Method for producing a handle

A handle and outer layer technology, applied in the field of manufacturing screwdriver handles, can solve the problem of lack of torsional rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

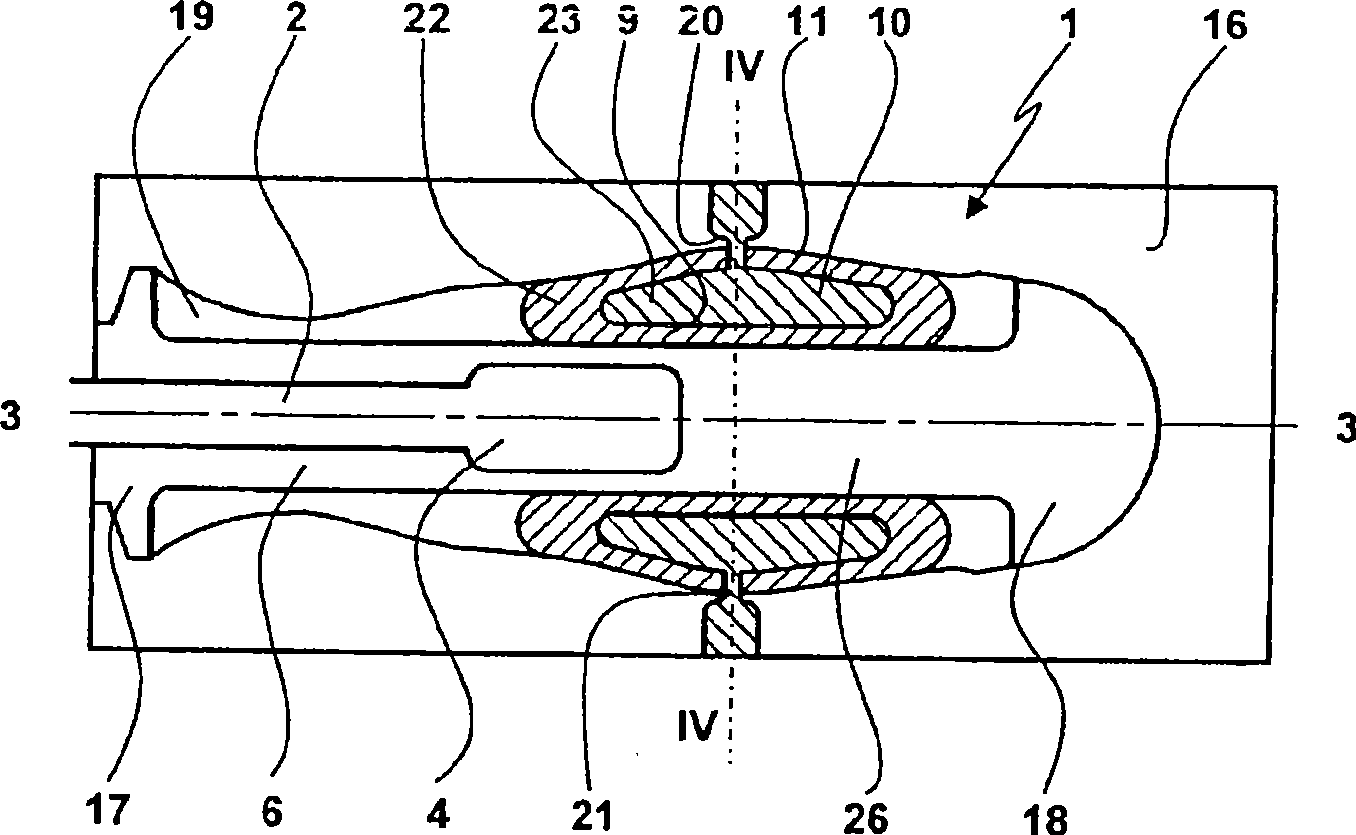

[0120] I. Universal application

[0121] In the following, for example, an outer layer is referred to as a handle layer, the outer outer surface of which forms the handle outer surface which is acted upon by the user's hand, while an inner layer adjoins the outer layer radially inwards and encloses a handle core. , the handle core is made of hard plastic and encases a handle rod. However, as a departure from this, for example, the outer layer can be located inside the handle and / or at least one inner layer, handle core jacket or the like can be arranged intermediately between the inner layer and the handle core.

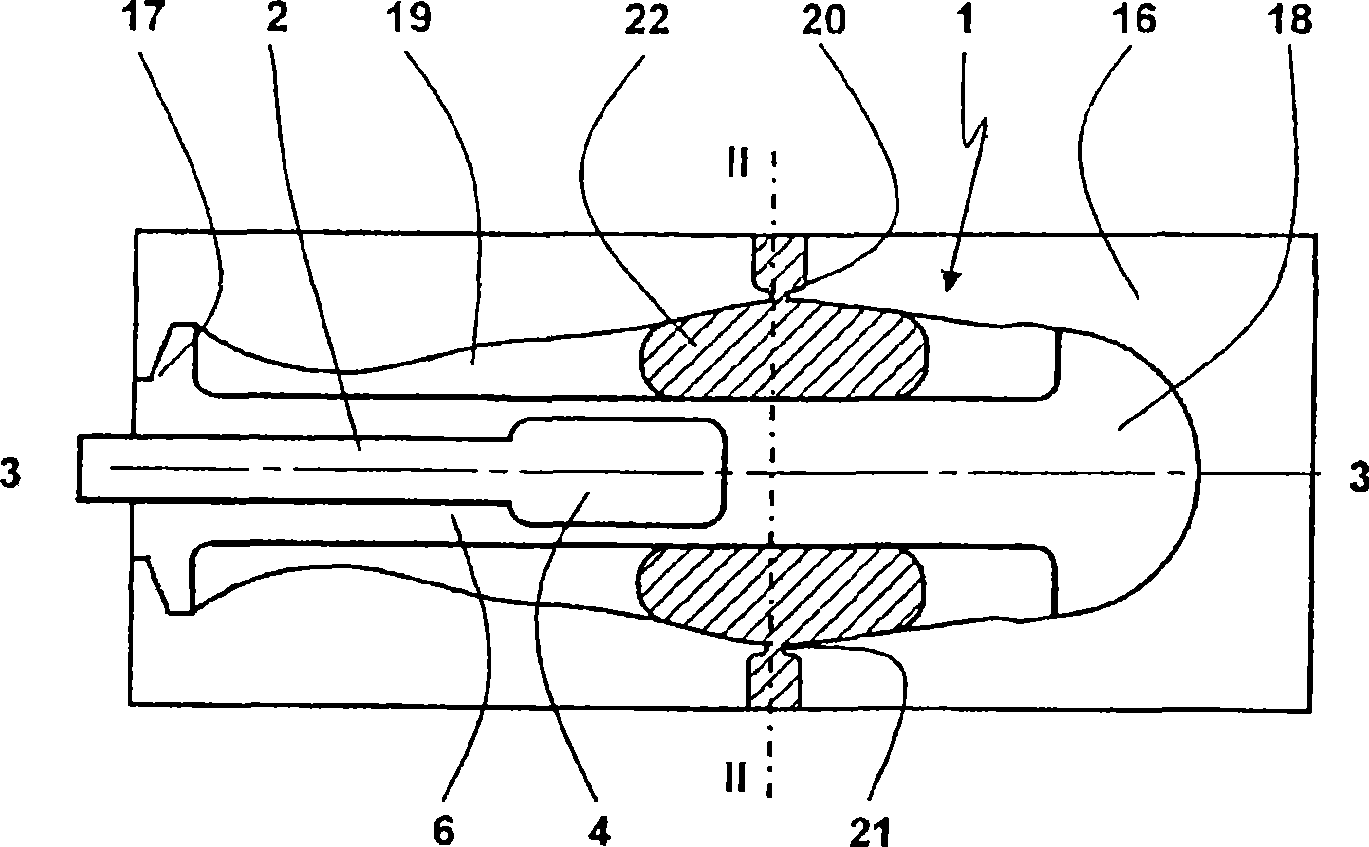

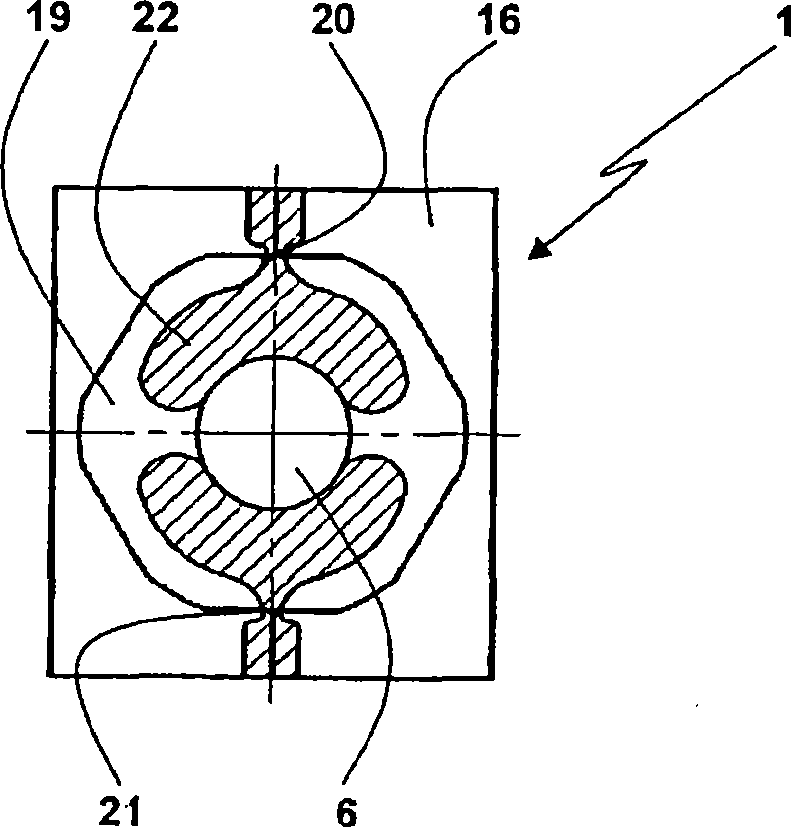

[0122] The invention relates to a handle 1 for a tool, in which a shank 2 of a functional part of the tool is accommodated radially inside and a force of the tool user can be exerted on its radially outside outer surface area, wherein the force can be

[0123] In the direction of the longitudinal axis 3-3

[0124] perpendicular to the longitudinal axis

[0125] To...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com