Apparatus for realizing joint signal transmission

A signal transmission and packaging technology, applied in the direction of connection, clamping/spring connection, current collector, etc., can solve the problems of limited size of the joint step surface, insufficient space for installation, easy winding or even breaking of the signal transmission line, etc., to achieve Resolves the effect of limited joint size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

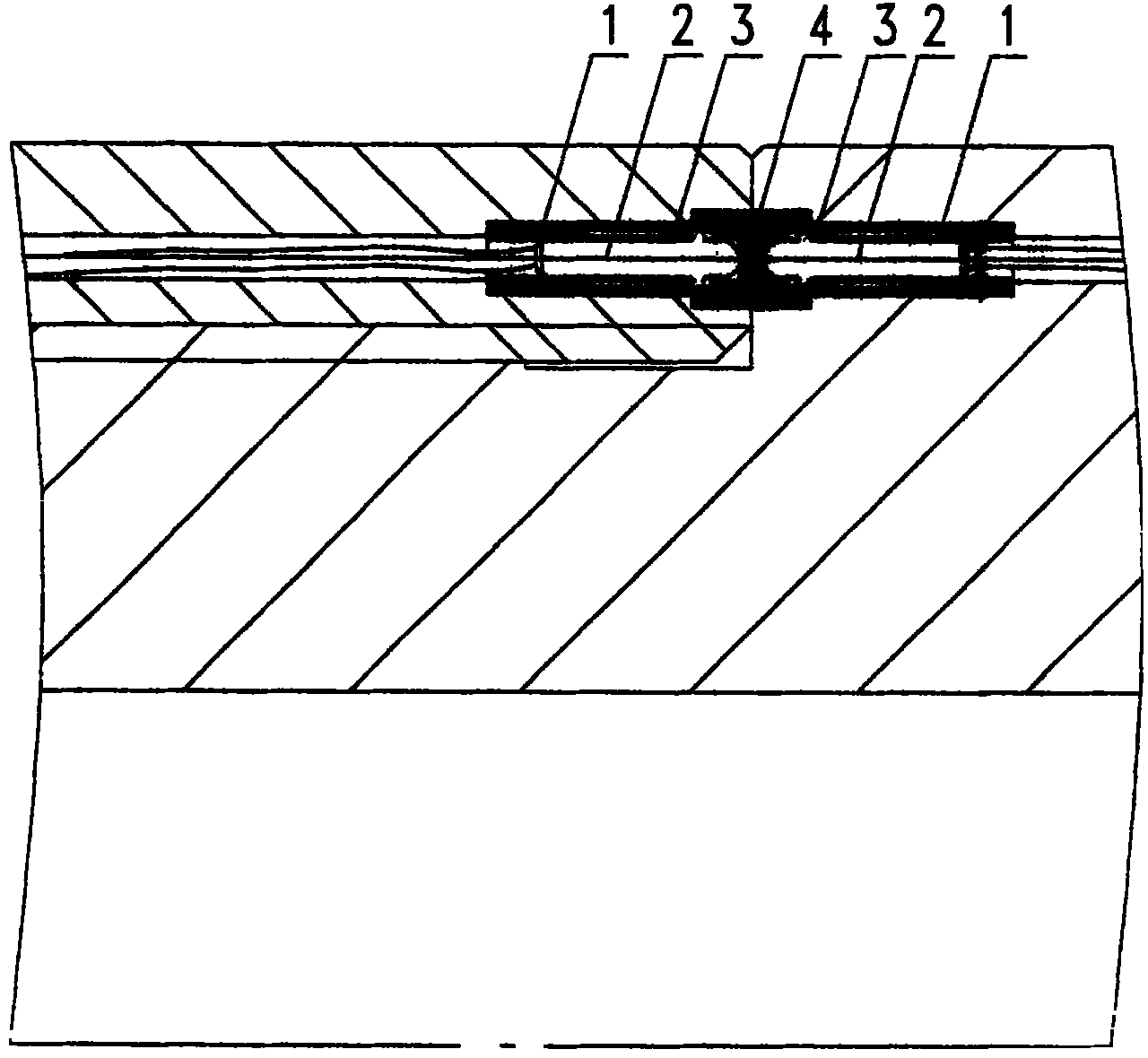

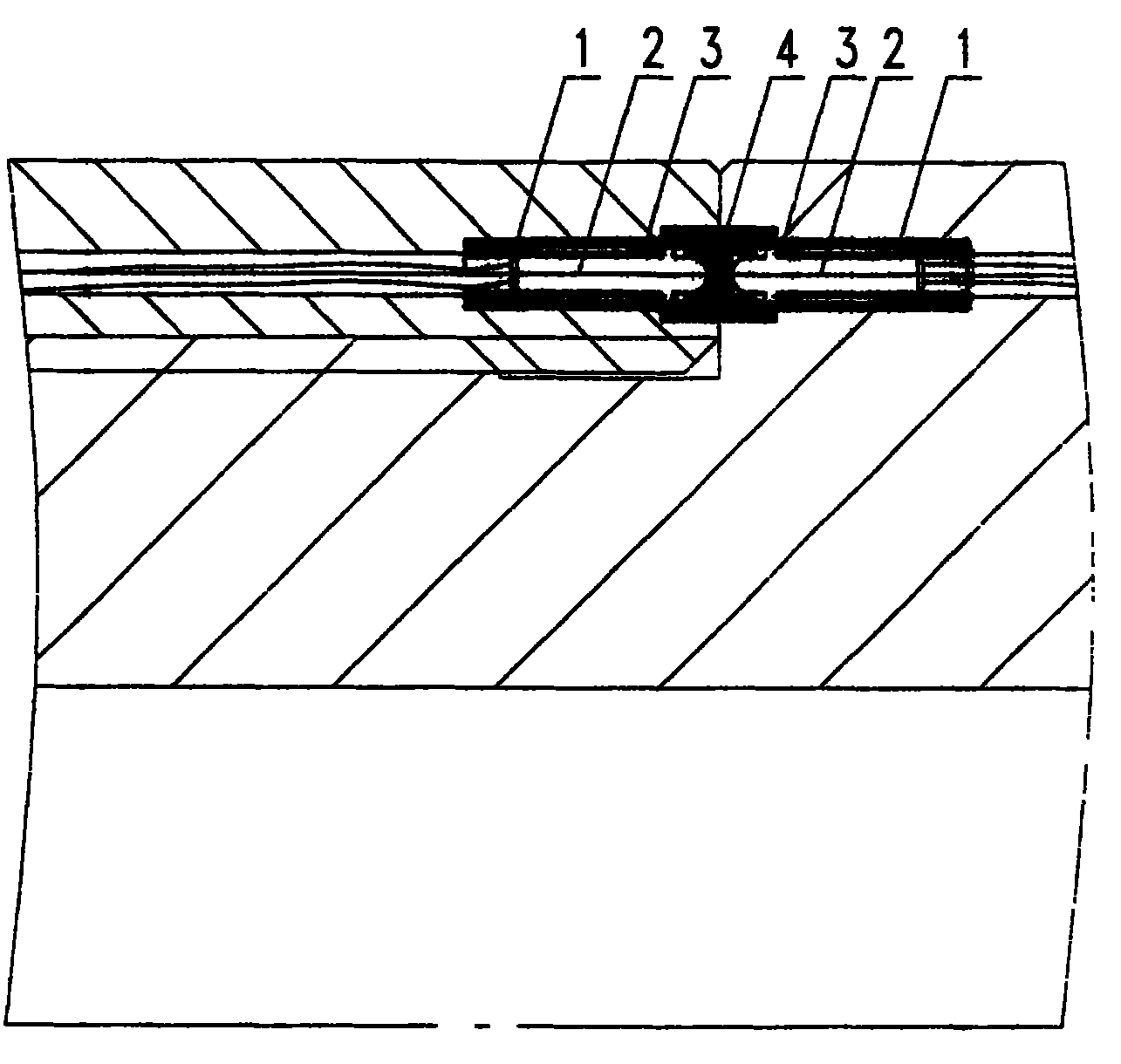

[0009] Attached below figure 1 The present invention is further described.

[0010] as attached figure 1 As shown, a device for realizing joint signal transmission is mainly composed of an insulating sleeve 1 , a conductor rod 2 , a spring 3 , and a conductor ring 4 . First process the axial holes at the joints of the two joints respectively, install the insulating sleeve 1, the conductor rod 2 and the conductor ring 4 in the axial holes respectively, the conductor rod 2 is set in the inner cavity of the insulating sleeve 1, and the insulating sleeve 1 can hold the conductor rod 2 and the conductor ring 4 are not in contact with the joint, and the inner cavity of the insulating sleeve 1 is processed into a step shape, and the outer surface of the conductor rod 2 is also processed into a step shape. A spring 3 is installed in the annular space, and the spring 3 can keep the conductor rod 2 and the conductor ring 4 in a contact state all the time, and the conductor rod 2 is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com