Atmosphere protection heat treatment technology of ultrahigh strength D6AC steel thin-wall tube

An ultra-high-strength, protective treatment technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of large deformation, large machining allowance, poor dimensional stability, etc., and achieve solid solution strengthening and phase change strengthening. , Improve comprehensive mechanical properties, increase the effect of dispersion strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

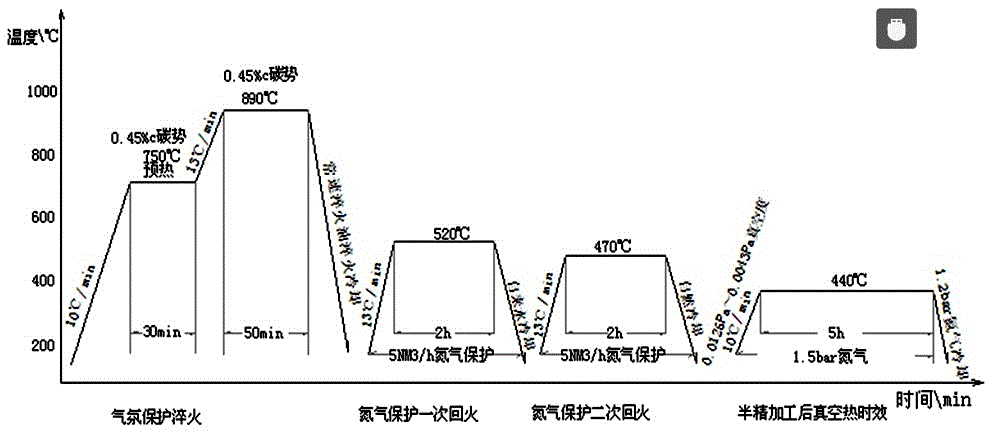

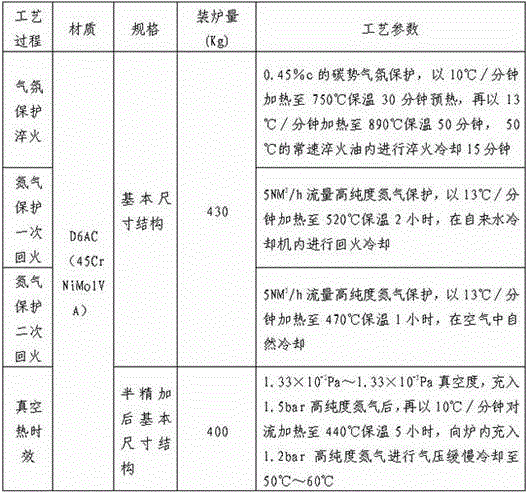

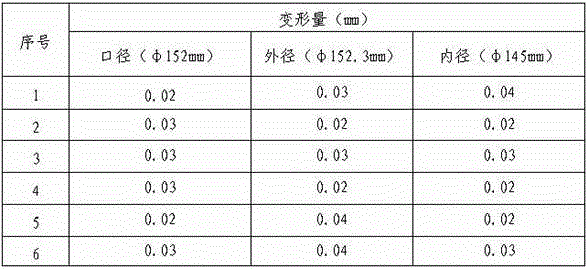

[0022] Example: high-strength D6AC steel thin-walled pipe fittings, material 45CrNiMo1VA, atmosphere protection quenching is under the protection of a carbon potential atmosphere of 0.45% c, heated to 750°C at 10°C / min for 30 minutes, and then preheated at 13°C / min Minute heating to 890°C for 50 minutes, then transferred to 50°C normal speed quenching oil for quenching and cooling for 15 minutes, and then cleaned; secondary nitrogen protection tempering: the first tempering is to the furnace with 5NM 3 After filling high-purity nitrogen at a flow rate of / h, heat it at 13°C / min to 520°C for 2 hours, and then temper and cool it in a tap water cooler; 3 After being filled with high-purity nitrogen at a flow rate of / h, it is heated at 13°C / min to 470°C for 1 hour, and then naturally cooled in the air. The same batch of thin-walled pipe fittings is tested for hardness, and the pipe fittings with the highest hardness value and the lowest hardness value are selected for tensile tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com