Multi-degree-of-freedom parallel mechanism vibration damping platform used for motor vehicle seat

A technology for motor vehicles and degrees of freedom, applied in vehicle seats, seat suspension devices, special positions of vehicles, etc. Isotropic, simple and compact structure, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

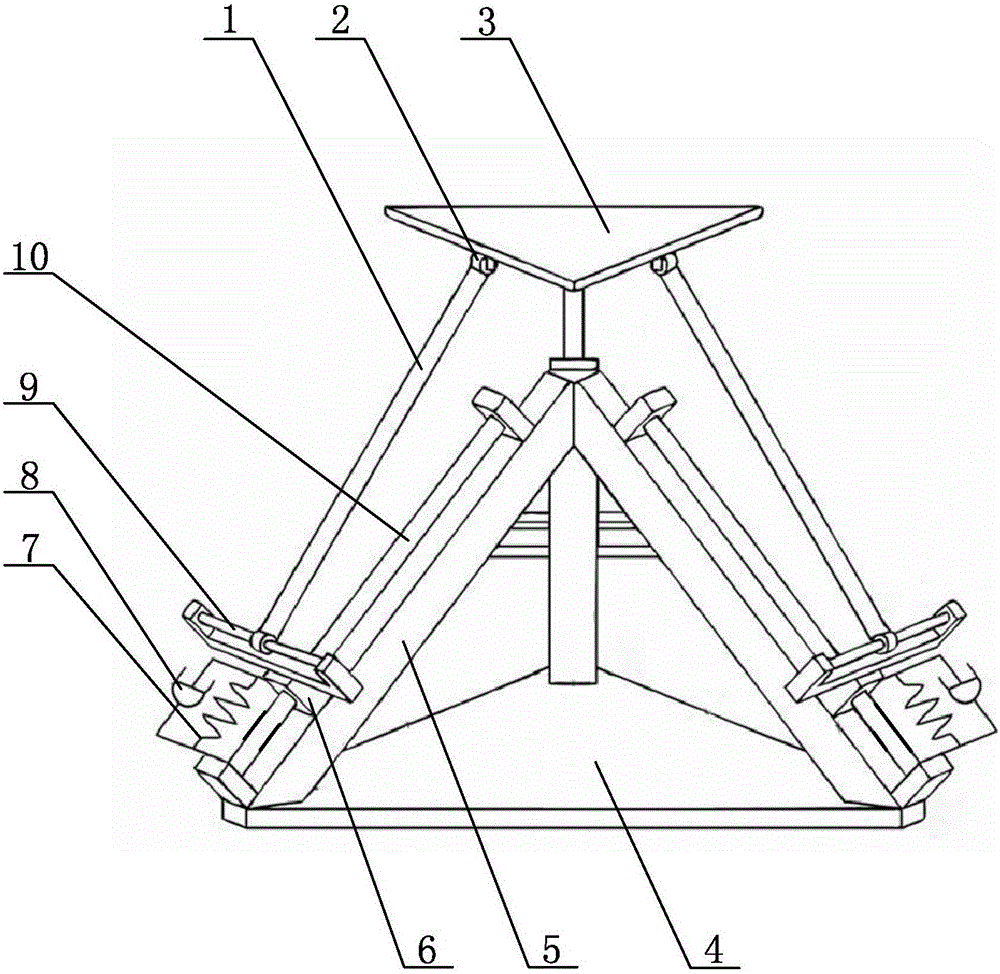

[0016] Such as figure 1 As shown, the multi-degree-of-freedom parallel mechanism vibration damping platform for motor vehicle seats includes a fixed platform 4 and a bearing platform 3 above the fixed platform 4, the bearing platform 3 is connected to the motor vehicle seat, and the connection between the bearing platform 3 and the fixed platform 4 The three branches are connected by three branches with the same structure, and the three branches are evenly distributed at 120° around the vertical centerline of the fixed platform 4. The three branches all include springs 7, dampers 8, moving pairs, cylindrical pairs and rotating pairs;

[0017] The fixed platform 4 is provided with a bracket 5, and the bracket 5 is equipped with a moving pair. The moving pair includes a sliding shaft 10 and a slider 6. The sliding shaft 10 is fixed on the bracket 5, and the sliding block 6 slides axially on the sliding shaft 10. A spring 7 and a damper 8 are installed between 6 and the bottom en...

Embodiment 2

[0022] On the basis of Embodiment 1, the damper 8 is a controllable passive electromagnetic damper, the electromagnetic damper is connected to the current regulation unit and the force sensor, and the current regulation unit and the force sensor are connected to the controller.

[0023] The control system can be turned on or off selectively. When the control system is turned off, the electromagnetic damper itself has a certain damping characteristic and works in a passive damping state. When the control system is turned on, the electromagnetic damper detected by the force sensor The data is transmitted to the controller, and the controller determines the magnitude of the current input to the electromagnetic damper according to the data simulation calculation, thereby changing the damping value, and optimizing the vibration reduction effect on the premise of avoiding the resonance frequency to the human body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com