Shift control device for automatic transmission

A technology of automatic transmission and control device, which is applied in the direction of transmission control, components with teeth, climate sustainability, etc., can solve problems such as speed limit on the upshift side, and achieve the effect of preventing deterioration of operating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Embodiments of the present invention will be described in detail below with reference to the drawings and the like.

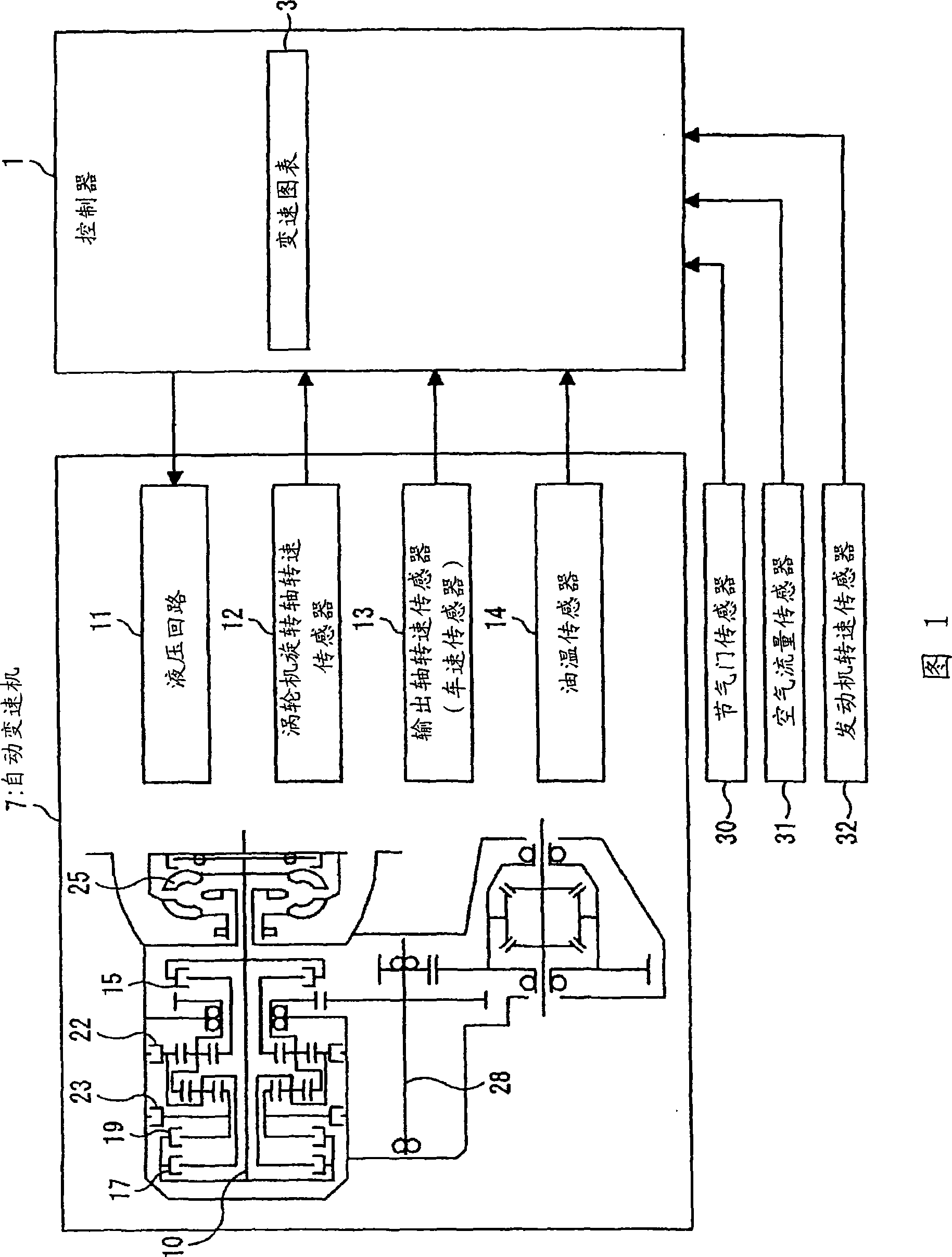

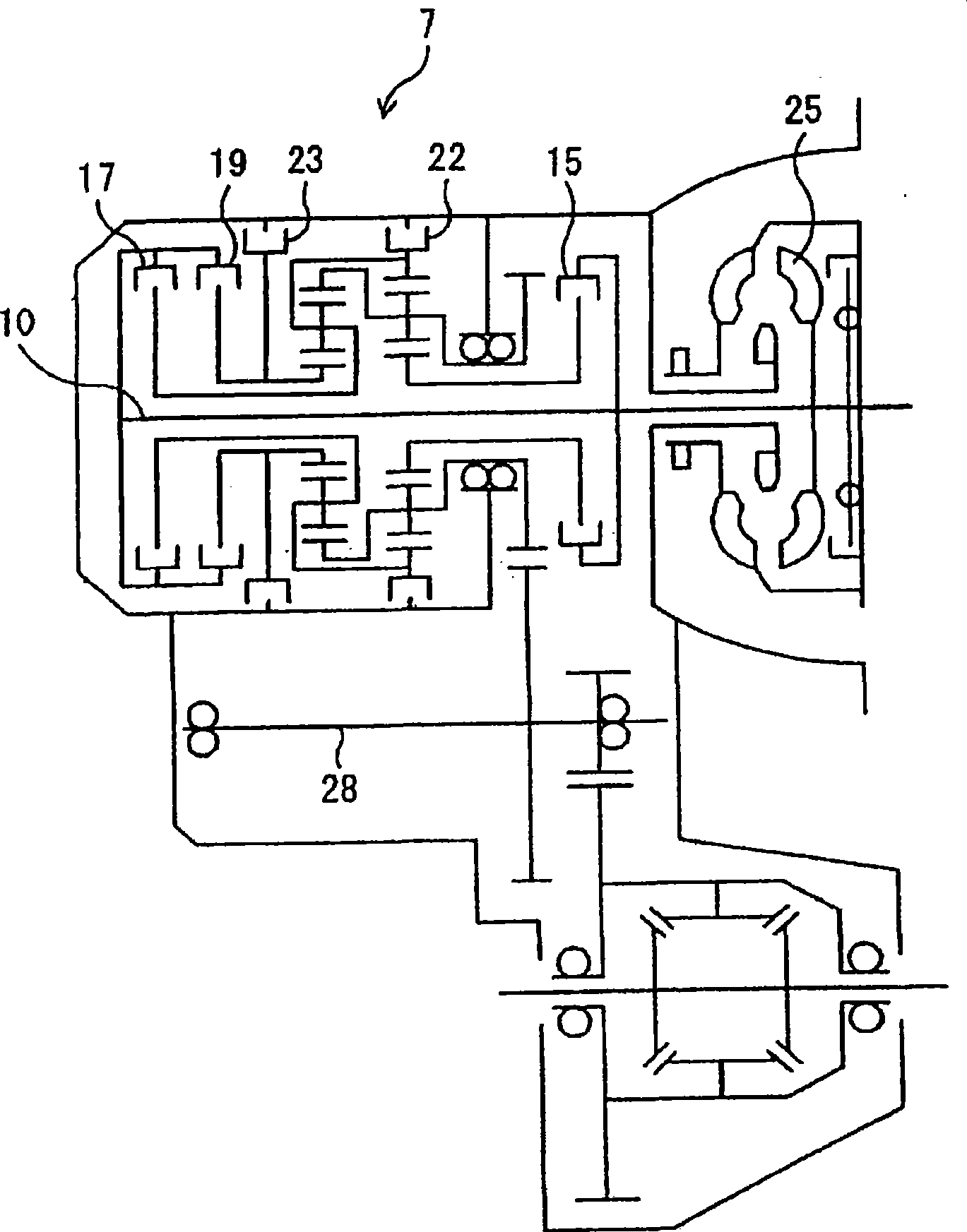

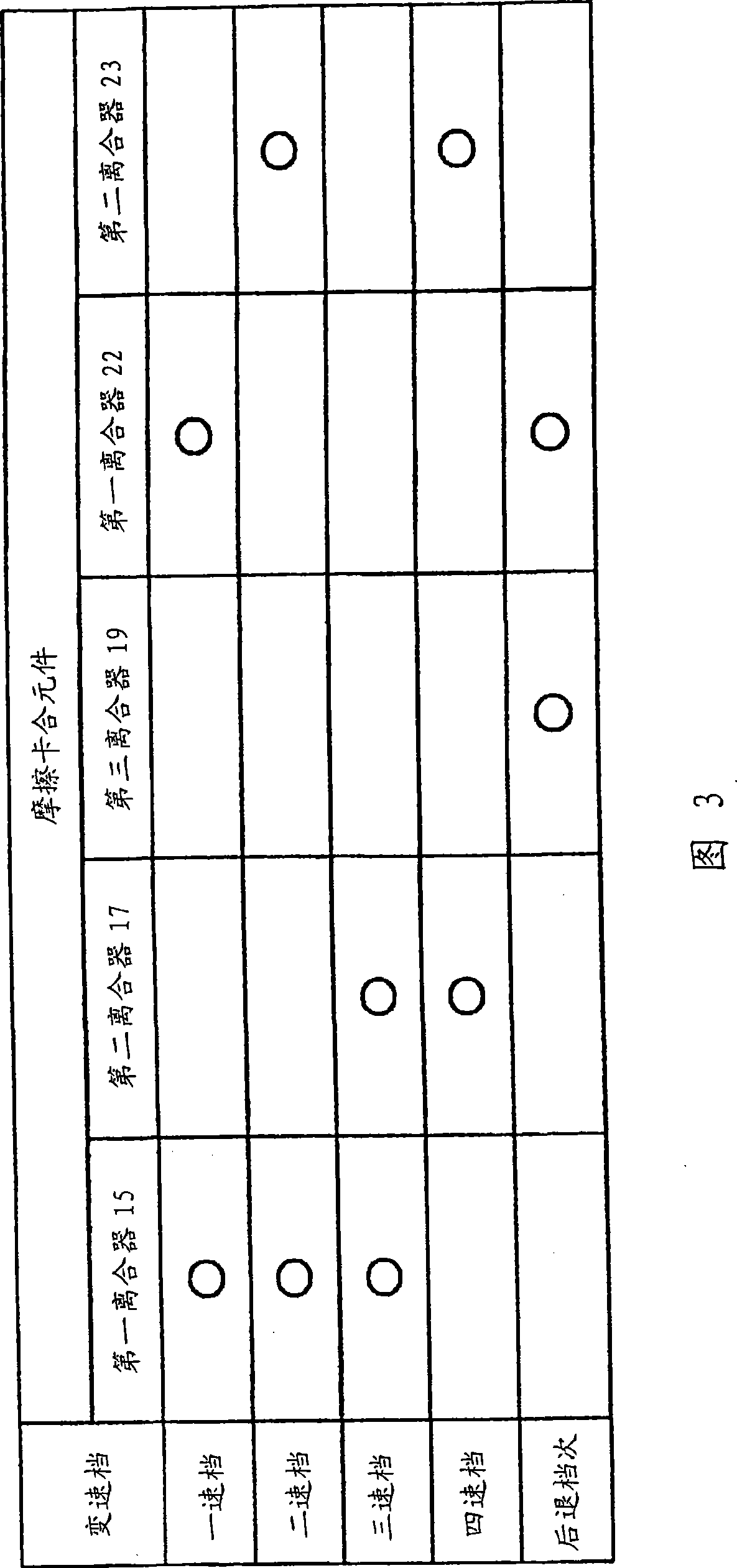

[0055] FIG. 1 is a functional block diagram showing the configuration of a shift control device of an automatic transmission according to this embodiment. figure 2It is a block diagram showing the structure of the automatic transmission. As shown in FIG. 1 , this variable speed control device is configured to include: a controller 1, an input shaft rotational speed sensor (turbine shaft rotational speed sensor) 12 for detecting the rotational speed NT of the turbine 25 and the turbine shaft 10, and an output for detecting the rotational speed No of the output shaft 28. Shaft rotational speed sensor (vehicle speed sensor) 13, oil temperature sensor 14 for detecting the temperature of ATF (automatic transmission fluid), throttle sensor 30 for detecting the throttle opening degree of the engine not shown in the figure, and air flow sensor for detecting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com