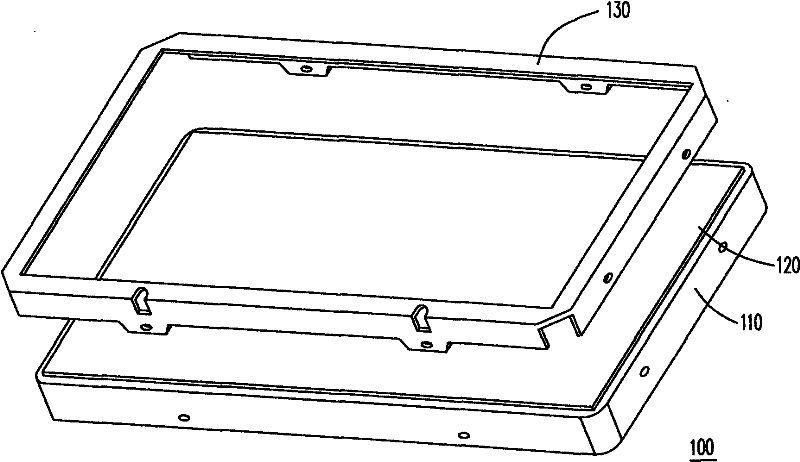

Liquid crystal display module and assembly method thereof

A technology of liquid crystal display module and assembly method, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of complicated assembly steps and high assembly cost, and achieve the effects of reducing assembly cost, increasing assembly yield, and simplifying assembly steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail together with the accompanying drawings.

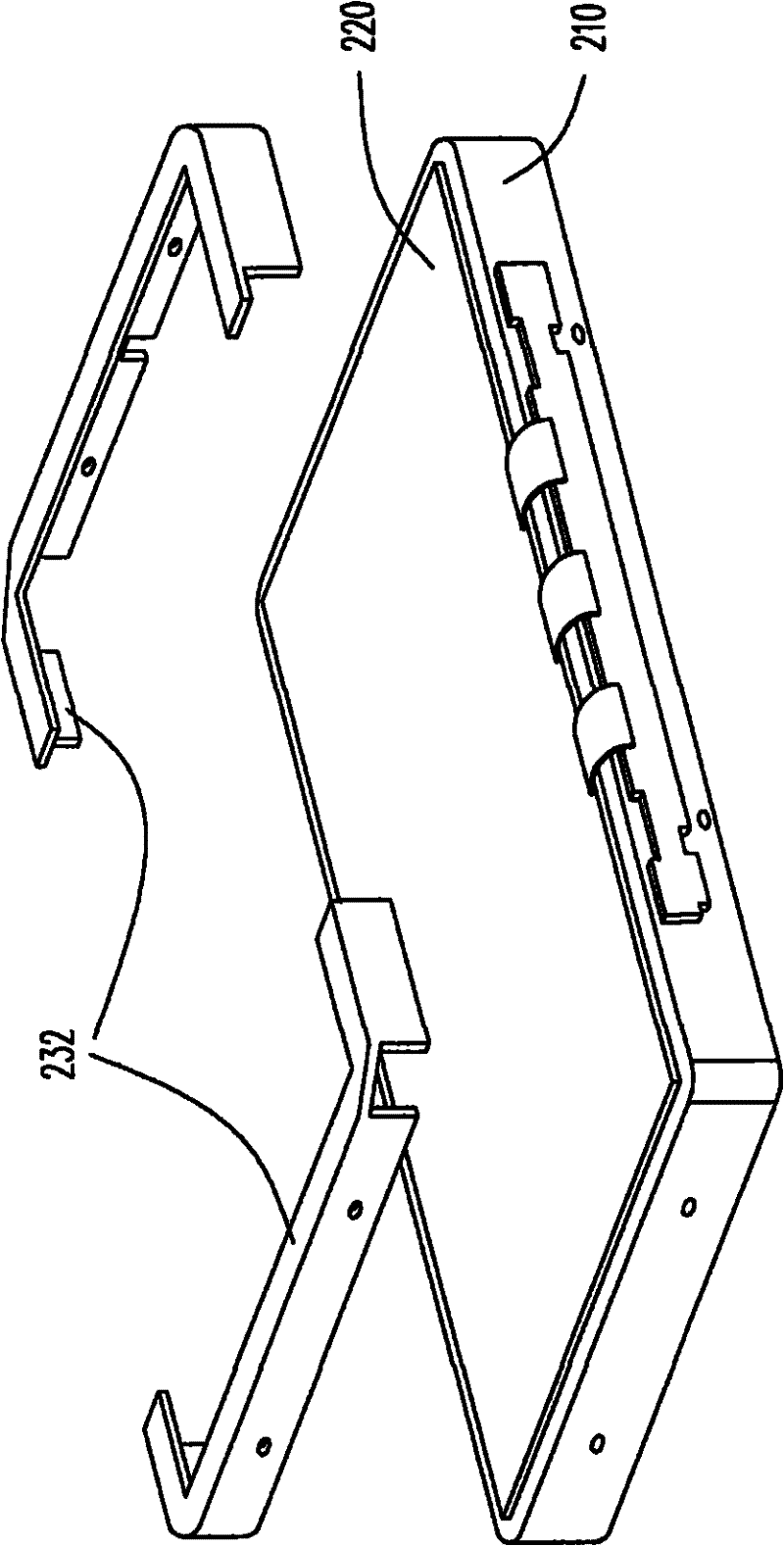

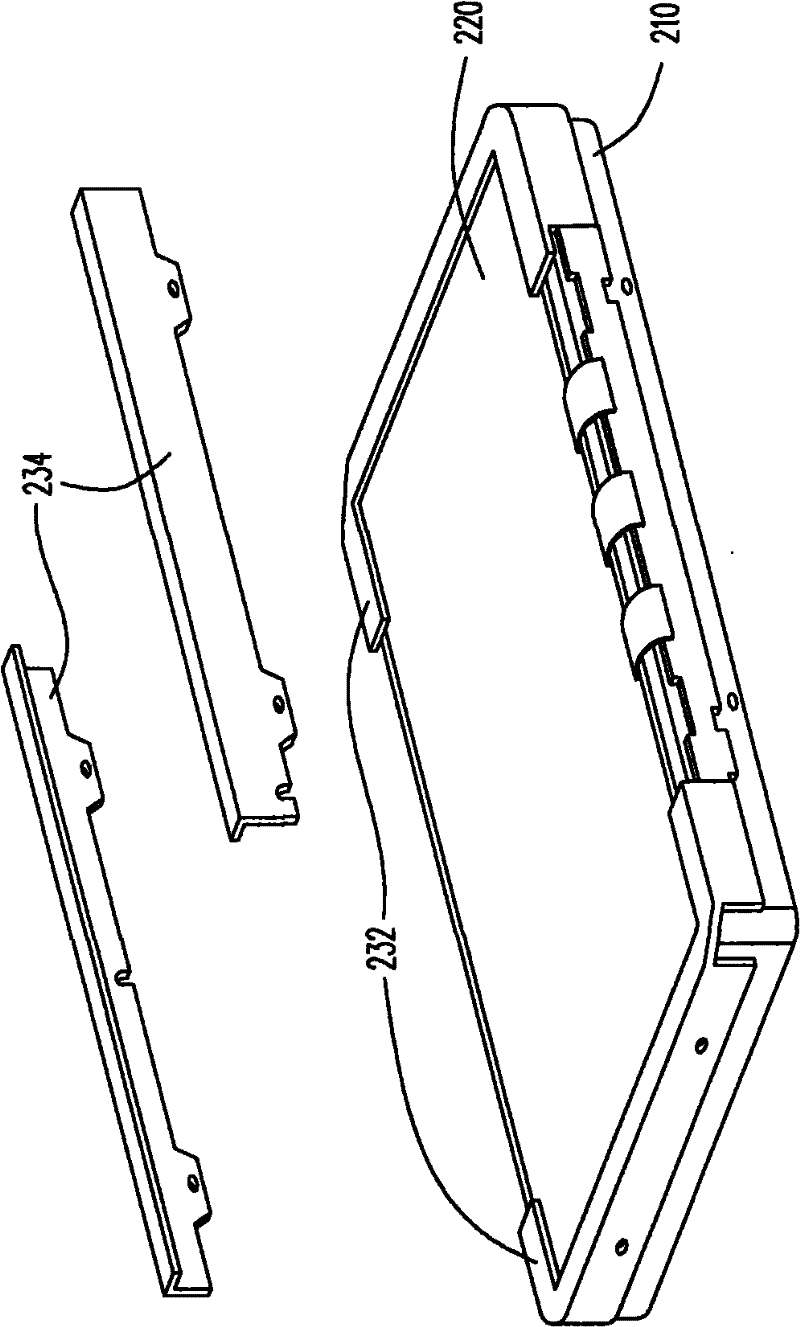

[0049] Figure 3A-Figure 3D The assembly process of a liquid crystal display module according to an embodiment of the present invention is shown in sequence, Figure 4A-Figure 4D for Figure 3A-Figure 3D A cross-sectional view of the structure in the assembly flow shown.

[0050] First, if Figure 3A and Figure 4A As shown, the backlight module 310 has a bearing frame 320 , and the bearing frame 320 has a first edge 320 a and a second edge 320 b opposite to each other on the light emitting side 310 a of the backlight module 310 . In this embodiment, a fitting portion 322 protruding from the light emitting side 310 a is formed on the first edge 320 a of the carrying frame 320 , and a top surface of the second edge 320 b is a plane 324 . In this way, when the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com