Method for reducing polycrystalline silicon loss in mask etching process

A polysilicon and polysilicon layer technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, semiconductor devices, etc., can solve problems such as poor charge bearing capacity and unstable electrical performance of flash memory devices, achieve good electrical performance, and reduce polysilicon loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

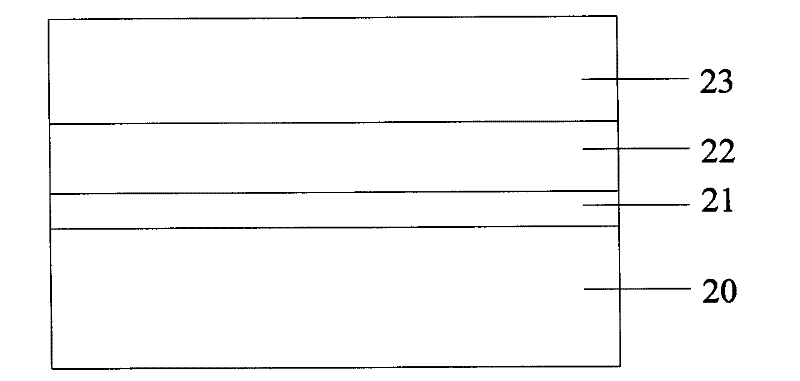

[0026] Please refer to image 3 , image 3 Shown is a flowchart of a method for reducing polysilicon loss during mask etching process according to a preferred embodiment of the present invention. The present invention proposes a method for reducing polysilicon loss in a mask etching process, which is applied to the fabrication of floating gates of flash memory devices. The method includes the following steps:

[0027] Step S100: providing a semiconductor substrate;

[0028] Step S200: forming a first insulating layer on the semiconductor substrate;

[0029] Step S300: forming a polysilicon layer on the insulating layer;

[0030] Step S400: forming a second insulating layer on the polysilicon layer;

[0031] Step S500: forming a mask layer on the second insulating layer;

[0032] Step S600: pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com