Method for finishing a gear surface

A finishing and gear technology, applied in the direction of elements with teeth, belts/chains/gears, gear teeth, etc., can solve the problem of not knowing the information about the amount of blank removal, not allowing it, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The following description is merely exemplary in nature and is not intended to limit the invention, its application or uses.

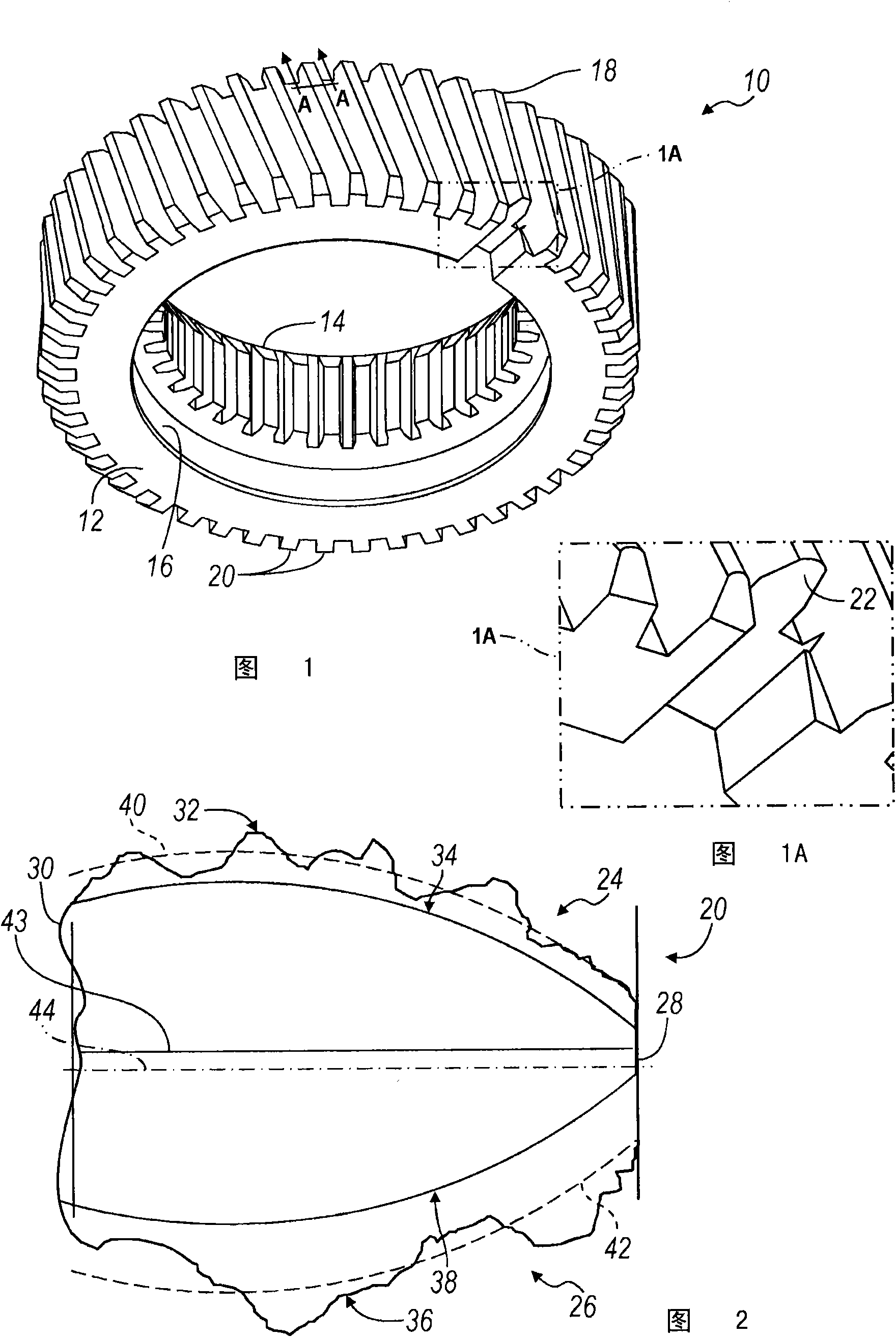

[0077] refer to figure 1 , an exemplary workpiece for use with the present invention is indicated by reference numeral 10 . In the example provided, while workpiece 10 is a spur gear, workpiece 10 may be other types of gears without departing from the scope of the present invention. The workpiece 10 includes a first side 12 disposed opposite a second side 14 . The workpiece 10 also includes an inner surface 16 and an outer surface 18 . A plurality of gear teeth 20 are disposed on the outer surface 18 . Each tooth 20 extends from the first side 12 to the second side 14 . In the example provided, the teeth 20 are disposed at an angle relative to the first side 12 and the second side 14 (ie, the teeth 20 are helical teeth). However, it should be understood that the gear teeth 20 may be arranged in other configurations and angles on the outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com