Lost motion assembly in a valve bridge for use with a valve train comprising a hydraulic lash adjuster

A technology for slack adjusters, components, applied in the direction of engine components, machines/engines, non-mechanically actuated valves, etc., which can solve the problems of occupying available gaps, catastrophic damage to engines, excessive extension of hydraulic slack adjusters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

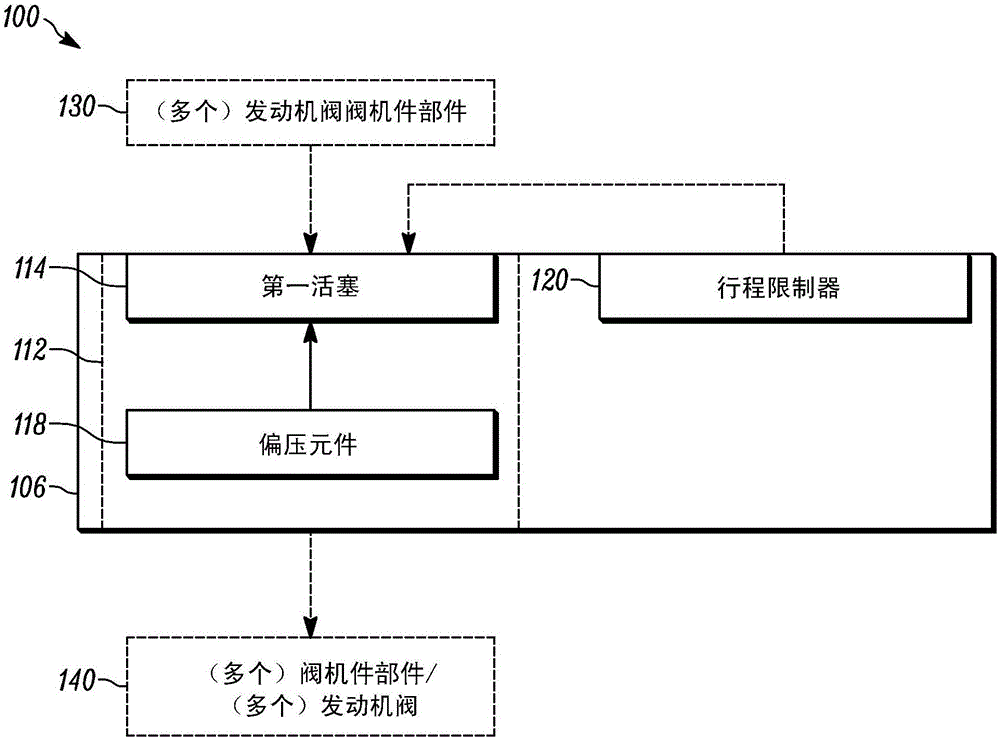

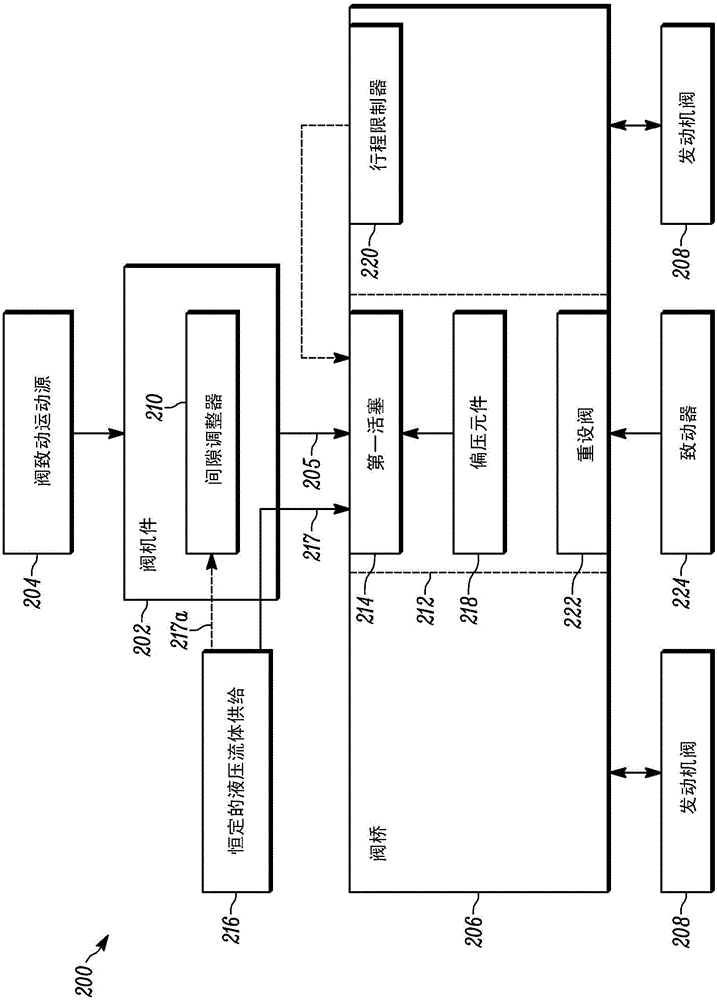

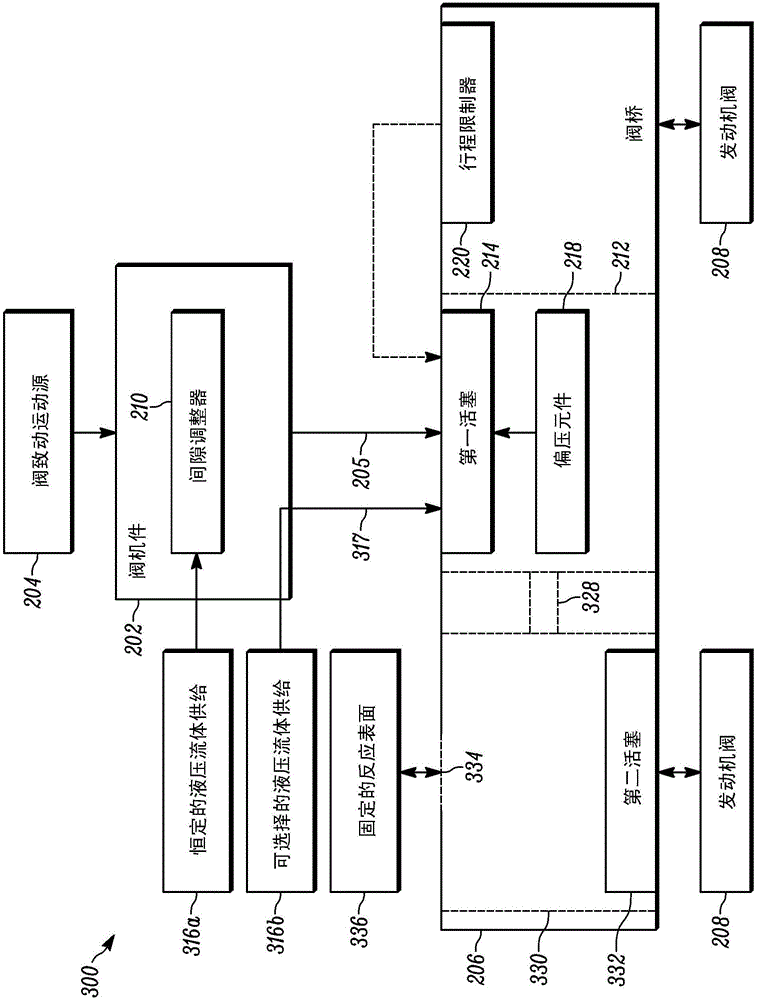

[0022] see now figure 1 , the lost motion assembly 100 according to the present disclosure includes a lost motion housing 106 having a first piston cylinder 112 formed therein and a first piston 114 disposed in the first piston cylinder 114 . In general, the lost motion housing 106 may be embodied by any component of the valve train (eg, pushrod, rocker arm, valve bridge, etc.). However, for purposes of illustration, various embodiments are described in detail below in which the lost motion housing 106 is embodied by a valve bridge. As is known in the art, the first piston 114 may be configured (as shown in the various embodiments below), selective application of hydraulic fluid thereto allows the first piston 114 to switch between the operating mode or another mode. Alternate between the mode of operation in which all valve actuation motions applied thereto (including any auxiliary valve actuation motions) are caused to be transmitted through, and the other mode in which som...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com