Water-solubility polyphenylene sulfide and preparation method thereof

A technology of polyphenylene sulfide and sulfonated polyphenylene sulfide, which is applied in the field of water-soluble polyphenylene sulfide and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

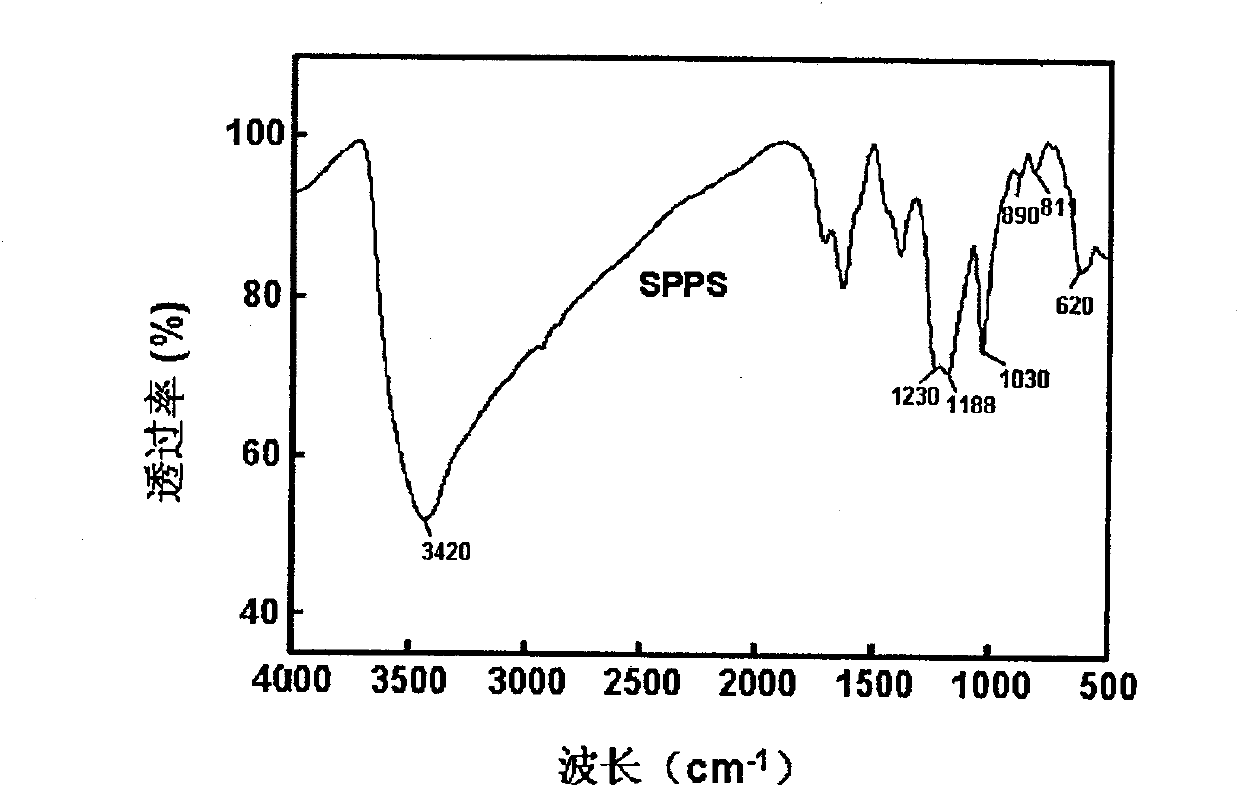

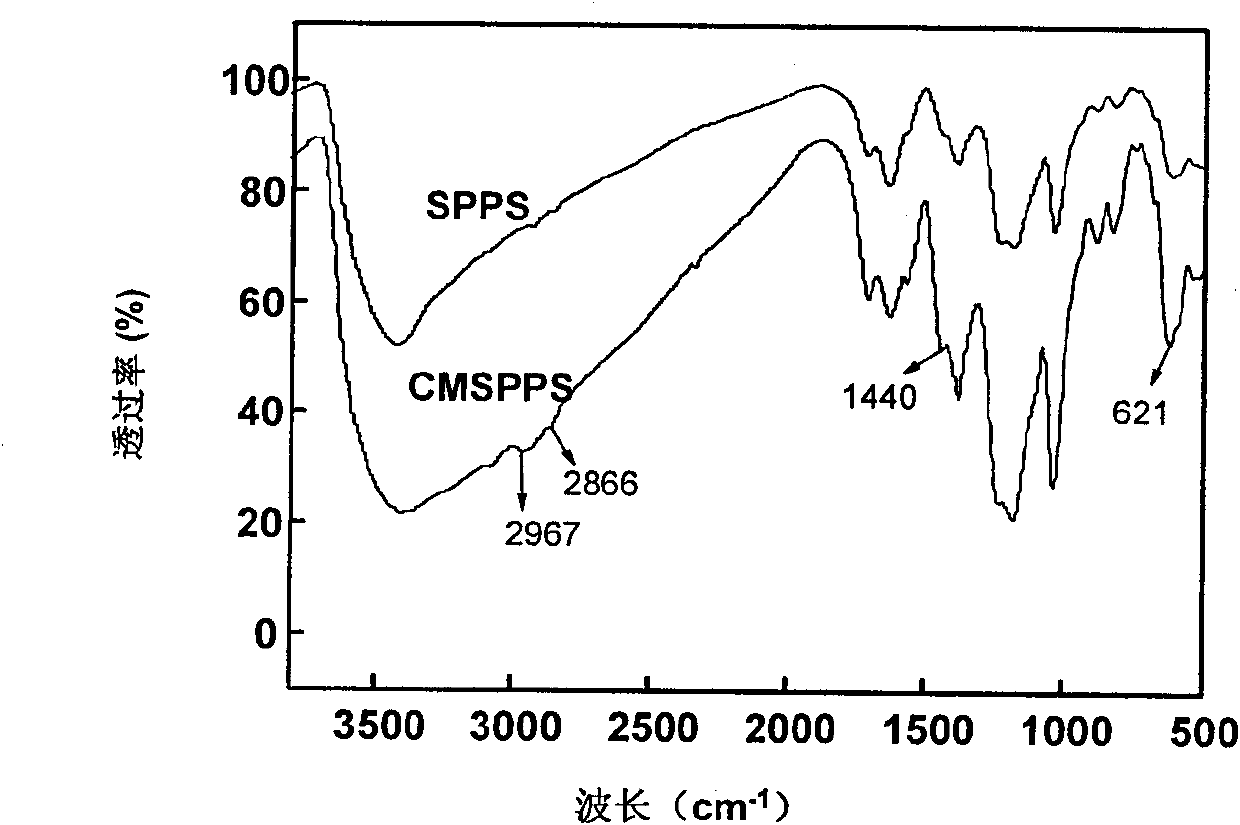

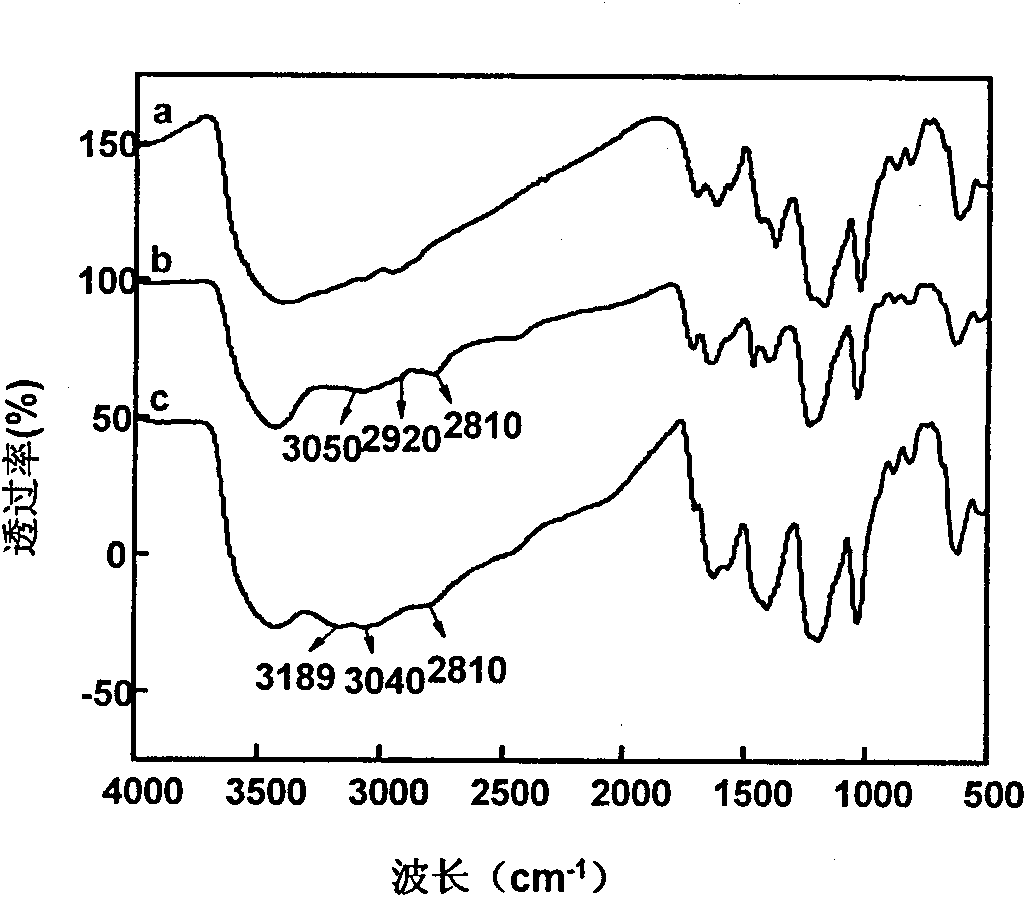

Method used

Image

Examples

Embodiment 1

[0042] Sulfonate 10g of polyphenylene sulfide with 200ml of sulfuric acid with a fume content of 20-25% at 105°C for 4h, then when the temperature of the mixture is lowered to 15°C, first add the sulfonated polyphenylene sulfide The mass fraction is counted as 3% iron trichloride catalyst, and then 30ml of 1,4-dichloromethoxybutane is added dropwise thereto while stirring, and reacted for 4h at 30°C, and then use a salt content of 4% The ice-water mixture was purified and washed repeatedly until the pH value of the filtrate was 7, and the obtained solid was dried to constant weight; first, the obtained chloromethylated polyphenylene sulfide solid was added into 70 mL of trimethylamine aqueous solution with a concentration of 2 mol / L and stirred to dissolve, and then Adjust the pH to 4.0-5.0, and react at 20°C for 7 hours, then add absolute ethanol to precipitate, filter with suction, and wash repeatedly with absolute ethanol 4-5 times, and dry the obtained solid at 80-90°C to c...

Embodiment 2

[0044] Sulfonate 10g of polyphenylene sulfide with 150ml of sulfuric acid with a fume content of 20-25% at 80°C for 4 hours, then when the temperature of the mixture is lowered to 15°C, first add the sulfonated polyphenylene sulfide The mass fraction is counted as 5% ferric chloride catalyst, and then 50ml of 1,4-dichloromethoxybutane is added dropwise to it while stirring, and reacted for 6h at 15°C, and then use a salt content of 4% The ice-water mixture was purified and washed repeatedly until the pH value of the filtrate was 7, and the obtained solid was dried to constant weight; first, the obtained chloromethylated polyphenylene sulfide solid was added into 60 mL of diethanolamine aqueous solution with a concentration of 5 mol / L and stirred to dissolve, and then Adjust the pH to 8.0-9.0, react at 40°C for 10 hours, then add absolute ethanol to precipitate, filter with suction, and wash repeatedly with absolute ethanol for 4-5 times, and dry the obtained solid at 80-90°C to...

Embodiment 3

[0046] Sulfonate 10g of polyphenylene sulfide with 130ml of sulfuric acid with a fume content of 20-25% at 105°C for 2 hours, then when the temperature of the mixture is lowered to 15°C, first add the sulfonated polyphenylene sulfide The mass fraction is counted as 2% ferric chloride catalyst, then 70ml of chloromethoxyoctane is added dropwise to it while stirring, and reacted for 12h at 0°C, and then purified with an ice-water mixture with a salt content of 4%. And repeatedly washed until the pH value of the filtrate was 7, and the obtained solid was dried to constant weight; first, the obtained chloromethylated polyphenylene sulfide solid was added into 50 mL of trimethylamine aqueous solution with a concentration of 5 mol / L and stirred to dissolve, and then the pH was adjusted to 9.0- 10.0, and react at 20°C for 7h, add absolute ethanol to precipitate, filter with suction, and wash repeatedly with absolute ethanol 4-5 times, and dry the obtained solid at 80-90°C to constant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com