Three-dimensional orientation controllable single crystal part directional solidification starting end structure and directional solidification method for seed crystal method

A technology of directional solidification and three-dimensional orientation, which can be used in self-solidification methods, chemical instruments and methods, single crystal growth, etc., and can solve problems such as uncontrollable secondary orientation of single crystals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

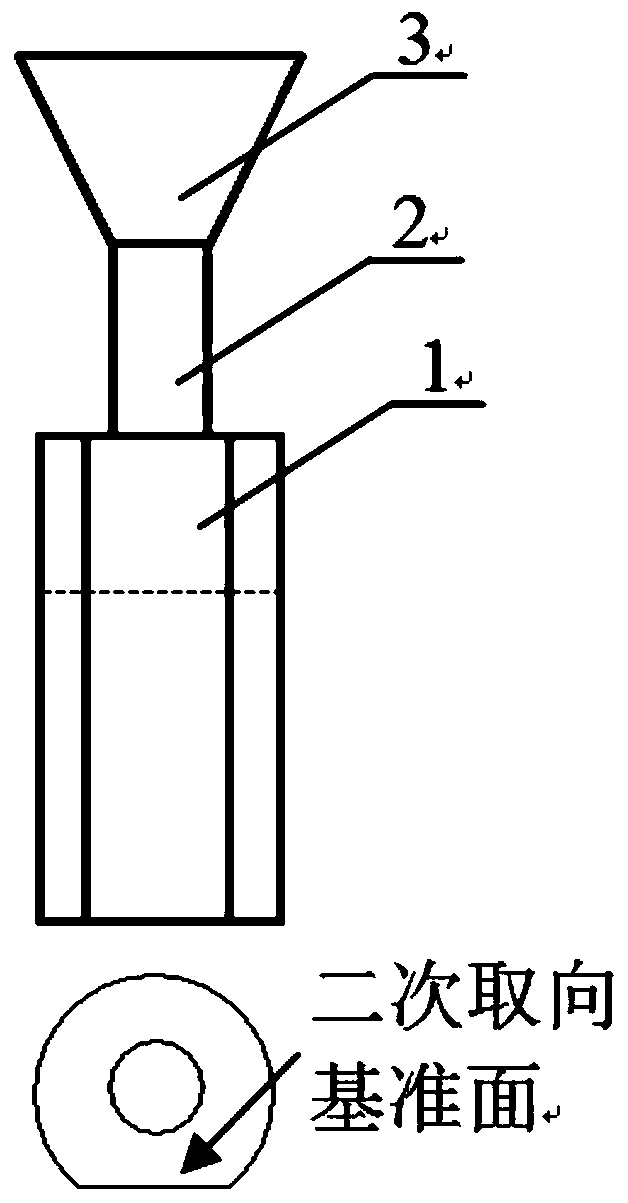

[0031] Such as figure 1 As shown, the starting end structure includes a cylindrical seed cavity 1 with a secondary orientation reference plane at the lower end, a constriction 2 connected to the top of the seed cavity 1, and a single crystal plate or single crystal casting connected to the upper end of the constriction 2 The cavity 3, the diameter of the cylindrical seed crystal cavity is 2.5-3 times the diameter of the constriction, and the height of the seed crystal is 0.5-0.8 times the height of the seed crystal cavity;

[0032] The diameter of the seed crystal cavity is 10 mm, the height is 20 mm, the width of the secondary reference plane is 8 mm; the diameter of the constriction is 4 mm, and the height is 6 mm.

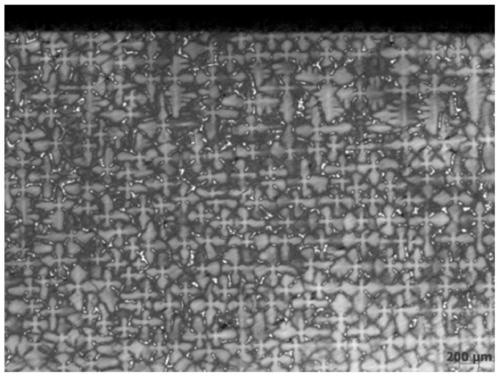

[0033] A second-generation single crystal superalloy with a Re content of 3% was used to grow a single crystal by the seed crystal method in an industrial large-scale dual-zone heating ZGD-15 vacuum single crystal furnace, and a total of two different secondary ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com