Method for bonding plastics and method for releasing bond in the plastic composite and plastic composite

A technology of composites, plastics, applied in the field of chemistry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

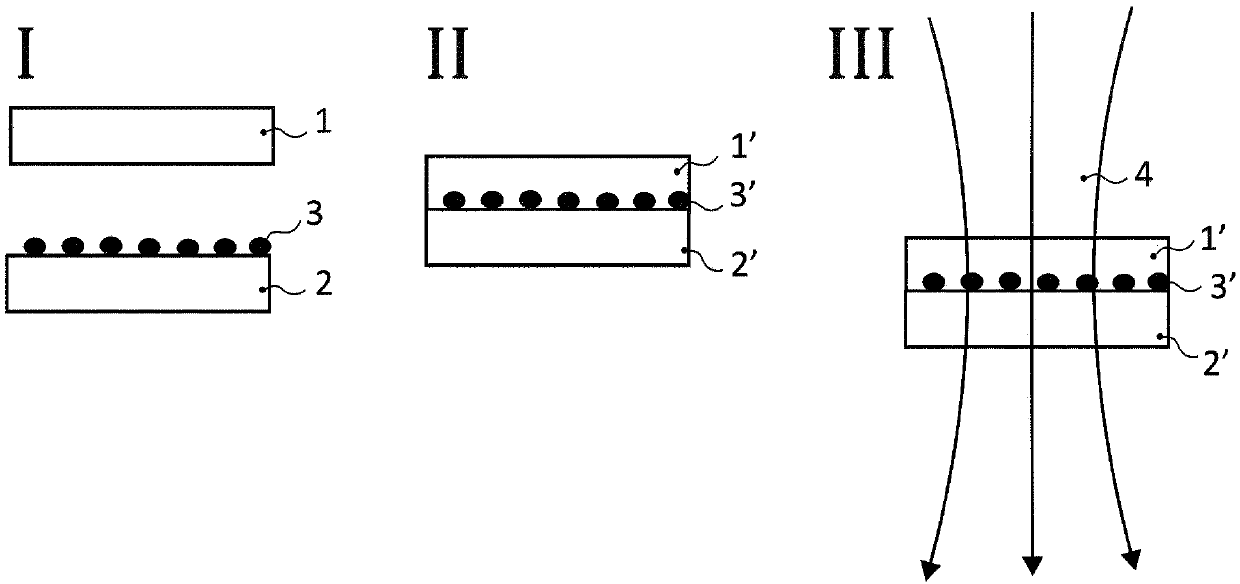

[0079] Samples of plastic moldings with a size of 1 cm x 1 cm made of bisphenol A-based polycarbonate (PC) should be compared with 1 cm x 1 cm samples of plastic moldings made of polyvinylamine (PVAm) functionalized with amino groups. Plastic molded body connection. The glass transition temperature of polycarbonate (PC) is about 145°C, while that of polyvinylamine (PVAm) is about 130°C.

[0080] A ring made of gold is applied on a plastic body made of PC, the dimensions are: outer diameter 5 mm, ring thickness (Ringdicke) 1 mm, ring height 150nm. A plastic coverage of 10% is thereby achieved.

[0081] The plastic bodies to be joined made of PC and PVAm were then brought into contact with each other in the area where the rings were located, and the two bodies were exposed to an electromagnetic pulse of 60 T for 7 ms.

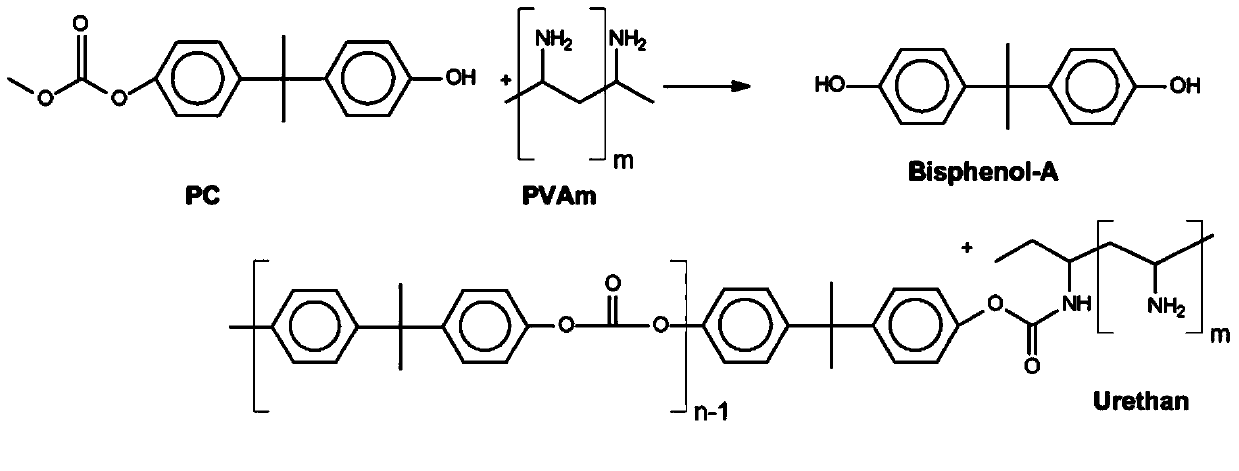

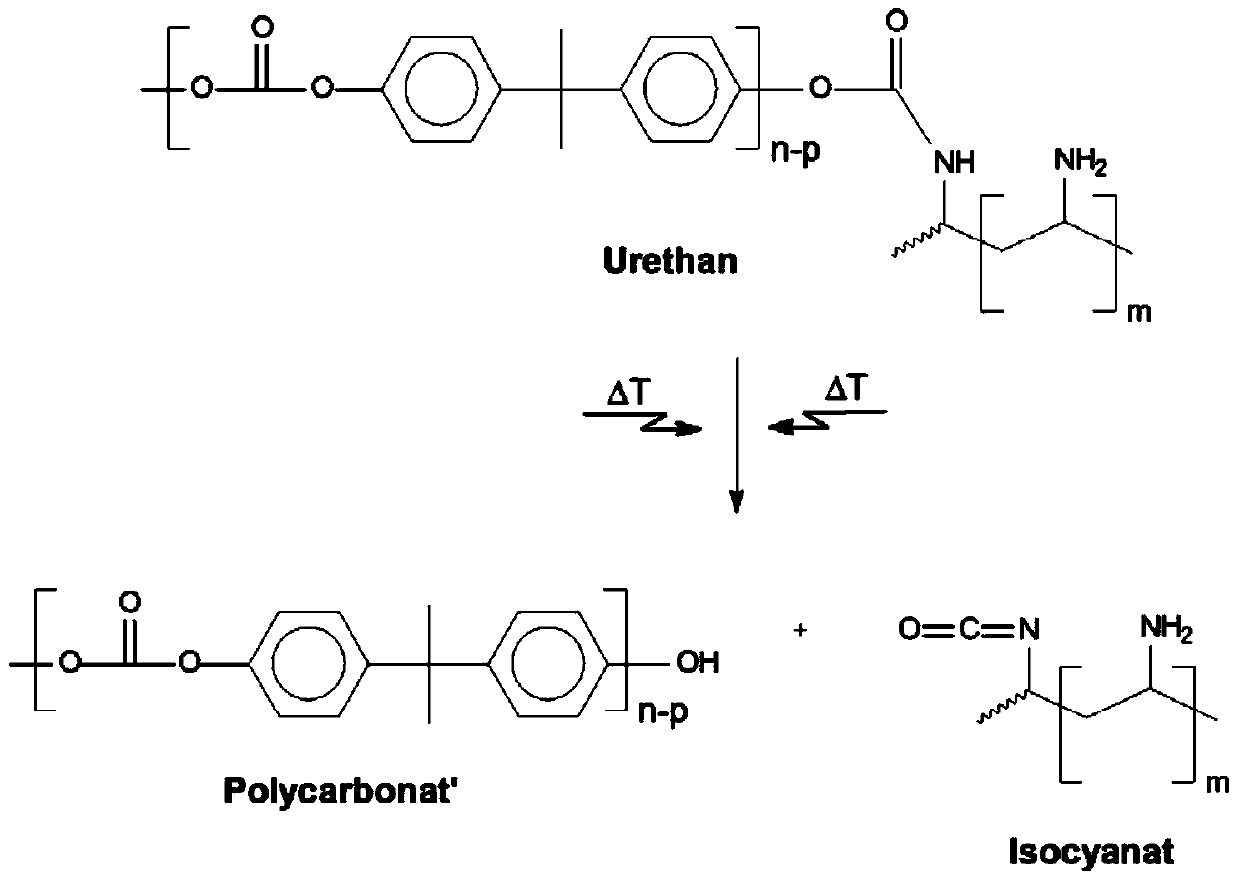

[0082] The coupling reaction triggered after reaching the activation energy proceeds as follows:

[0083]

[0084] Diagram 1

[0085] Bisphenol-A = Bisp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com