Raw material for preparing thin film, bag product, packaging thin film and preparation method thereof

A film and raw material technology, which is applied in household packaging, packaging, food packaging, etc., can solve the problems of poor pressure bearing performance, poor barrier performance, and unstable film of bubble bags, so as to achieve unbreakable properties, solve tensile properties, and increase rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

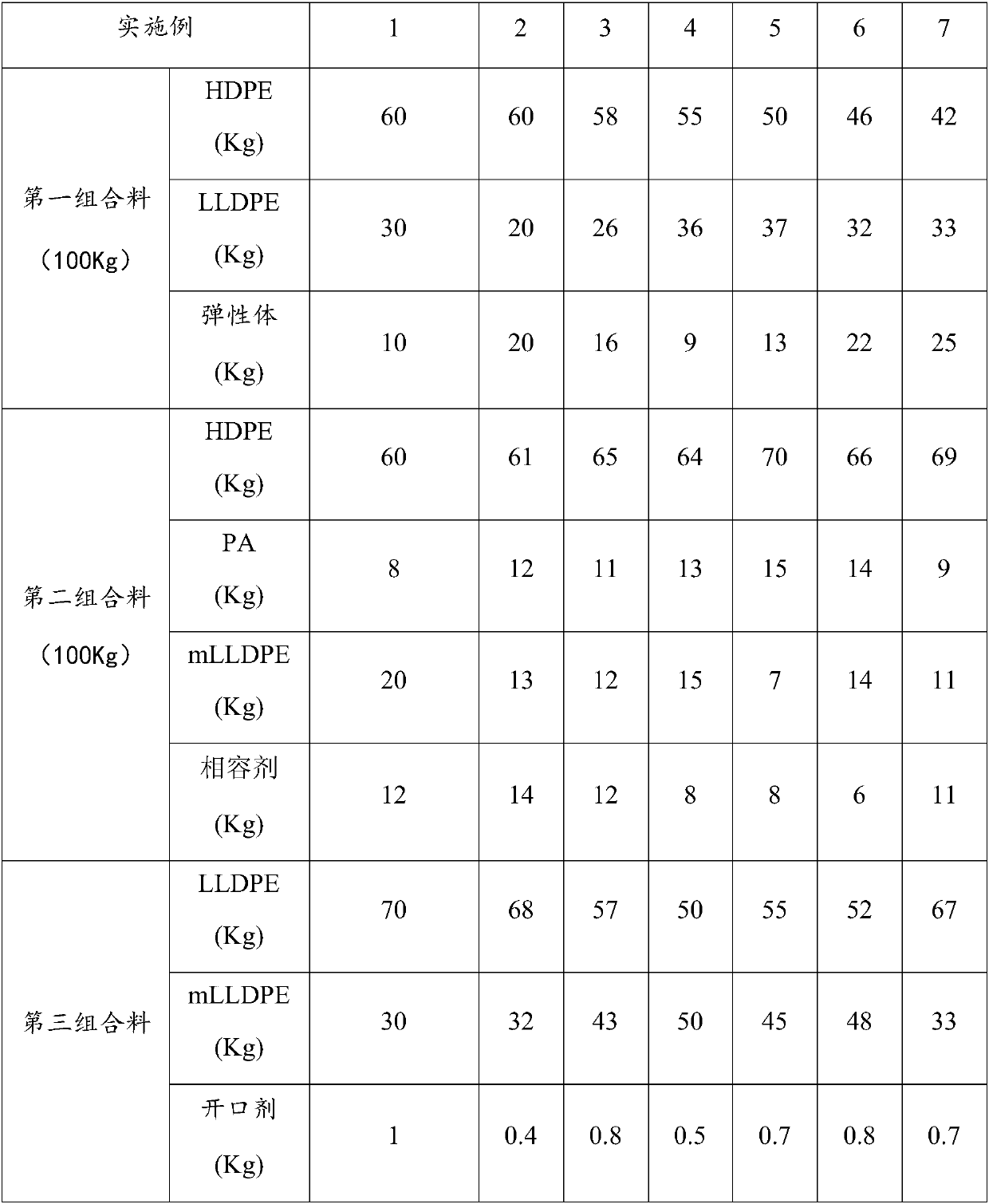

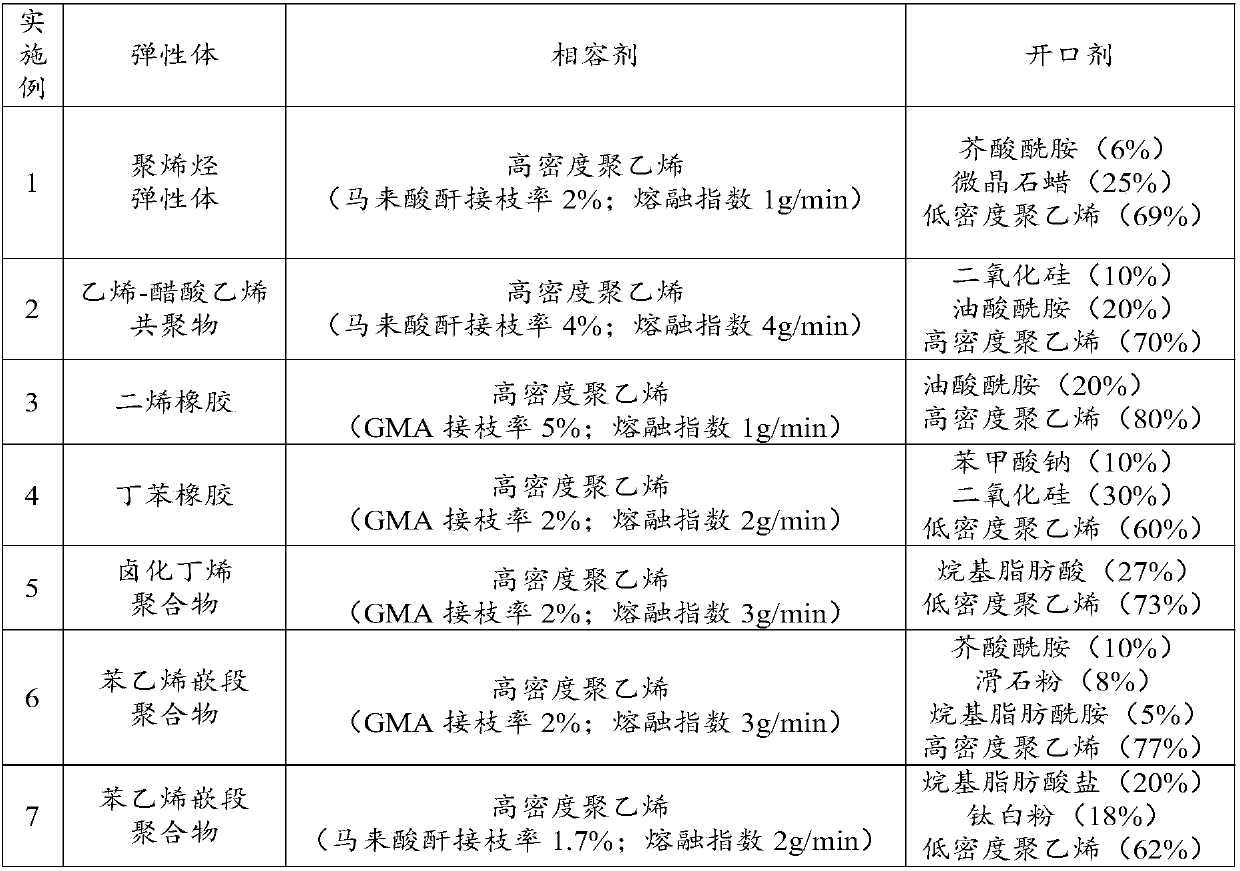

[0074] A raw material for the manufacture of thin films, the composition of which is as follows.

[0075] According to parts by weight, the first group of materials is composed of 40-60 parts of high-density polyethylene, 30-40 parts of linear low-density polyethylene, and 10-15 parts of polyolefin elastomer. The elastomer is a polyolefin elastomer. The second group material is composed of 60-70 parts of high-density polyethylene, 8-15 parts of polyamide, 10-15 parts of metallocene polyethylene and 5-20 parts of compatibilizer in parts by weight. The compatibilizer is high-density polyethylene with a maleic anhydride graft rate of 2% and a melt index of 1 g / min. According to parts by weight, the third group of materials is composed of 50-70 parts of linear low-density polyethylene, 30-50 parts of metallocene polyethylene, and 0.5-1 part of antiblocking agent. The blocking agent is silicon dioxide.

[0076] The component contents of the raw materials provided in Examples 2-7...

Embodiment 8

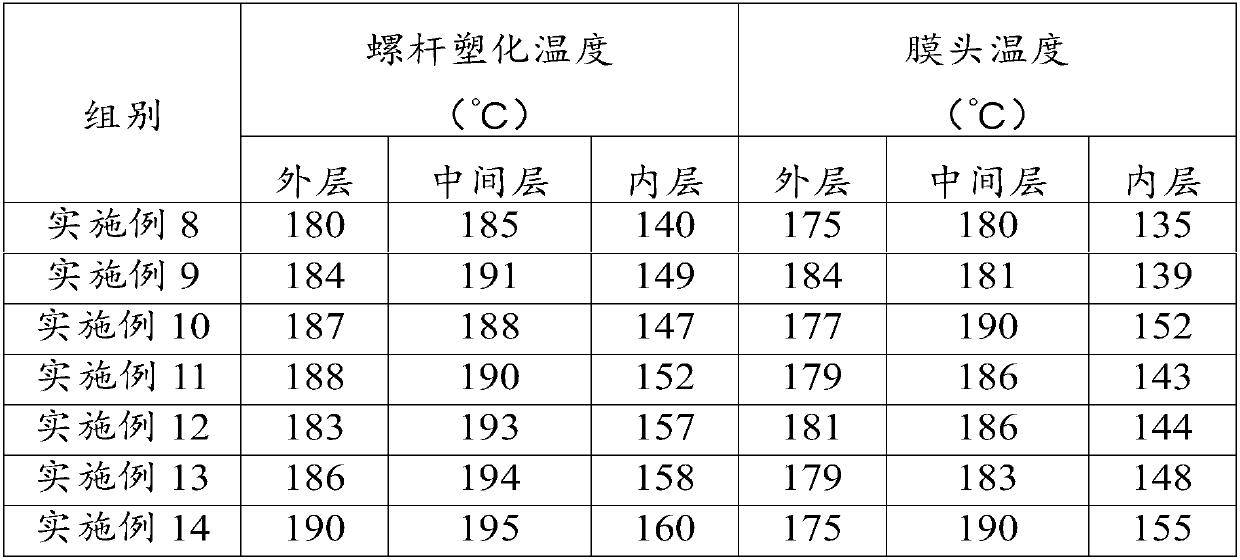

[0085] The raw materials provided in Example 1 were used to prepare a three-layer co-extrusion film through a PE co-extrusion blown film machine. The outer layer of the co-extrusion blown film machine sets the plasticizing temperature of the screw at 180°C and the film head temperature at 175°C; the middle layer sets the plasticizing temperature of the screw at 185°C and the temperature of the film head at 180°C; the inner layer sets the plasticizing temperature of the screw at 140°C. The membrane head temperature is 135°C. The thickness of the prepared co-extruded film is 1.5C.

[0086] Examples 9-14 correspond to the raw materials of Examples 2-7 to prepare a three-layer co-extruded film according to the process flow of Example 8. The conditions are shown in Table 3, and the corresponding film properties are shown in Table 4.

[0087] Table 3 Processing Conditions

[0088]

[0089] Table 4 three-layer co-extruded film properties

[0090]

[0091] What the inventor k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Transverse tensile strength | aaaaa | aaaaa |

| Longitudinal tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com