Chip stacker having outer support for truss and method for turning truss with the support

A truss, material accumulation technology, applied in the field of truss support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

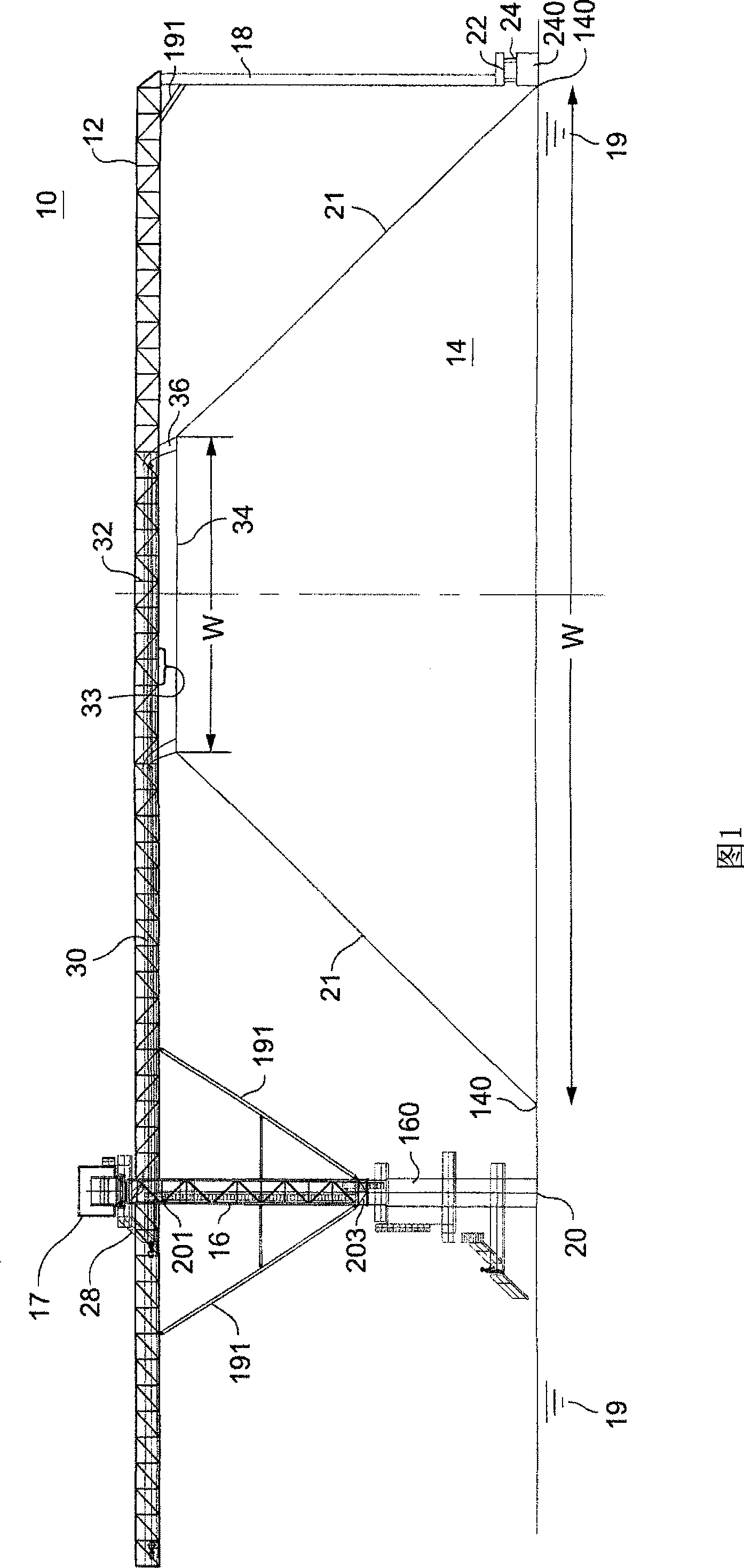

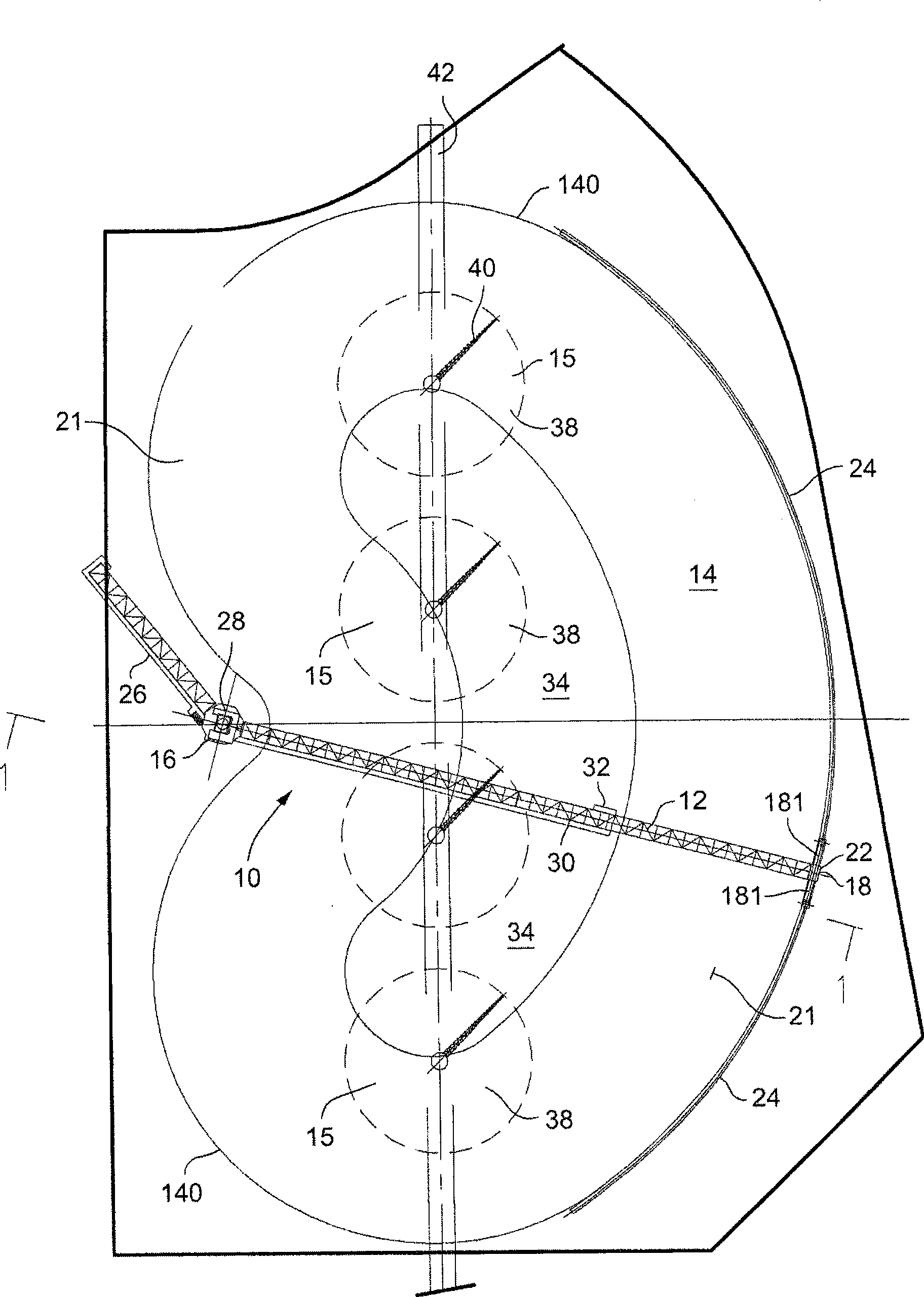

[0016] FIG. 1 is a side view of a chip stacker 10 having an upper horizontal truss 12 extending above a chip pile 14 . figure 2 It is a top view of the sawdust stacker, the sawdust pile and the piled up sawdust recovery system 15.

[0017] The truss 12 is supported by a central strut 16 and outer struts 18 . The struts 16 , 18 are located at opposite ends of the truss 12 . The center post 16 is the pivot of the truss. The truss moves in an arc around the central strut. The arc may be a complete circle or an arc forming a part of a circle. As the truss pivots about the central strut, the outer struts 18 move with the truss in an arc.

[0018] The truss 12 may be a lattice structure, such as a lattice truss or other weight-reducing, high-strength support structures. Similarly, struts 16, 18 may be formed from a lattice structure or a reduced weight, high strength support structure. The central pillar can also be a full or partial concrete column 160 . The center pillar 16...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap