Pressure-variable inflator

A pump and pressure technology, applied in the field of pumps, can solve problems such as inability to effectively carry out large volume or high-pressure air intake, easy to touch by mistake, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Regarding the technology, means and effects used in the present invention, a preferred embodiment is given and described in detail below with drawings, which are for illustration purposes only, and are not limited by this structure in the patent application.

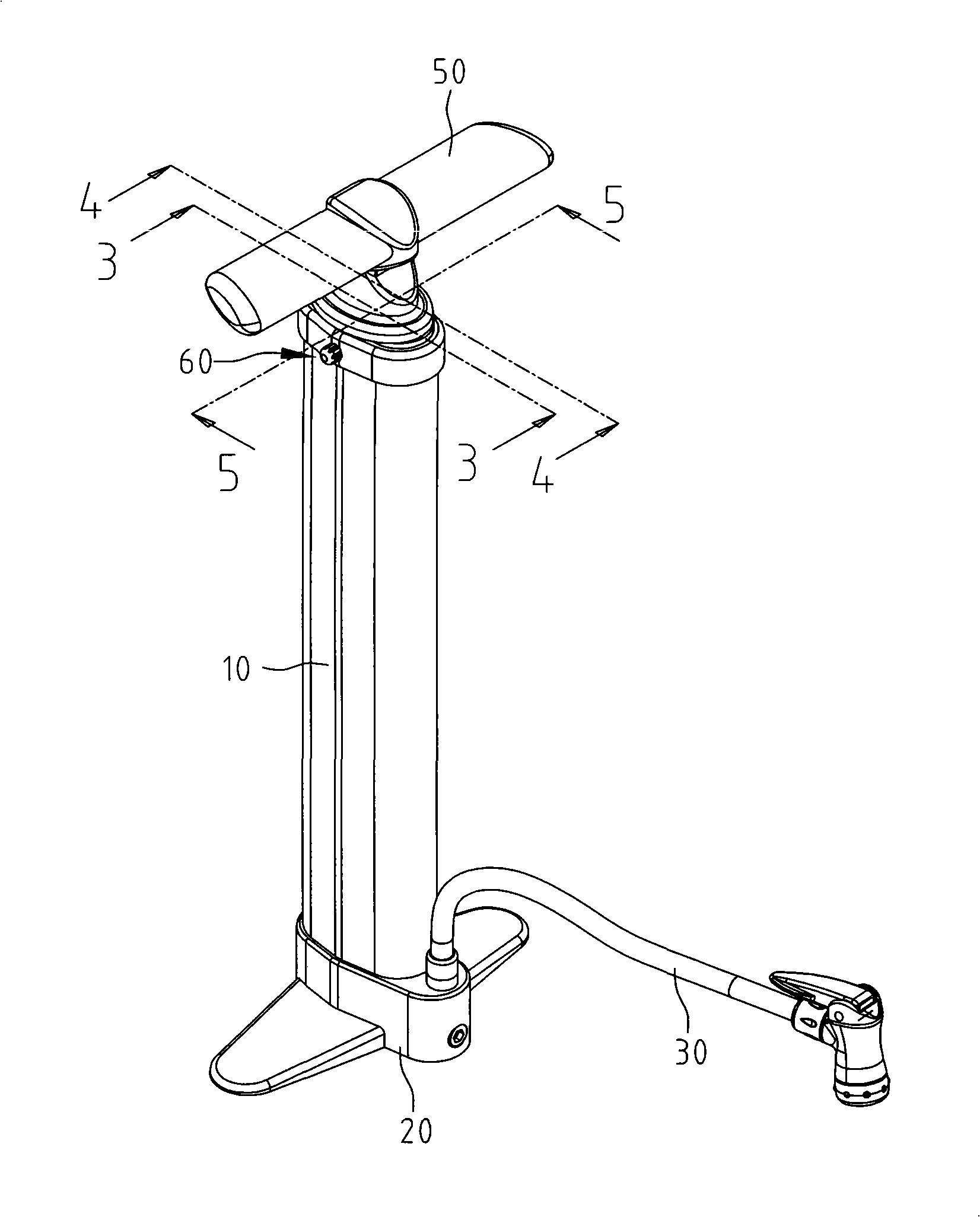

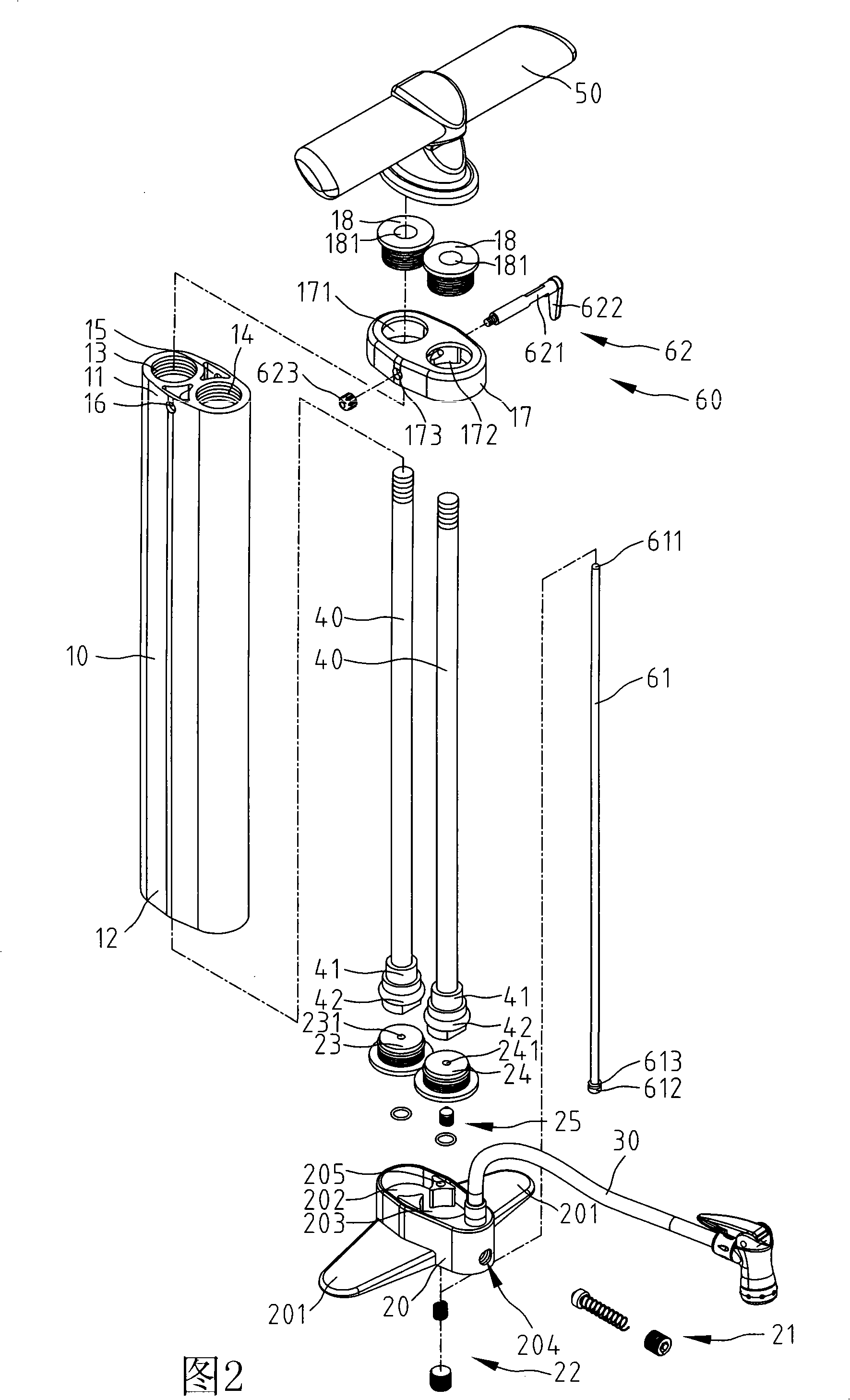

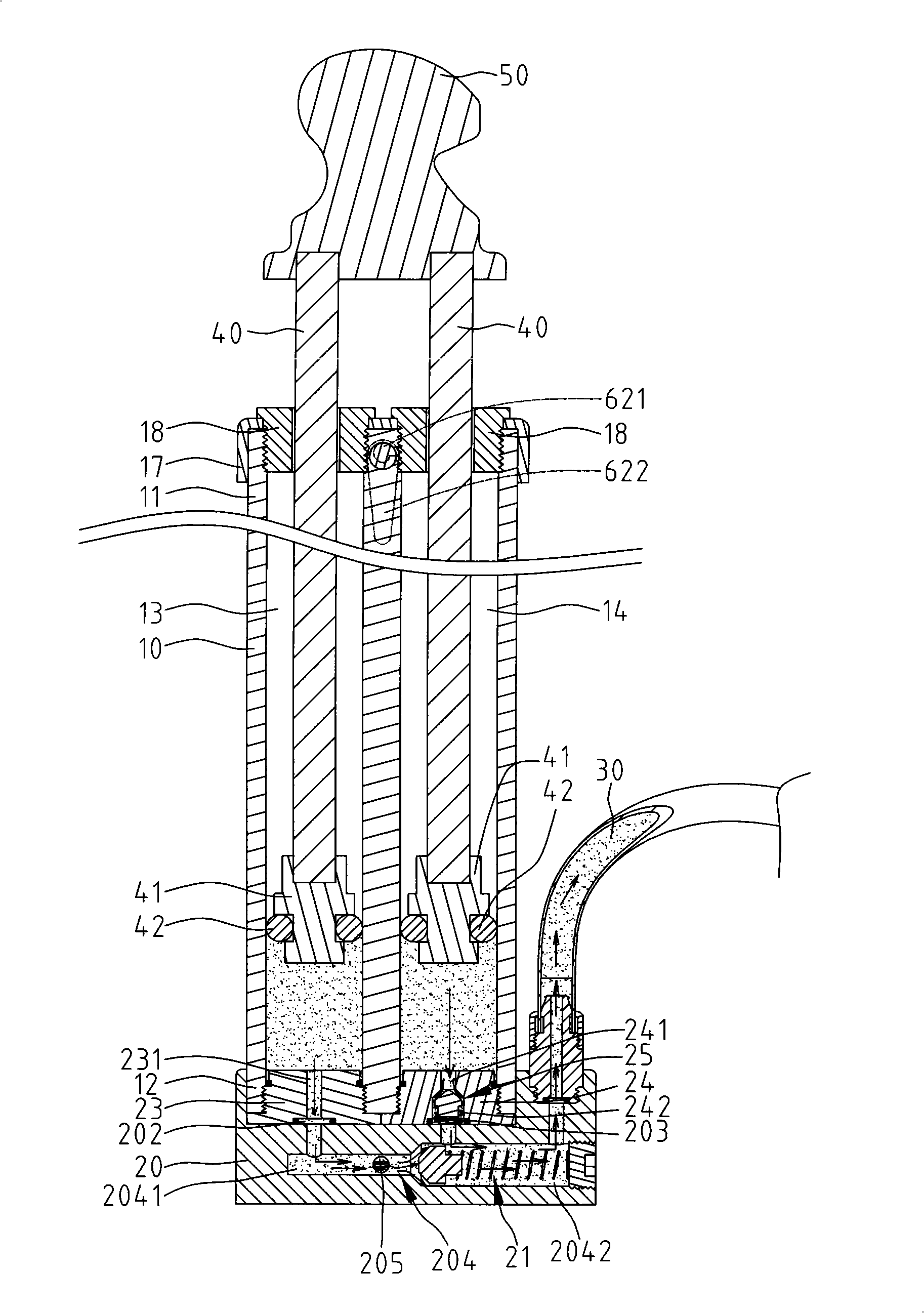

[0029] refer to figure 1 2 is a three-dimensional appearance view and a three-dimensional exploded view of the first embodiment of the pump of the present invention. The pump of the present invention includes a cylinder body 10 , a base 20 , a hose 30 , two piston rods 40 , a handle 50 and a control device 60 .

[0030] The barrel 10 includes a first end 11 and a second end 12 , the first end 11 is combined with the base 20 , and the second end 12 is combined with the handle 50 . The cylinder 10 also includes two air chambers 13, 14 and an accommodating space 15, both of which axially pass through the first end 11 and the second end 12, wherein the first end 11 is also provided with a hole 16, the said The hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com