Device for testing resistance across steel plate surface for appliances

A surface resistance and testing device technology, applied in the direction of measuring devices, measuring resistance/reactance/impedance, measuring electrical variables, etc., can solve problems such as difficulty in quantification and uniformity, uneven downforce, and low work efficiency, and meet the requirements of Requirements, stable and uniform down pressure, shortening the effect of human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Describe in detail below in conjunction with accompanying drawing:

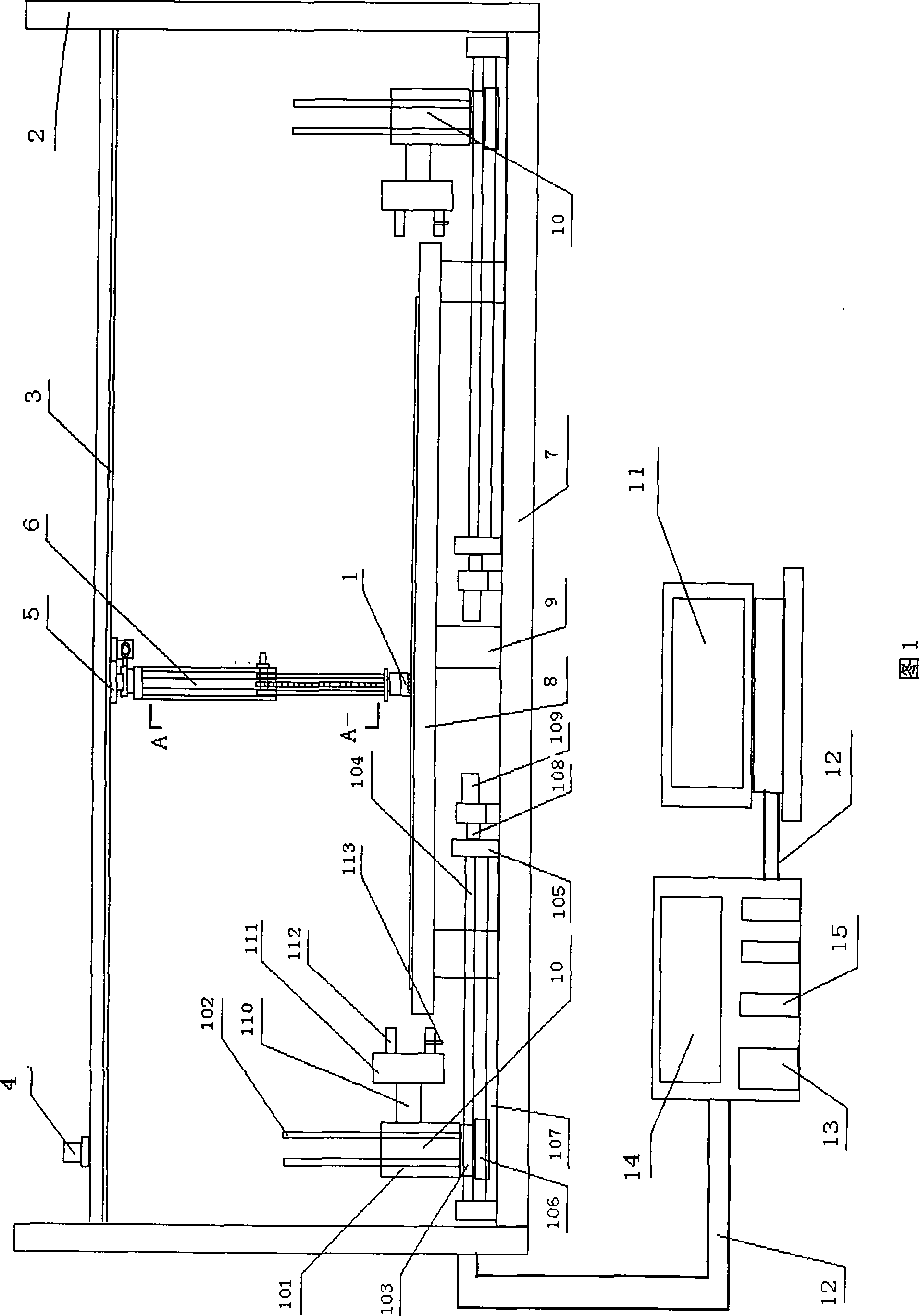

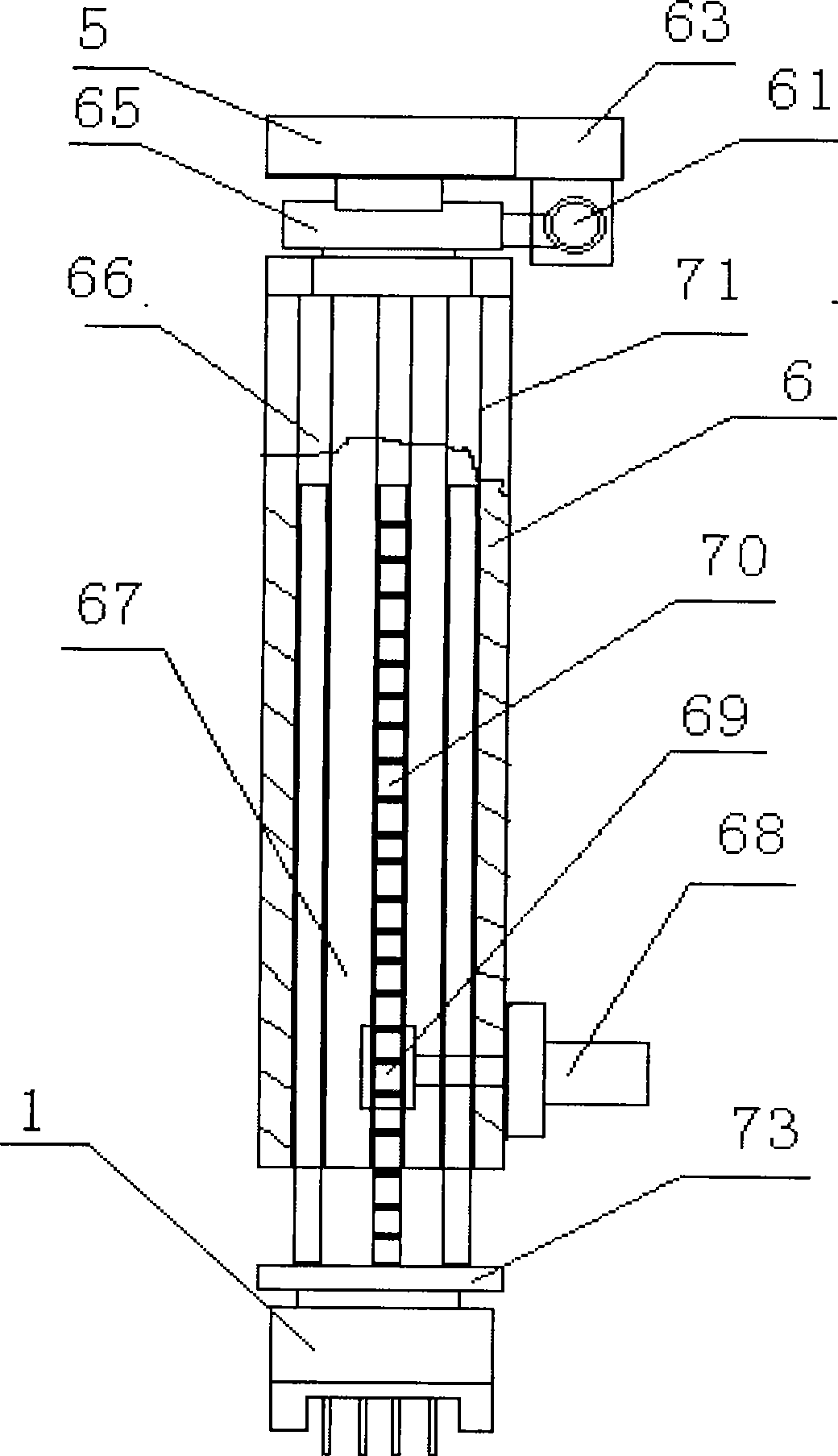

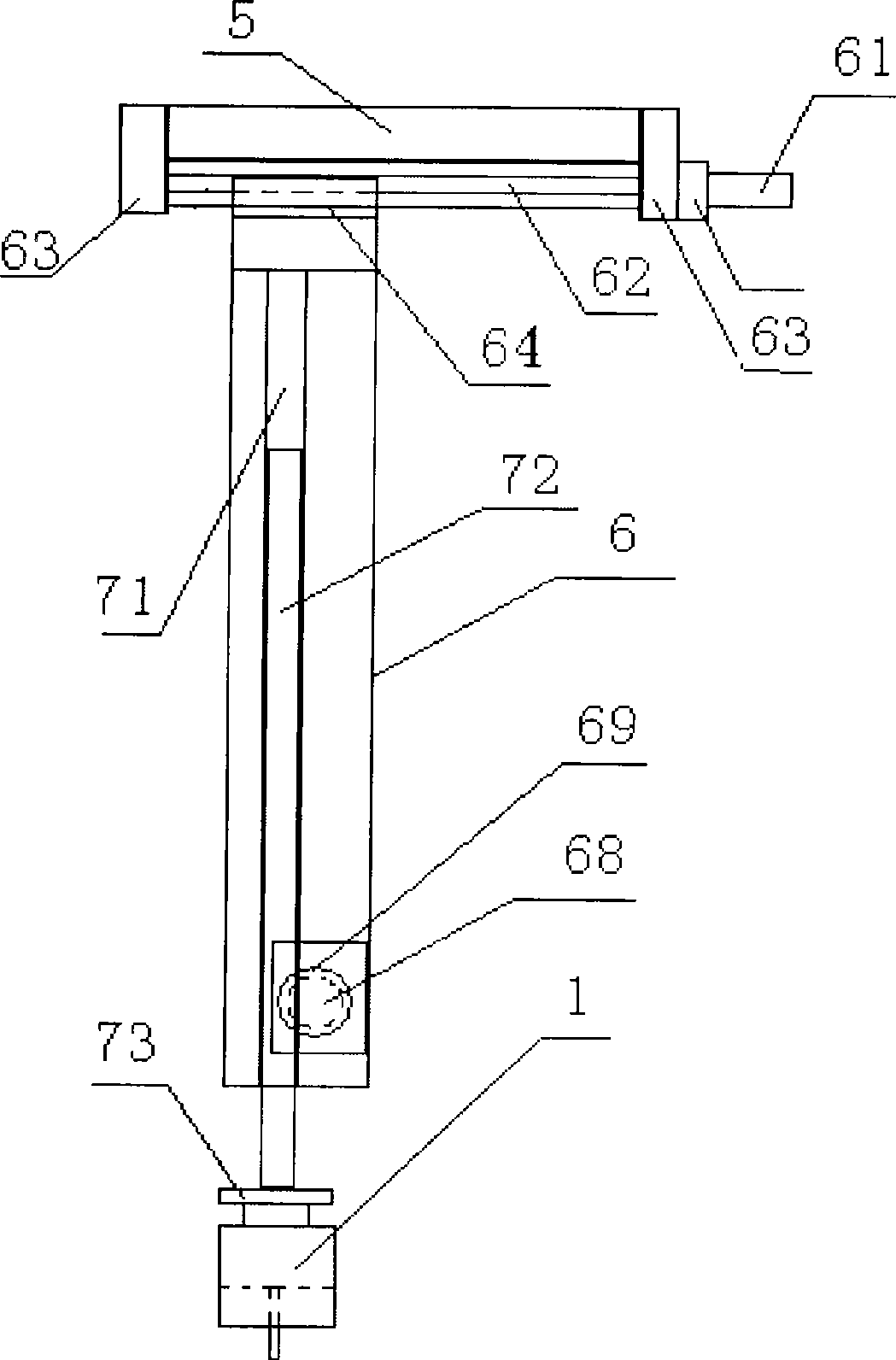

[0018] Steel plate surface resistance test device for household appliances: the horizontal slideway 3 is connected with threads or bolts on the bracket 2; the power device 4 and the slider 5 are connected with threads or bolts on the horizontal slideway 3; Connect the lifting mechanism 6, two or four probes 1 are connected in parallel at the lower end of the moving mechanism 6 by threads or bolts, the bracket 2 and the bottom plate 7 are connected by threads or bolts, and the lower end surface of the sample table 8 is connected by threads or bolts to the bracket 9. The sample flipping device 10 is connected to the bottom plate 7 by threads or bolts, the computer 11 is connected to the PLC controller 13 through the wire 12, and the PLC controller 13 is connected to the servo motor controller 15, the power device 4 and the surface resistance through the wire 12 respectively. The data processor 14 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com