Vacuum insulated glass building component and method and apparatus for its manufacture

A technology of vacuum insulating glass and components, which is applied in the direction of building components, building structures, buildings, etc., can solve the problem of unreliable mechanical load of vacuum insulating glass plate for a long time, and achieve the effect of high thermal insulation value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

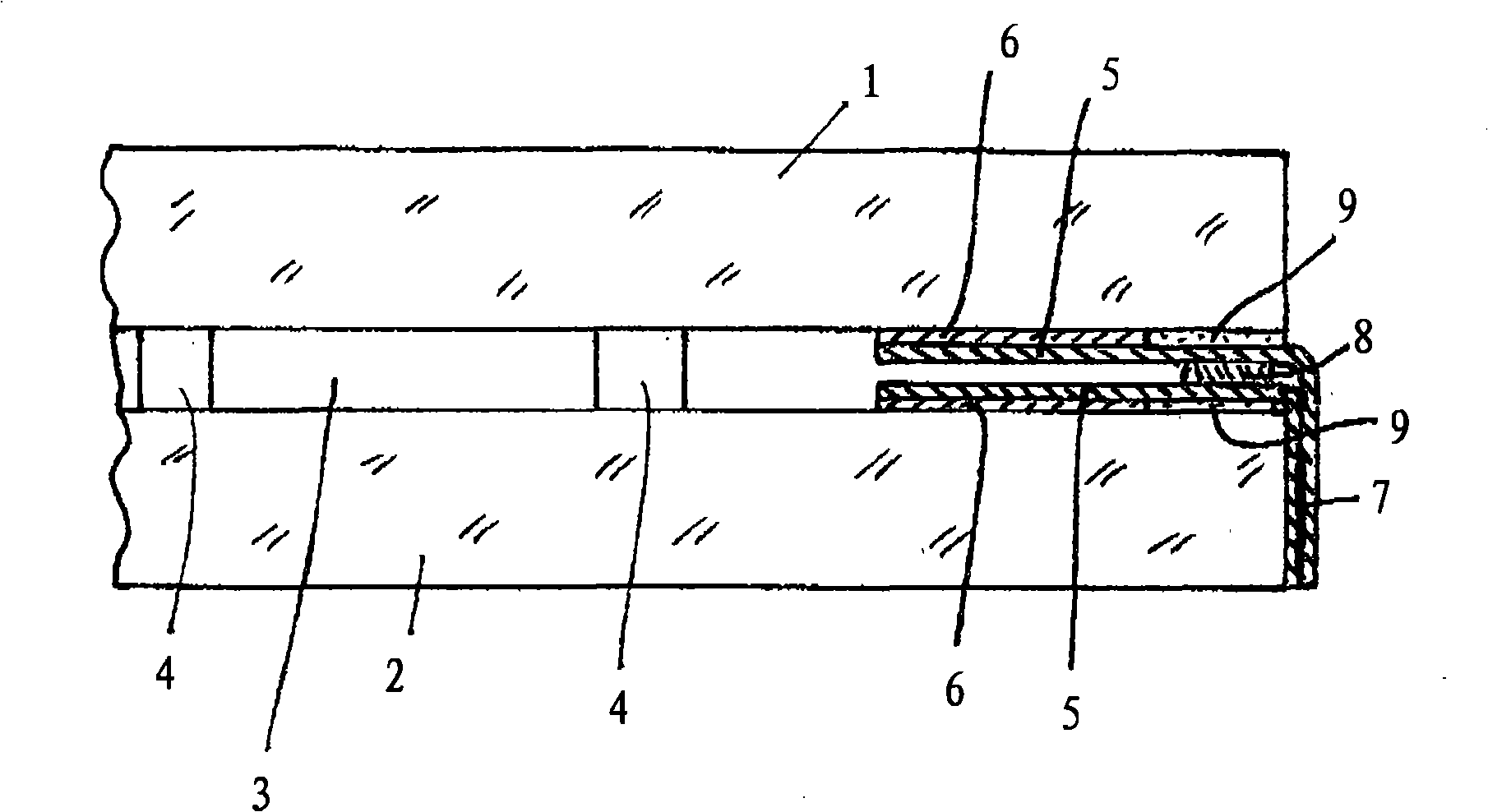

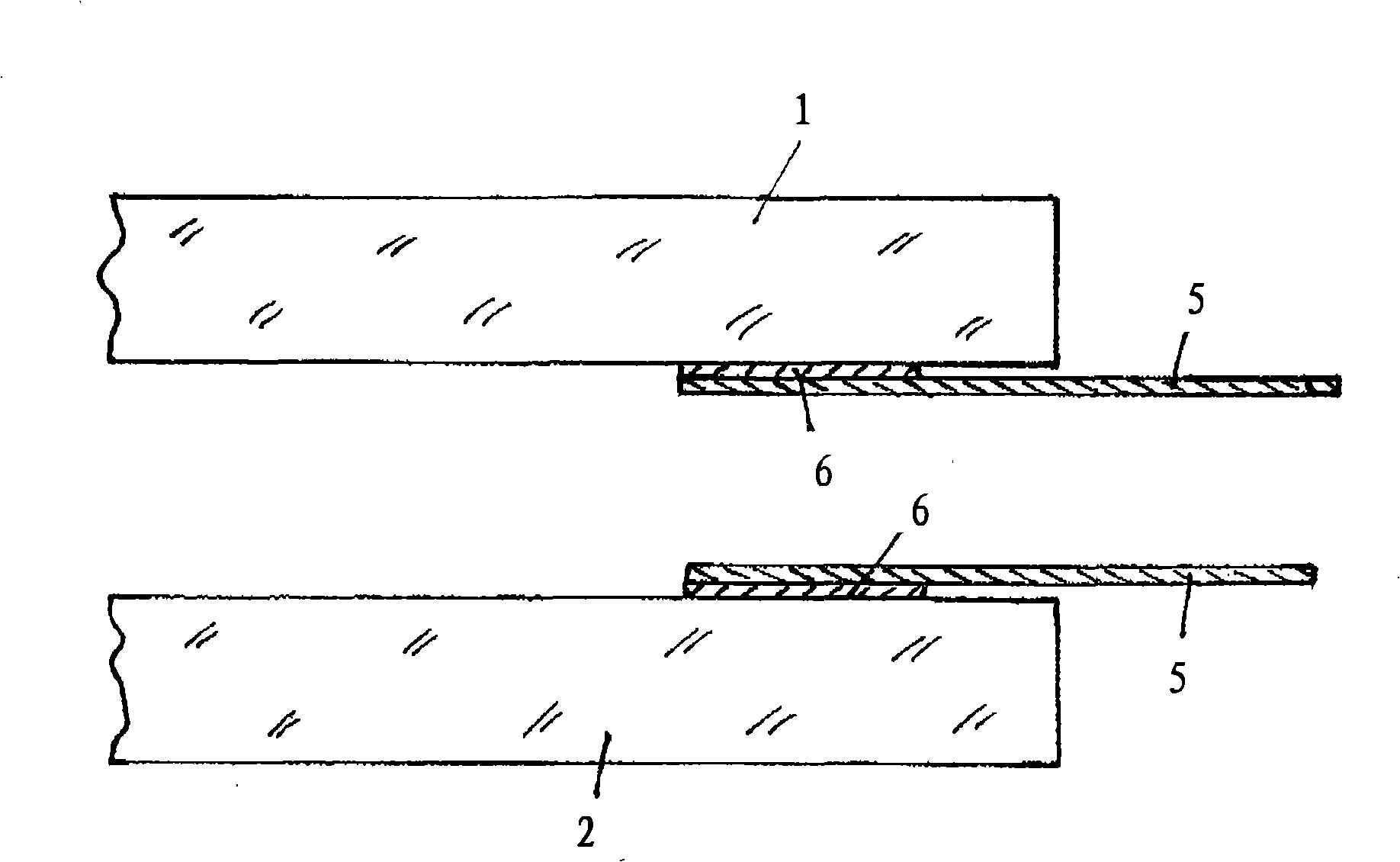

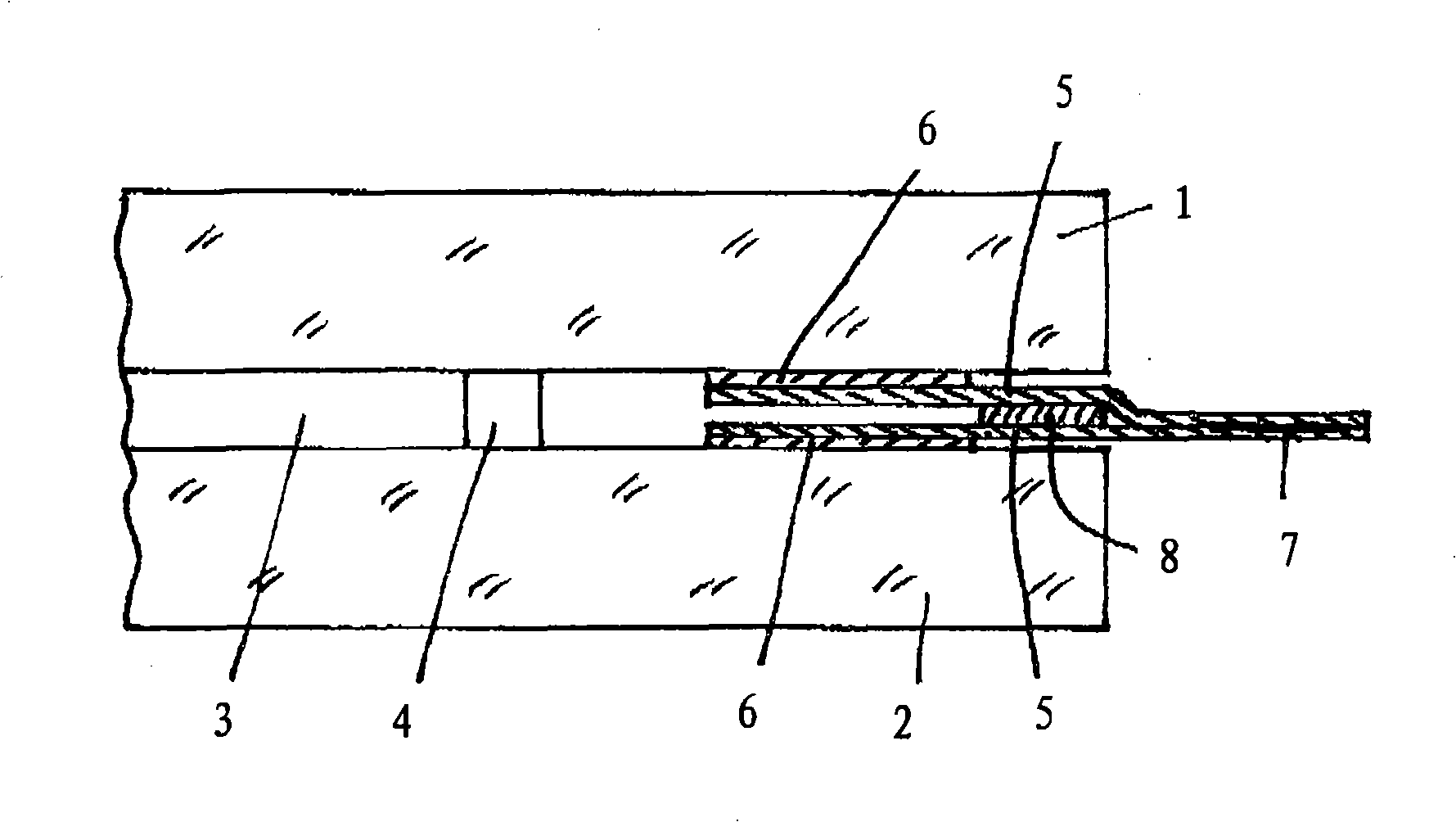

[0029] figure 1 The edge region of a vacuum insulating glass component with a produced edge composite in the form of a vacuum insulating glass disk is shown in a sectional view. This structure consists of a top disc 1 (outer disc) and a lower disc 2 (inner disc), which are separated from each other by a disc gap 3 . There is a vacuum in the disc gap 3 . The two disks 1 and 2 are held at a set relative distance by spacers 4 which are fixed in a mesh arrangement on the lower disk 2 , for example by gluing, and on which the top disk 1 is supported. The spacers are shown as smaller glass cylinders, but they can also be formed as beads and can be made of metal.

[0030] The top disc 1 and the lower disc 2 may each have a thickness of 4 mm and the disc gap may have a thickness preferably in the range of 0.7 mm to 1 mm.

[0031] On the edge of each of the two discs 1 , 2 is vacuum-tightly mounted a metal foil strip 5 . In this case, the metal foil strip 5 is preferably mounted on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com