Power transmission line

A power transmission line, hollow technology, applied in the direction of circuits, insulated cables, power cables, etc., can solve the problems of short life of power core wires, and achieve the effects of simple structure, prevent damage, and good pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

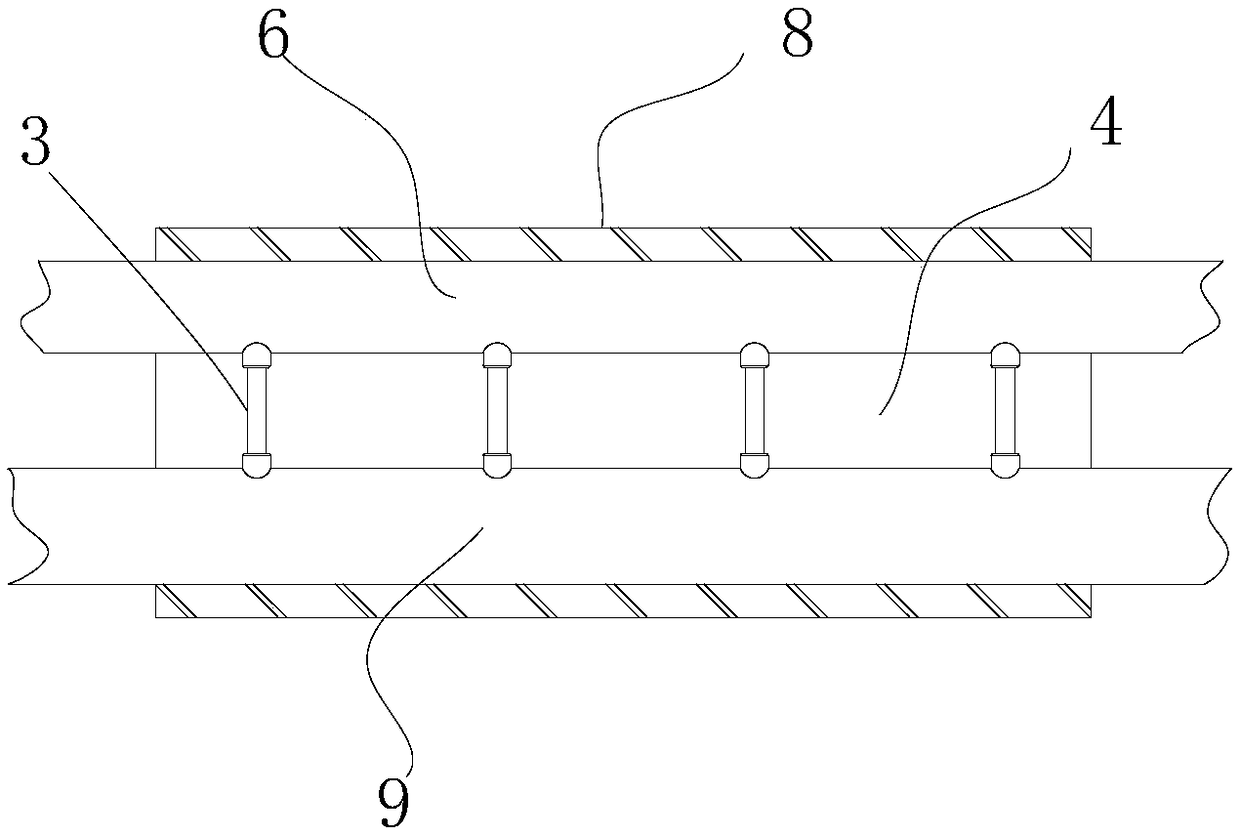

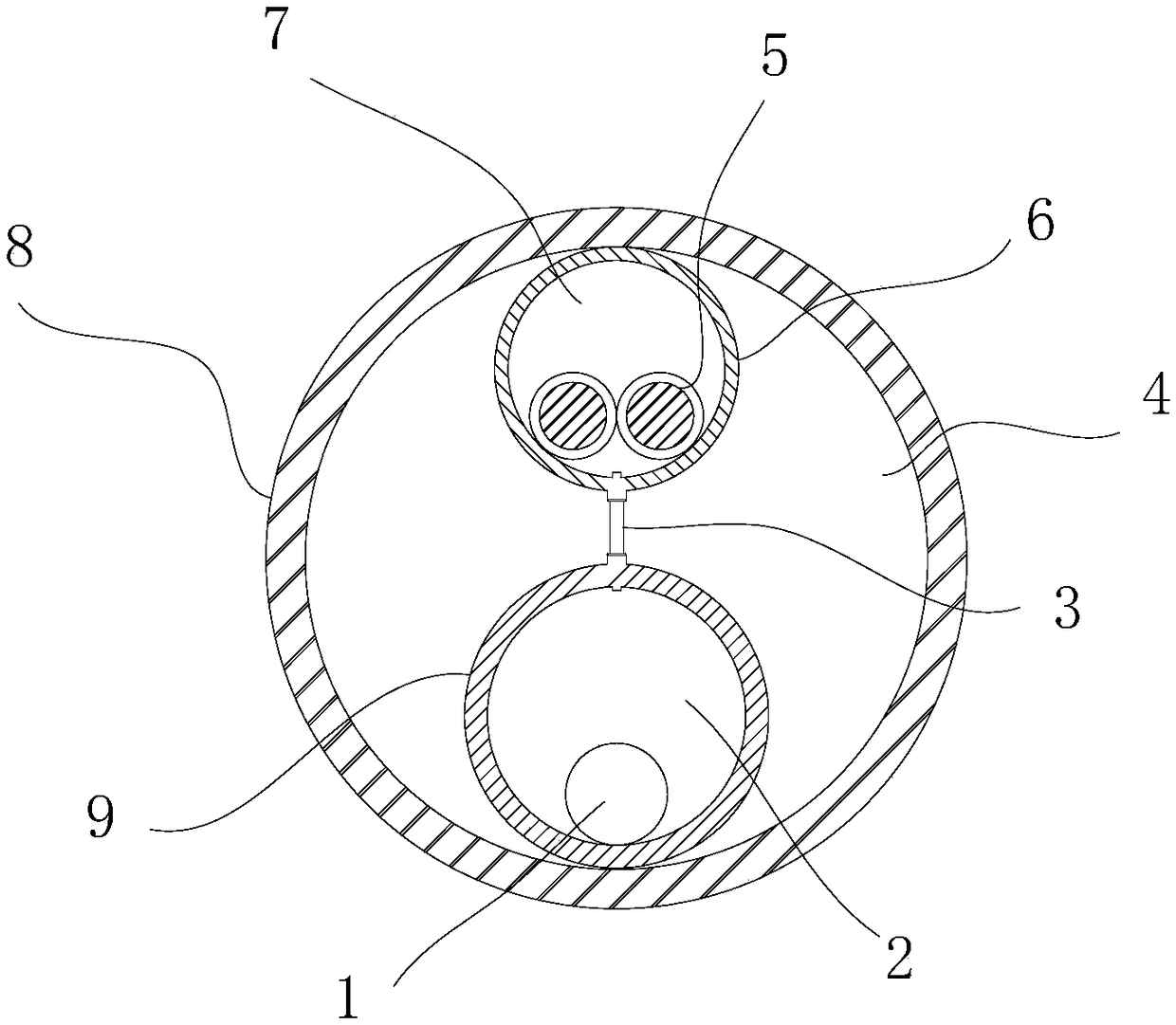

[0015] Such as figure 1 and figure 2 As shown, the power transmission line includes an outer coating layer 8, and an installation cavity 4 is provided in the outer coating layer 8, and an outer protective layer 6 and a hollow layer 9 are installed in the installation cavity 4;

[0016] The cross-sections of the outer protective layer 6 and the hollow layer 9 are circular hollow structures, which are equal in length to the entire outer covering layer 8. The outer protective layer 6 and the hollow layer 9 are both closed structures, and the outer protective layer has a A closed first air storage chamber 7, and a closed second air storage chamber 2 inside the hollow layer 9;

[0017] Two ends of the first air storage cavity 7 are respectively provided with a wire outlet hole, and the power supply core wire 5 passes through the wire outlet hole and is sealed and fixed with glue;

[0018] The outer protective layer 6 is located on the top of the hollow layer 9, the power supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com