Method for angle-dependent color value correction

A technology of angle correlation and angle, which is applied in the direction of color measurement device, spectrometry/spectrophotometry/monochromator, general parts of printing machinery, etc. It can solve the problem of incomparability and inability to realize reliable quality control of substrates, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

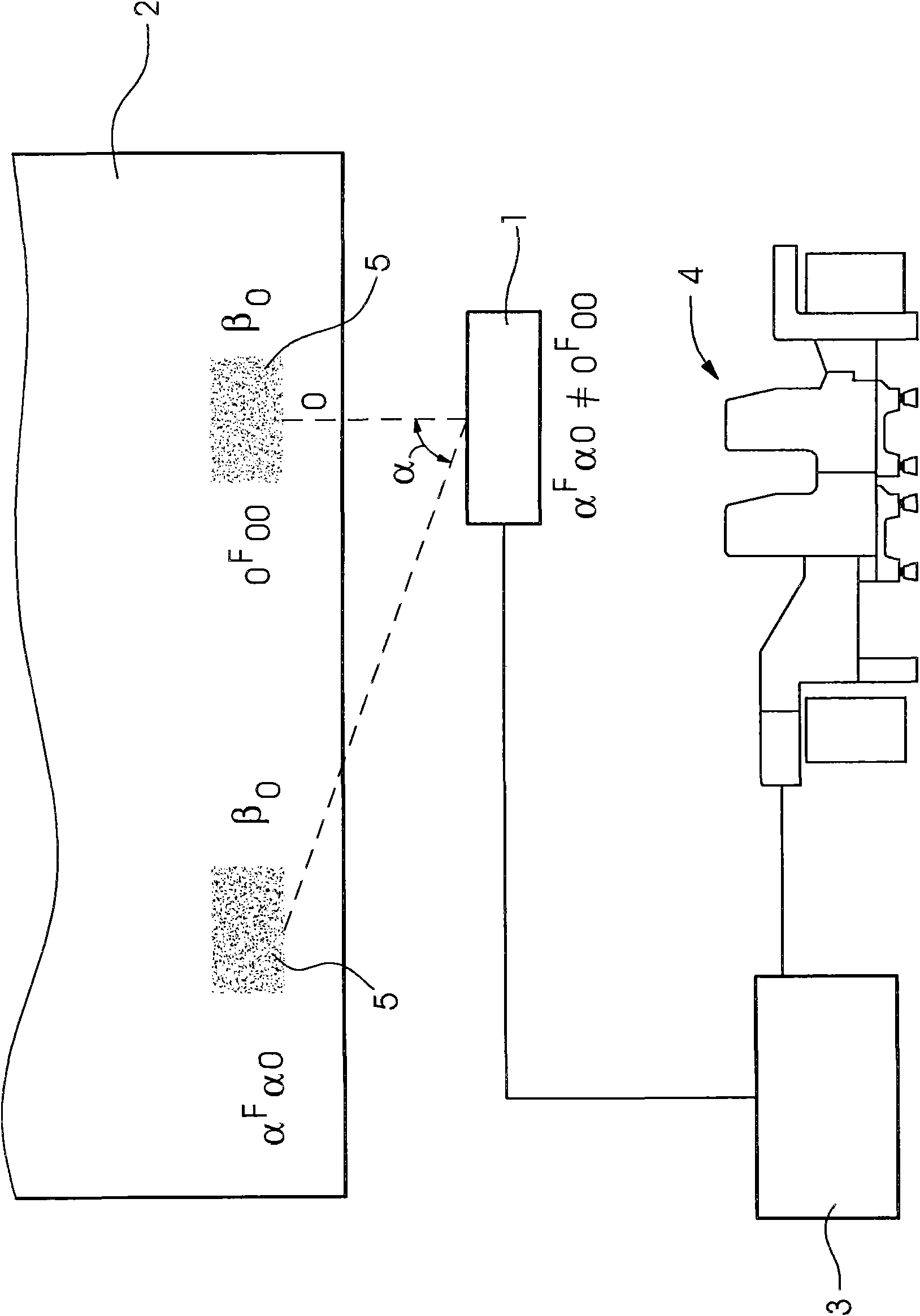

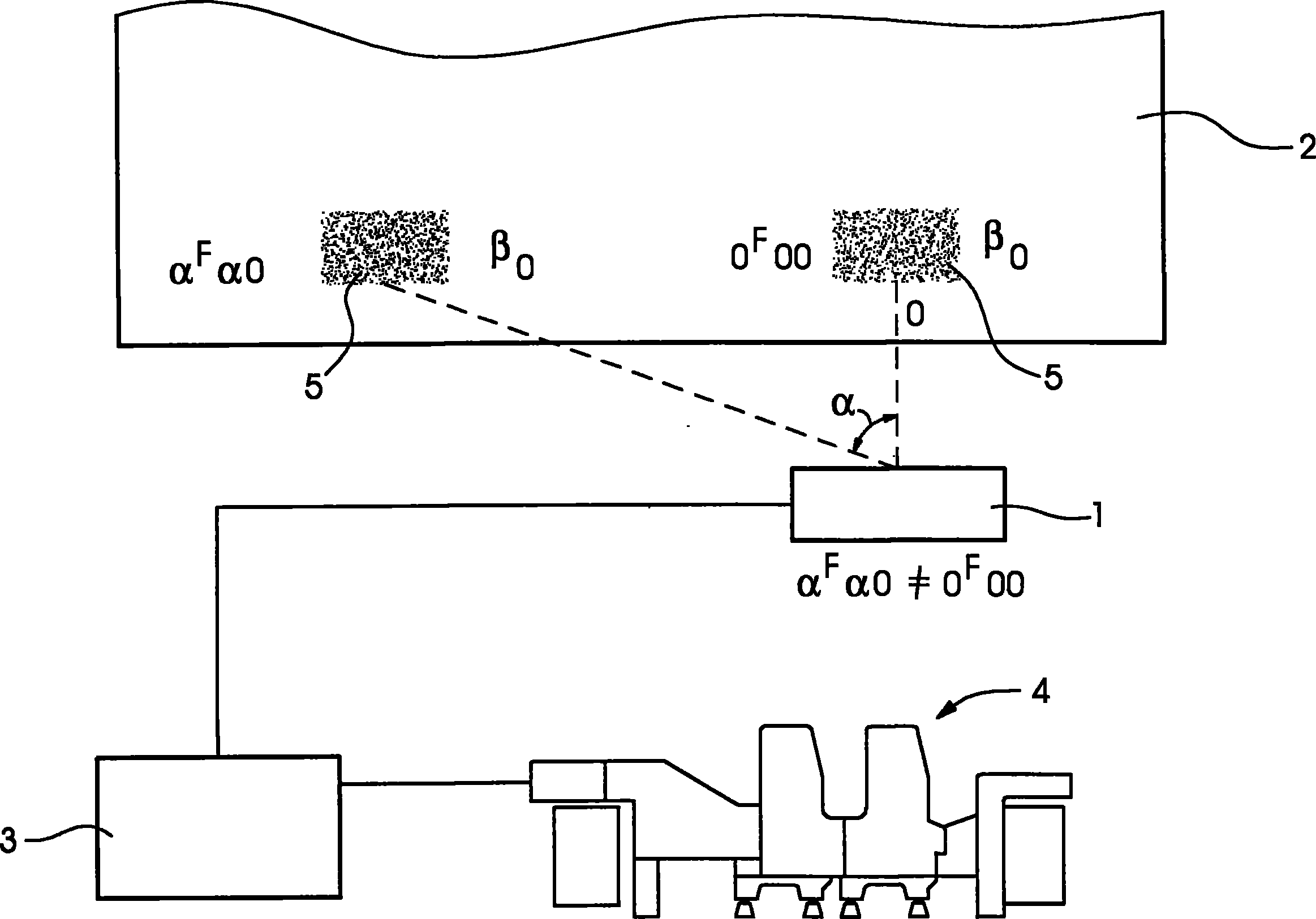

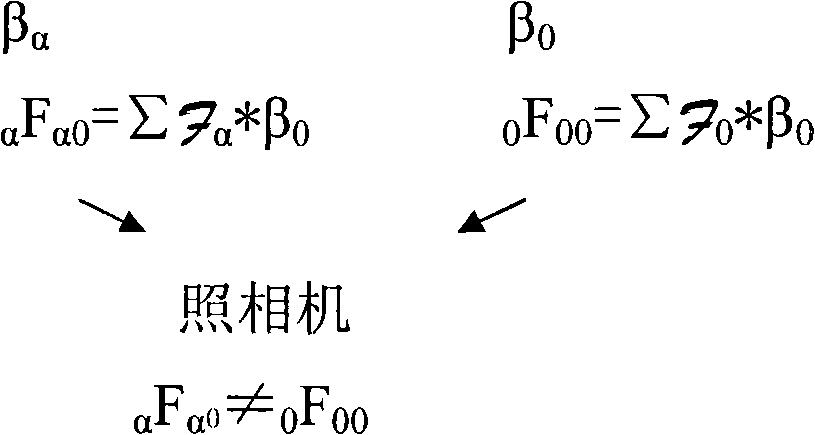

[0014] A sheet-fed offset printing press 4 is shown schematically in the figure. The sheet-fed offset printing press 4 includes, for example, two printing units, a feeder and a delivery. Furthermore, the printing press 4 is connected to a computer 3 , which simultaneously serves as a control computer for the printing press 4 . In addition, an RGB camera 1 is connected to the computer 3 as a color sensor, which in the present case detects a sheet-shaped printing material 2 . In the diagram shown, the color measurement of the printing material 2 is carried out outside the printing press 4 . However, the camera 1 can also be arranged in one of the printing units, preferably in the last printing unit of the printing press 4 , and detect the printing material 2 directly in the printing press. It can be seen in the figure that two color areas 5 of the same color are detected under different viewing angles α. The color area 5 on the right is detected under the viewing angle α=0, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com