Linear transmission module possessing self-lubricating unit

A transmission module, linear technology, applied in the direction of transmission, friction transmission, gear lubrication/cooling, etc., can solve problems such as insufficient lubrication, dripping, too little oil supply, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

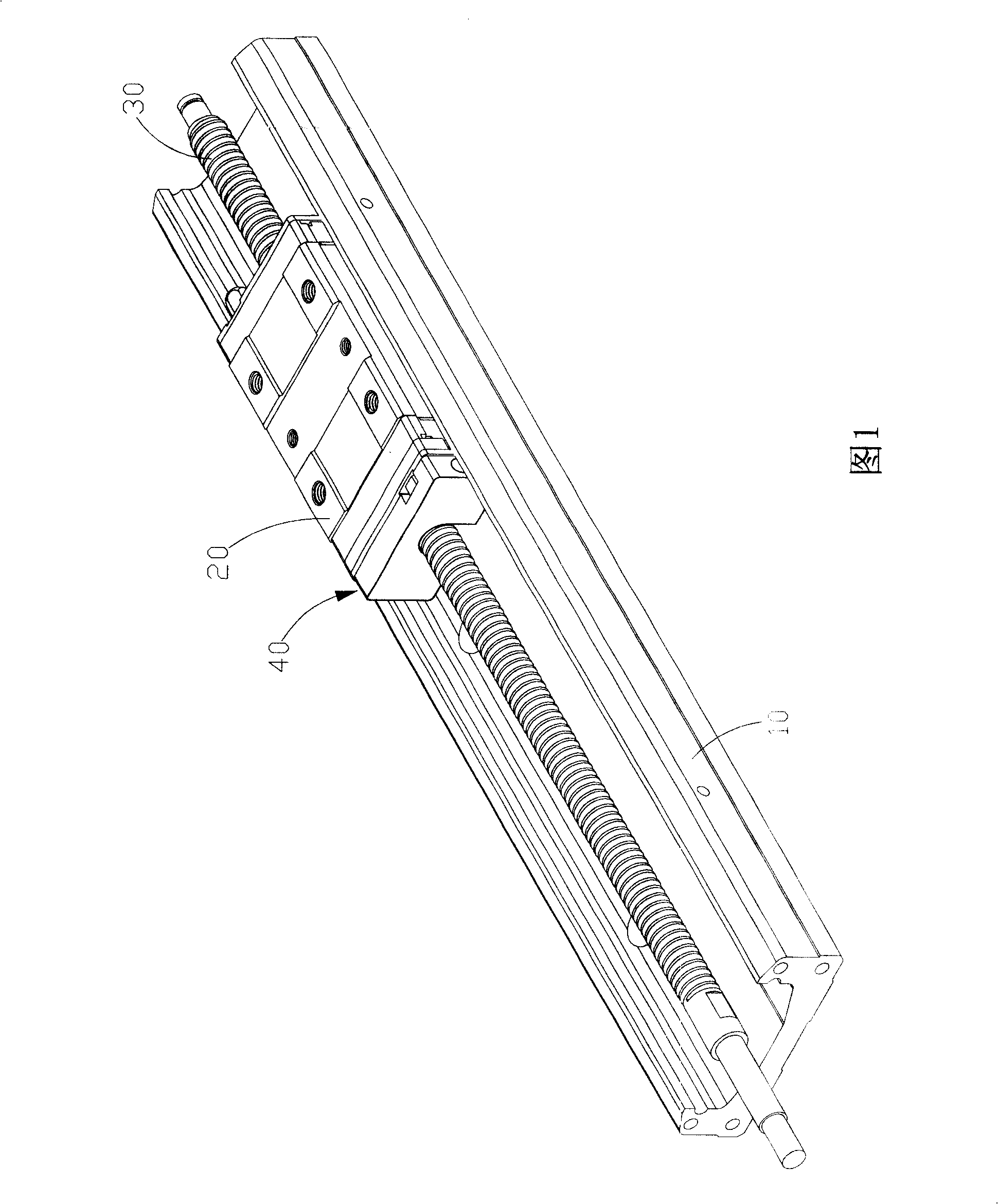

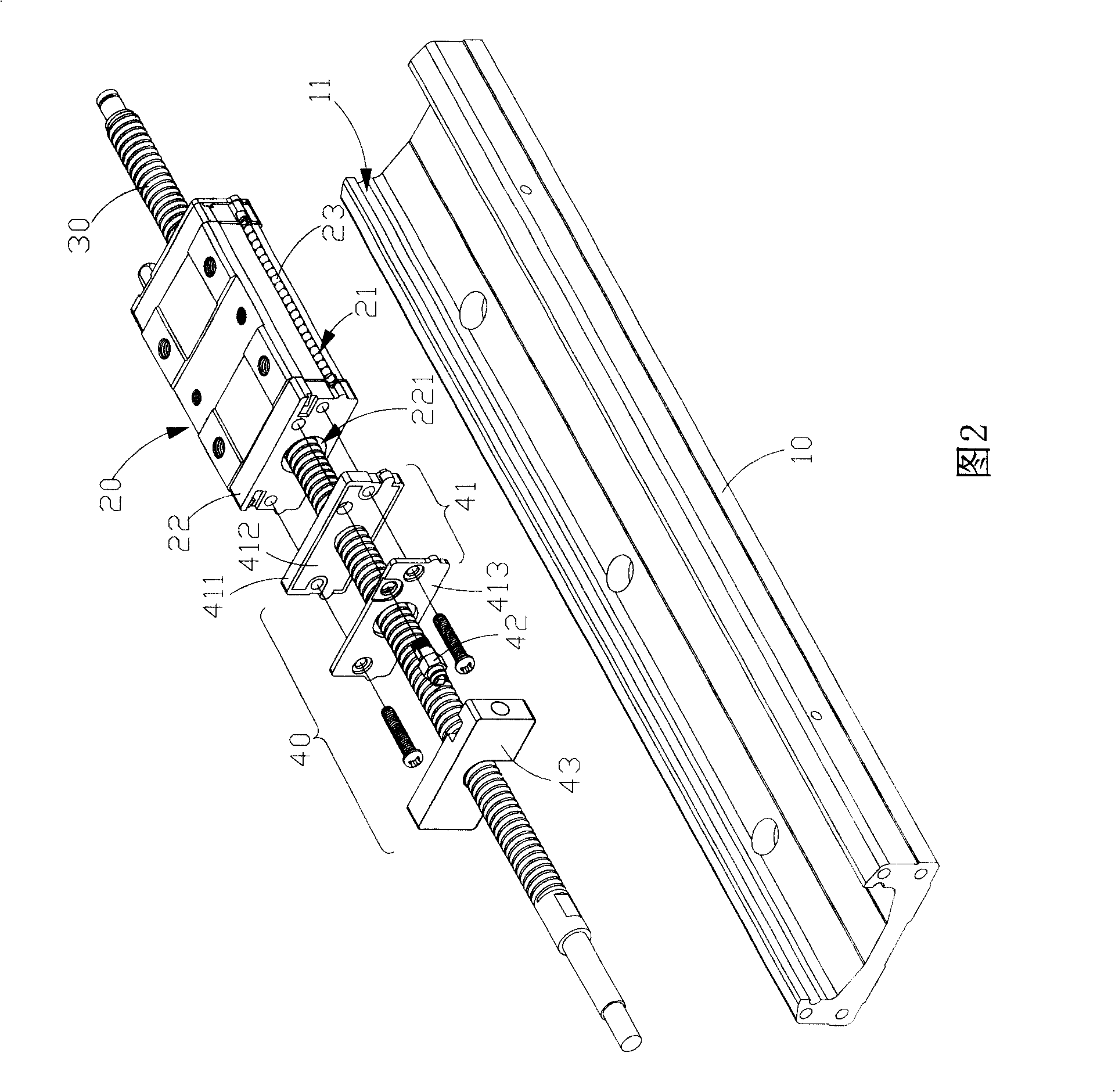

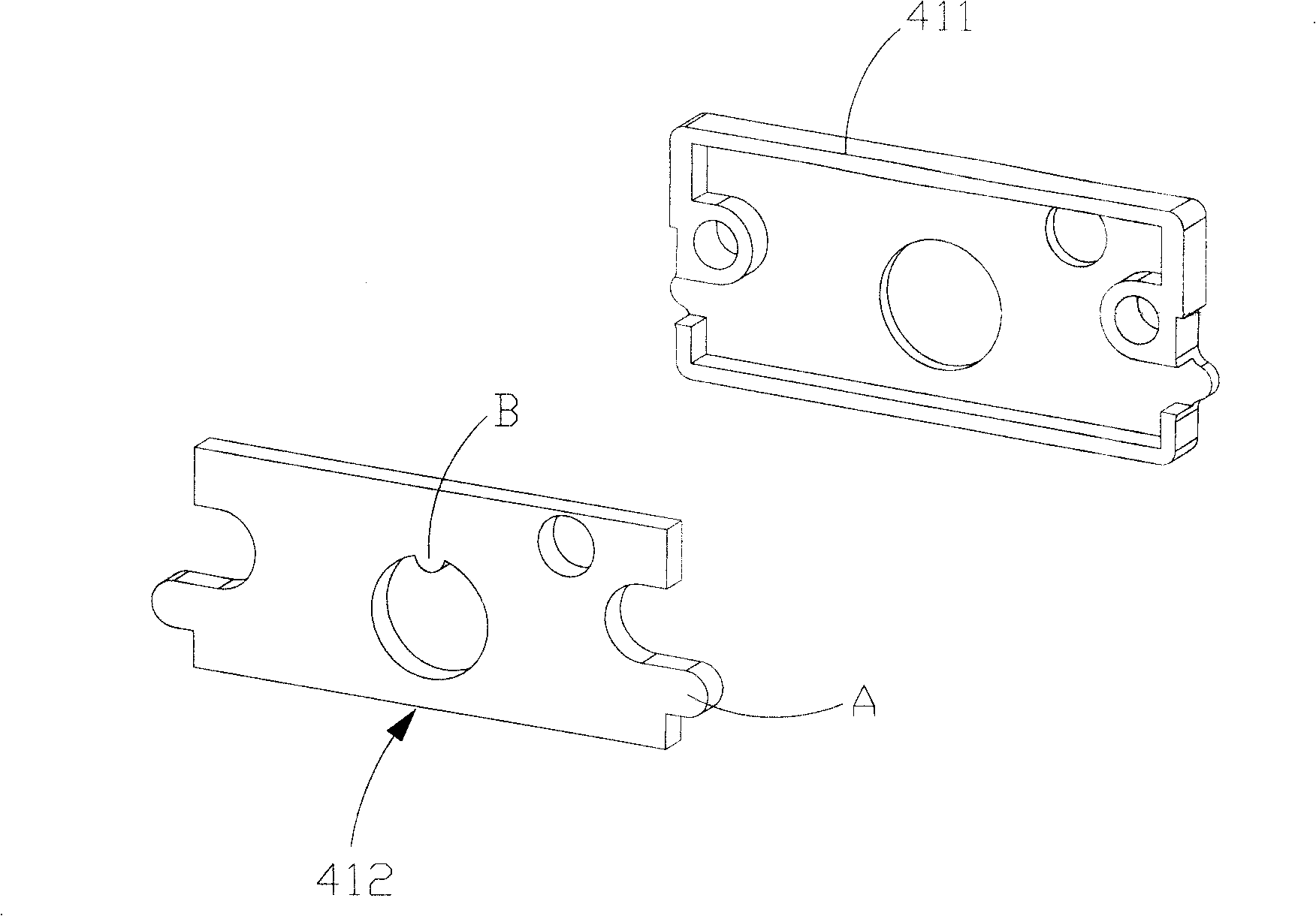

[0021] The embodiment of the linear transmission module with a self-lubricating unit of the present invention is shown in Figure 1 and Figure 2, including:

[0022] A slide rail 10, a strip-shaped groove 11 is respectively formed on the inner walls of both sides;

[0023] A slider 20, two grooves 21 are formed corresponding to the two grooves 11 of the slide rail 10 on both sides, and the two grooves 11 of the slide rail 10 and the two grooves 21 of the slider 20 are arranged side by side A plurality of rolling assemblies 23, the slider 20 is slidably installed on the slide rail 10 with these rolling assemblies 23, and the sliding block 20 passes through a screw hole corresponding to its sliding direction, which is not shown in the figure and has two ends Each group is provided with an end cover 22 with a through hole 221, and the two end covers 22 are used to restrict the rolling components 23 to be located in the slider 20;

[0024] A screw 30 is screwed in the screw hole o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com