Fastener locking structure for automobile

A fastener and anti-loosening technology, applied in the direction of threaded fasteners, locking fasteners, connecting components, etc., can solve the problem of reduced anti-loosening effect, complicated manufacturing process of triangular anti-rotation bosses, and triangular anti-rotation bosses. It is easy to damage and press the end face and other problems, so as to achieve the effect of preventing loosening and avoiding abnormal noise of the car body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Further illustrate structure of the present invention below in conjunction with accompanying drawing:

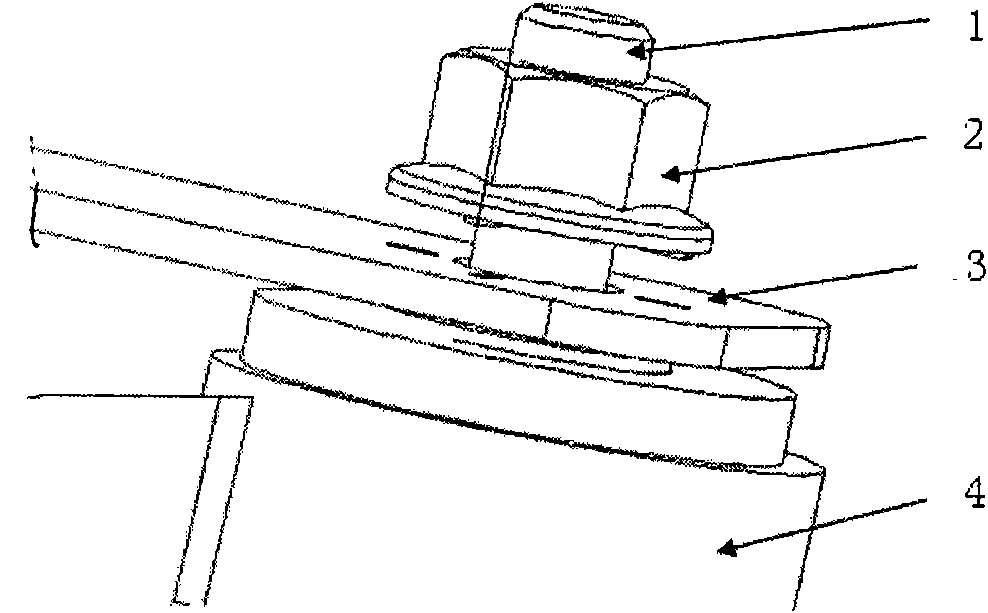

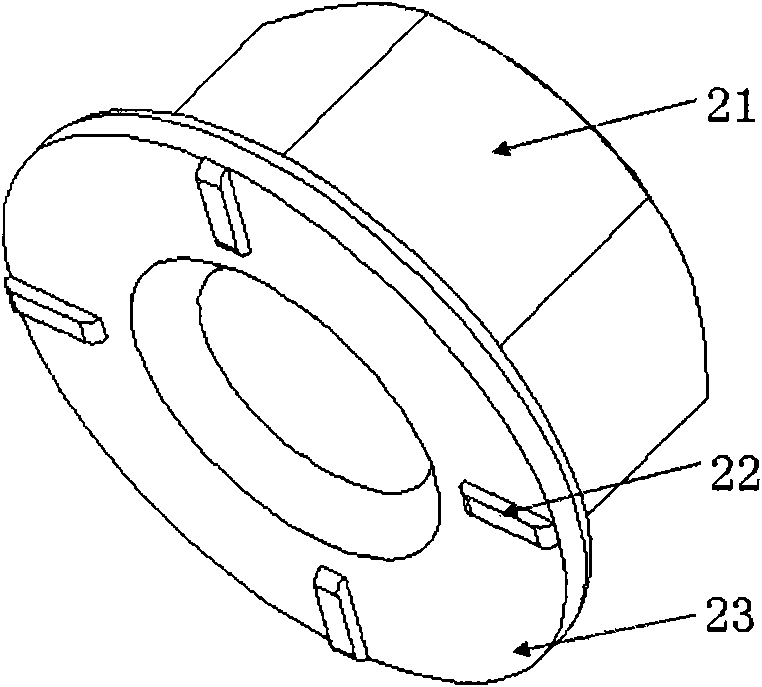

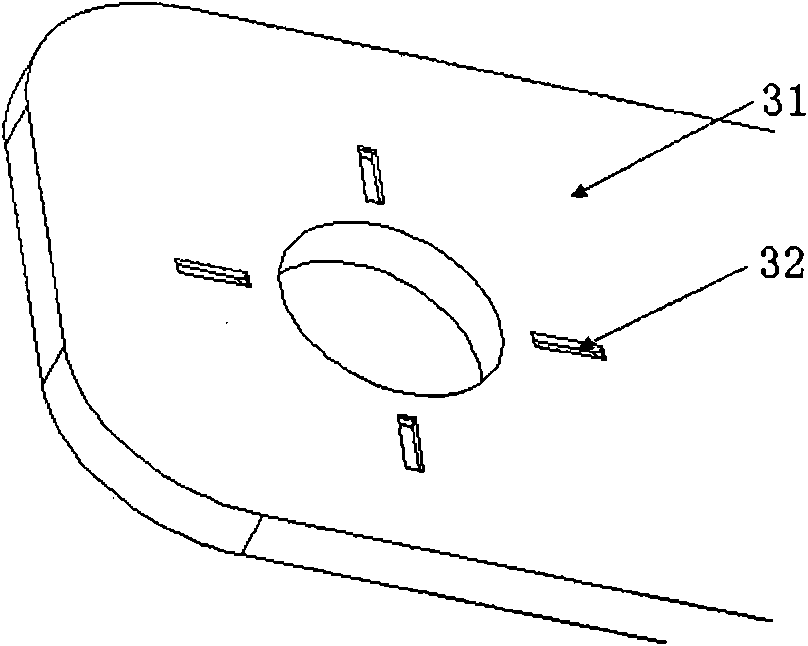

[0017] see figure 1 , the anti-loosening structure of the fastener includes a fastening bolt 1 , a nut 2 with an anti-rotation boss on the flange surface, a compression fitting 3 with an anti-rotation groove, and a body part 4 . The end face of the nut 2 combined with the compression fitting 3 is designed as a flange surface 23, and four anti-rotation bosses 22 are evenly arranged on the flange surface, correspondingly on the compression fitting 3 in contact with the nut. The compression end surface 31 is provided with four rotation grooves 32 , so that the anti-loosening bosses 22 of the nut flange surface 23 can fall into the anti-loosening grooves 32 of the compression fitting 3 .

[0018] see figure 2 , the anti-rotation boss 22 is a rectangular parallelepiped short side rounded corner boss, there are four, evenly distributed on the flange surface 23.

[0019]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com