Garlic combined harvester

A combined harvester and garlic technology, which is applied to excavator harvesters, harvesters, and topping machines, etc., can solve the problems of different lengths and long garlic stems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

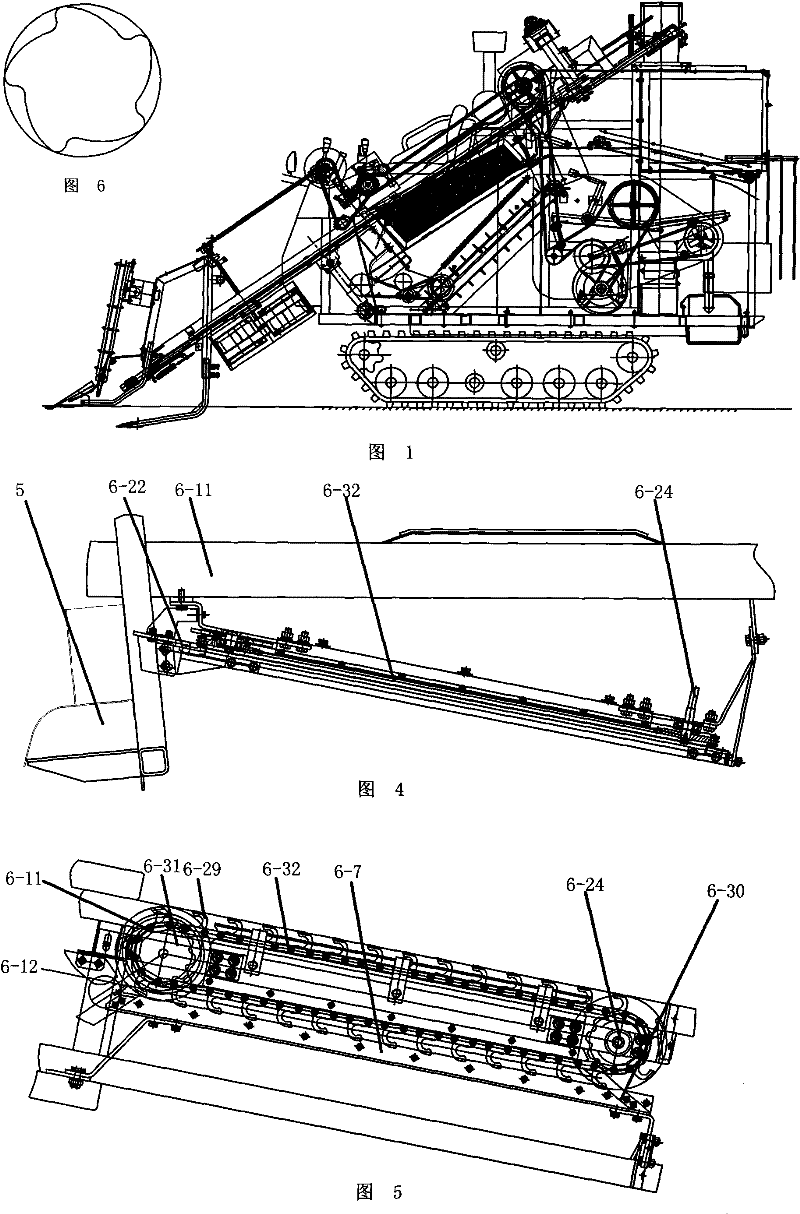

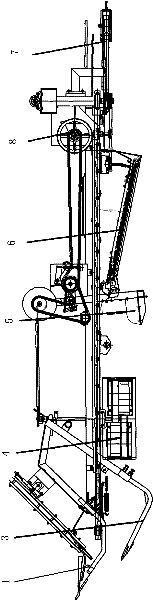

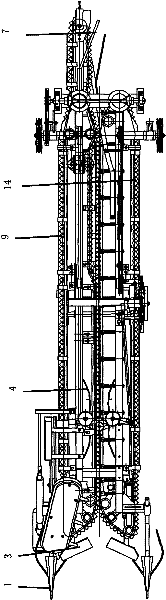

[0016] The garlic combine harvester of the present embodiment is as figure 1 As shown in , the whole machine is placed on the drive chassis obliquely, and the main structure is as follows figure 2 with image 3 Shown, identical with prior art, frame front end is equipped with left and right digging shovel 3 that is " eight " font distribution, and left and right digging shovel 3 both sides are left and right crop divider 1 . Above the left and right excavating shovels 3 are the left and right loops extending from front to rear to the rear end of the frame (that is, the left and right conveyor chains form loops respectively) to clamp the conveyor chains 14 and 9, and the two clamp conveyor chains are adjacent to each other. Edge clamping fit. The rear end of the frame is connected with the seedling throwing conveyer chain 7 as the seedling throwing device, which is used to throw out the garlic seedlings after cutting off the head of garlic. Its improvement is that the align...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com