Arc-shaped steel spring plate vibration isolation support of friction pendulum

A technology of spring steel plate and seismic isolation bearing, which is applied in the direction of earthquake resistance, bridge parts, building components, etc., can solve the need of difficult to ensure large displacement of upper and lower structures, rigidity and damping characteristics cannot be changed, and the vertical bearing capacity of rubber bearings Low and other problems, to achieve the effect of clear seismic isolation mechanism, obvious seismic performance, and large vertical bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

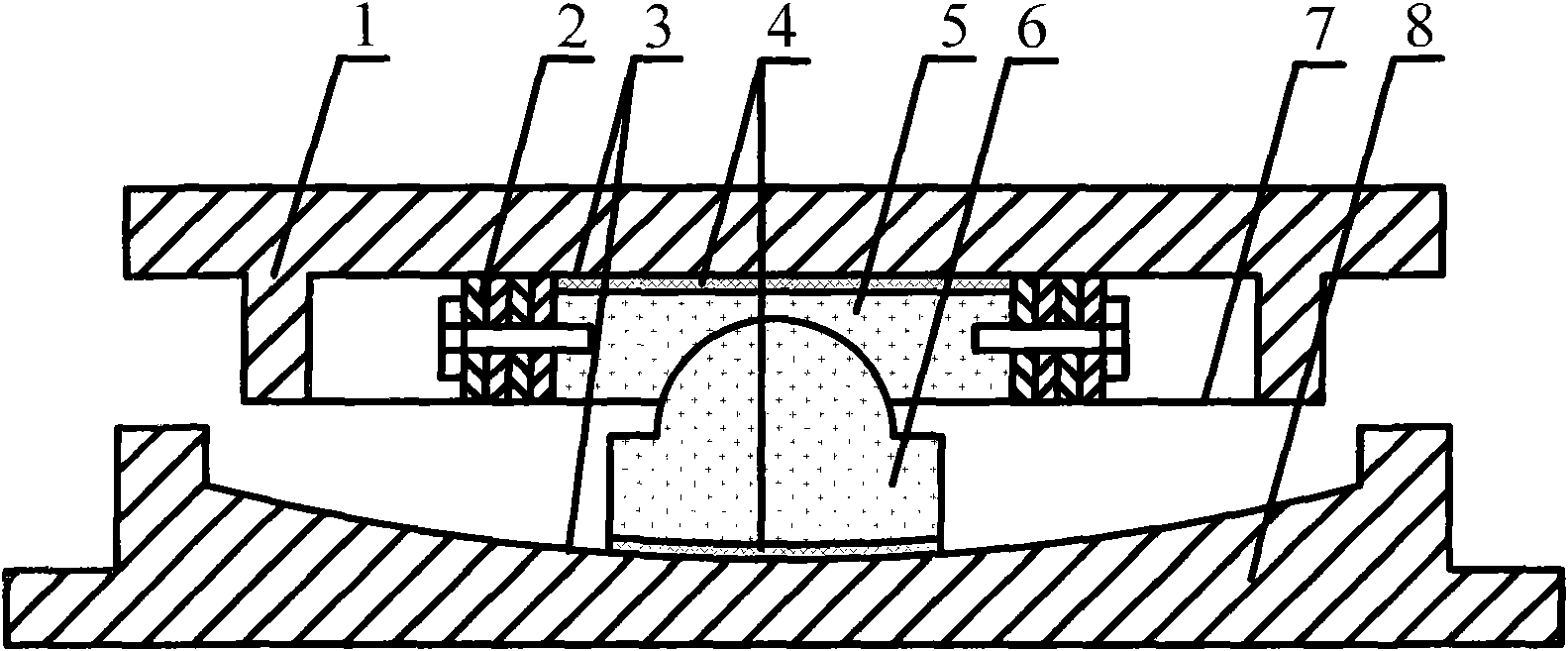

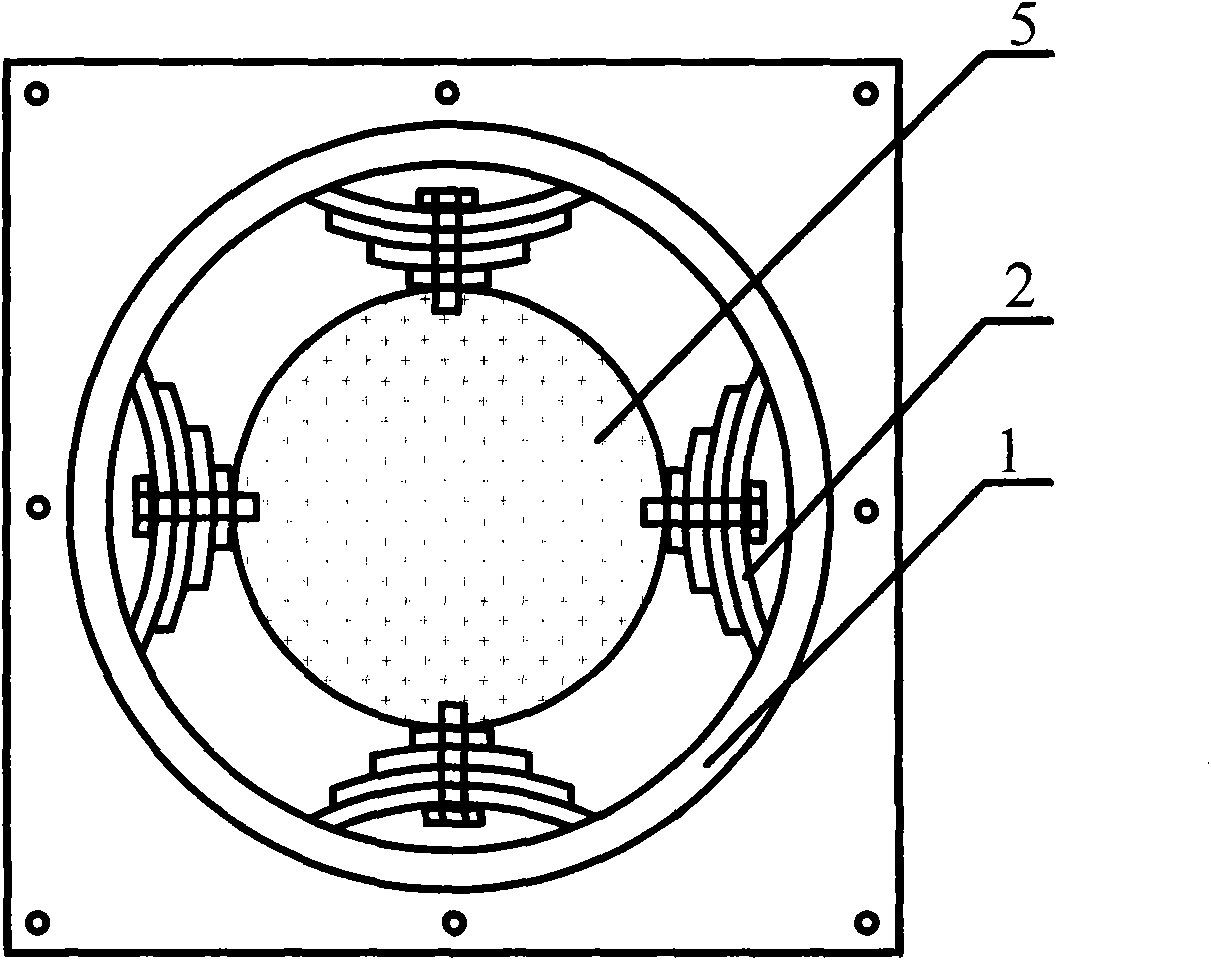

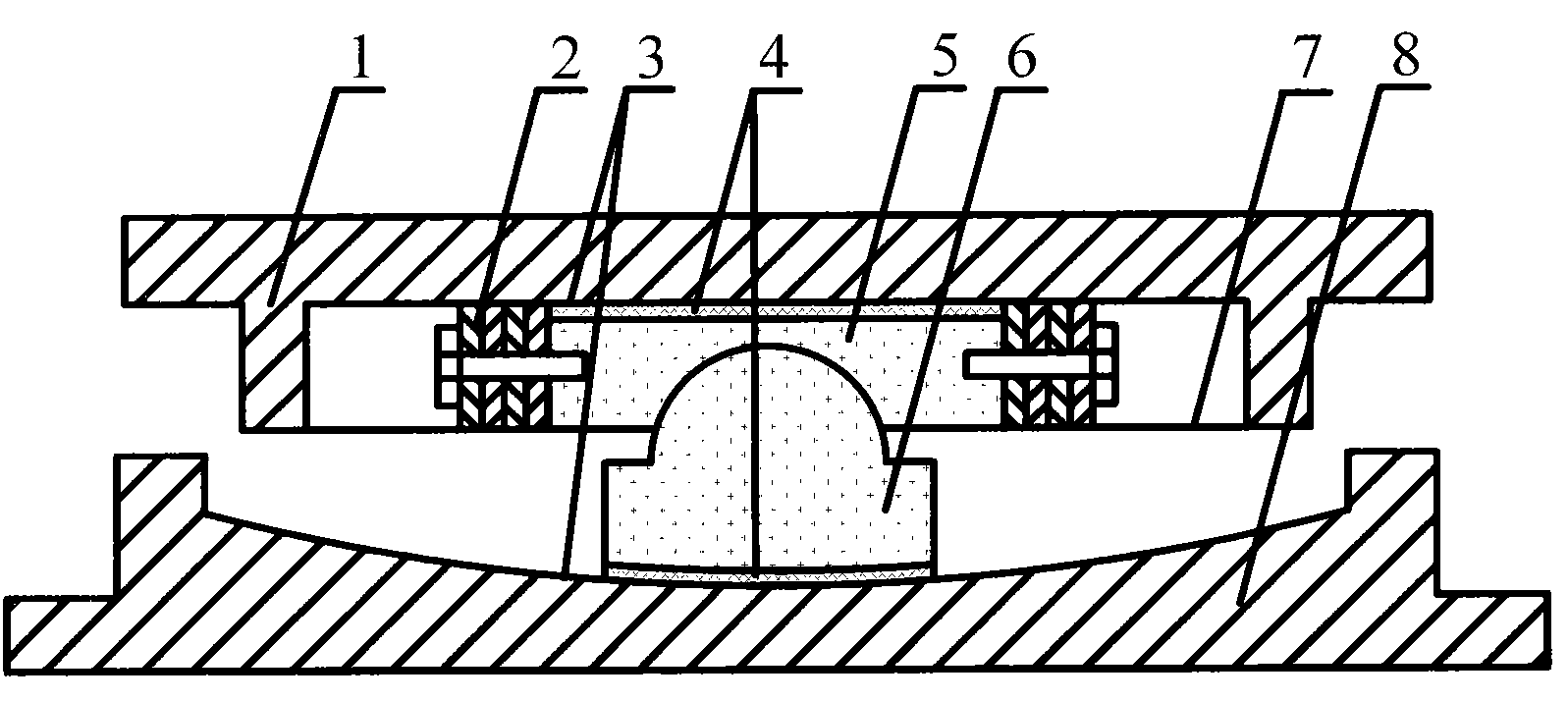

[0017] Friction pendulum bow type spring steel plate vibration isolation support is based on the ordinary spherical support, adding a cylindrical upper slider and a cylindrical double-convex spherical lower slider. The inner wall of the upper bearing plate is fixed with the cylinder A new type of composite shock-absorbing and isolating bearing composed of bow-shaped spring steel plates and other elastic components connected by sliders. It is mainly used for buildings, bridges, aqueducts and other large structures that require high seismic performance.

[0018] figure 1 It is a schematic diagram of the structure of the friction pendulum bow type spring steel plate vibration isolation bearing. Such as figure 1 and figure 2 As shown, the friction pendulum bow type spring steel plate vibration isolation bearing is composed of an upper bearing plate 1, a cylindrical upper slider 5, a cylindrical double-convex spherical lower slider 6 and a lower bearing plate 8, and the lower pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com