Tire building core assembly and disassembly station and method

A technology of cores and workstations, which is applied in the field of assembly and disassembly workstations of tire building cores, and can solve problems that have not yet been realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

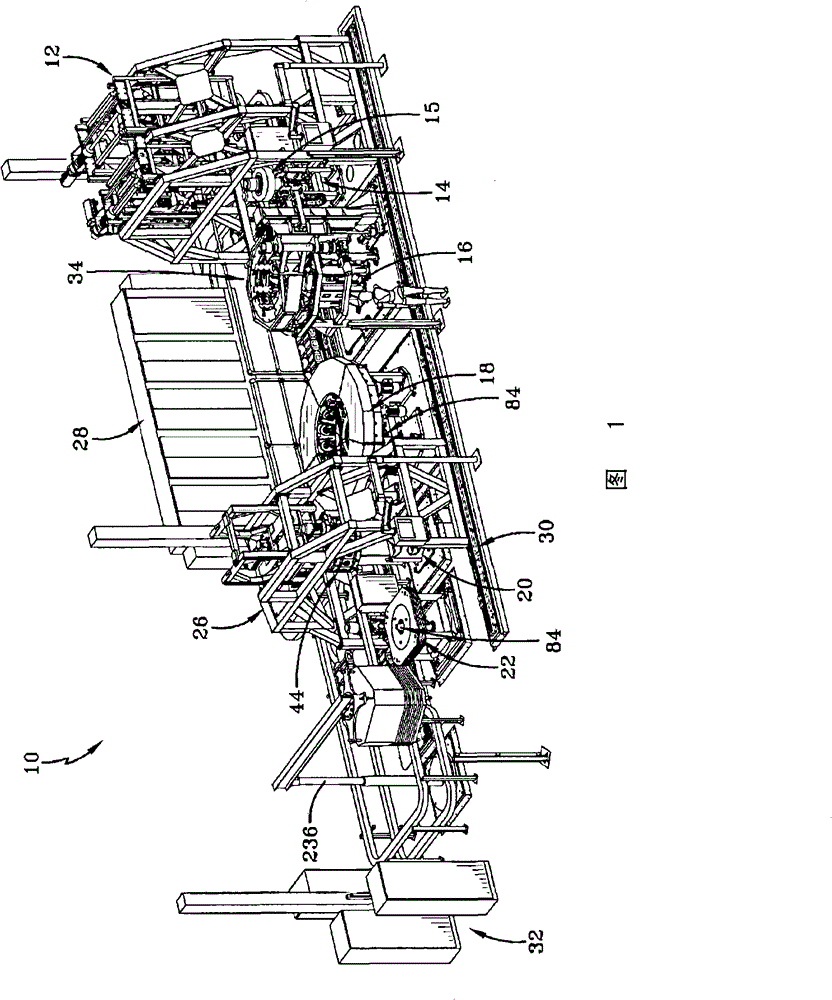

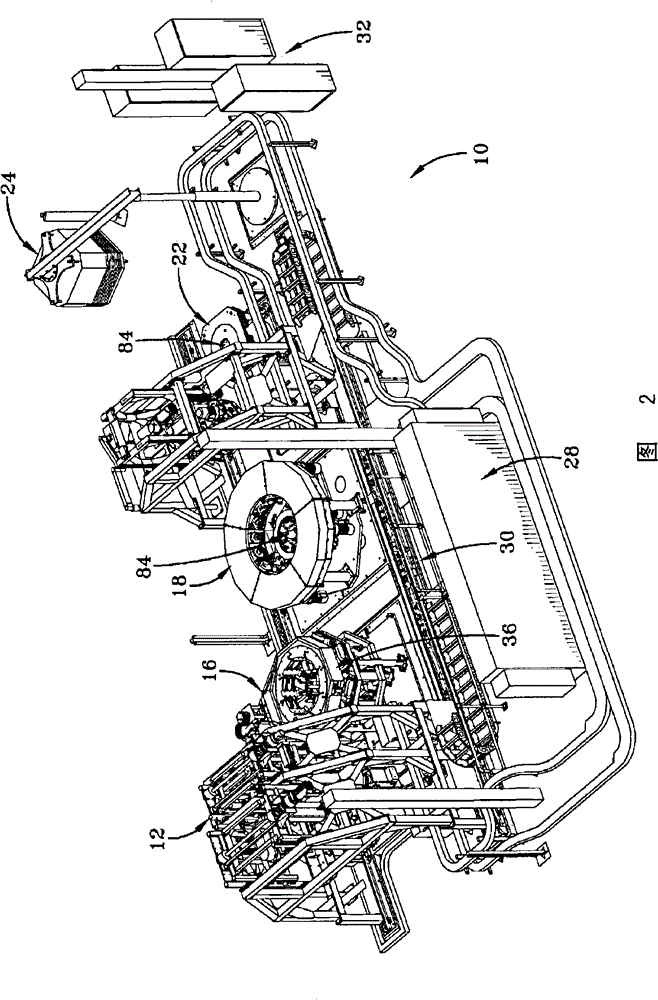

[0054] refer to figure 1 and figure 2 , the vulcanization line 10 of the present invention is shown as part of an integrated tire production line. The vulcanization line 10 is shown to include a plurality of stations arranged in a linear arrangement, however, other arrangements of stations may be used if necessary to accommodate equipment and / or user preference. The tire production line builds tires from components applied to segmented cores that approximate the size and configuration of the finished tire. In the incorporated by reference U.S. Patent Application No. 10 / 417,849, filed April 17, 2003, entitled "A Method for Curing Tires and a Self-Locking Tire Mold," the A segmented mold for molding tires. The mold has a central axis; a plurality of radially movable tread-forming segments; two sidewall-forming plates, a top sidewall-forming plate and a bottom sidewall-forming plate; The top locking ring of the device, each device for locking provides a predetermined angular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com