Manually-operated hair clipper

A manual operation and haircutting push technology, which is applied in metal processing and other directions, can solve the problems that cannot be widely used in individuals and families, clumsy assembly and disassembly, and difficult haircutting operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

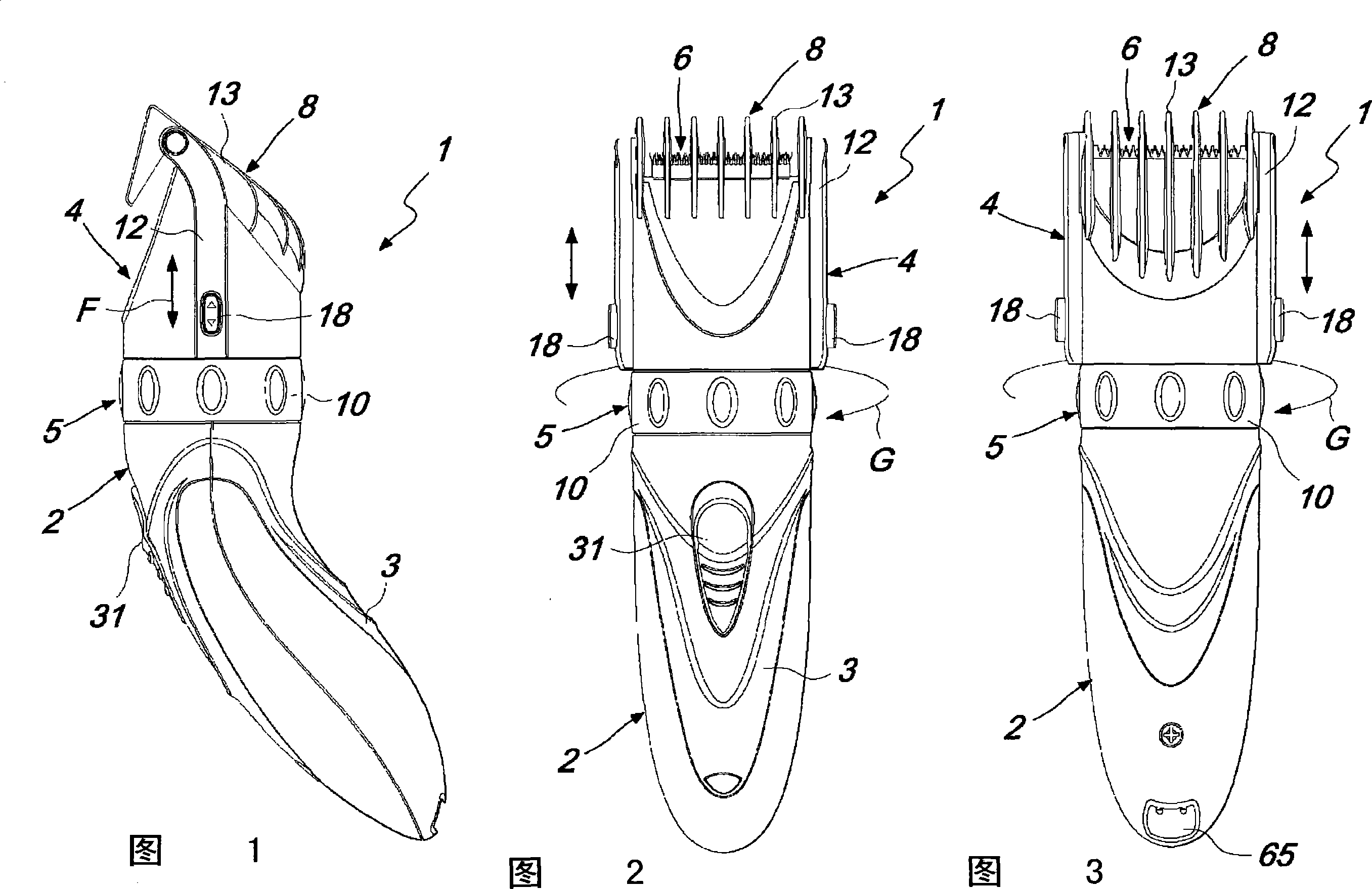

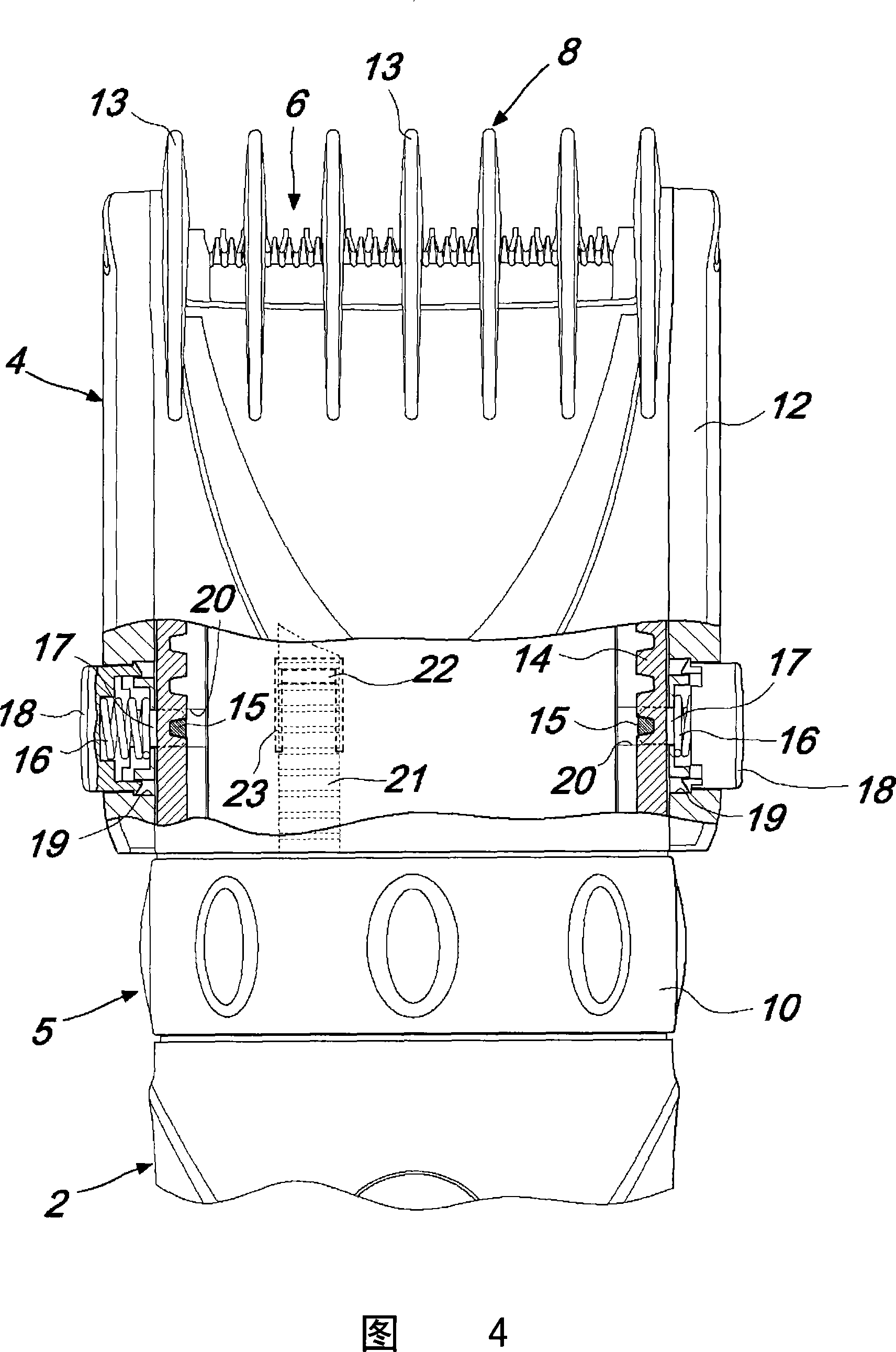

[0032] Referring to the drawings, reference numeral 1 generally denotes a manually operated hair clipper.

[0033] Hair clipper 1 comprises a substantially elongated housing 2 forming a handle 3 at one end and having a working head 4 at the opposite end.

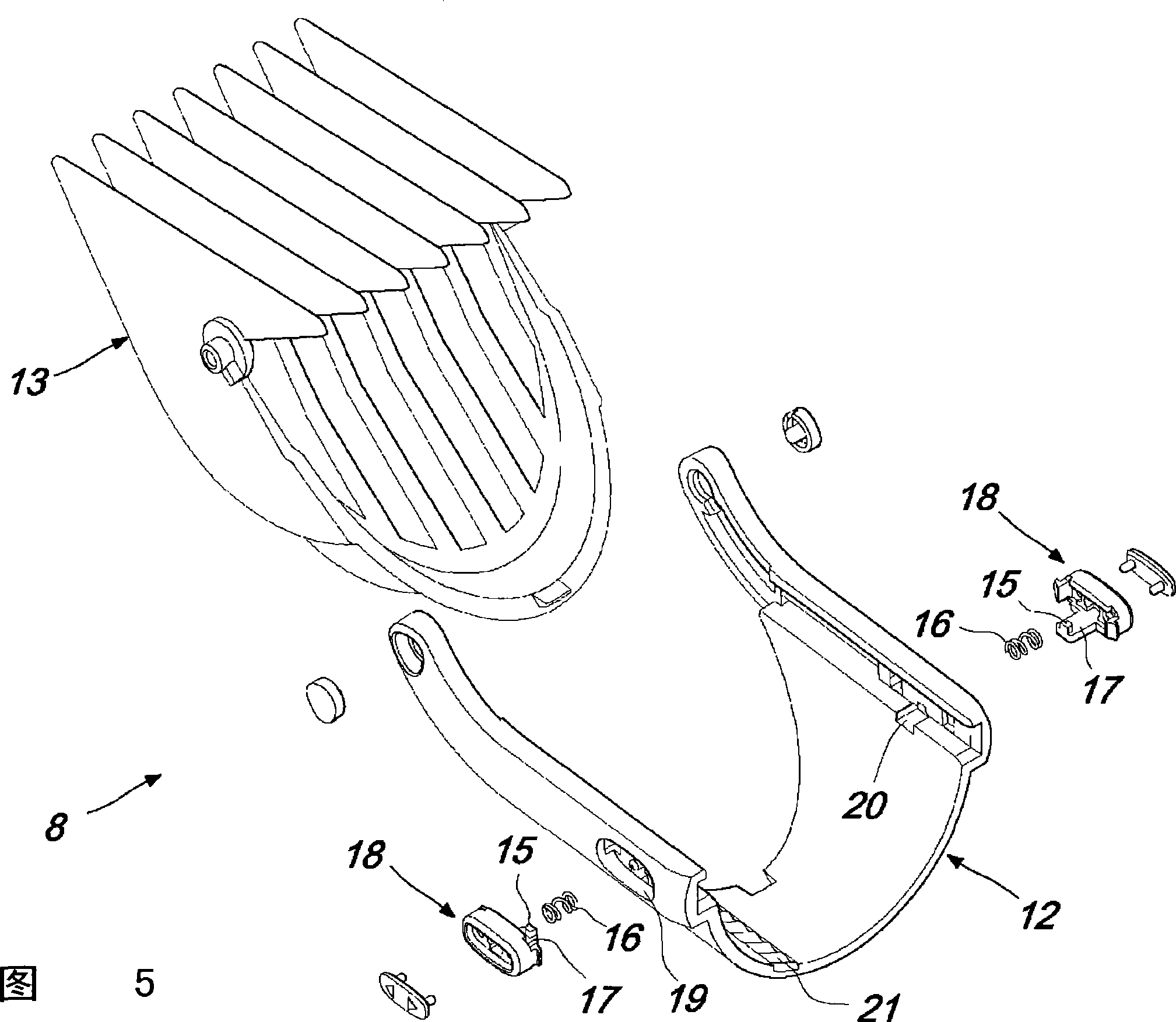

[0034] The working head 4 comprises a support body 5 for a shearing blade assembly 6 and a motor assembly 7 ; motion transmission means (to be described in detail below) are provided between the motor assembly 7 and the shearing blade assembly 6 .

[0035] At least one comb member 8 is associated with the support body 5 so that it can slide relative to the cutting blade assembly 6 along an approaching and spacing path (indicated by arrow F) for adjusting the cutting length.

[0036] First and second stop means are provided between the comb member 8 and the support body 5 and are arranged to temporarily lock the comb member 8 away from the shear blade assembly relative to the support body 5 depending on the desired cutting le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com