Can end for a can and such can

A can end, can lid technology, used in rigid containers, containers, packaging, etc., to solve the problems of continuous or temporary pressure increase, unsatisfactory cooling operation, high process temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

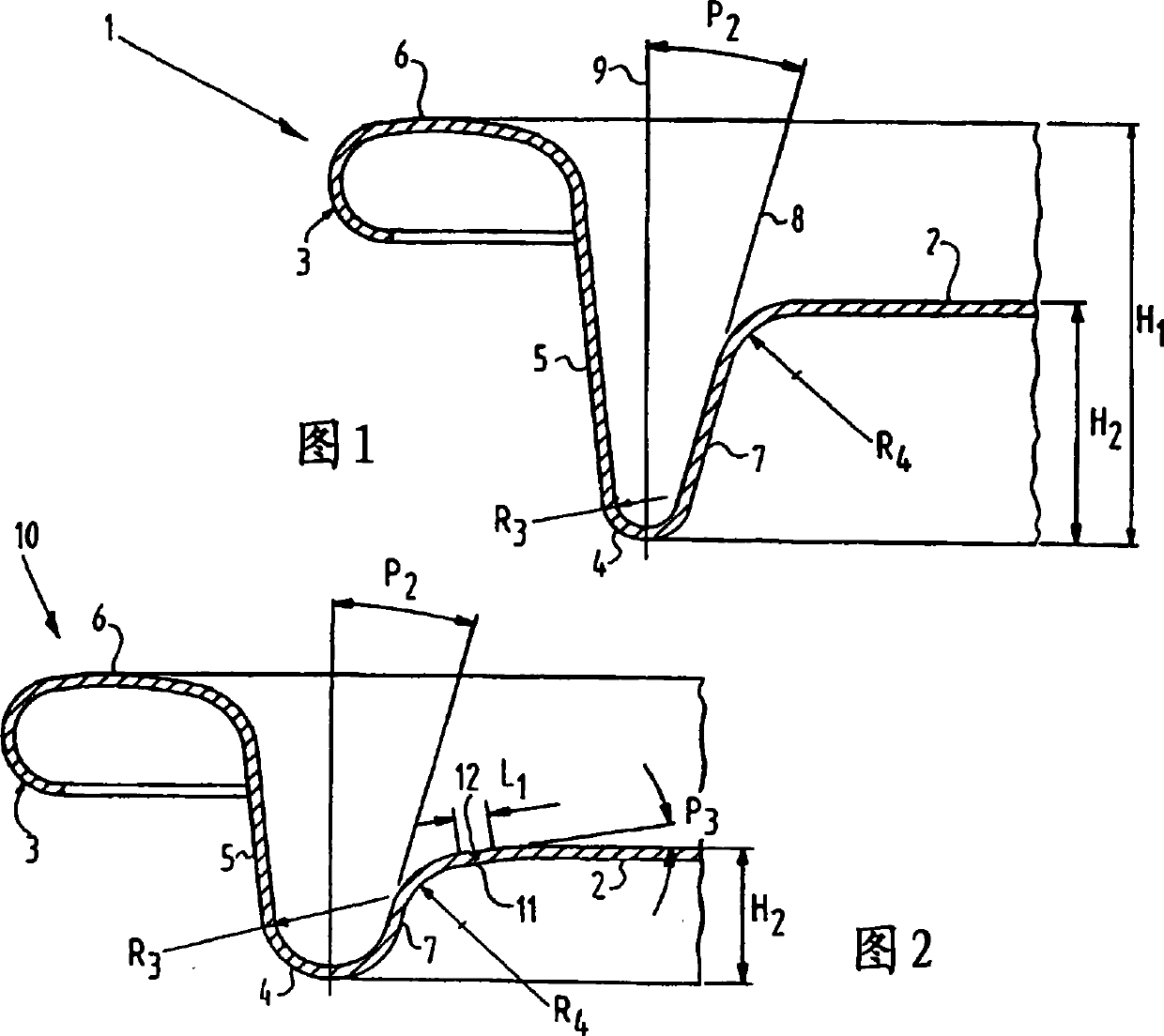

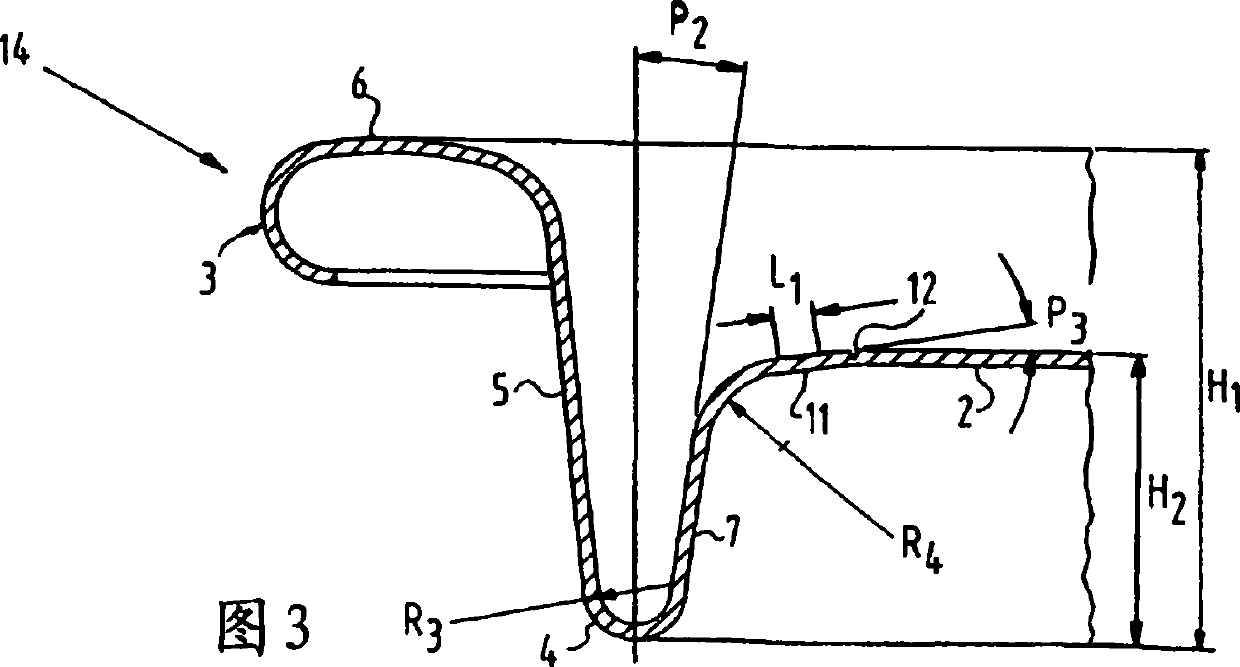

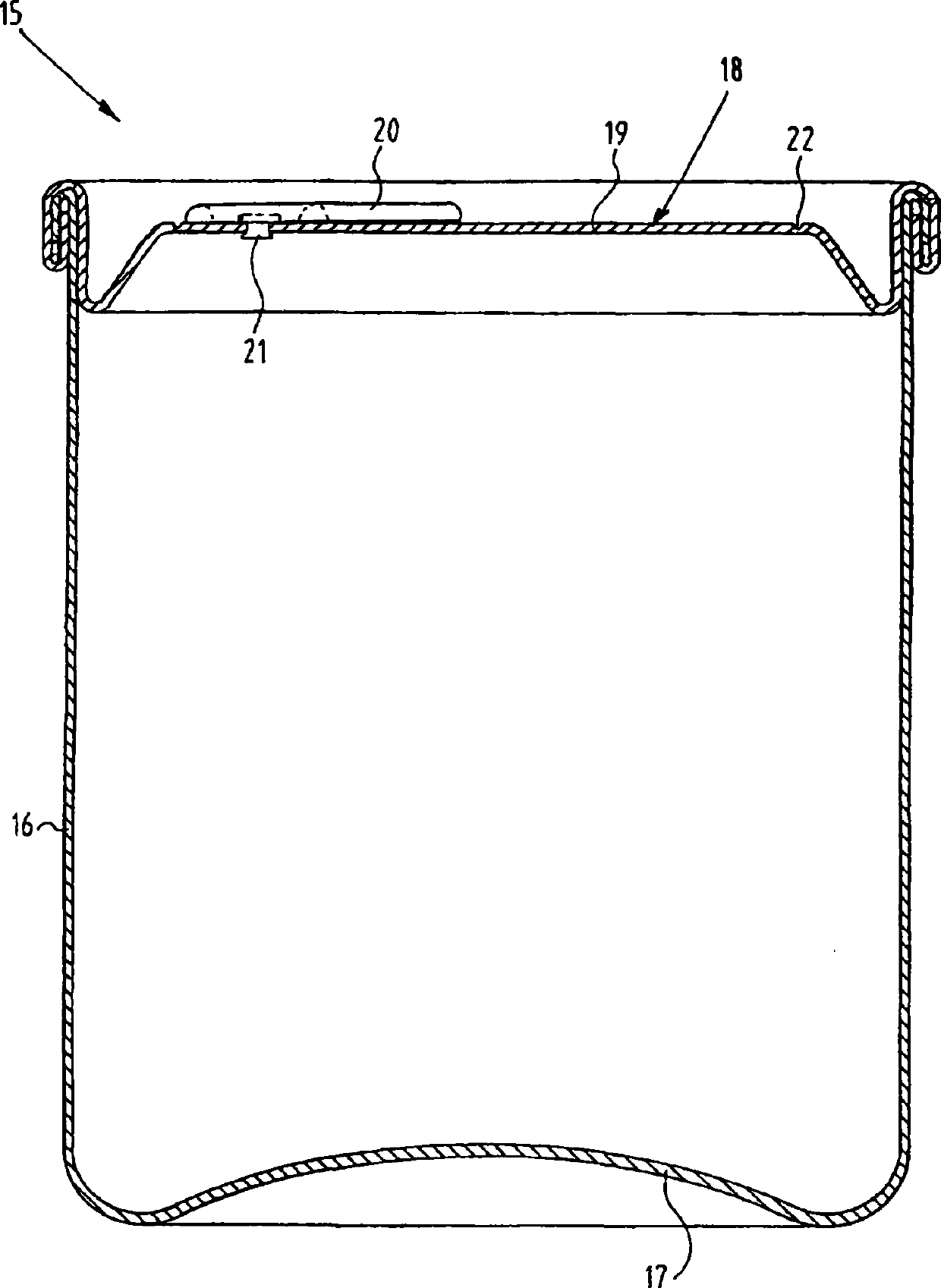

[0058] Figure 1 shows a can end or bottom 1 according to the invention. The can end has a central panel 2 and a can end fillet or bead 3 for attachment to the main body of the can, eg by sewing. The can end 1 also includes a reverse groove 4 connected to the seam panel 6 of the bead 3 by a transition wall 5 . The counter slot 4 is also connected to the panel 2 by the panel wall 7 .

[0059] Panel corner P 2 Determined by the slope 8 of the panel wall 7 relative to the vertical 9 . Panel radius R 4 Determines the curvature of the connection between panel wall 7 and panel 2 . Radius R of reverse groove 3 The inner curvature of the area between the panel wall 7 and the chuck wall 5 is determined. Finally, the depth H of the panel 2 is the distance between the underside of the reverse groove and panel 2, the cell depth H 1 is the distance between the stitched panel 6 and the underside of the reverse groove.

[0060] Panel corner P in tank end 1 2 is 15°, the panel radius...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com