Packaging structure for miniature electric field sensor and packaging method

A technology of electric field sensor and packaging structure, which is applied in the direction of microstructure device, processing microstructure device, microstructure technology, etc. It can solve the problems of electric leakage, shielding, and inability to measure, so as to achieve the effect of enhancing reliability and meeting application requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings.

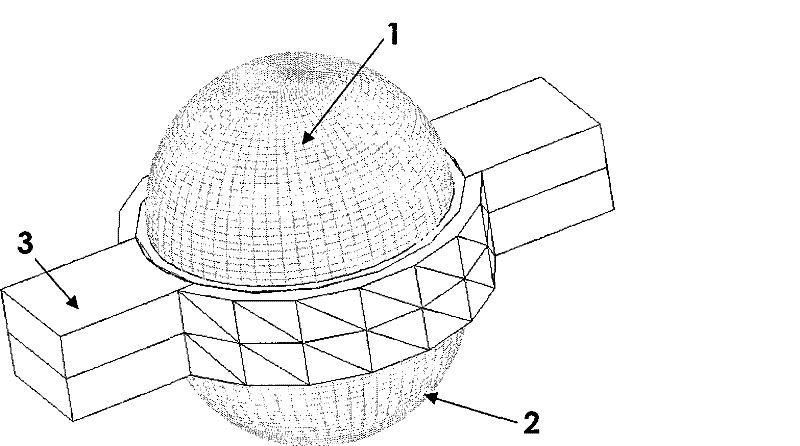

[0022] See figure 1 , the overall schematic diagram of the packaging structure of the miniature electric field sensor described in the present invention, figure 1 It is a three-dimensional view of the sensor package structure. this invention figure 1 The micro-electric field sensor packaging structure mainly includes: a first detection unit 1, a second detection unit 2 and two packaging support structures 3, and the first detection unit 1 and the second detection unit 2 are symmetrically placed between the two packaging support structures 3 inside, and fixedly connected with the packaging support structure 3 .

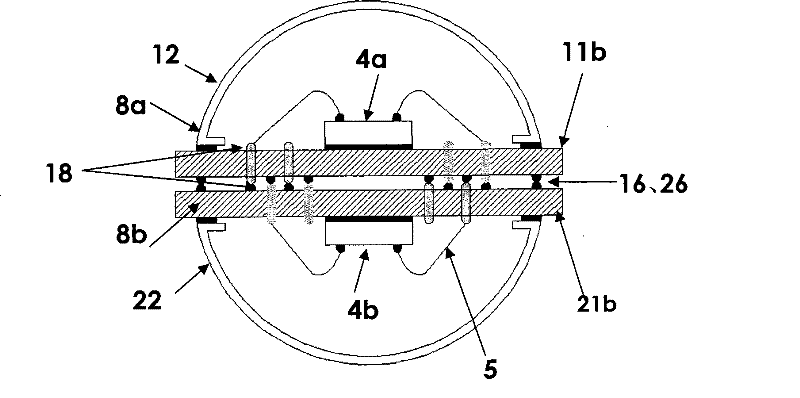

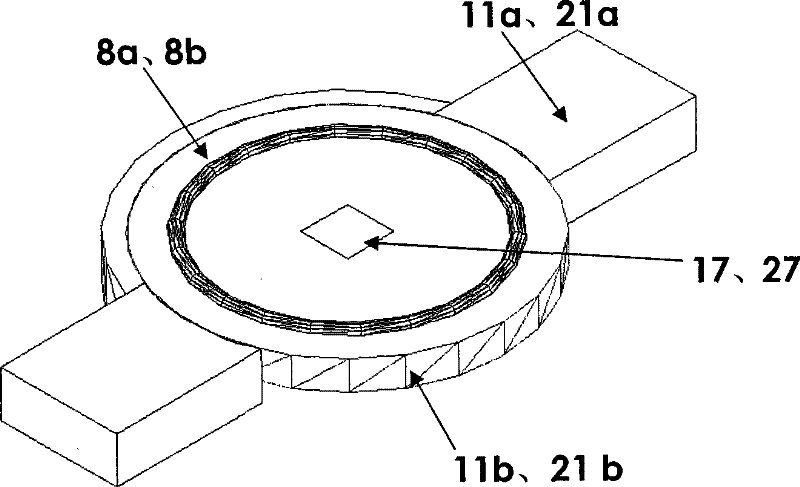

[0023] See figure 2 , showing the schematic structure of the first detection unit 1 and the second detection unit 2 and Figure 3A ,in:

[0024] The first detection unit 1 mainly includes a first sensor chip 4a, a first O-ring 8a, a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com