Method of stretching glass preform bar

A preform and glass technology, which is applied to glass manufacturing equipment, manufacturing tools, etc., can solve the problems of insufficient utilization of glass preforms and large fluctuations in the outer diameter of glass preforms, so as to improve the utilization rate and improve the drawing precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

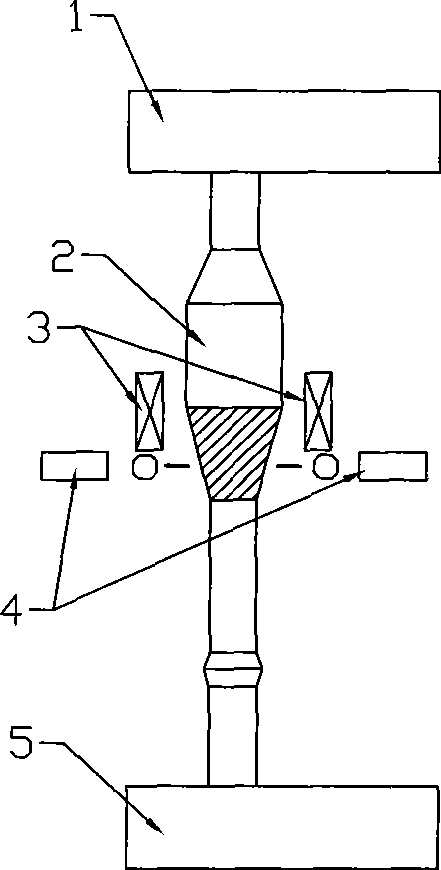

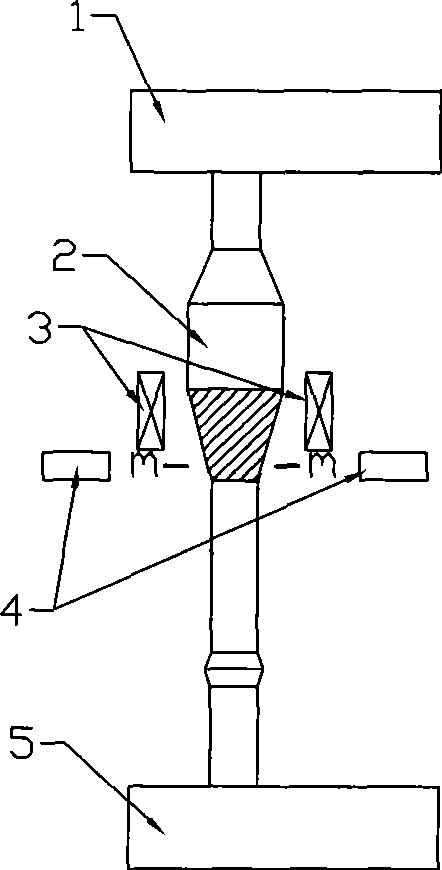

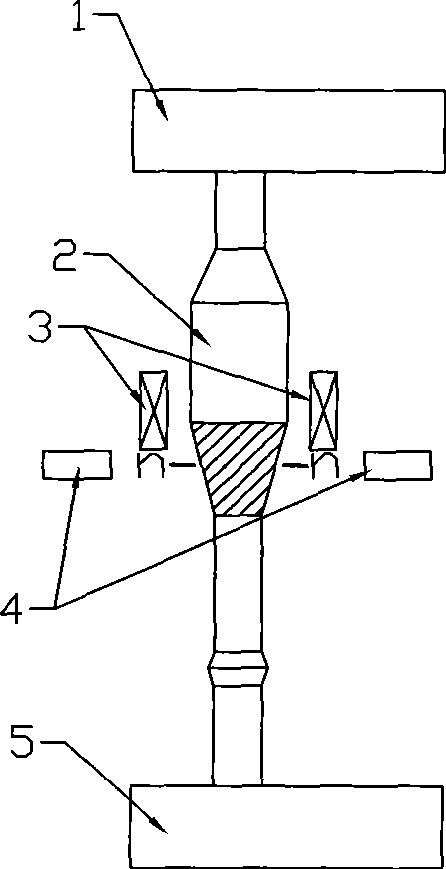

[0016] The present invention will be further described below in conjunction with the accompanying drawings of the description.

[0017] A method for stretching a glass preform, which is to clamp the upper end and the lower end of a glass preform 2 respectively on an upper fixture 1 and a lower fixture 5 for sequential heating, using the speed V1 of the upper fixture 1 and the speed V2 of the lower fixture 5 The difference between them is to stretch the glass preform 2. During the stretching process, the stability of the stretching force F is always ensured by adjusting the speed V1 of the upper clamp 1, and the diameter D0 and the setting of the caliper 4 are used to control the Measure the speed V2 of the clamp 5 under the control of the fixed-point diameter D01, which is characterized in that: the internal tension of the glass preform reflecting the stretching force F is measured by the gravity sensor 12, and the volume of the glass preform is constant during the stretching p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com