Gas packing bag for compactly holding articles and manufacturing method thereof

A manufacturing method and packaging bag technology, which are applied in the field of gas packaging bags and their manufacture, can solve the problems of gas packaging bags being punctured, gas packaging bags losing the effect of cushioning protection, increasing the cost of item packaging, etc., and achieving the purpose of strengthening the cushioning protection effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

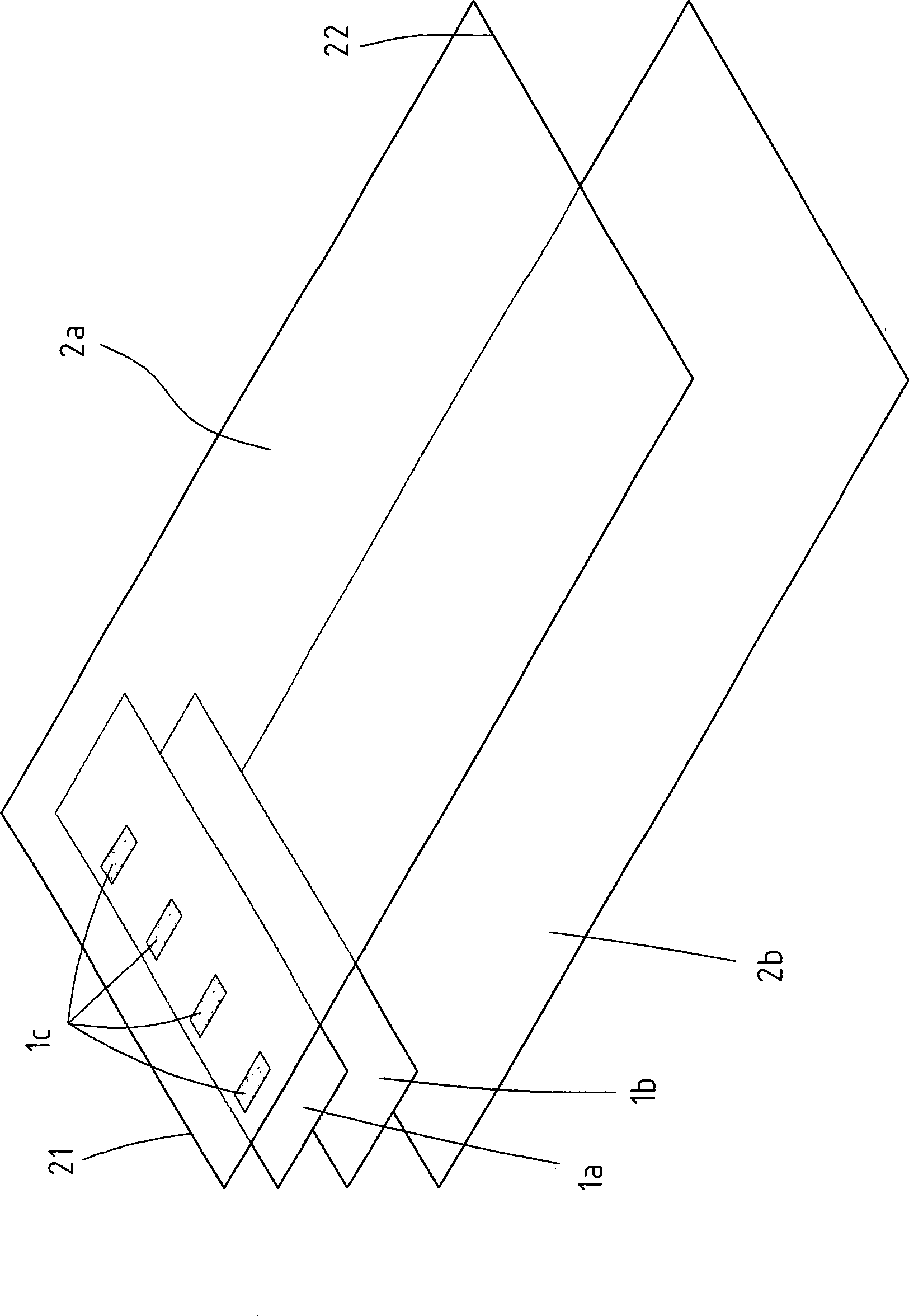

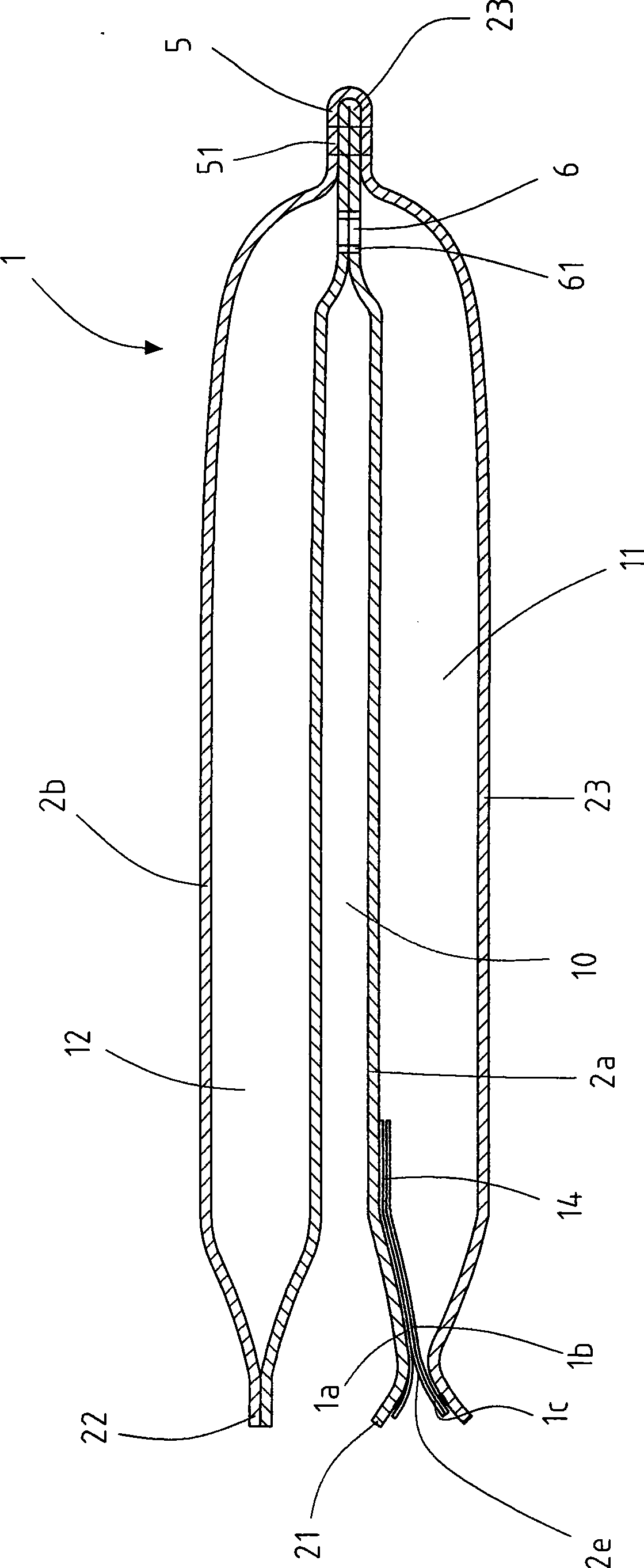

[0042] Figure 1 to Figure 5 Shown is a first embodiment of a gas packing bag of the present invention for tightly holding items.

[0043] The gas packaging bag 1 for tightly clamping articles of the present invention includes: a first outer film 2a and a second outer film 2b stacked up and down, a heat-sealed part 5, a first air chamber 11, a second air chamber 12, and a ventilation hole 6 , Accommodating space 10, etc.

[0044] The first outer membrane 2 a includes a first side 21 , a second side 22 and a folded edge 23 , the folded edge 23 is located between the first side 21 and the second side 22 . Fold the first outer membrane 2a in half along the folded edge 23, then fold the second outer membrane 2b in half according to the direction in which the first outer membrane is folded in half, so that the second outer membrane and the first outer membrane all face the same direction after being folded in half, and The second outer membrane 2b is located outside the first out...

no. 2 example

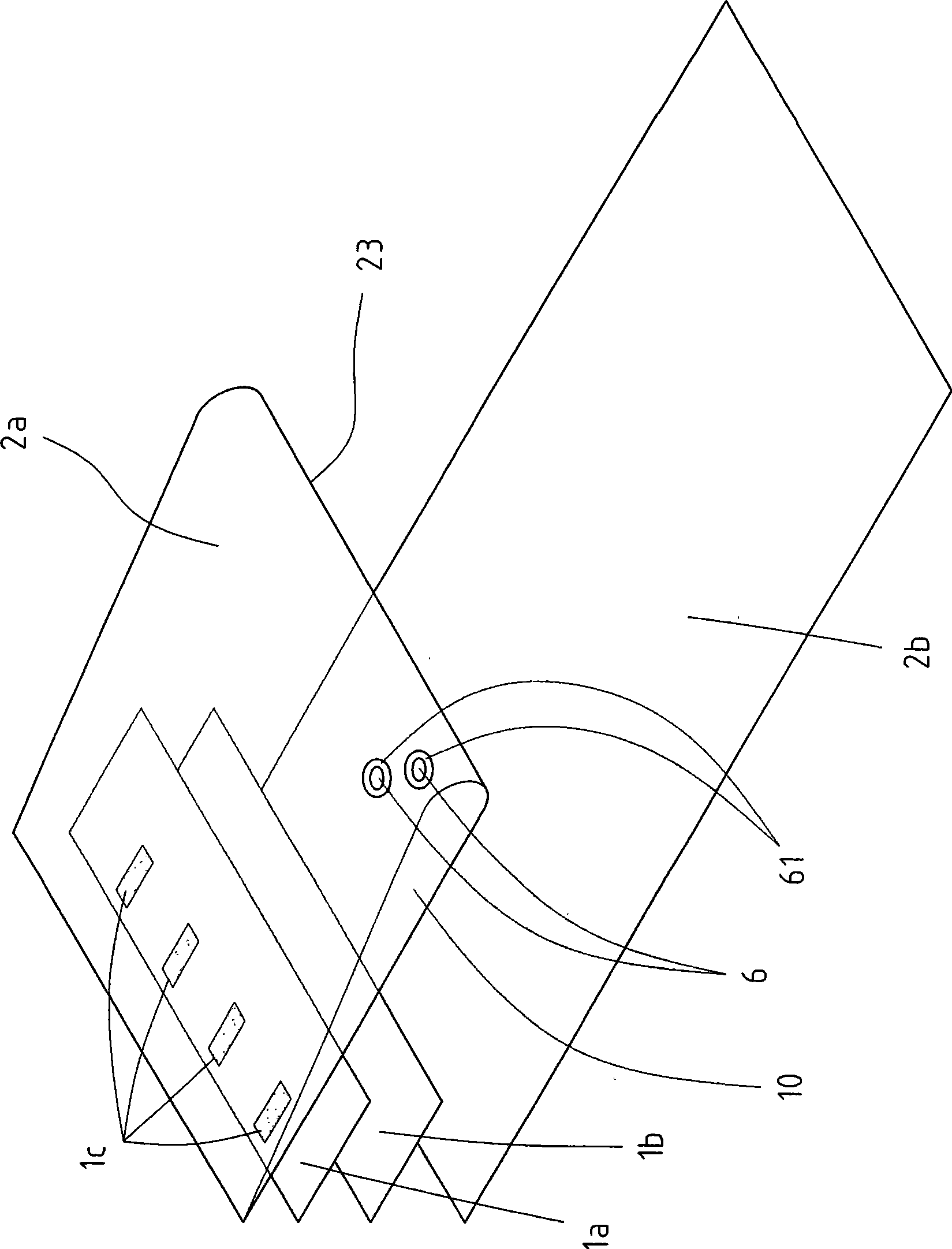

[0053] Figure 6A , Figure 6B and Figure 7 Shown is a second embodiment of the invention. The gas packaging bag 1 of the present invention also includes an inflation channel 9 located at the side of the first air chamber 11 , and a plurality of first air chambers 1 are located at one side of the inflation channel 9 side by side. The inflatable channel 9 is a gas-permeable space formed by heat-sealing the first outer film 2 a and the second outer film 2 b , and an inflatable port 9 a is formed at one end of the inflatable channel 9 . In addition, if Figure 7 As shown, each air inlet 2e is connected with a gas channel 14, wherein the gas channel 14 is coated with a heat-resistant material 1c between the two inner films 1a, 1b, and the two inner films 1a, 1b are bonded by means of heat sealing. formed between the two inner membranes.

[0054] After the gas entering the inflation port 9a expands the inflation channel 9, the first outer membrane 2a and the second outer memb...

no. 3 example

[0059] Figure 8 It is a cross-sectional view of the third embodiment of the present invention after inflation is placed into the object.

[0060] After the user puts the article 100 into the accommodating space 10, the first air chamber 11 and the second air chamber 12 tighten the article 100 by inflating the first and second air chambers, and then the accommodating space 10 is pumped out. The effect of tightening the article 100 by the first air chamber 11 and the second air chamber 12 is strengthened by forming a vacuum, so that the article 100 is fixed in the accommodating space 10 without shaking with the gas packaging bag 1 . After vacuuming is completed, the upper and lower ends of the first outer film and the second outer film are adhered by means of heat sealing to completely seal the accommodating space 10 so that the object 100 will not come out of the accommodating space 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com