Method for making personalized jacket for women

A production method and a technology for tops, applied in the field of garment processing, can solve difficult problems and achieve the effects of simple operation, fashionable and comfortable wearing, and strong personalization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

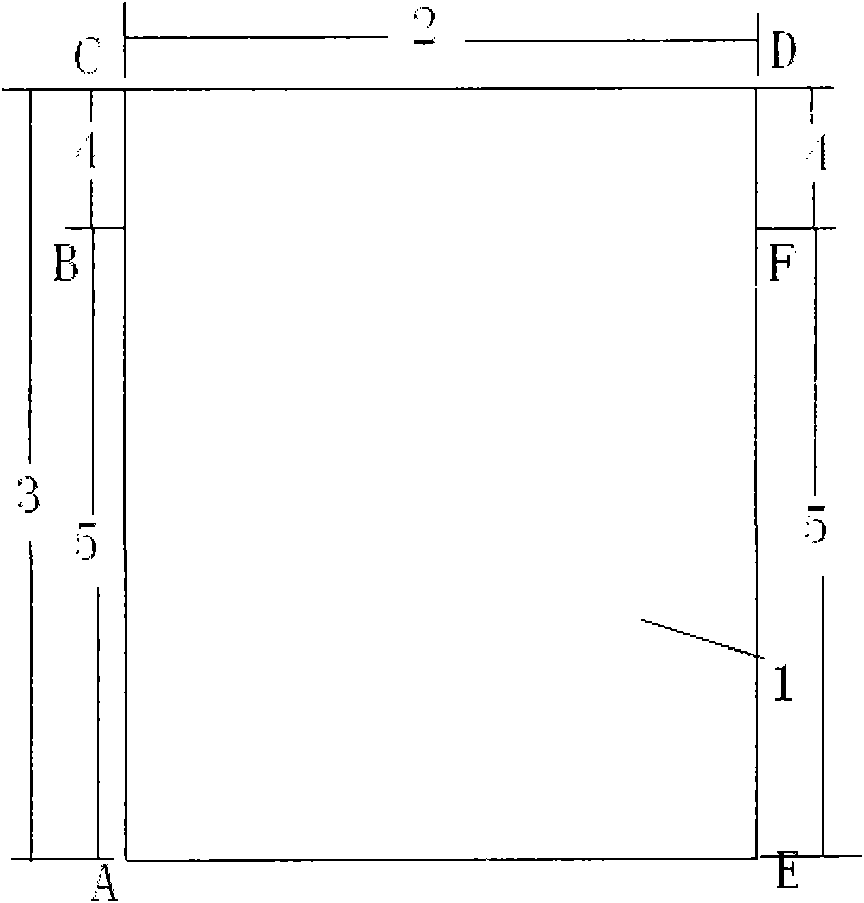

[0013] Such as figure 1 As shown, first cut out two pieces of horizontal elastic fabric (1), the size of the fabric: the width of the fabric is equal to (2), the length of the fabric is equal to the length of the garment plus the length of the two hems (3). Align the fronts of the two pieces of fabric facing inward, and seam the parts below the armhole (section AB, EF) of the two length sides to form a side seam (5). The two pieces of fabric in the armhole part (section BC, section FD) must Separate and overlock individually to form the armhole (4).

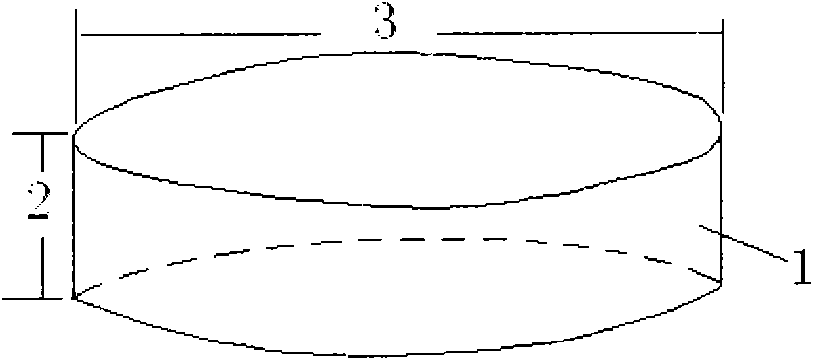

[0014] Such as figure 2 As shown, knit a loop fine rib collar (1) with a needle: the height (2) is 5 cm, and the width (3) is the shoulder width measurement.

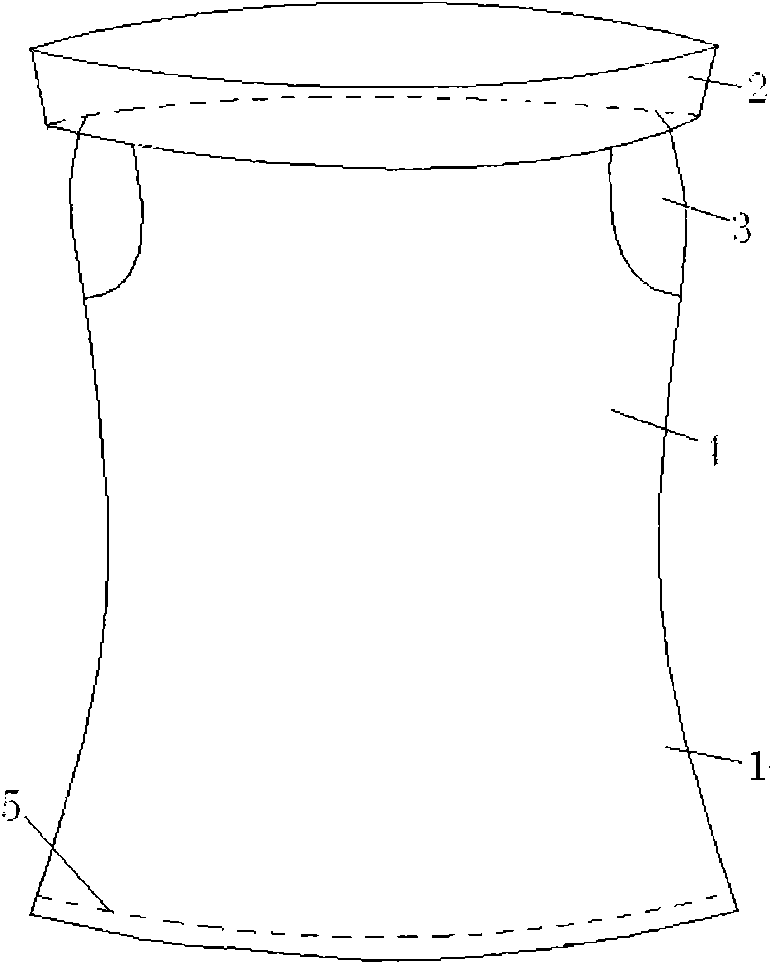

[0015] Such as image 3 As shown, the ribbed collar and the upper edge of the body (4) are sewn together to form a one-line collar (2), the bottom edge is folded inward and cut and sewed (5), and finally a personalized women's top (1) is formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com