LED bubble and manufacture method of LED bubble

A technology of LED light bulbs and manufacturing methods, which is applied to components of lighting devices, damage prevention measures for lighting devices, semiconductor devices of light-emitting elements, etc., can solve problems such as high energy consumption, short service life, and low light efficiency, and achieve plug-in The connection is convenient and stable, and the effect of color change can be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be further described in detail below with reference to the accompanying drawings. The above and other objects, features and advantages of the present invention will be apparent to those skilled in the art from the detailed description of the present invention.

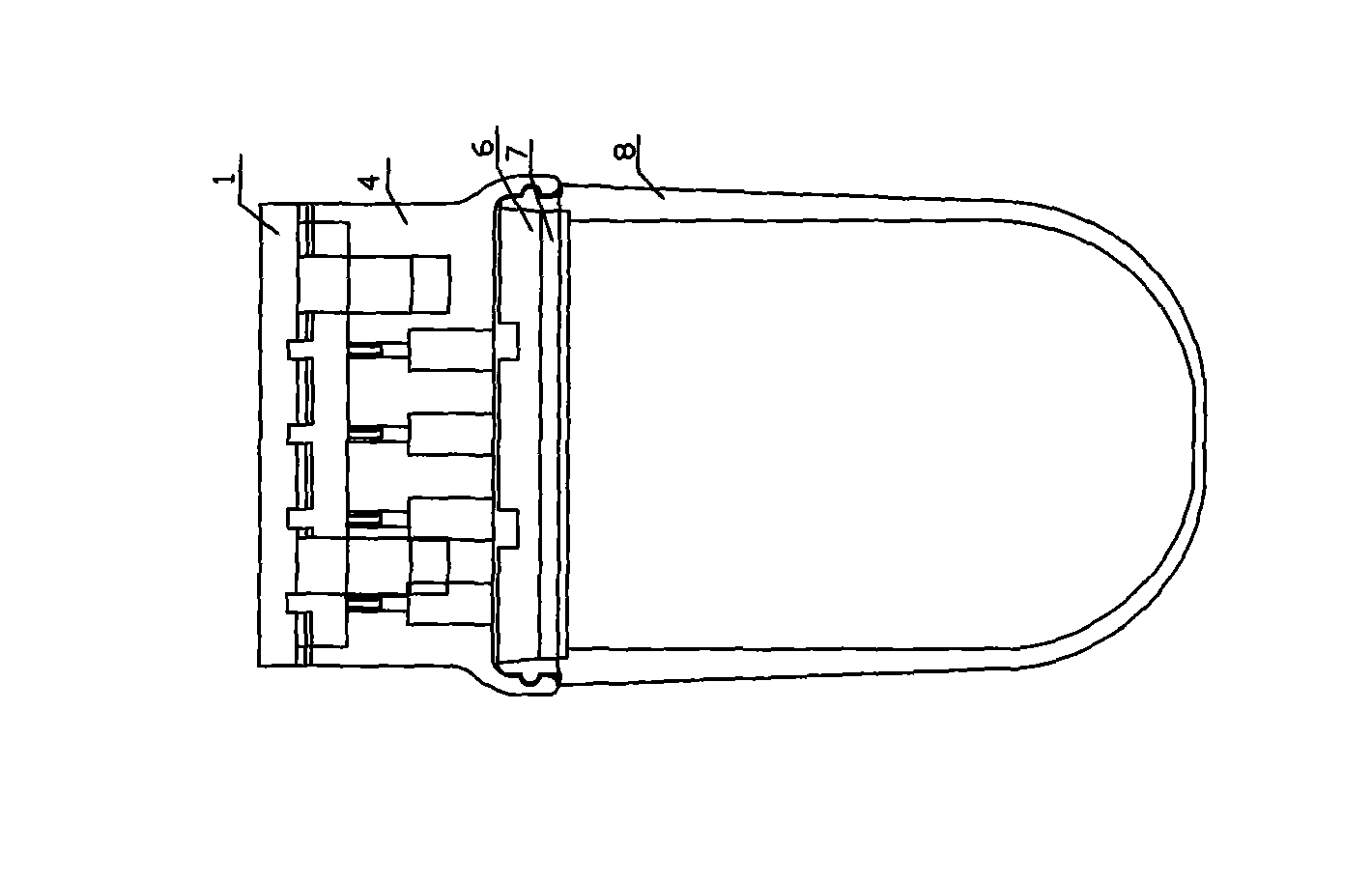

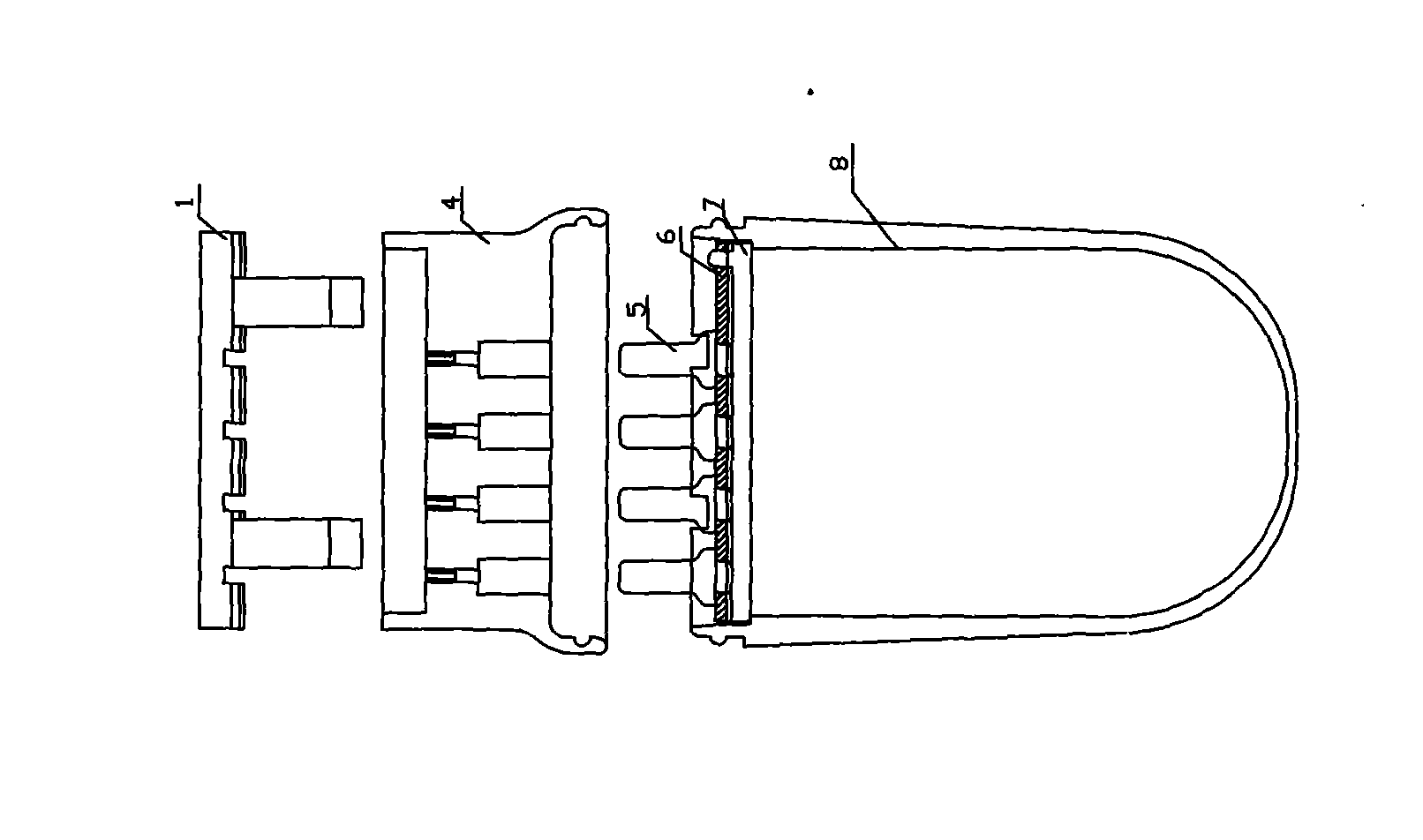

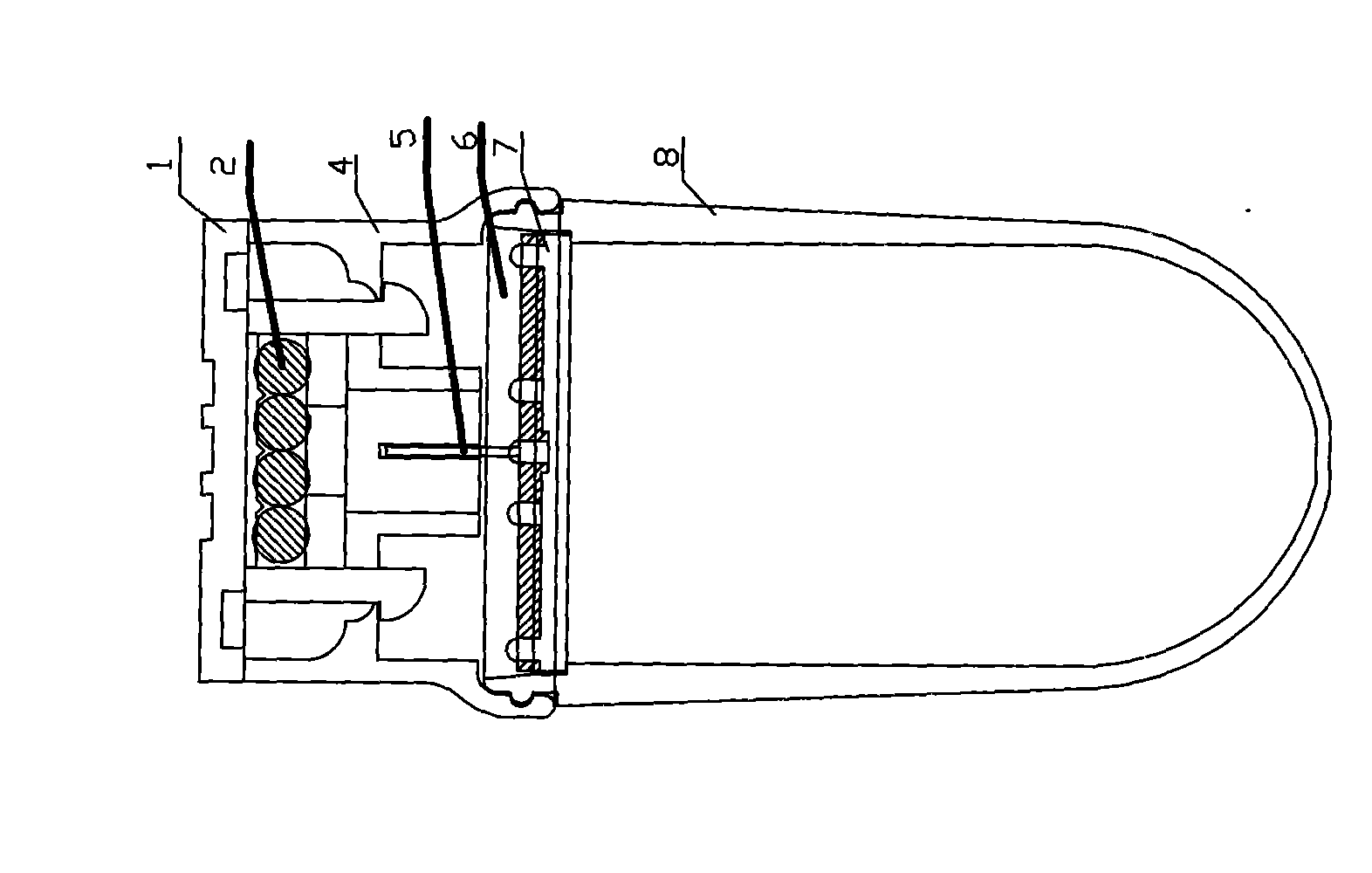

[0027] The first preferred embodiment of the present invention is as follows figure 1 , figure 2 , image 3 , Figure 4 As shown, an LED light bulb is proposed, including a lamp housing 8 and a lamp socket 4, the lamp socket 4 is connected with the lamp housing 8; the lamp housing 8 is provided with an LED chip (not shown in the figure) as a light source. The lamp housing 8 is provided with a PCB board 6, and the PCB board 6 is potted in the lamp housing 8 through silica gel; the LED chip is fixedly arranged on the PCB board 6; the LED chip The in-line electrode sheet 5 and the plug-in electrode sheet 3 are connected to the four connection contacts 2 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com