Method of horizontally multistage indirect evaporation cooling refrigeration

An evaporative cooling and stage evaporation technology, applied in the energy field, can solve the problems of uneven and inconsistent outlet water temperature, large mixed water loss, etc., and achieve the effects of saving power transmission and distribution, wide application occasions, and reduced device height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

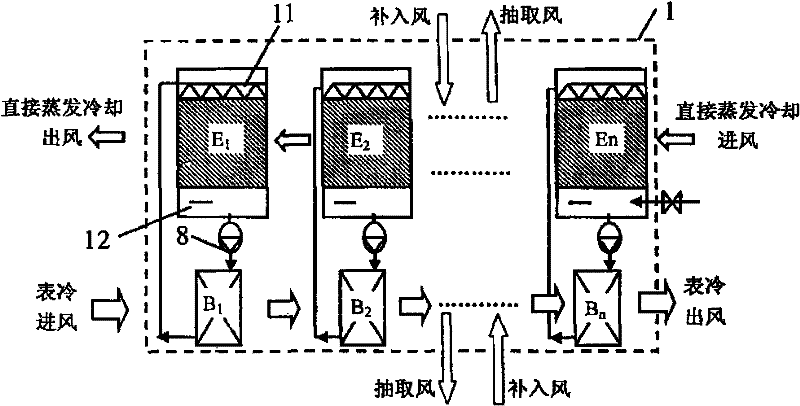

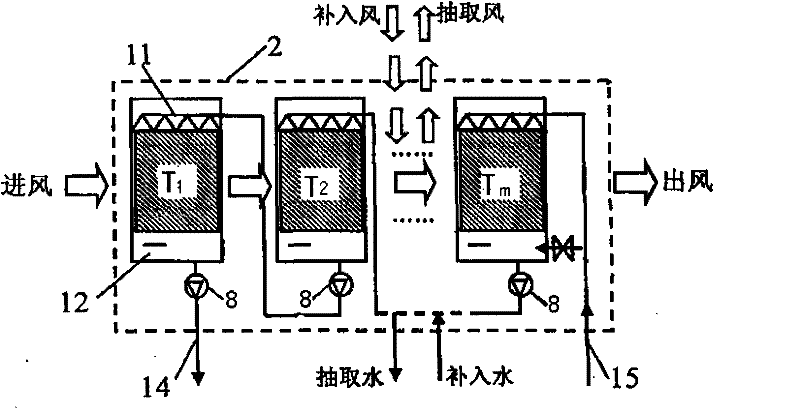

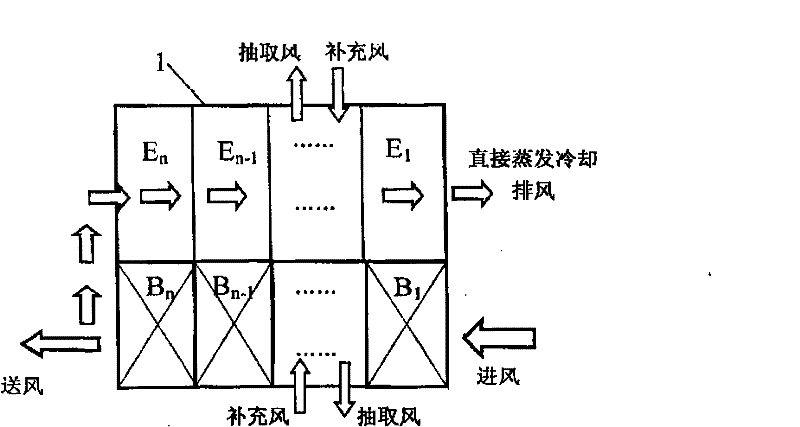

[0040] The invention provides a horizontal multi-stage indirect evaporative cooling refrigeration method. The present invention will be described below in conjunction with the accompanying drawings.

[0041] The basic unit of multi-stage indirect evaporative cooling heat recovery refrigeration1 (such as figure 1 shown), by n-stage direct evaporative cooling module E 1 ~E n and n-stage surface cooler B 1 ~B n constitute. The air intake on the side of the surface cooler is from the first stage of the surface cooler B 1 Countercurrent enters and passes through surface cooler B in turn 1 ~B n Cooled by isohumidity. Direct Evaporative Cooling Module E 1 ~E n All stages and surface cooler B 1 ~B n Each stage is connected by water pump 8 one by one, and the cold water prepared by the direct evaporative cooling module of each stage is input into the air outlet side of the corresponding surface cooler under the action of water pump 8. After cooling the air inlet of the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com