Print head and printer equipped with such print head

A printing head and printing head technology, applied in the field of printers and printing heads, can solve the problems of printing whiteness reducing the printing performance of printing paper, no specified adjustment amount, and the printing striker cannot reach the printing paper, etc., so as to prevent the reduction of printing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

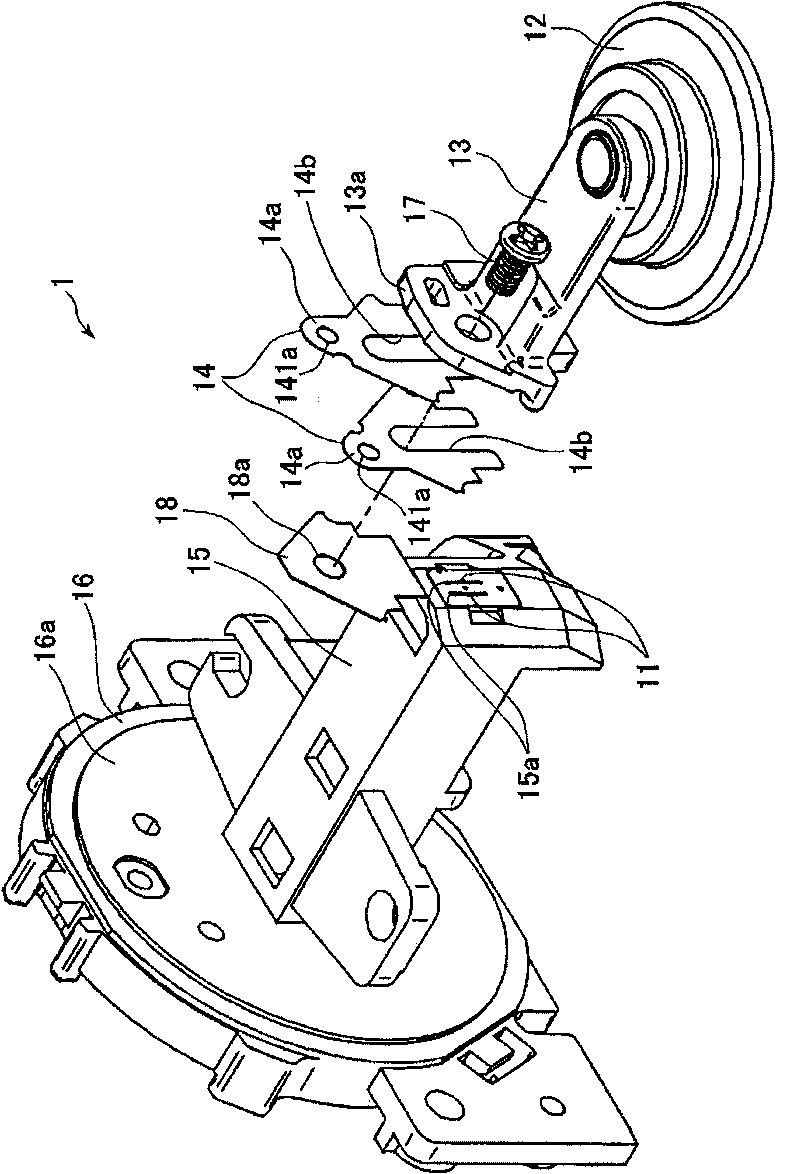

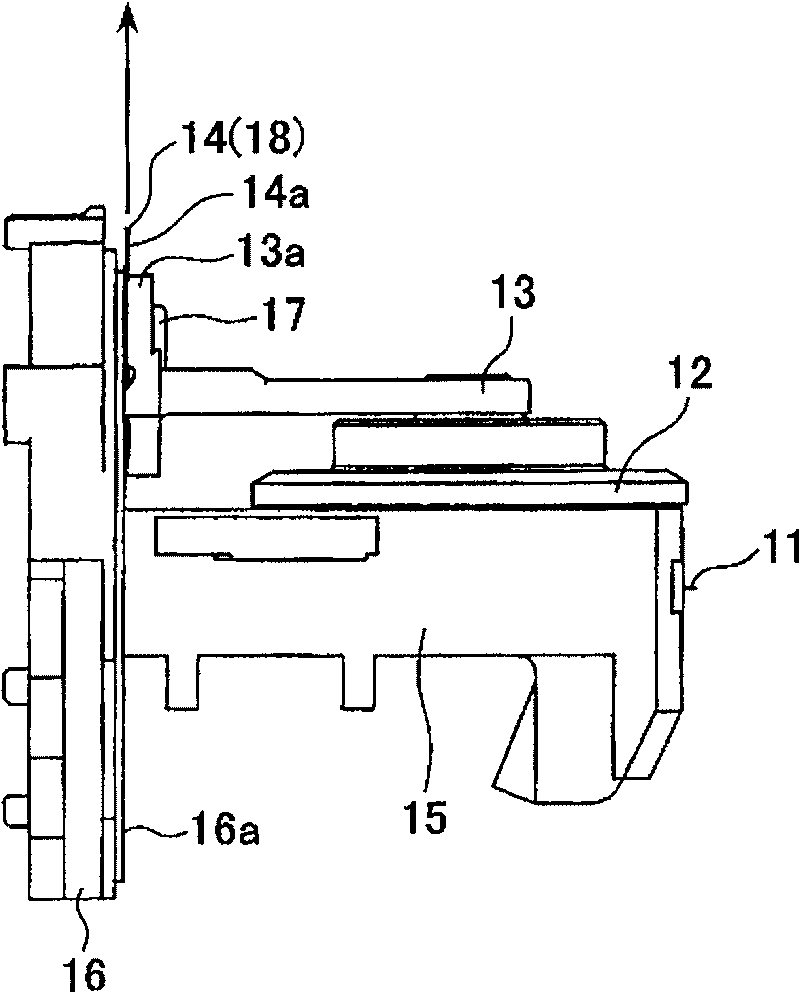

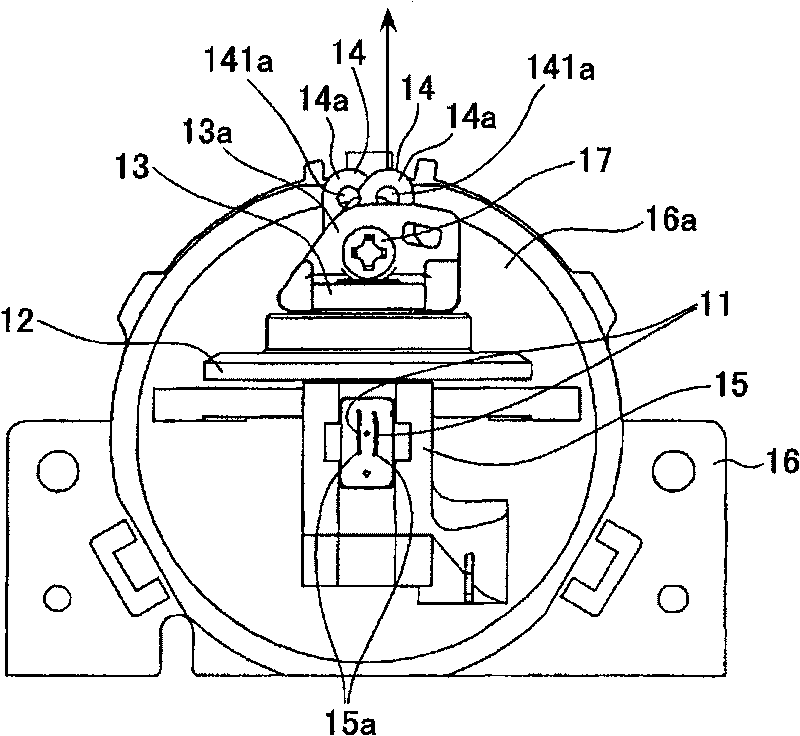

[0029] A print head according to an embodiment of the present invention will be described with reference to the following drawings. The print head 1 is used in a dot impact type printer, and the tip of the striker 11 strikes the printing surface of a printing medium such as printing paper 20 via the ink ribbon 32 to perform printing.

[0030] print head 1, such as Figure 1 to Figure 4 As shown, it includes a striker 11 , a drawing roller 12 , a roller support portion 13 for supporting the drawing roller 12 , a pull-out spacer 14 , a striker frame 15 , a frame 16 , and a spacer 18 for height adjustment. In the frame 16, a plurality of rods not shown are arranged radially, one end of each of the plurality of rods is fixed to the rear end of the plurality of striker pins 11, and a magnetic force generator for swinging the plurality of rods is also arranged. unillustrated coils, yokes, etc.

[0031] The lever is swung by magnetic attraction, and the tip of the striker 11 protru...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap