Pre-seal structure of post-subsidence pouring belt and construction method thereof

A closed structure and construction method technology, which is applied in the direction of building structure and construction, can solve the problems that the settlement structure cannot be closed in advance and cannot meet the requirements of the project progress, so as to meet the requirements of structural bearing and force, reduce construction costs, and ensure the quality of the project. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

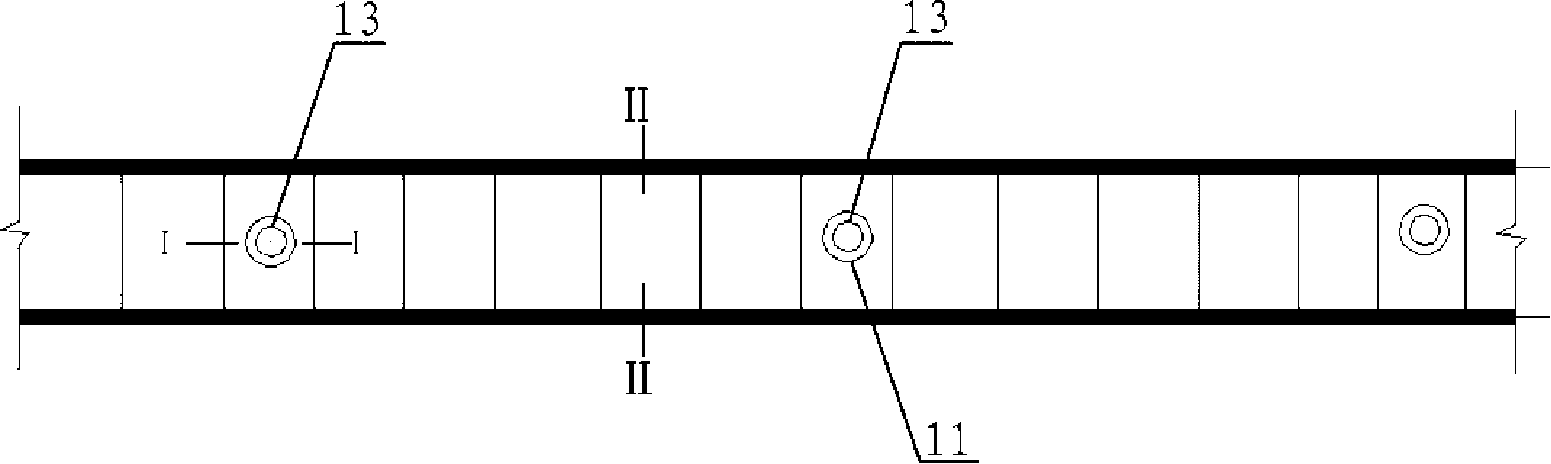

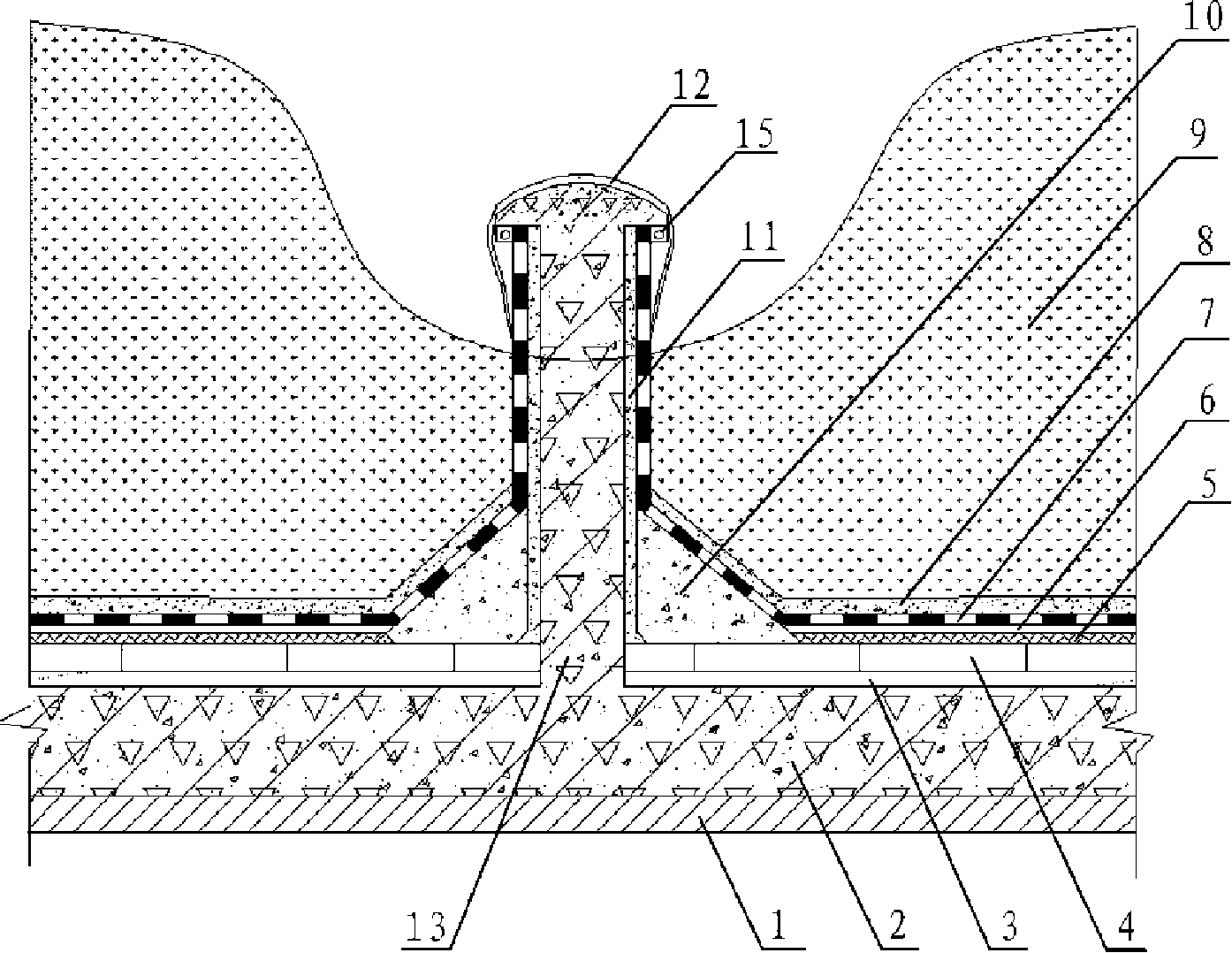

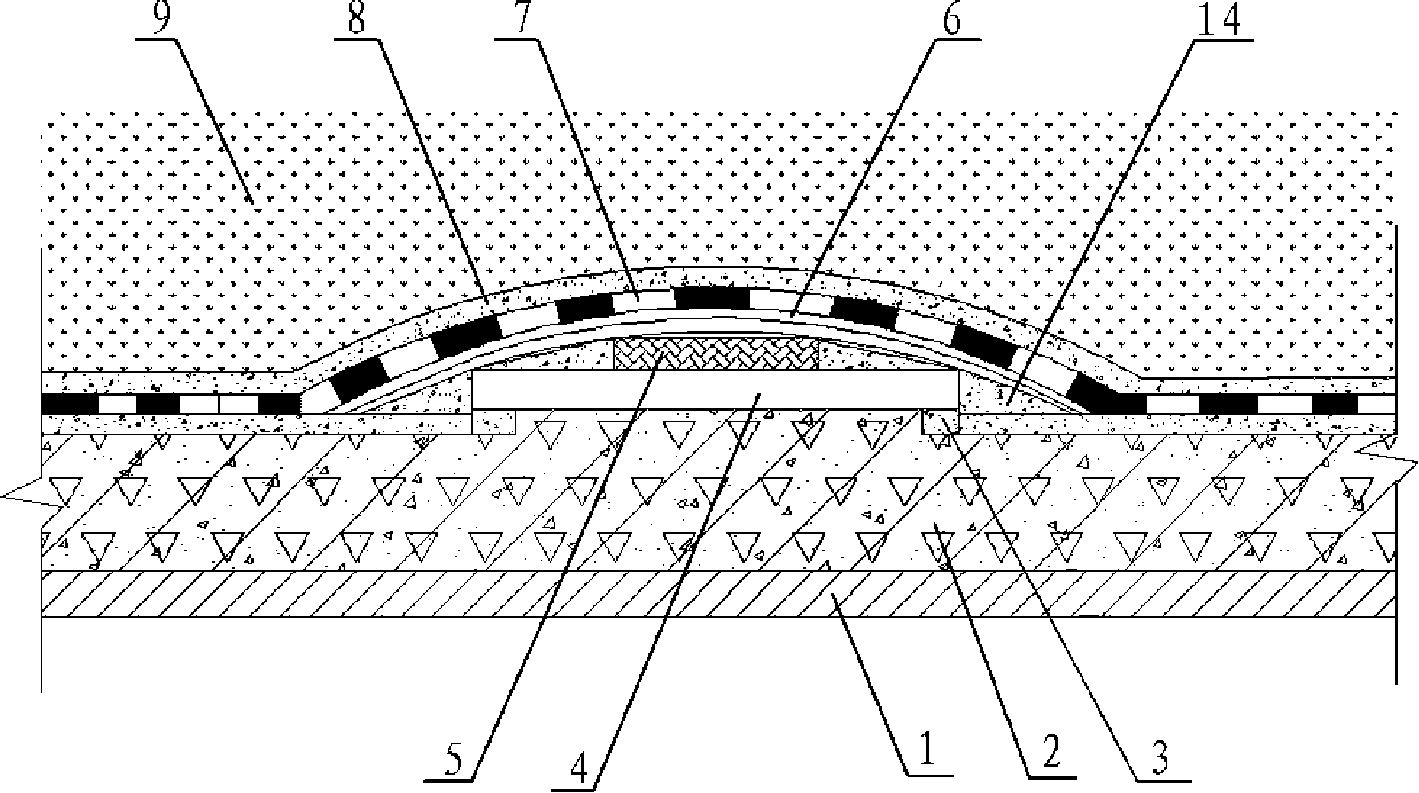

[0029] Examples see figure 1 , figure 2 , image 3 As shown, this pre-sealed structure of the post-settling cast belt is characterized in that: the post-settled cast strip is made at the unsettled place of the structure, and the post-settled cast strip formwork 1 is laid on the bottom surface of the settlement space 2 inside the settled post-settled cast strip. A reinforcement cage is arranged in the settlement space 2, and a mortar layer 3 is laid on the surface of the pouring belt and both edges after settlement, and a concrete cover plate 4 is laid on the surface of the mortar layer 3, and the transition layer is sequentially connected from bottom to top on the concrete cover plate 4 , waterproof layer, concrete protective layer 8 and backfill soil 9; reserve concrete pouring holes 13 on the concrete cover plate 4, and vertically connect concrete pouring pipes 11 on the pouring holes 13, the pipe diameter is 300mm, and the pipe spacing is 4000mm. The root of the concrete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com