Vacuum suction type gas packing bag and packing method thereof

A packaging method and packaging bag technology, which are applied in the vacuum suction beam type gas packaging bag and its packaging field, can solve the problems of gas packaging bag loss of buffer protection, gas packaging bag puncture, damage or scratches, etc., to solve the problem of being vulnerable to Item puncture, strengthen buffer protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

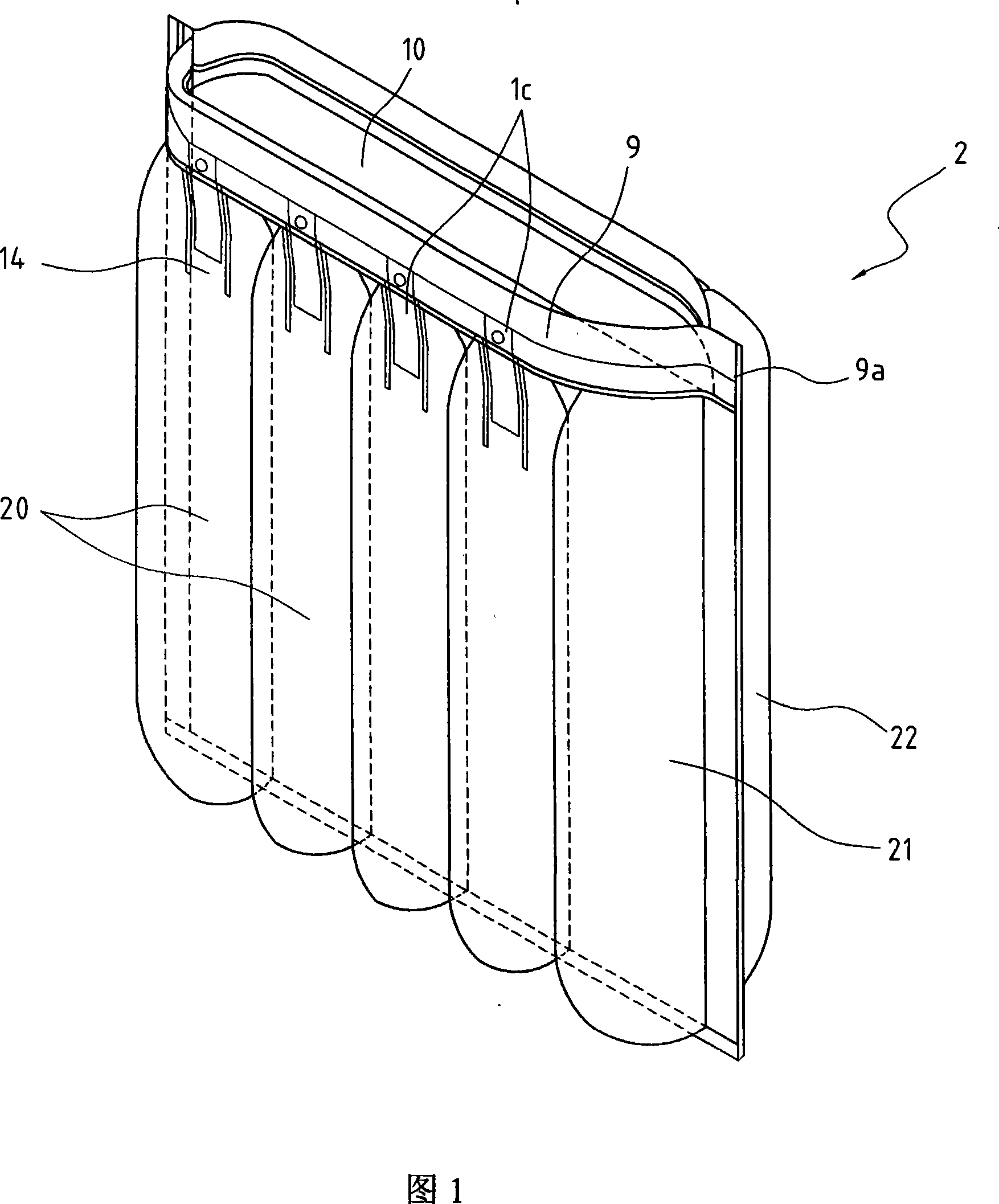

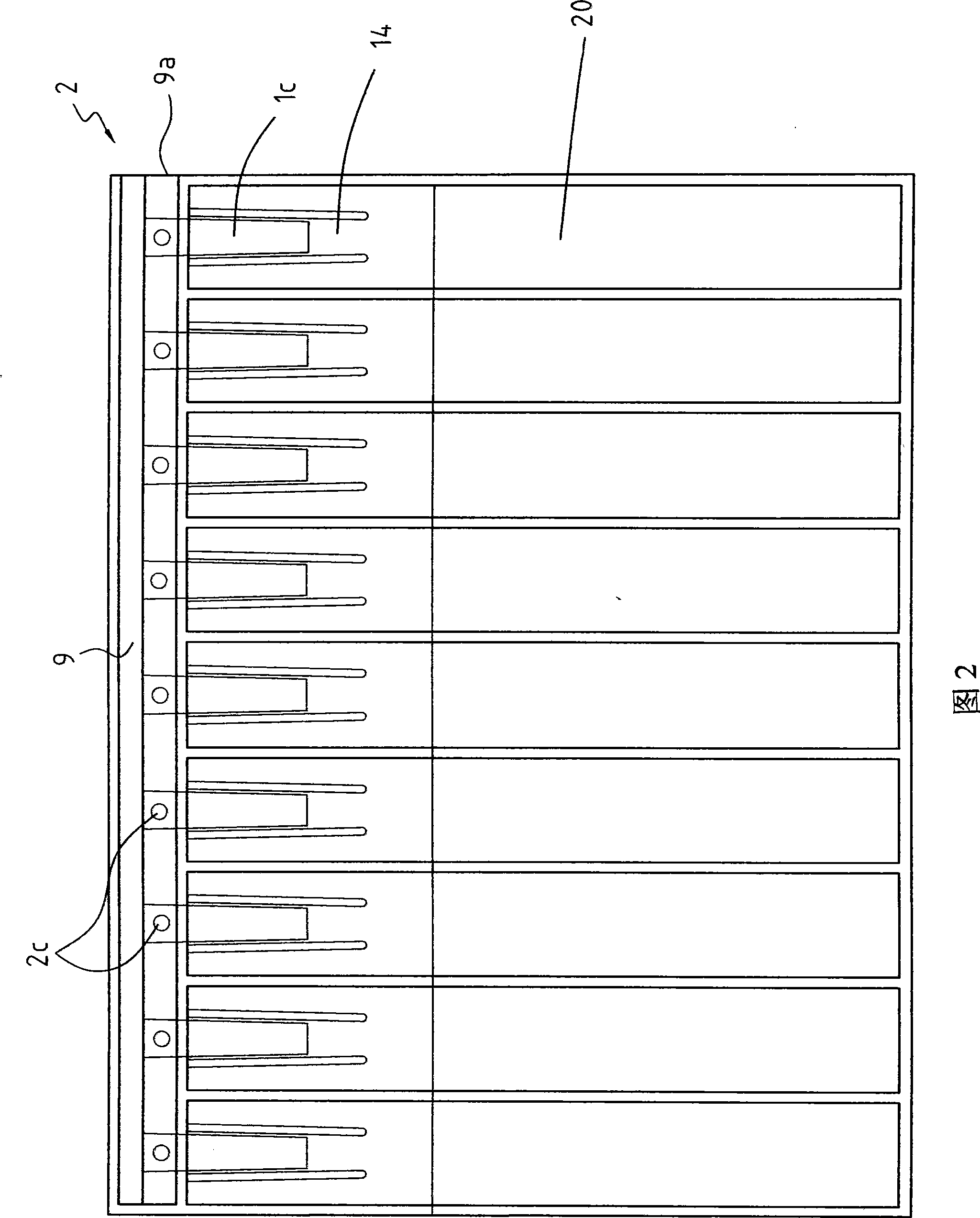

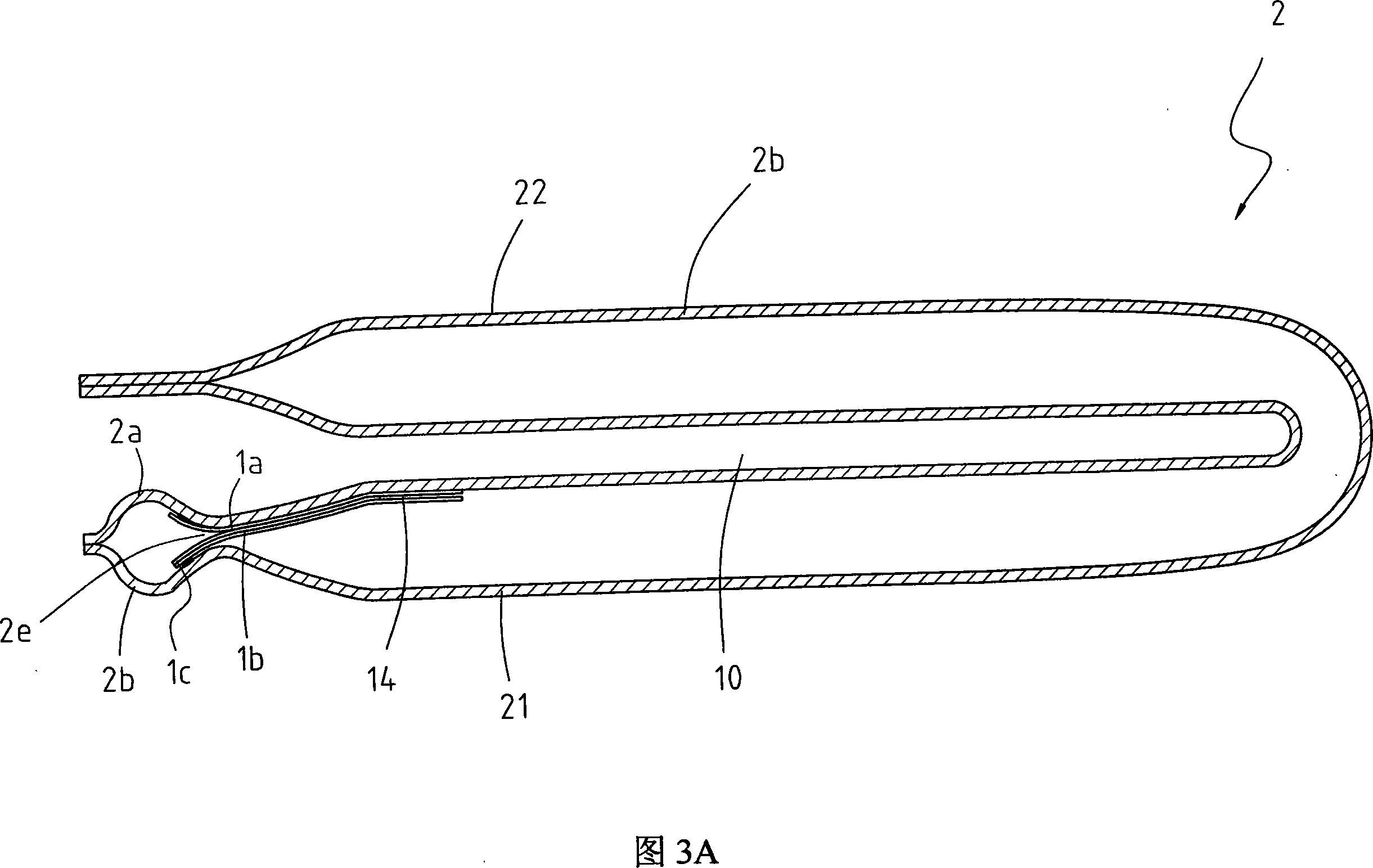

[0041] figure 1 , figure 2 , Figure 3A , Figure 3B , Figure 4 and Figure 5 Shown is the first embodiment of the vacuum beam-type gas packaging bag of the present invention.

[0042] The vacuum beam-absorbing gas packaging bag of the present invention includes: an air column sheet 2 provided with an inflation channel 9 and an accommodating space 10 .

[0043] The air column sheet 2 includes at least one air column 20, and each air column 20 includes an air inlet 2e. The air inlet allows gas to enter the air column 20 through the inflation channel 9 to inflate the air column.

[0044] In the present invention, the air column sheet 2 includes two outer membranes 2a, 2b that are stacked up and down, and two inner membranes 1a, 1b that are arranged between the two outer membranes. At least one strip of heat-resistant material 1c is coated. First, use heat sealing means to form heat sealing points 2c on the inner and outer films, such as Figure 3B, the heat sealing poi...

no. 2 example

[0051] Image 6 A second embodiment of the present invention is shown. The air column sheet 2 includes a plurality of parallel air columns 20, and a cutting line 8 is arranged between the air columns 20 and the air columns 20. The cutting line runs through the entire length of the gas packaging bag for the user to cut along the cutting line 8. cut, so that each air column 20 can be used independently, or according to the user's requirements to cut the required number of air columns 20, that is, according to the size and size of the packaged items to cut the required number. In addition, each air column 20 is provided with an air inlet 2e.

no. 3 example

[0053] Figure 7 A third embodiment of the present invention is shown. The gas column sheet 2 only includes one gas column 20, and a plurality of gas inlets 2e are provided on the gas column sheet, so that the gas enters the gas column 20 along the plurality of gas inlets 2e and the plurality of gas passages 14, so that the gas column 20 Rapid inflation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com