Drying system for a hair removing device

一种烘干系统、毛发去除的技术,应用在烘干系统领域,能够解决很差烘干效率、多烘干时间等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

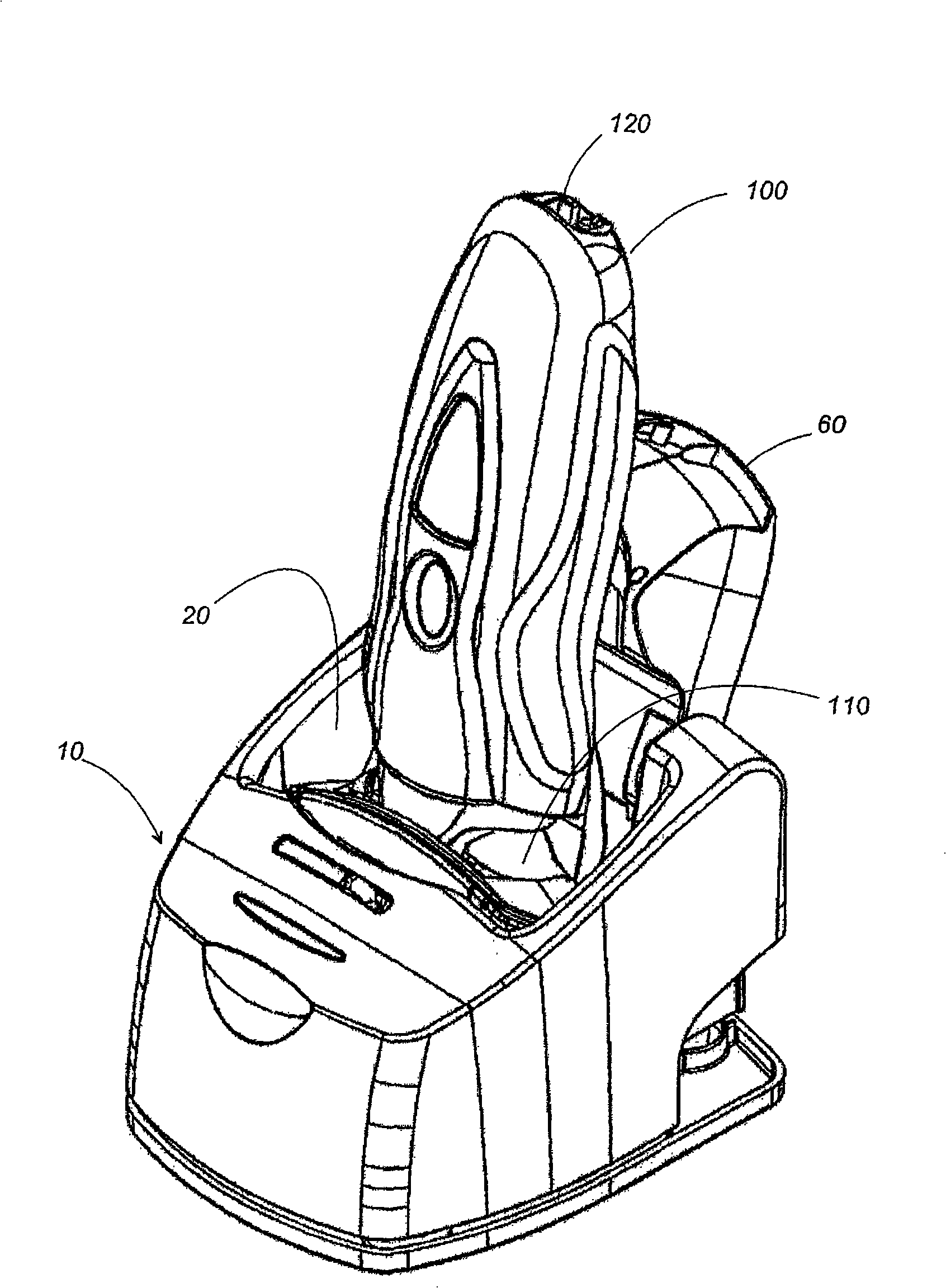

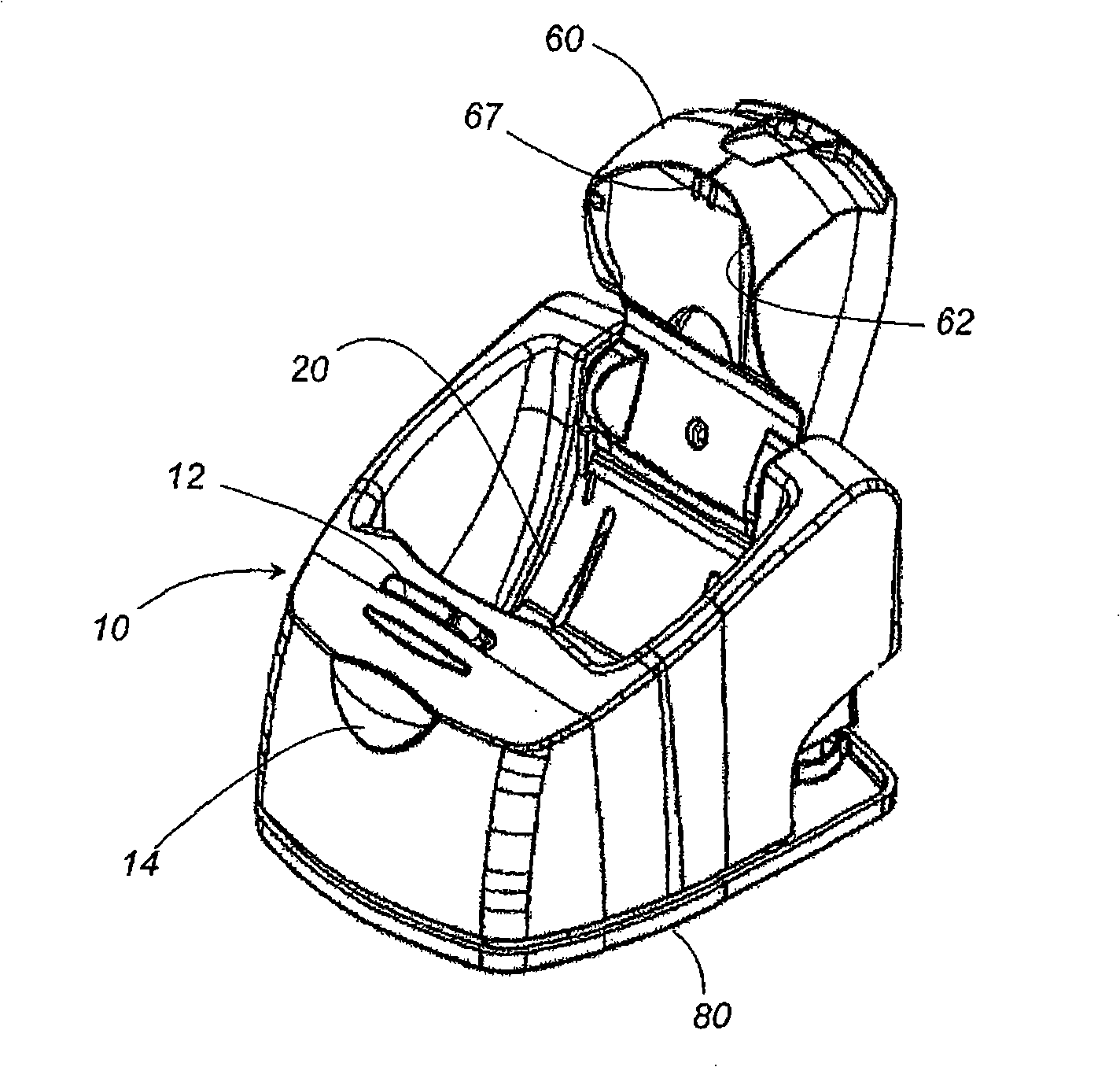

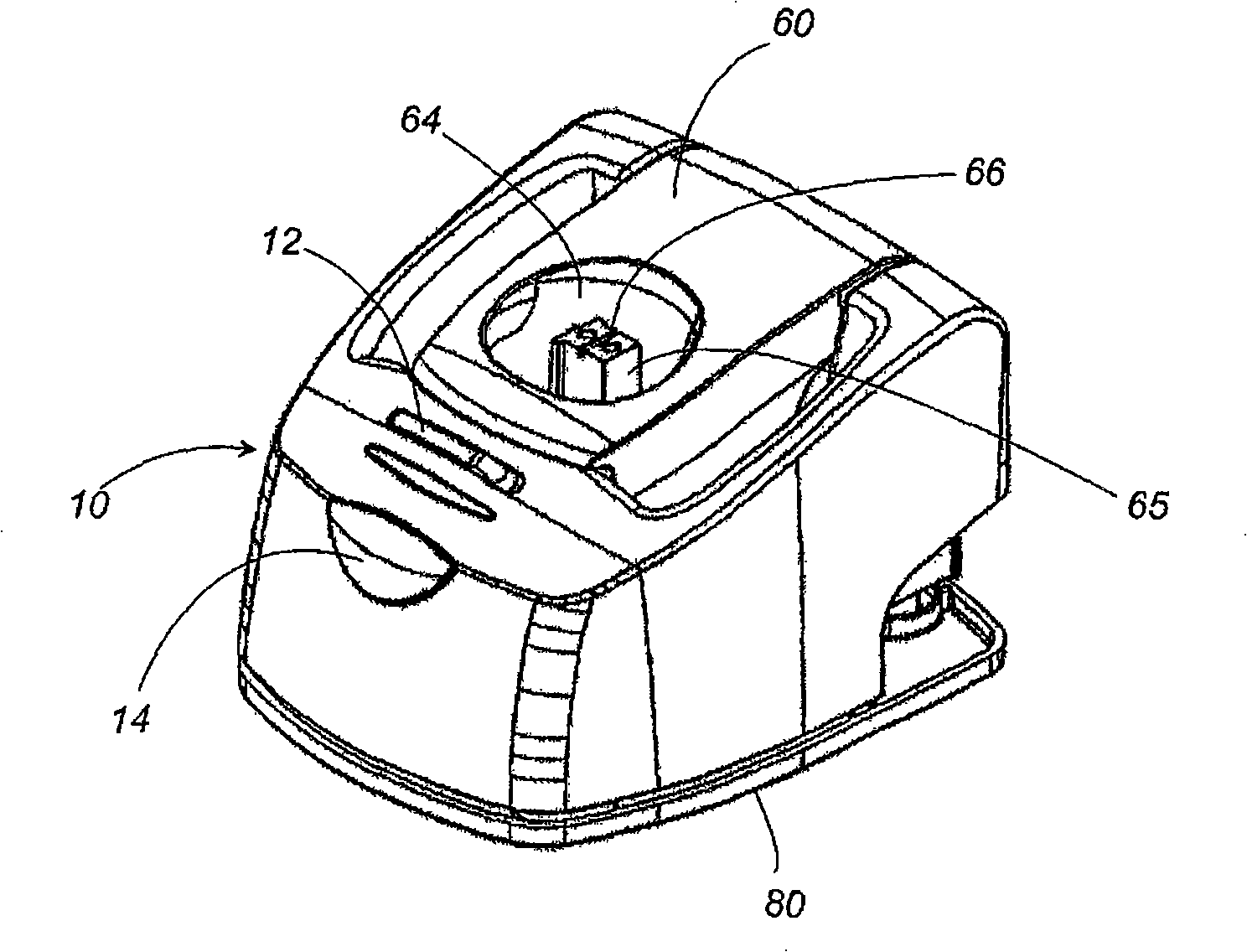

[0025] now refer to Figure 1 to Figure 5 , which shows a drying system for a hair removal device according to a preferred embodiment of the present invention. In this embodiment, a dry shaver 100 is shown as a typical example of a hair removal device having a washable head 110 and a rechargeable battery 130 for driving the inner blades. However, the drying system is equally applicable to other types of hair removal devices, including epilators with perforated heads and the like.

[0026] The drying system has a housing 10 configured with a drying chamber 20 for detachably receiving a head 110 of a shaver. The shell 10 is provided with a heater 30 and a blower 40 , the heater 30 is used to heat the cutter head, and the blower 40 is used to generate a forced air flow for drying or cooling the cutter head 110 . like Figure 2A and 2B As shown, the lid 60 is pivotally connected to the upper end of the housing 10 so as to be movable between an open position which opens the dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com