Aluminum box packing machine

A packaging machine and aluminum box technology, applied in packaging, transportation packaging, packaging protection, etc., can solve the problems of inability to meet the filling and sealing of aluminum boxes, and the inability to install heating devices on container conveyor belts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

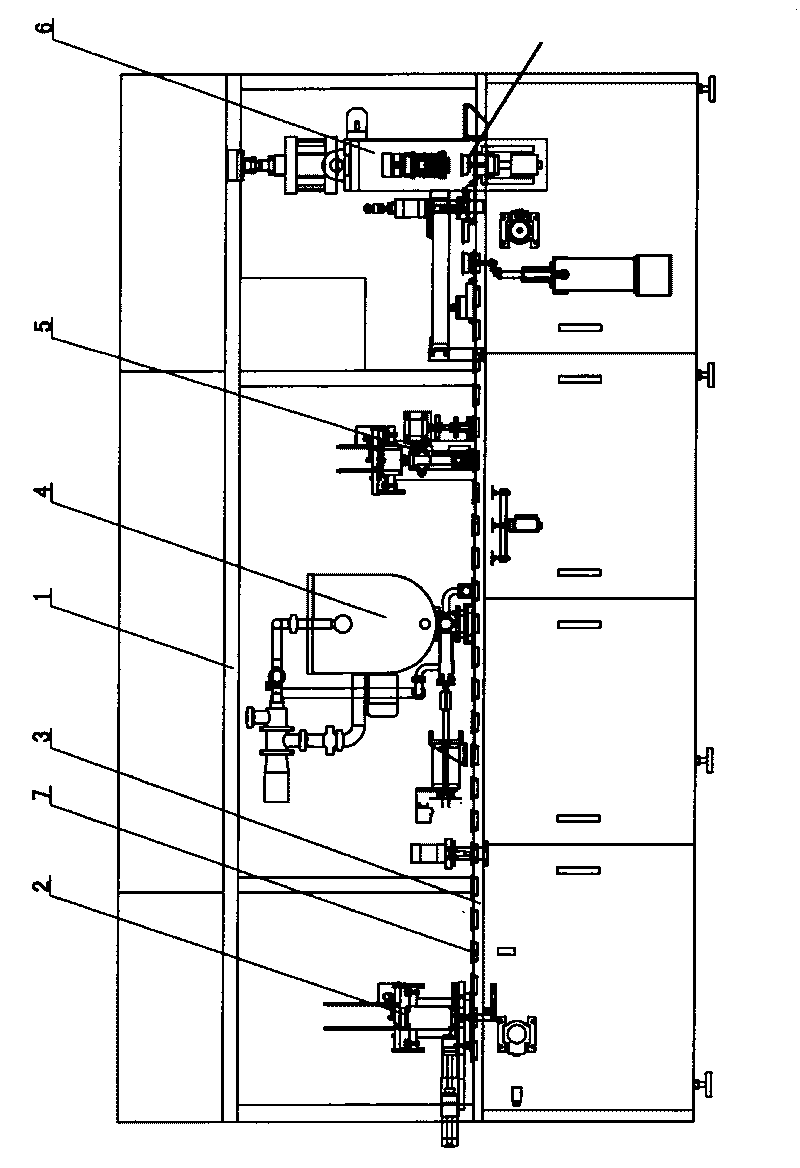

[0031] Such asfigure 1 As shown, this aluminum box packaging machine includes a frame 1 and a container conveyor belt 3, along which an aluminum box supply device 2, a filling device 4, a parafilm placement device 5 and a sealing device 6 are arranged in sequence.

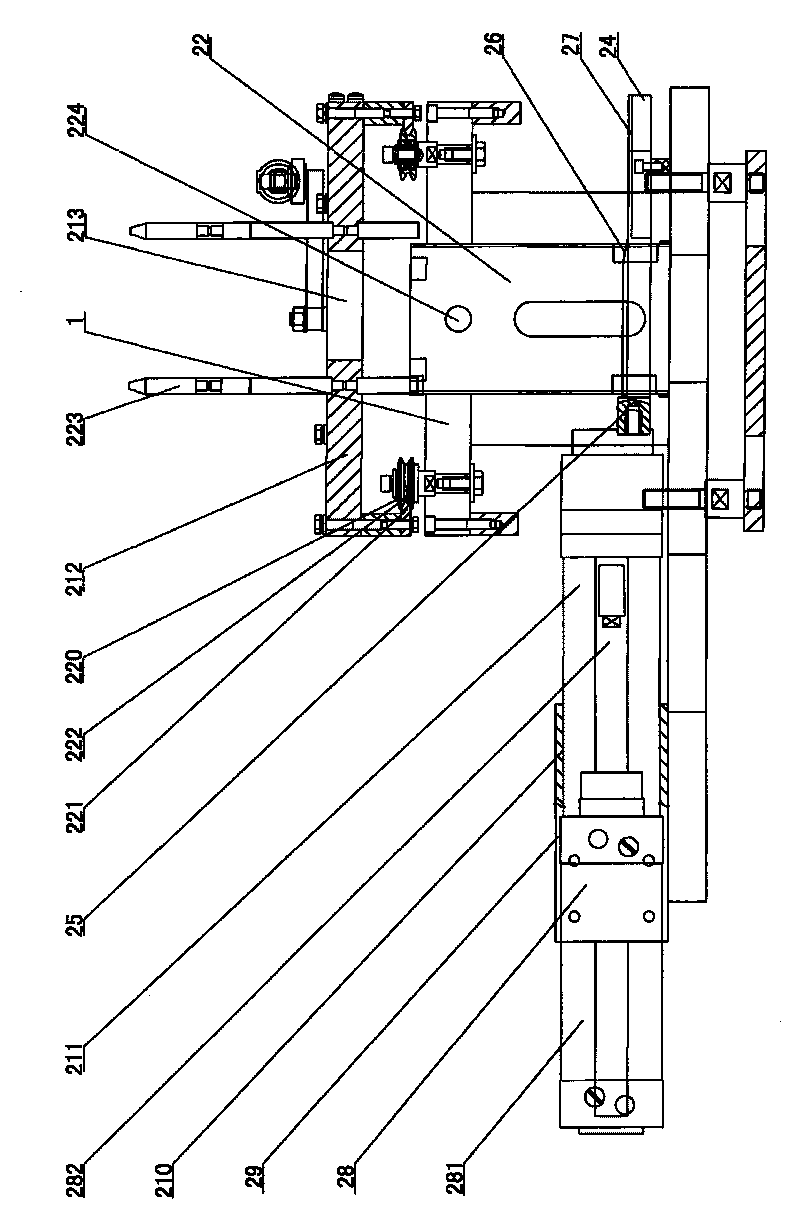

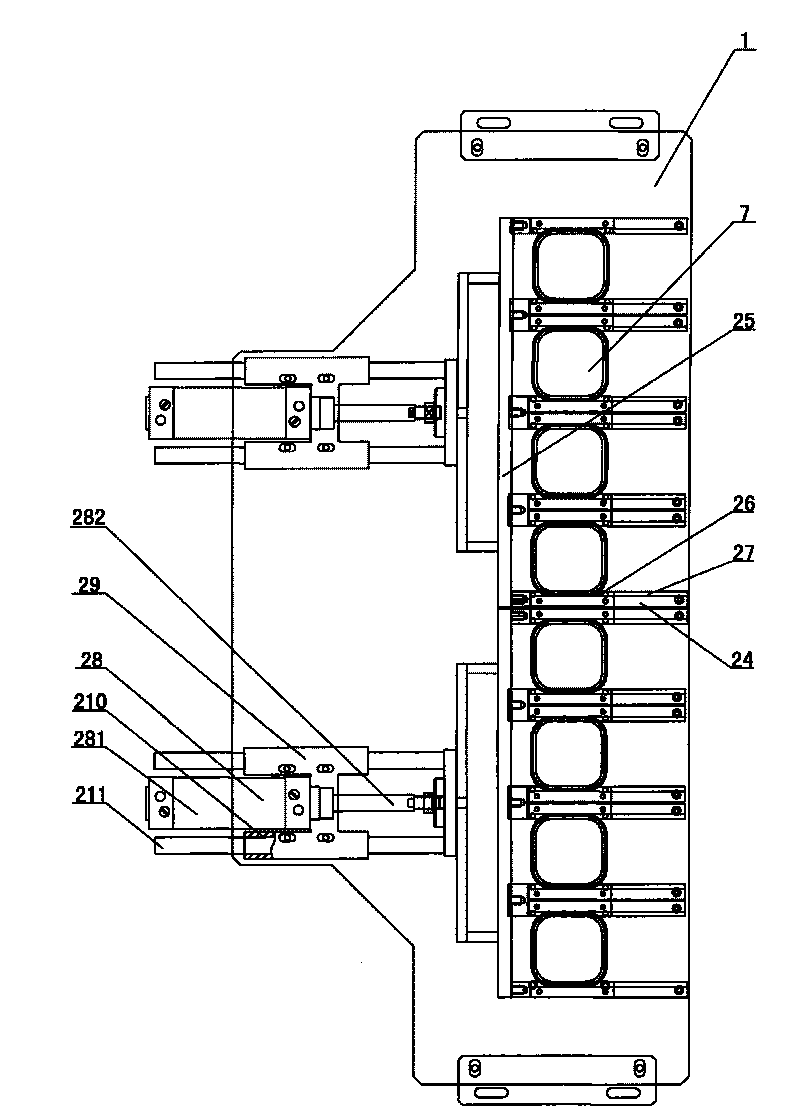

[0032] Such as Figure 2-5 As shown, this aluminum box supply device includes an aluminum box accommodating groove 22, a box dividing mechanism and an aluminum box adding device.

[0033] The aluminum box accommodating groove 22 is used for placing stacked aluminum boxes 7 .

[0034] The box-separating mechanism includes a box-separating fork and a box-separating fork driving mechanism for driving the box-separating fork to reciprocate.

[0035] The box-dividing fork is arranged below the aluminum box accommodating groove 22, and the box-dividing fork comprises two box-dividing bars 24 and a connecting rod 25 (in this embodiment, each box-dividing fork shares a connecting bar 25), and the two box-dividing bars 24 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com