Electromagnetic driver with elastic resetting mechanisms

An electromagnetic drive, elastic reset technology, applied in mechanical equipment, engine components, valve operation/release devices, etc., can solve the problem of not improving the response speed, no magnetic core buffer protection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

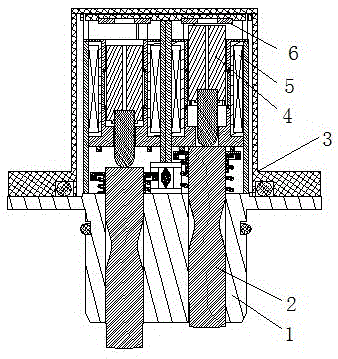

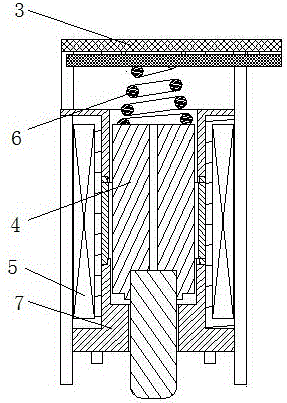

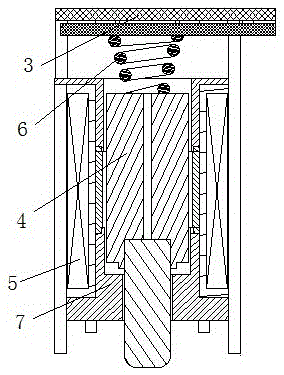

[0022] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0023] It can be seen from the accompanying drawings that this solution includes a pin sleeve and a valve casing fixed on the pin sleeve. A valve pin is arranged inside the pin sleeve, and an electric drive mechanism that can push the valve pin to move is arranged inside the valve casing. The electromagnetic drive mechanism includes There are inner yoke sleeve, electromagnetic solenoid and magnetic core; the magnetic core is set in the inner yoke sleeve, and the electromagnetic solenoid is wound outside the inner yoke sleeve; the magnetic core can move in the inner yoke sleeve, and the magnetic core can pass through the push rod Push the valve pin to move; there is an elastic reset mechanism between the magnetic core and the valve shell.

[0024] The elastic reset mechanism in this s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com