Projected roller plane

A flat and end face technology, applied in the direction of roller table, roller column, furnace, etc., can solve the problems of metal pivot oxidation, hindering rotation, restricting cylinder rotation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

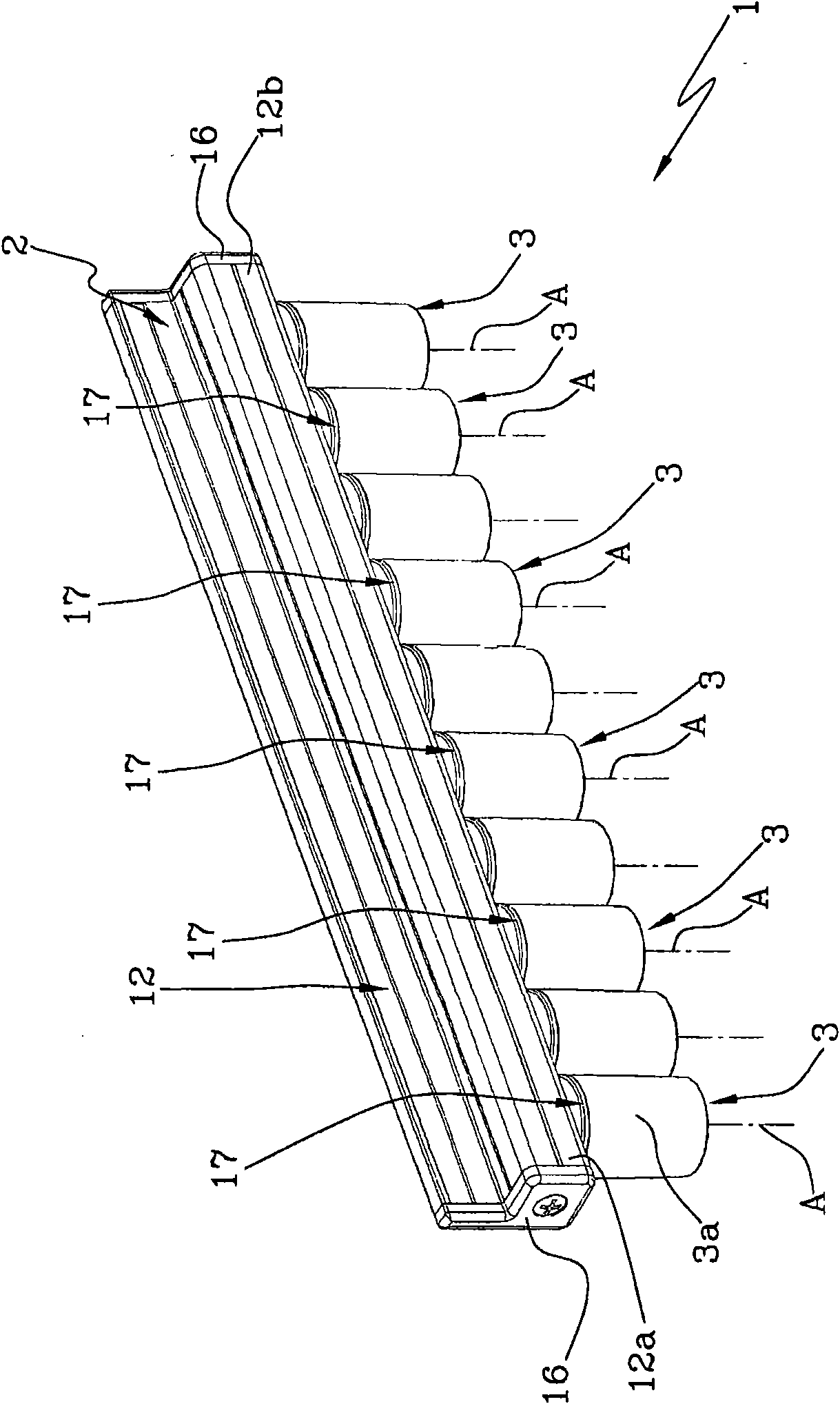

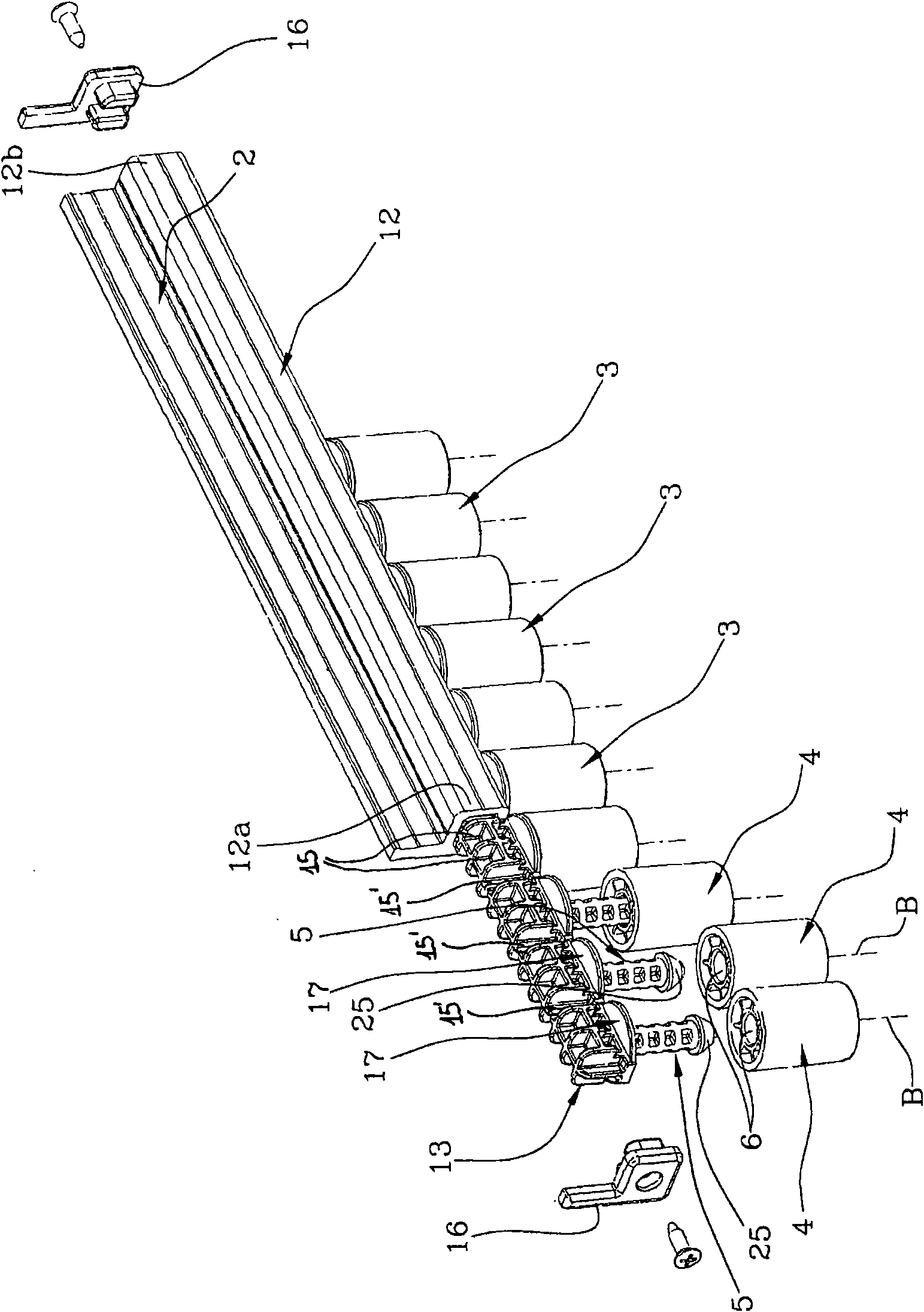

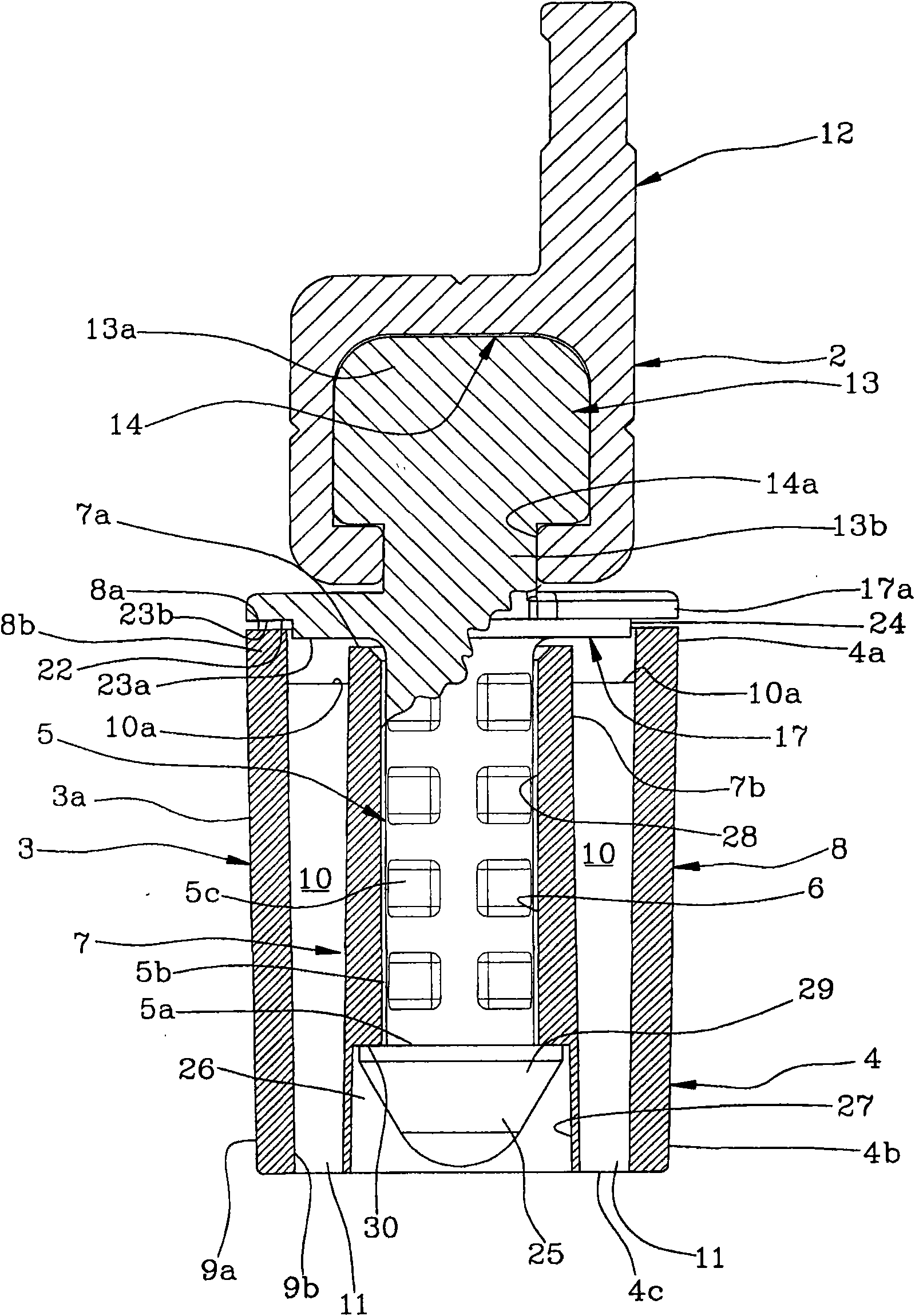

[0025] Referring to the accompanying drawings, number 1 represents the roller plane of the present invention as a whole.

[0026] The roller plane 1 comprises a support 2 and a plurality of rollers 3 which are rotatably and protrudingly associated to the support 2 .

[0027] The support 2 , which will be described in more detail herein below, is fixed in a predetermined orientation along a transport line (not shown) such that the roller plane 1 defines the edges and / or slide tracks of said article transport line.

[0028] The rollers 3 are arranged with their axes of rotation A parallel to each other.

[0029] In the described embodiment, the roller plane 1 is prearranged to be mounted such that the axis of rotation A of the roller 3 is arranged on a preferably inclined plane, while the roller 3 is inclined downward in a direction spaced from the support 2 .

[0030] More preferably, the axis of rotation A of the roller 3 is on a substantially vertical plane.

[0031] In an ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap