Support element

A technology for supporting components and pressure parts, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of large dead volume, imprecise timing, non-optimal response characteristics, etc., and achieve short and accurate timing , the effect of short response delay time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

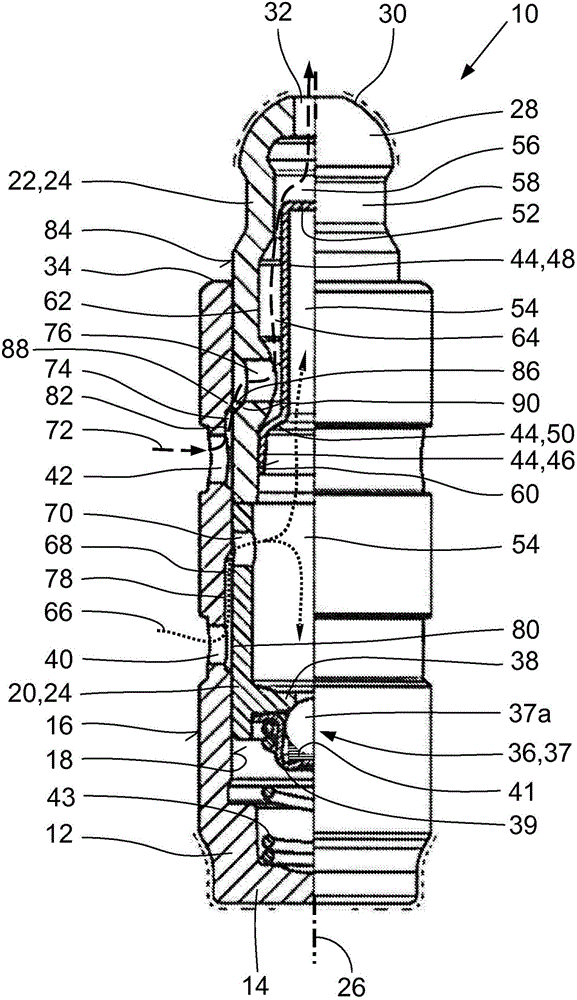

[0021]The hydraulic support element 10 has a substantially pot-shaped housing 12 with a housing bottom 14 and a peripheral side 16 . The housing 12 can be inserted into a receiving bore of a cylinder head (not shown) of the internal combustion engine. The hydraulic channels that supply the hydraulic support element 10 with hydraulic medium open into receiving bores in the cylinder head. In the axially continuous cylindrical bore 18 of the housing 12 is accommodated a piston 24 axially assembled from the working part 20 and the pressure part 22 in a manner capable of moving axially along the longitudinal central axis 26 of the support element 10 . In this case, the working part 20 bears against the pressure part 22 of the piston 24 without play and with axial contact.

[0022] The dome-shaped head 28 of the pressure part 22 of the piston 24 serves as a support for a likewise not shown rocker arm of a valve drive (not shown) of the internal combustion engine. An opening of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com