Forming apparatus

A technology of compression forming and arching, which is applied in the direction of wood compression, metal processing, and joining of wooden veneers. It can solve the problems of cracks in the cutting part, changes in cutting strength, and inability to process with high precision, and achieves rapid and easy forming and processing. cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The best mode of the forming apparatus according to the present invention will be described below with reference to the accompanying drawings.

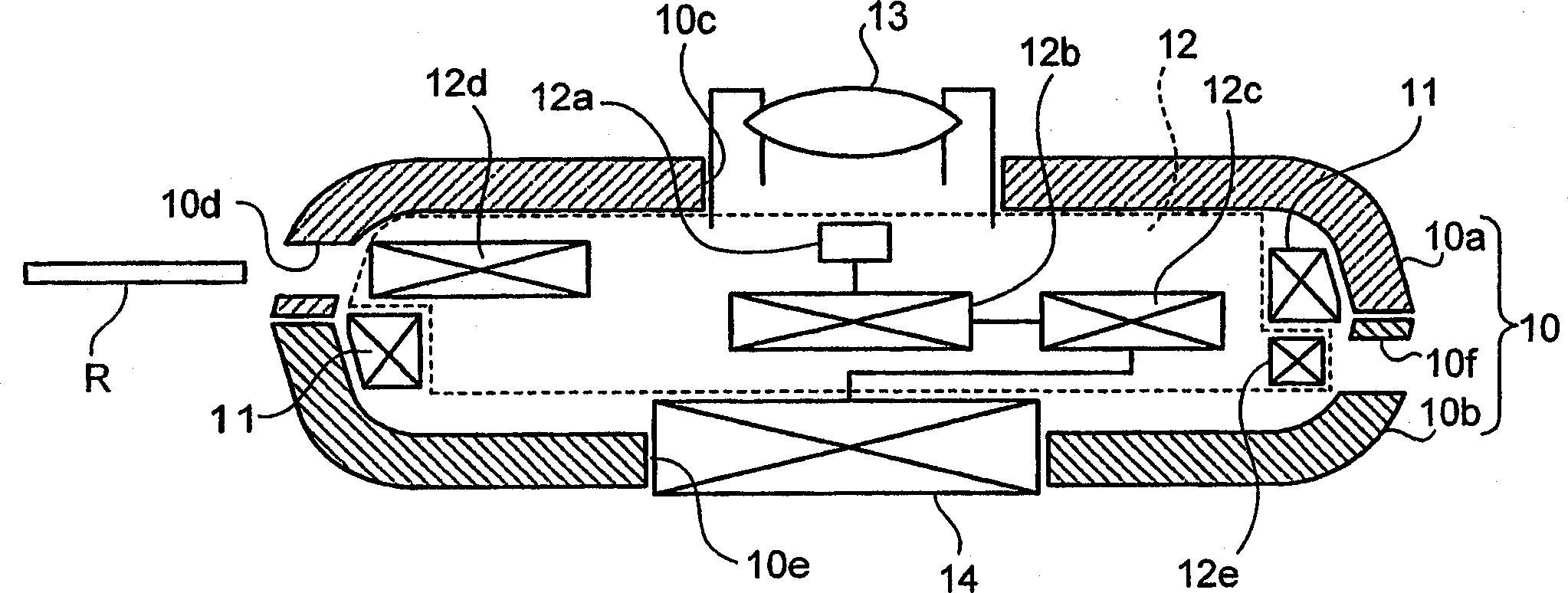

[0068] figure 1 is a sectional view showing an electronic device in which compressed wood produced by a forming device according to an embodiment of the present invention is used as an exterior material. figure 1 A digital camera is shown as an example of an electronic device in . The digital camera has a reinforcement frame 11 and an internal mechanism 12 within an external material 10 formed of compressed wood products. The digital camera also has a taking lens 13 and a liquid crystal monitor 14 , and the taking lens 13 and the liquid crystal monitor 14 are exposed to the outside of the external material 10 . The internal mechanism 12 includes an image pickup device 12a such as a CCD, a drive circuit 12b for driving the image pickup device 12a, a drive circuit 12c for driving a liquid crystal monitor 14, a recording device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com