Hydrogenation method for producing high-quality low-sulfur diesel fraction

A low-sulfur diesel and fraction technology is applied in the field of hydrogenation for producing high-quality low-sulfur diesel fractions, which can solve problems such as lack of diesel raw materials, and achieve the effects of low investment and operating costs, simple device flow, and reduced loading volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

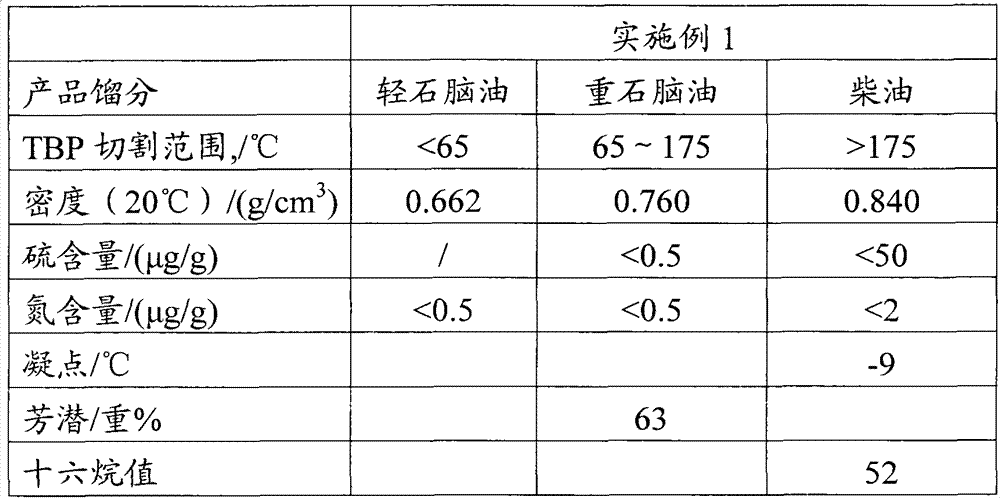

Embodiment 1

[0047] The feedstock I in this embodiment is a mixed feedstock oil H of low-quality straight-run diesel with high aromatics and naphthenic content and MIP diesel fuel, and the raw material II is a straight-run diesel with low sulfur and nitrogen content and good properties. P, the properties of the two feedstock oils are shown in Table 1.

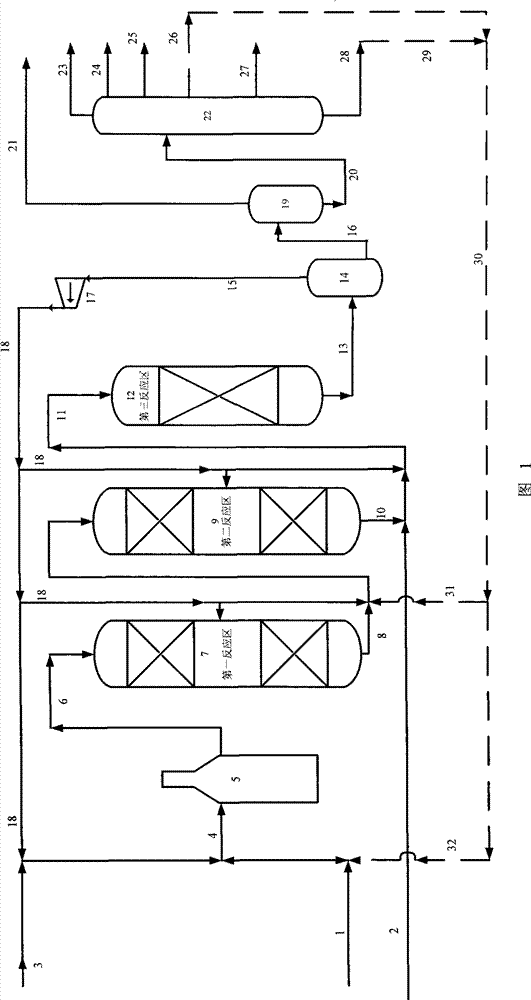

[0048] The feedstock oil H, which accounts for 68.2% by weight of the total feed, is mixed with hydrogen or hydrogen-rich gas, enters the first reaction zone after being preheated by the heating furnace, and sequentially contacts and reacts with the protective agent E and the hydrorefining catalyst A. The first reaction The zone effluent directly enters the second reaction zone without any intermediate separation, and continues to contact and react with the hydrocracking catalyst C. After the raw material oil P, which accounts for 31.8% by weight of the total feed, is mixed with part of the hydrogen-rich gas, it is preheated by the heating fur...

Embodiment 2

[0051] The feedstock I in this embodiment is a mixture of coker diesel from naphthenic crude oil, catalytic diesel and a light wax oil to form feedstock oil J. Feedstock II is a feedstock with a lower nitrogen content and a lighter distillation range. Naphthenic crude oil is straight-run diesel K. The properties of the two feedstock oils are shown in Table 1.

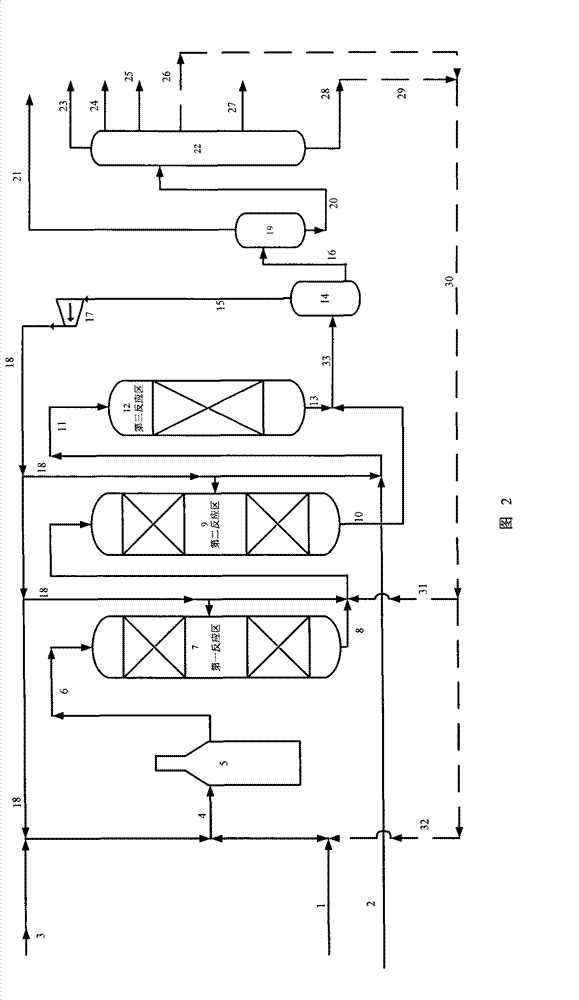

[0052] The feedstock oil J, which accounts for 70% by weight of the total feed, is mixed with hydrogen or hydrogen-rich gas, enters the first reaction zone after being preheated by the heating furnace, and sequentially contacts and reacts with the protective agent E and the hydrorefining catalyst A. The first reaction The zone effluent directly enters the second reaction zone without any intermediate separation, and continues to contact and react with the hydrocracking catalyst C. After mixing the feedstock oil K, which accounts for 30% by weight of the total feed, and part of the hydrogen-rich gas, after being preheated b...

Embodiment 3

[0055] The feedstock I of this embodiment is made by mixing two inferior catalytic cracked diesel oils and a normal three minus one light wax oil to form feedstock oil L, where light wax oil accounts for 49% by weight of the mixed feedstock L, and feedstock II is a nitrogen-containing For low-volume straight-run diesel M, the properties of the two feedstock oils are shown in Table 1.

[0056] The feedstock oil L, which accounts for 80% by weight of the total feed, is mixed with hydrogen or hydrogen-rich gas, enters the first reaction zone after being preheated by the heating furnace, and sequentially contacts and reacts with the protective agent E and the hydrorefining catalyst B. The first reaction The zone effluent directly enters the second reaction zone without any intermediate separation, and continues to contact and react with the hydrocracking catalyst D. After mixing the feedstock oil M, which accounts for 20% by weight of the total feed, and part of the hydrogen-rich gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dry point | aaaaa | aaaaa |

| dry point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com