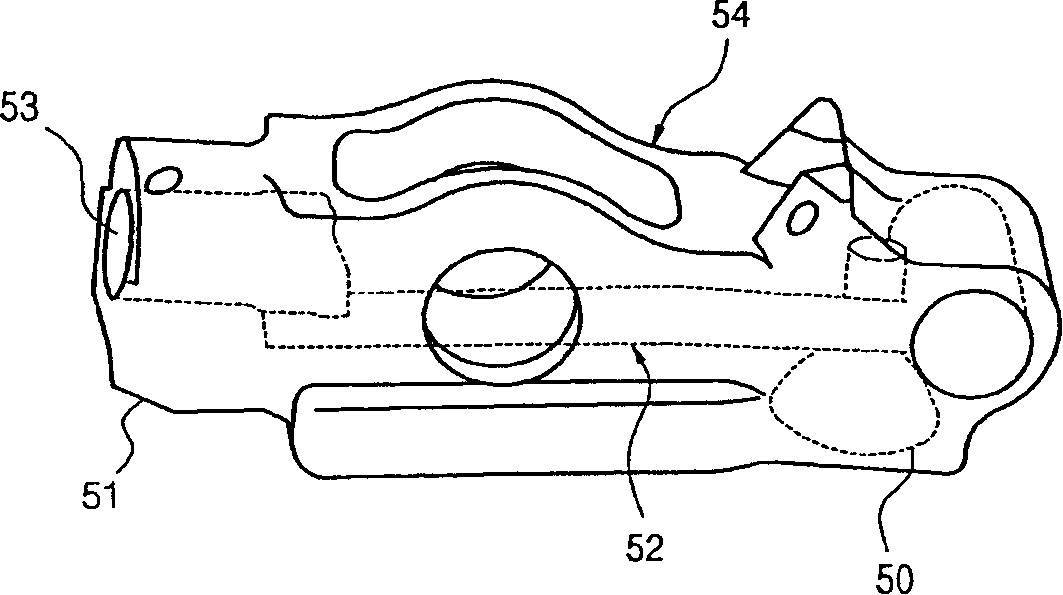

Support element

ActiveCN106471224AIncrease volumeShort response delay timeValve arrangementsMachines/enginesCouplingInternal combustion engine

The invention relates to a double-flow hydraulic support element (10) for a switchable drag lever of a valve drive of an internal combustion engine. A piston (24) is arranged in an axial bore (18) of the housing (12) of the support element in an axially movable manner, and the piston (24) consists of a hollow cylindrical pressing part (22) and a cup-shaped working part (20). A head (28) of the pressing part (22) is used as a bearing for the drag lever and projects beyond the housing edge (34), and an opening for the flow of a hydraulic medium is formed in the end face (30) of the head (28). The housing (12) has a first passage (40) and a second passage (42) axially spaced from the first passage for the hydraulic medium. The support element (10) has a hydraulic clearance-compensating device (36) with a ball non-return valve (37) for the drag lever. In order to achieve an optimal actuation of the coupling means, a sleeve (44) which is closed on one side is inserted into the pressing part (22); the closed end (52) of the sleeve (44) reaches the region of an outer annular groove (58) in a sealing manner below the dome-shaped head (28) of the pressing part (22); a storage space (54) for supplying the clearance-compensating device (36) with the hydraulic medium is formed radially within and axially outside of the sleeve (44), in the pressing part (22), and in the working part (20) of the piston (24); the storage space (54) is connected to the first passage (40) in the housing (12) via a passage opening (70) in the working part (20); an actuation space (56) formed between the sleeve (44) and the pressing part (22) of the piston (24) for hydraulically supplying the coupling device is connected to the second passage (42) in the housing (12) via a radial passage opening (76) in the pressing part (22); and the volume of the storage space (54) is substantially greater than the volume of the actuation space (56).

Owner:SCHAEFFLER TECH AG & CO KG

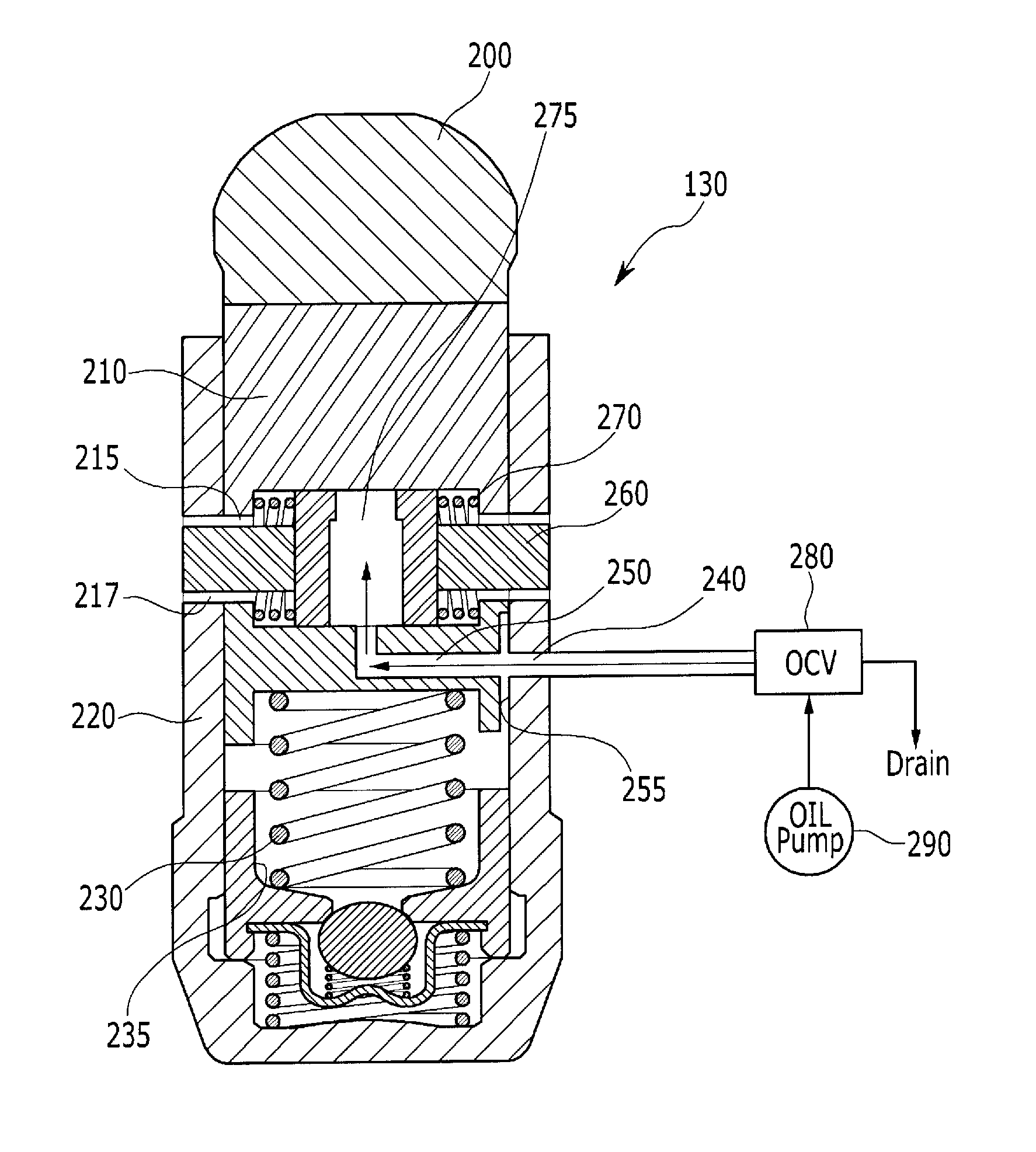

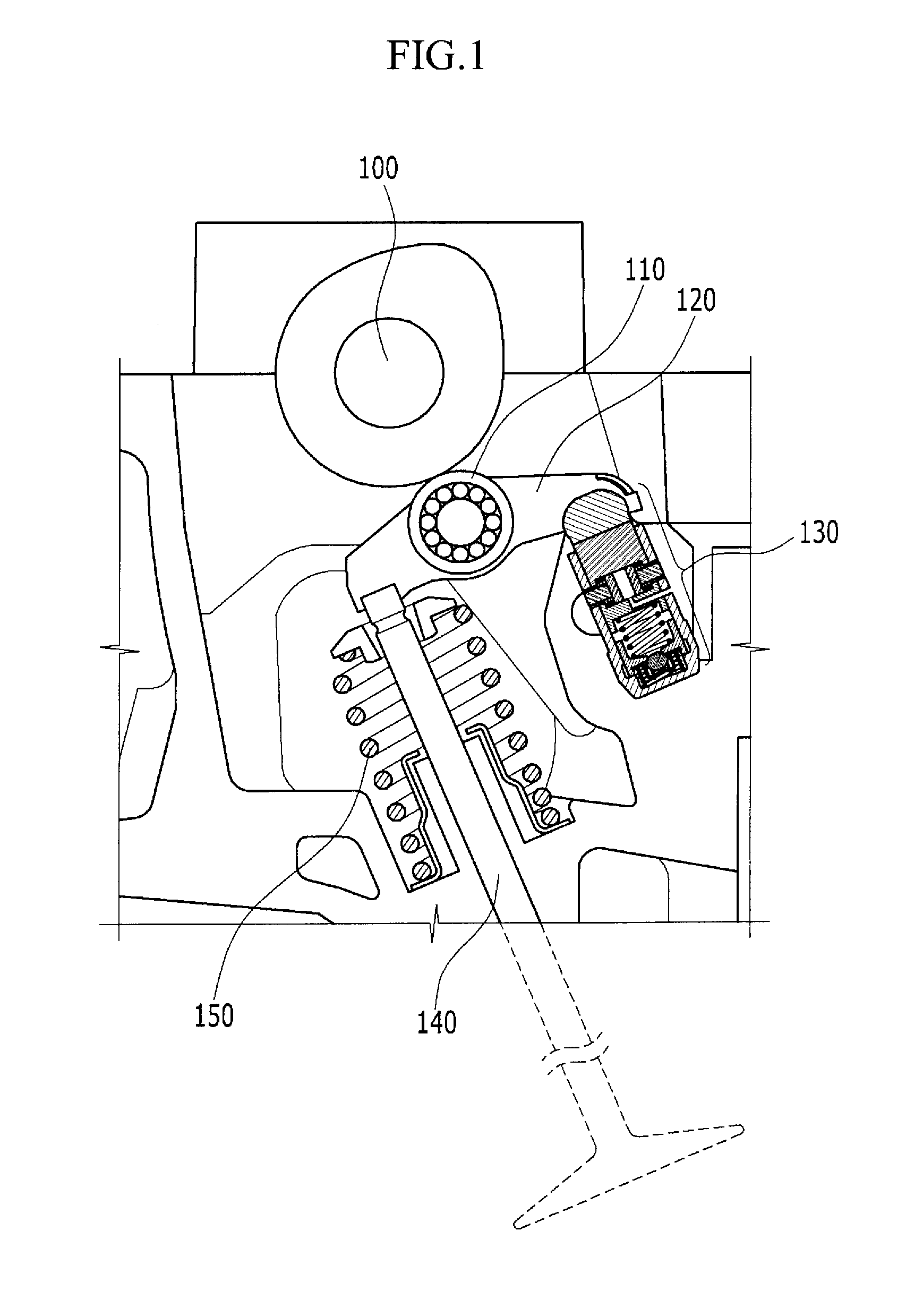

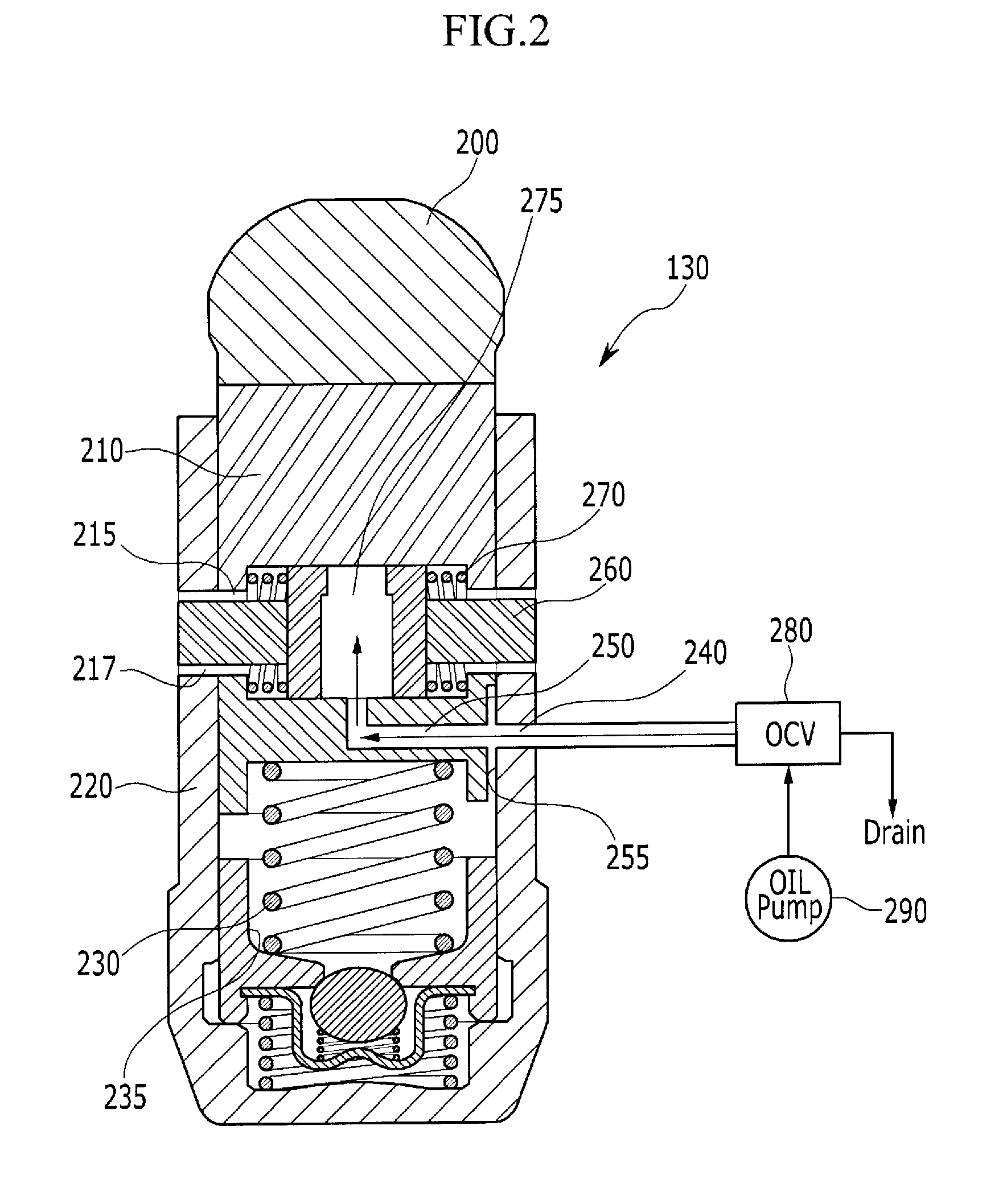

Engine equipped with variable valve device

ActiveUS20120067313A1Small structureReduce weightValve arrangementsMachines/enginesControl valvesHydraulic clearance

An engine that may be provided with a variable valve device may include an hydraulic pressure lash adjuster pivotally supporting one side of a swing arm, a valve supporting the other side of the swing arm, and an operating portion pushing a portion of the swing arm downwards so as to pivotally move the valve based on the hydraulic pressure lash adjuster, wherein the hydraulic pressure lash adjuster includes a housing in which an insertion hole may be formed therein, a slave piston that may be slidably inserted into the insertion hole, a master piston of which an end thereof may be placed into the insertion hole with a predetermined gap from the slave piston, wherein the other end of the master piston protrudes out of the housing and may be engaged with the one side of the swing arm, and an oil control valve that opens or closes a passage communicating with a master chamber that may be formed between the master piston and the slave piston in the housing.

Owner:HYUNDAI MOTOR CO LTD +1

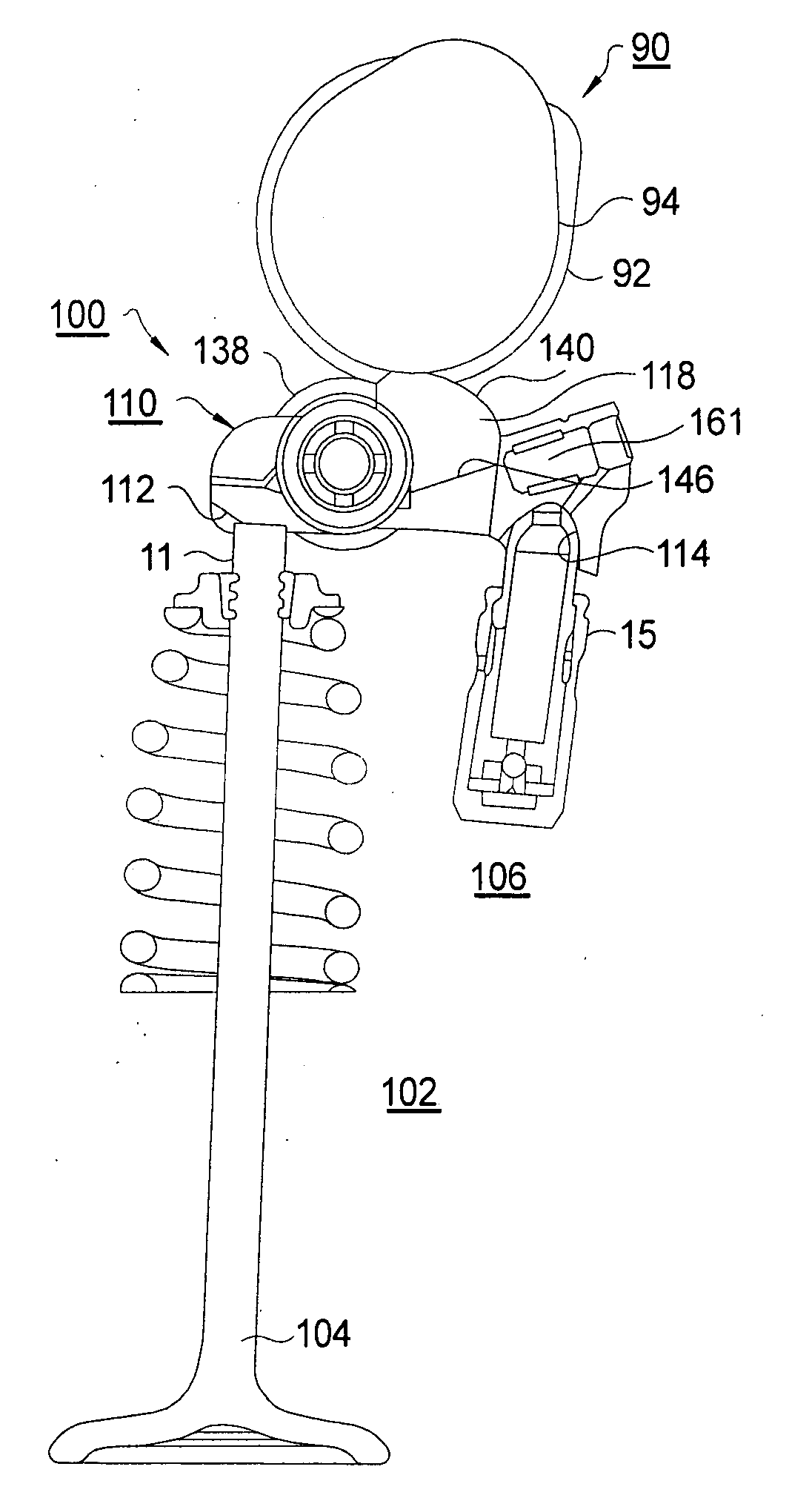

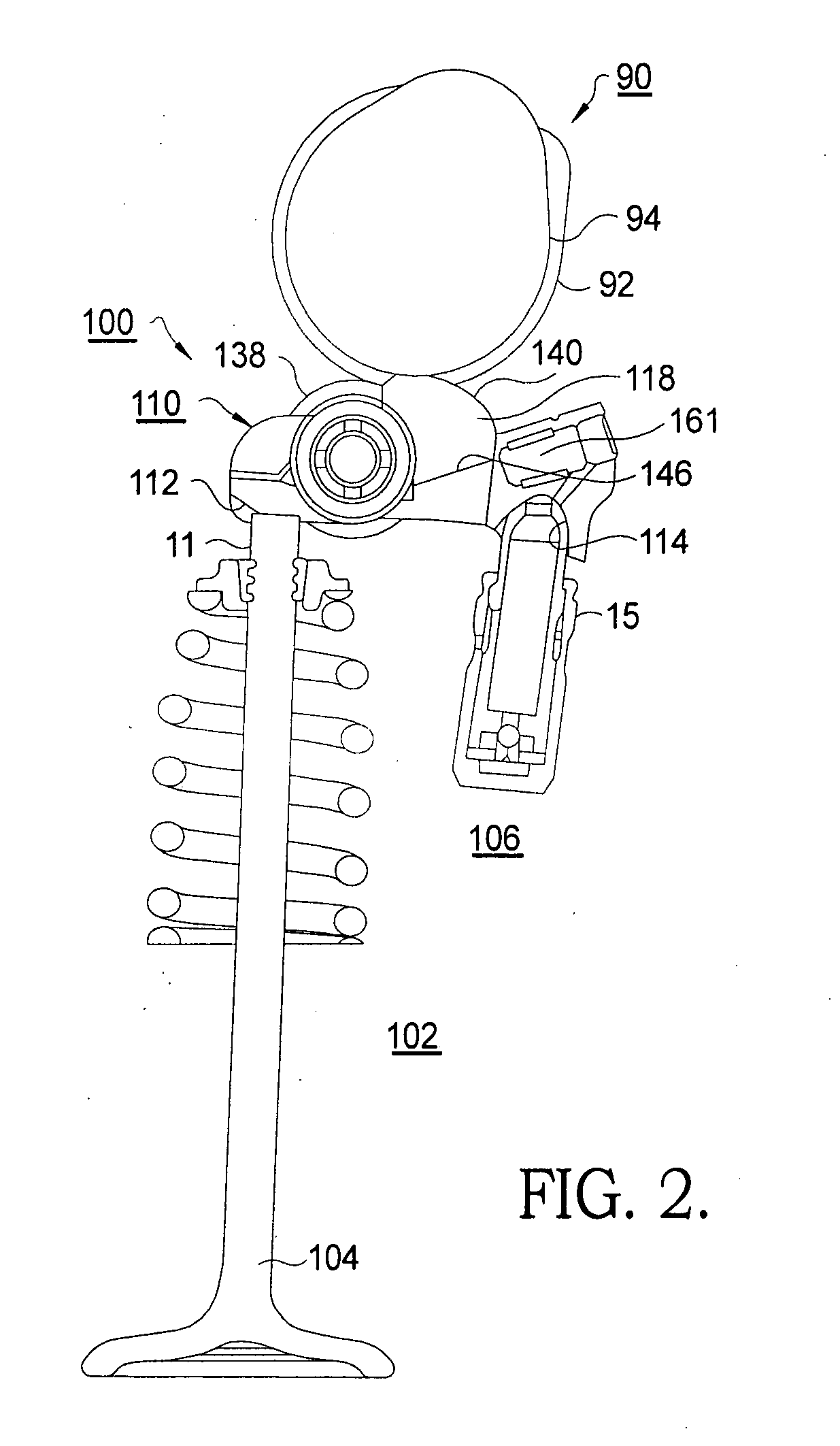

Roller finger follower assembly for valve deactivation

A roller finger follower rocker arm assembly for deactivating an engine valve. A follower body pivots on a hydraulic lash adjuster, and engages a valve stem or lifter. The body receives a reciprocating member having a first and second rollers outboard of the body for following eccentrics of a cam lobe that straddles the body, the body having elongate openings on either side of the reciprocating member. A locking pin selectively locks and unlocks the body to the reciprocating member. The reciprocating member does not make contact with the cam lobe and functions only as a link between the latching mechanism and the rollers. The pin engages the reciprocating member by a latching spring and is disengaged by pressurized oil supplied through the hydraulic lash adjuster. Means is provided for limiting axial growth of the HLA during deactivation mode of the rocker arm assembly.

Owner:DELPHI TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com