Closure of dispenser for determined dosage of powder

A technology of a dispenser and a dispensing device, which is applied in the direction of powder material distribution, etc., can solve the problems of lack of portability and convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

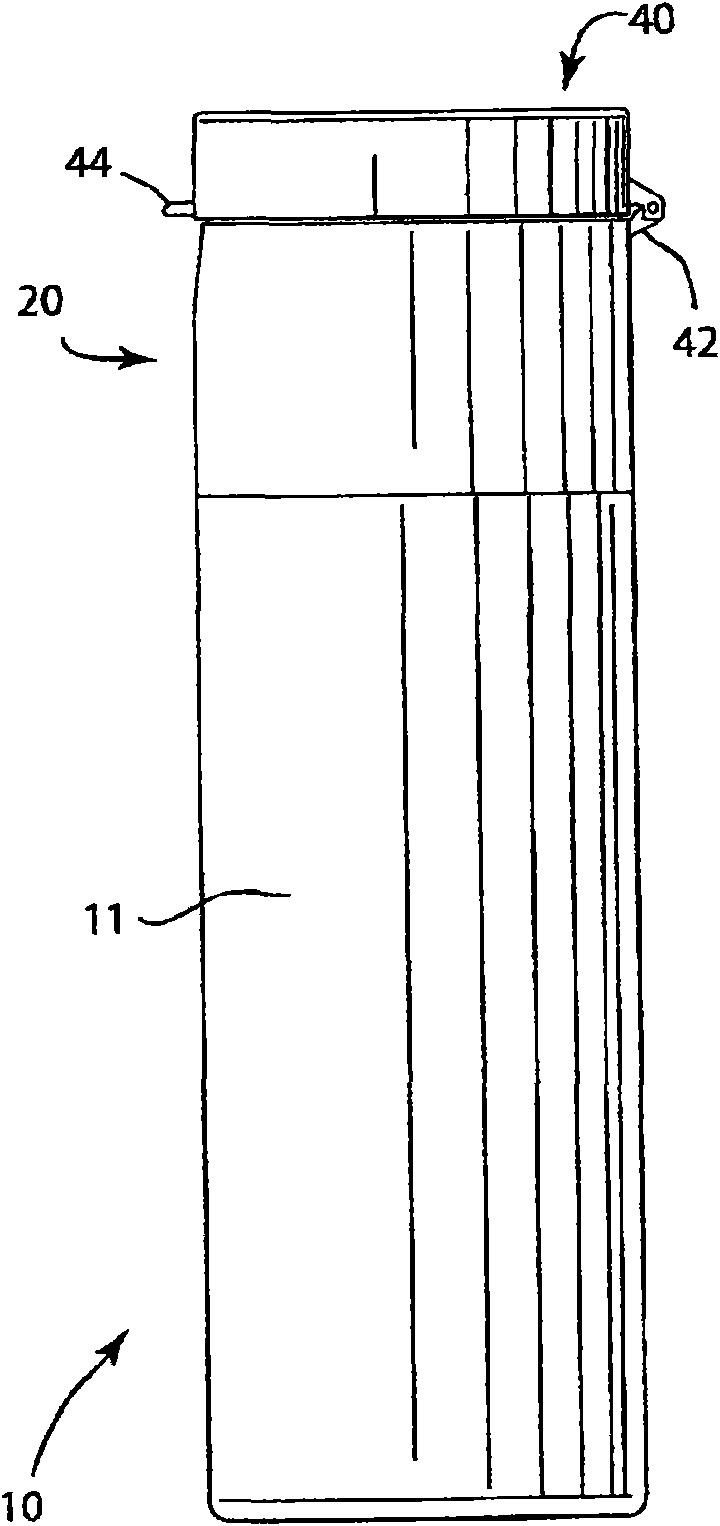

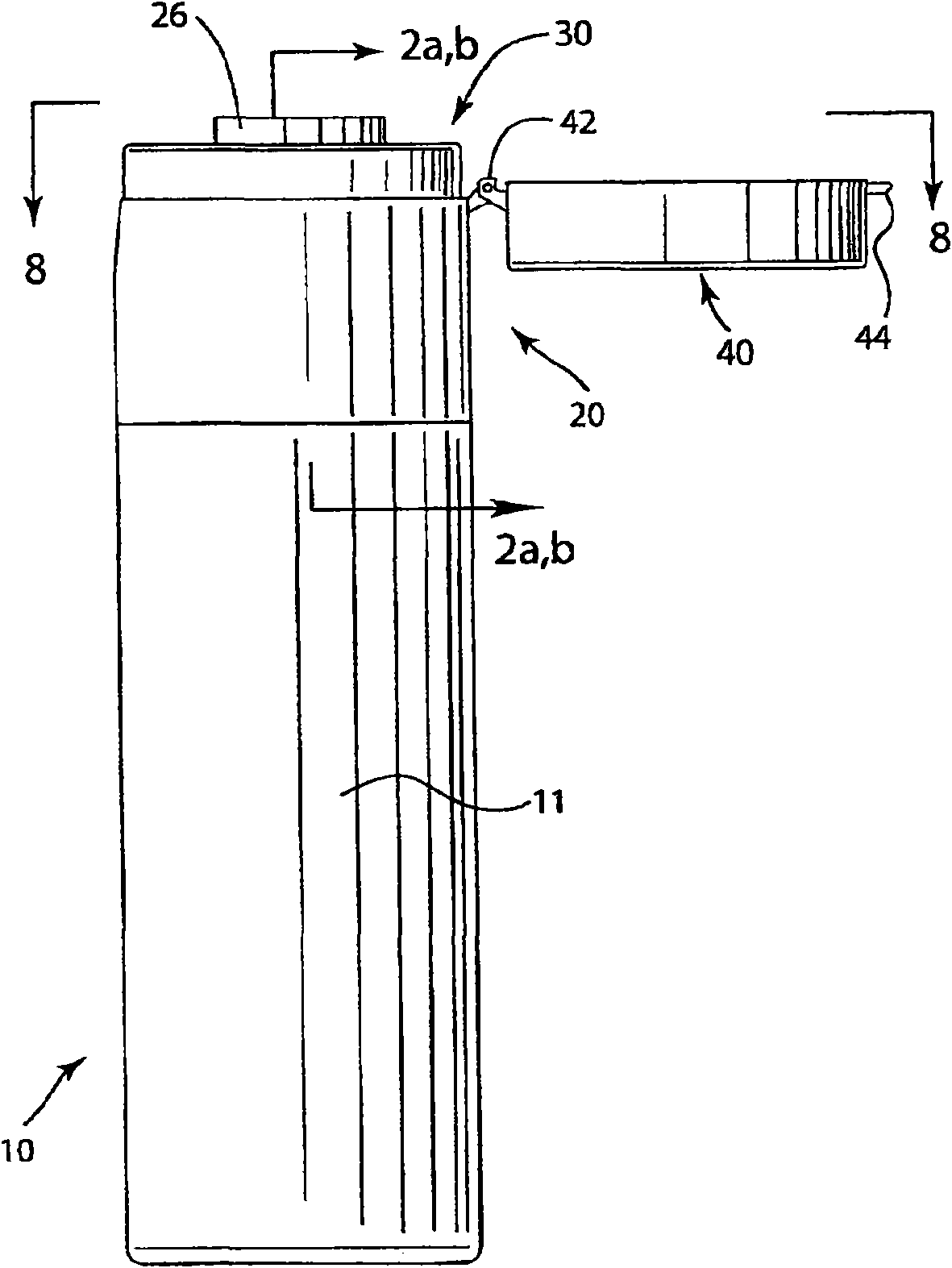

[0031] Now refer to views, in particular Figure 1a and Figure 1b , the container 10 includes a container body 11 , a closure 20 and a cap 40 . Cap 40 is pivotally connected to closure 20 by hinge 42 . Such as Figure 1bAs shown, a tab 44 is provided on the cap 40 which allows a user to easily grip the cap 40 to remove the cap 40 from the top of the closure 20 . Cap 40 preferably provides a primary moisture-tight seal to the contents of container 10 .

[0032] Advantageously, container 10 has a height of 1 to 10 inches and a diameter of 1 to 4 inches. In alternative configurations, if the container is not in cylindrical configuration, the width and depth of the container are in the range of 1 to 4 inches.

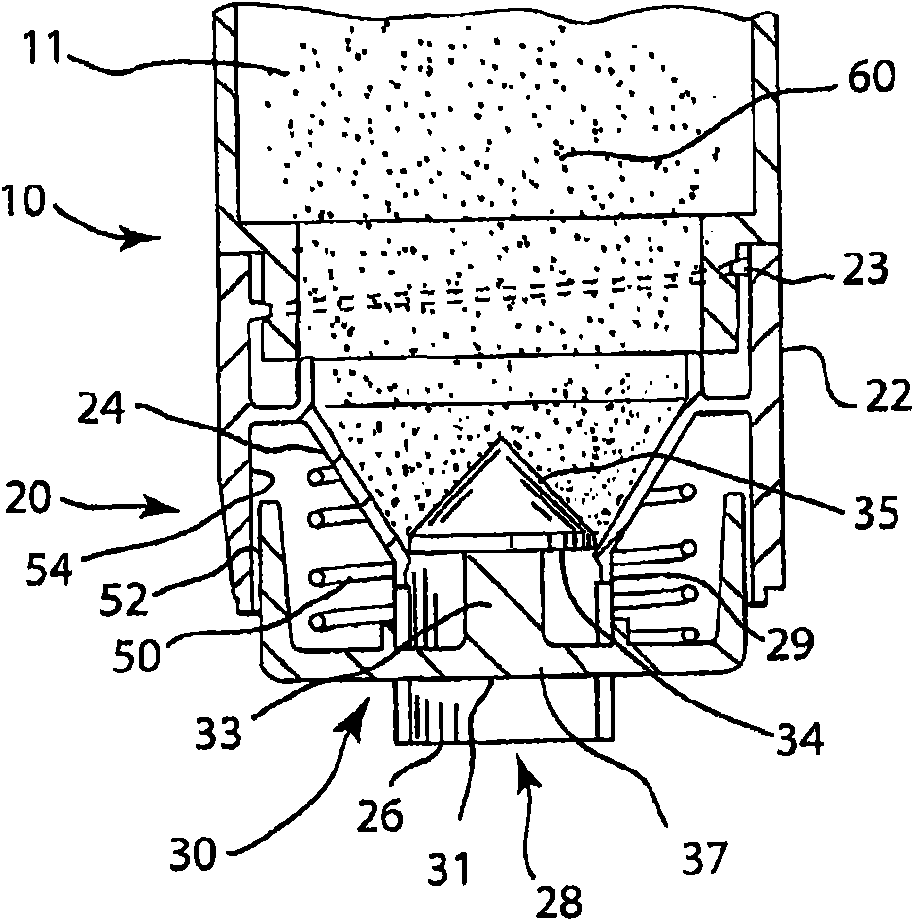

[0033] Referring now to Figure 2 to Figure 5 , closure 20 includes a bottom 22 that includes threads 23 that engage complementary threads (not shown) at the top of container body 11 . The bottom 22 has an inclined or conical wall 24 which leads to a nozzle 26 having...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com