Big opening angle stack wafer transmitting transducer

A technology for transmitting transducers and chips, which is applied in the direction of sound-generating devices, instruments, and fluids using vibrations, etc. It can solve the problems of small beam width and reduce the working frequency of transducers, so as to increase the opening angle of the transmitting beam and improve the transmission efficiency. The effect of high sensitivity and emitted sound energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The stacked wafer emitting transducer of the present invention will be described in detail below with reference to the accompanying drawings and examples.

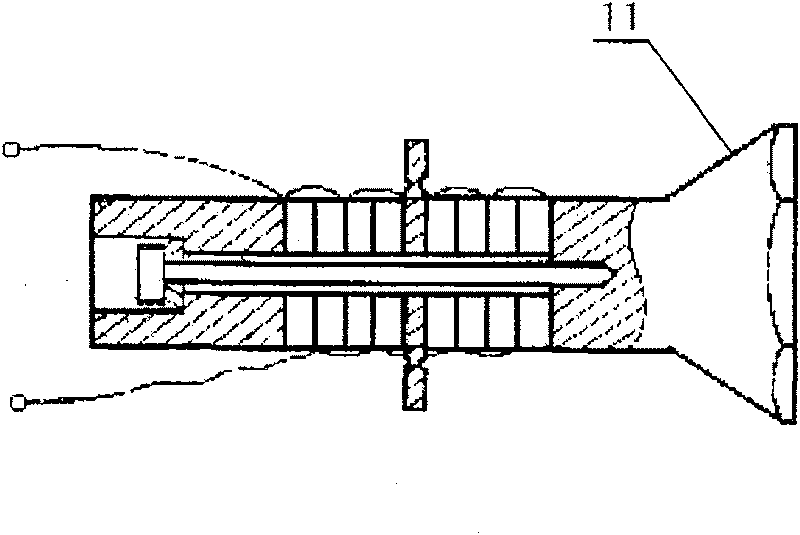

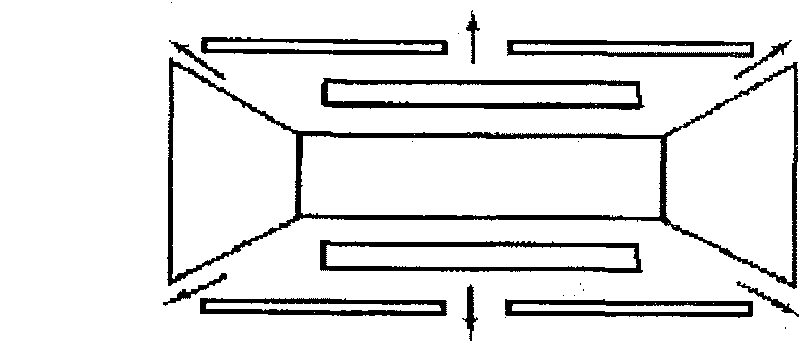

[0039] The stacked wafer emission transducer of this example comprises piezoelectric wafer stack 2, front cover plate 1, backing 5, prestressed screw 6, waterproof sound-permeable layer 8 and output cable 7 etc., as Figure 6 shown.

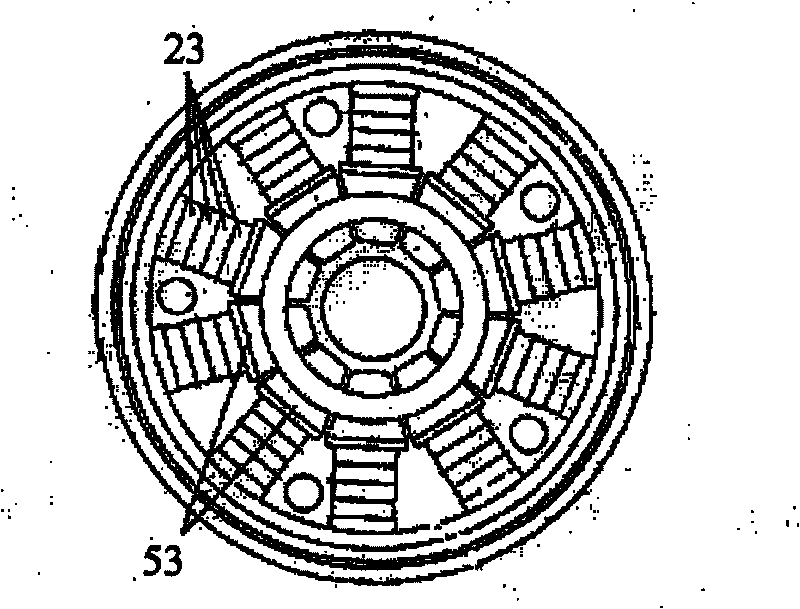

[0040] In the piezoelectric wafer stack 2, the wafers are made of piezoelectric ceramic PZT with a hole in the center, and the polarization directions of every two adjacent wafers are opposite (see Figure 8 ). Between the chips, and between the chip and the front cover 1 and the backing 5, a thin metal sheet 3 is clamped to weld the leads 4. The wafer, the metal sheet 3, the front cover 1 and the backing 5 are glued together with epoxy resin. Die stack wiring such as Figure 8 As shown, a parallel connection is used to ensure that the same phase voltage is applied to each chip at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com