Apparatus for sensing gearbox shifting positions

A technology for shifting devices and gearboxes, which is applied in the directions of transmission control, transportation and packaging, and components with teeth, etc., and can solve problems such as expensive, complex assembly, and complex space structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

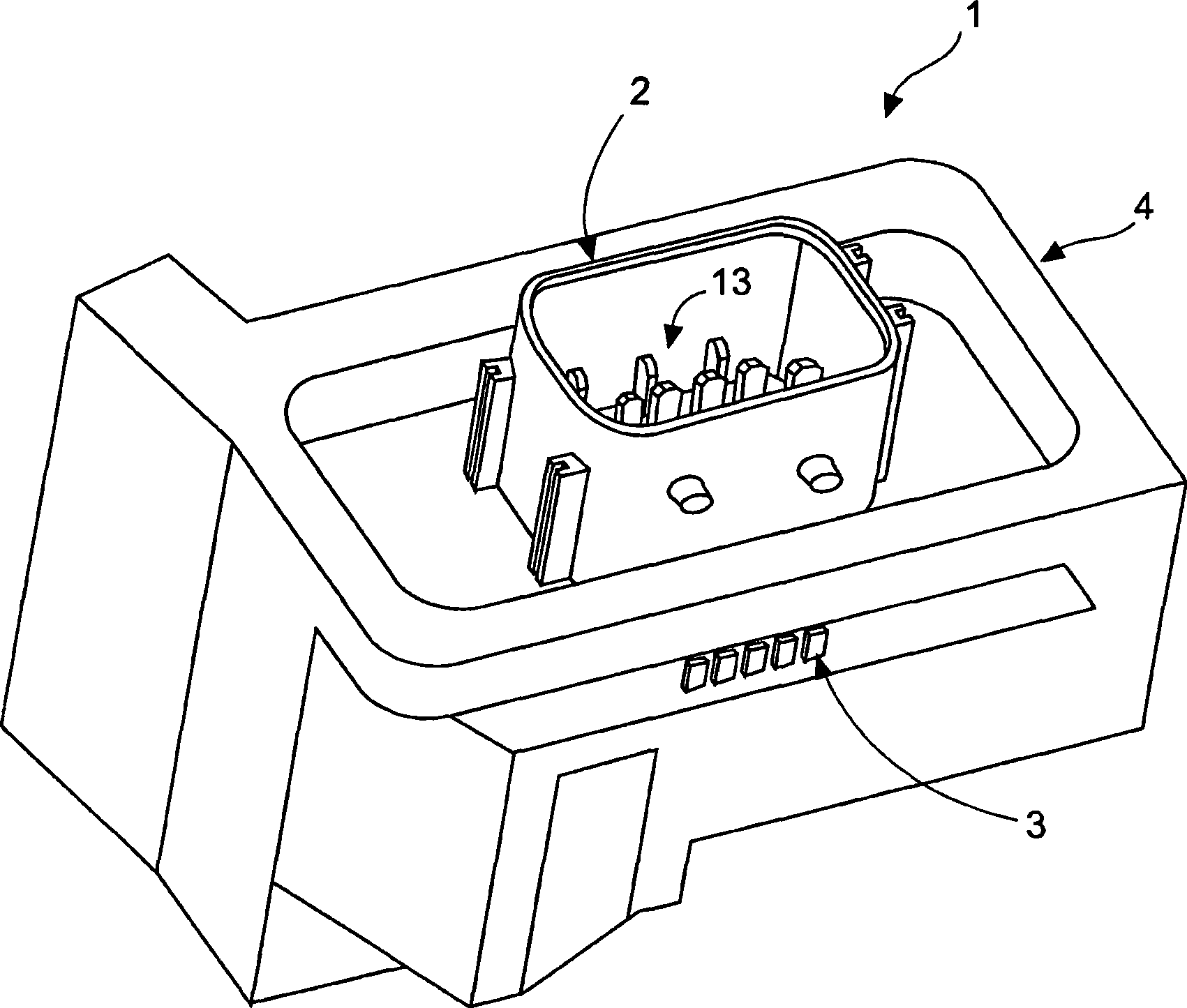

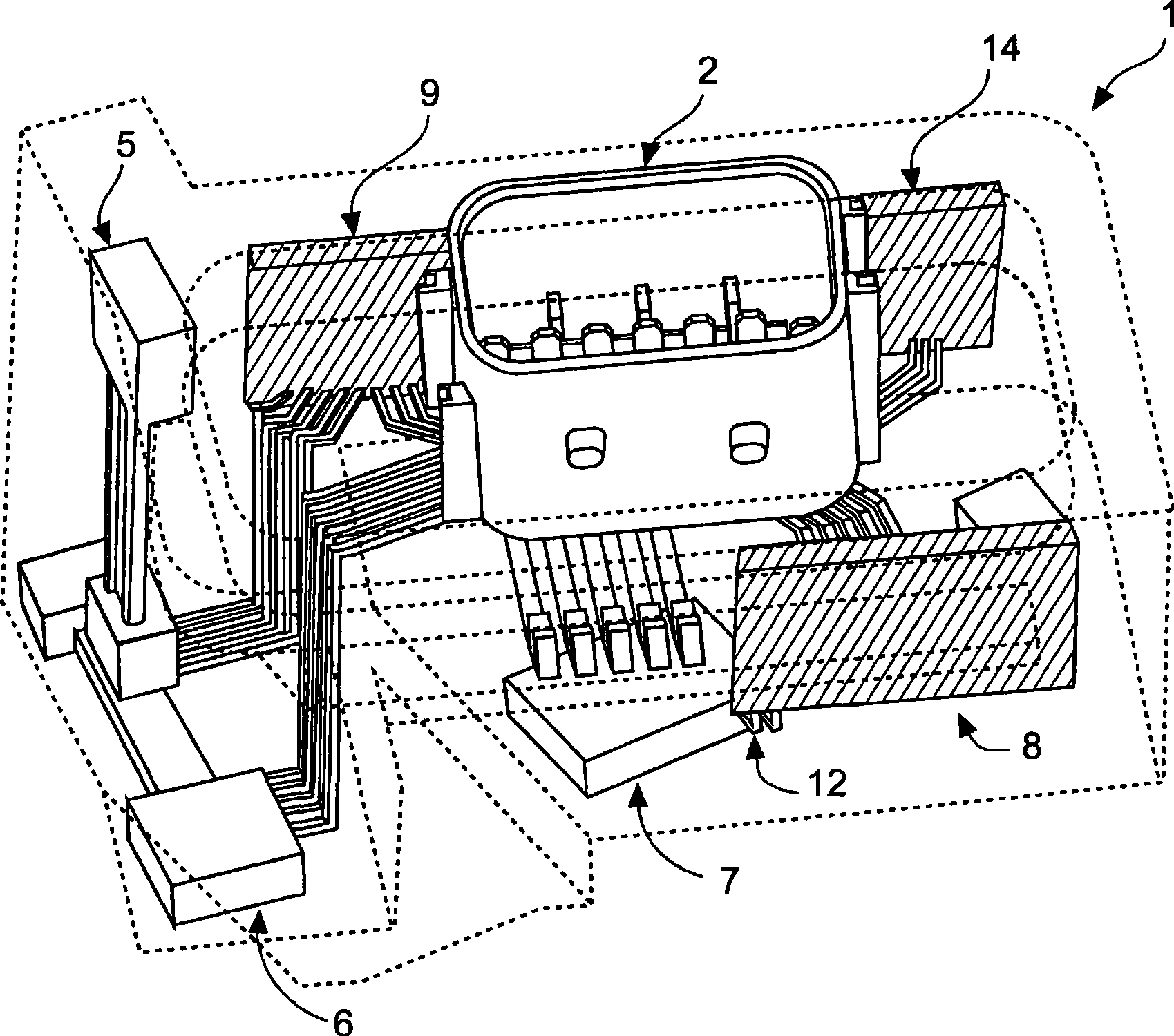

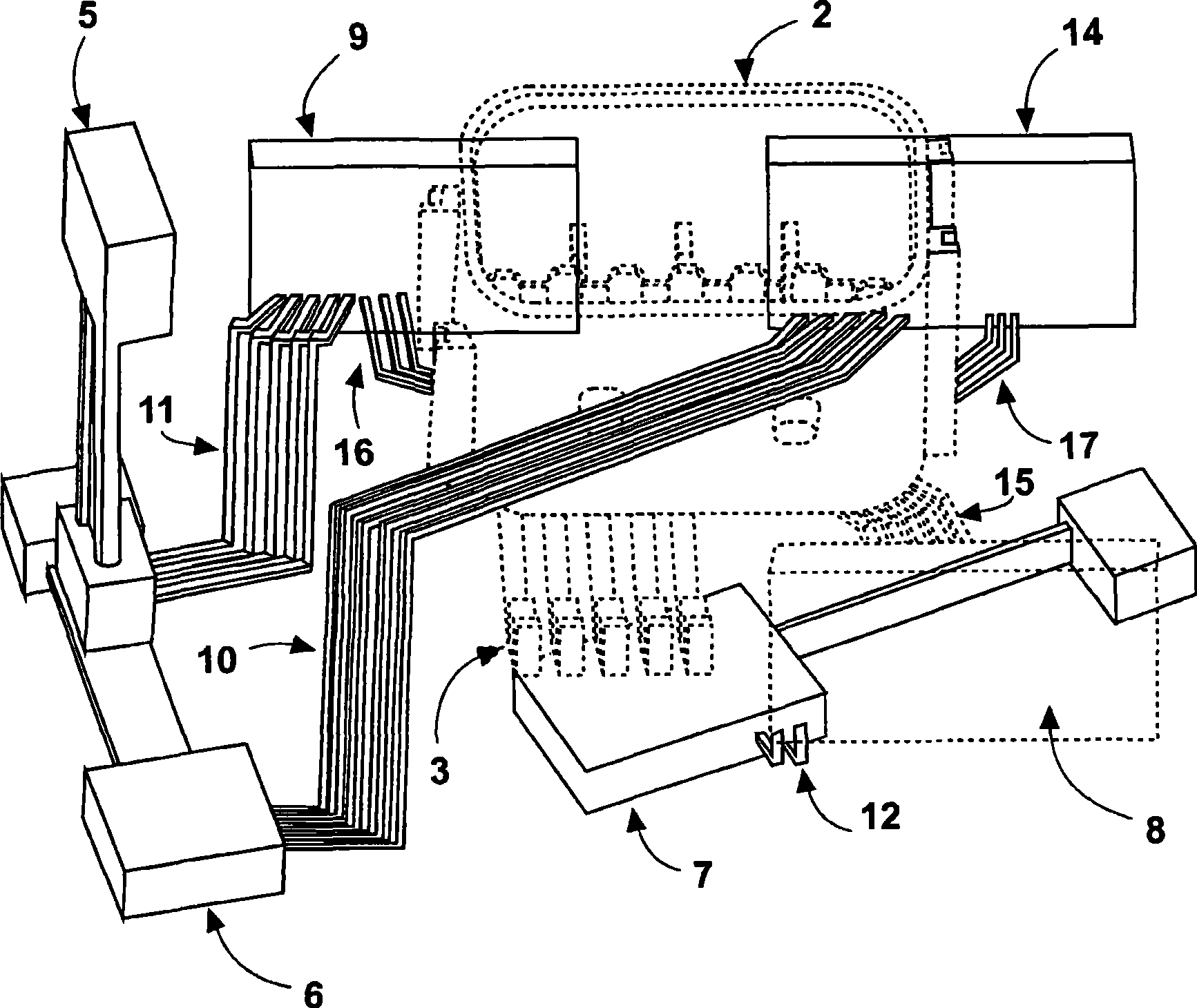

[0019] figure 1 An embodiment of a sensor module according to the invention is shown. A closed housing 4 surrounds the sensor module 1 according to the invention. The first interface 2 and the second interface 3 protrude from the housing. The first interface 2 has an inner metal contact row 13 . These contacts transmit signals of a sensor (not shown) installed in the sensor module 1 and a signal of the second interface 3 to an electronic control unit (Electronic-Control-Unit=ECU, not shown). The second interface 3 also has a row of contacts. Advantageously, the first interface 2 can be embodied as a plug-in connection according to the IP6K9K standard. Of course, other embodiments are also conceivable, as long as the interface can be coupled to the electronic control unit of the gearbox actuator. Therefore, the electronic control unit of the gearbox actuator must have an interface corresponding to the first interface 2 . In an advantageous embodiment, the electronic contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com