A vibration-damping component of a washing machine and the washing machine

A washing machine and component technology, which is applied in the field of laundry equipment, can solve the problems such as the noise of the outer tub parts colliding with the box and the shutdown of the washing machine, and achieve the effects of reducing vibration noise, reducing the amount of swing, and improving the vibration reduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

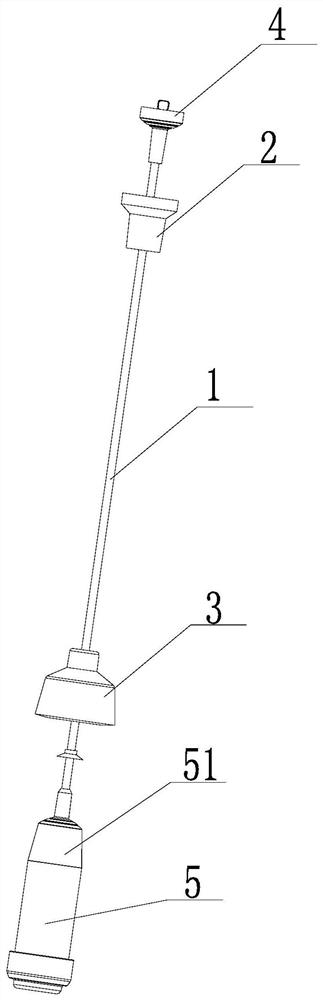

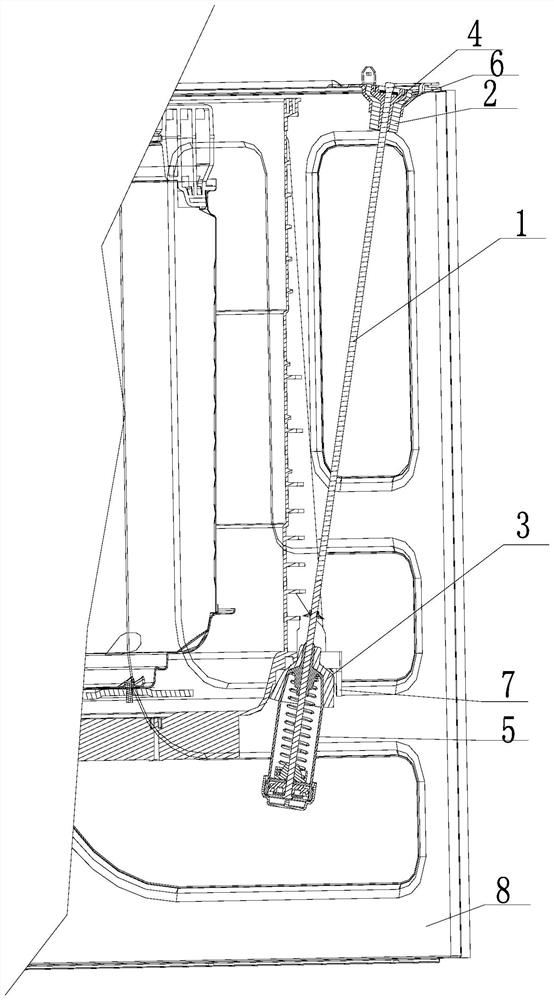

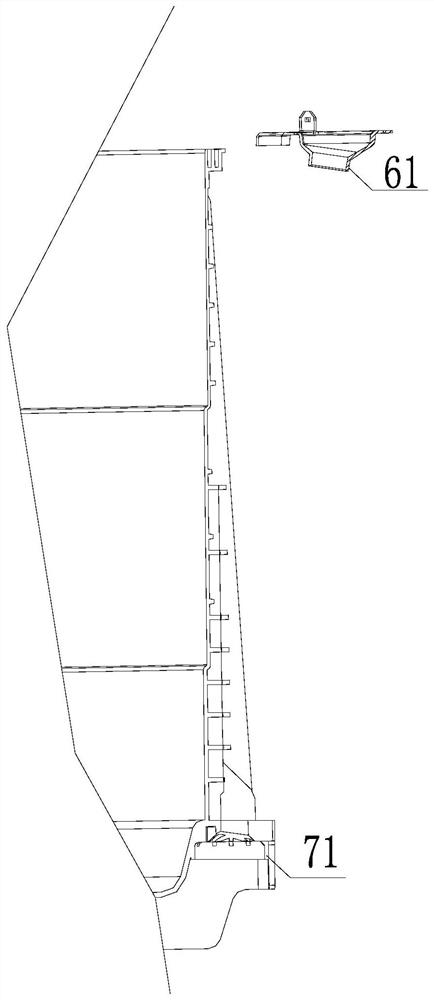

[0061] like Figure 1-3 As shown, in this embodiment, the vibration damping component of the washing machine is arranged on the pulsator washing machine.

[0062] The vibration damping component of the washing machine, including

[0063] A boom 1, one end of the boom 1 is provided with a boom seat 4, and the other end is provided with a vibration damping unit 5,

[0064] It is characterized in that it also includes

[0065] The first damping sleeve 2 for blocking the displacement of the boom base 4 is sleeved on the outer side of the boom base 4;

[0066] The second damping sleeve 3 for blocking the displacement of the vibration damping unit 5 is sleeved on the outer side of the vibration damping unit connecting end 51 , and the vibration damping unit connecting end 51 is the end connecting the vibration damping unit 5 with the washing machine.

[0067] The first damping sleeve 2 is provided with a through hole that matches the shape and size of the boom seat 4 .

[0068] ...

Embodiment 2

[0077] like Figure 1-Figure 3 As shown, in this embodiment, the vibration damping component of the washing machine is arranged on the pulsator washing machine.

[0078] The vibration damping component of the washing machine, including

[0079] A boom 1, one end of the boom 1 is provided with a boom seat 4, and the other end is provided with a vibration damping unit 5,

[0080] It is characterized in that it also includes

[0081] The first damping sleeve 2 for blocking the displacement of the boom base 4 is sleeved on the outer side of the boom base 4;

[0082] The second damping sleeve 3 for blocking the displacement of the vibration damping unit 5 is sleeved on the outer side of the vibration damping unit connecting end 51 , and the vibration damping unit connecting end 51 is the end connecting the vibration damping unit 5 with the washing machine.

[0083] Compared with the first embodiment, the more specific

[0084] The shape of the outer side of the first damping sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com