Automatic feeding device for stacked porous material

A technology of automatic feeding and feeding devices, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of production line production efficiency constraints, design costs, high manufacturing costs, core rods cannot be designed with supports, etc., to achieve cost Inexpensive, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

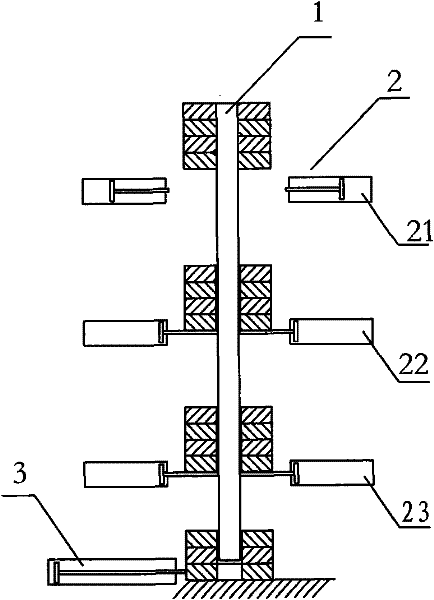

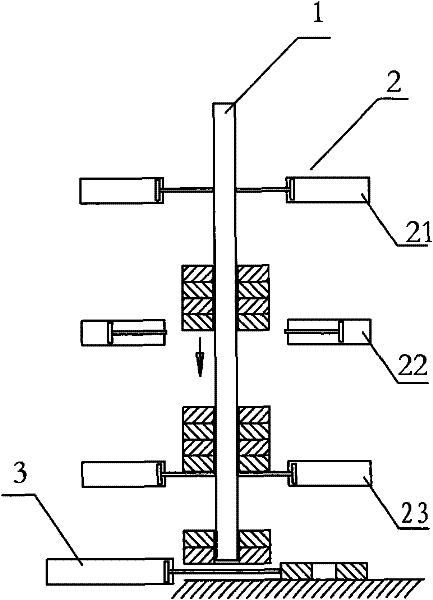

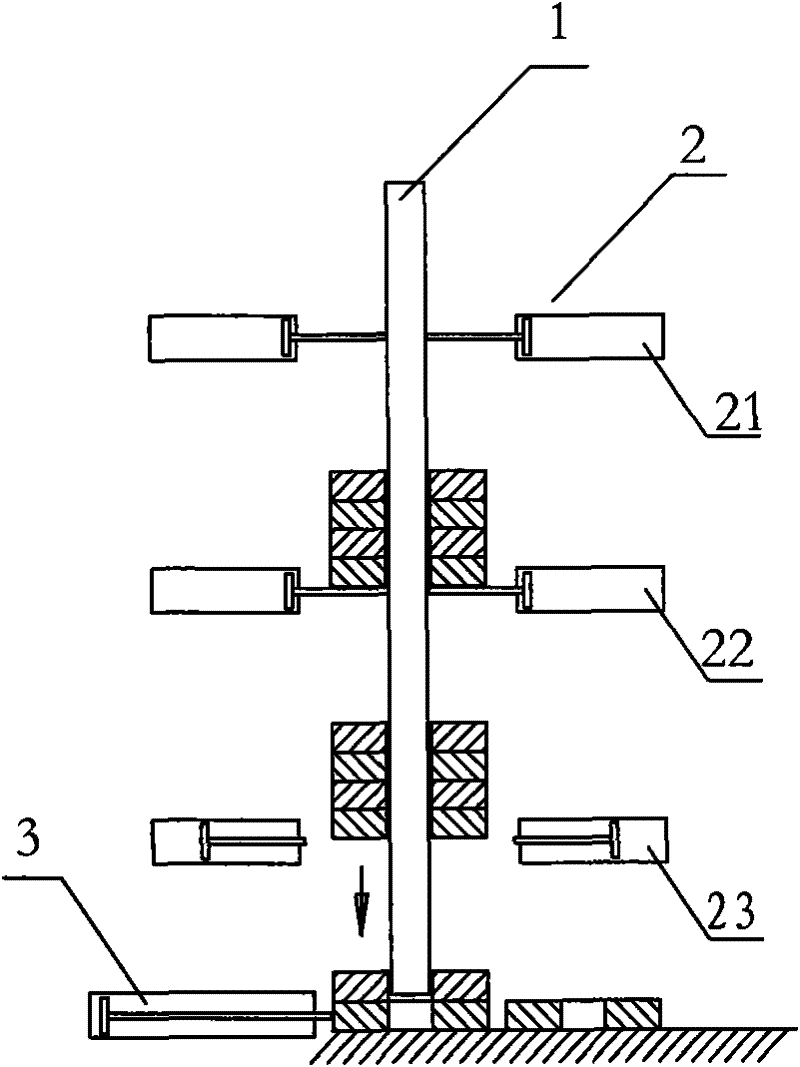

Image

Examples

Embodiment 3

[0031] The controlled telescopic link in embodiment 3 is an air cylinder or a hydraulic cylinder, but in fact it can also be a mechanical structure such as a rack and pinion.

[0032] Such as Figure 8 and Figure 9 The fourth embodiment shown differs from the above-mentioned embodiments in that the corer rod 1 is a composite rod composed of a plurality of struts, so as to adapt to the polygonal inner hole of the porous material. The controlled clamping rod mechanism in this embodiment can be any one of the above-mentioned specific embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com