Resealable beverage can end and methods relating to same

A resealing, can end technology, used in the field of beverage can ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention provides a resealable end for a beverage can and related methods of making and using the resealable end. The examples described below illustrate several aspects of the invention, but are not limiting.

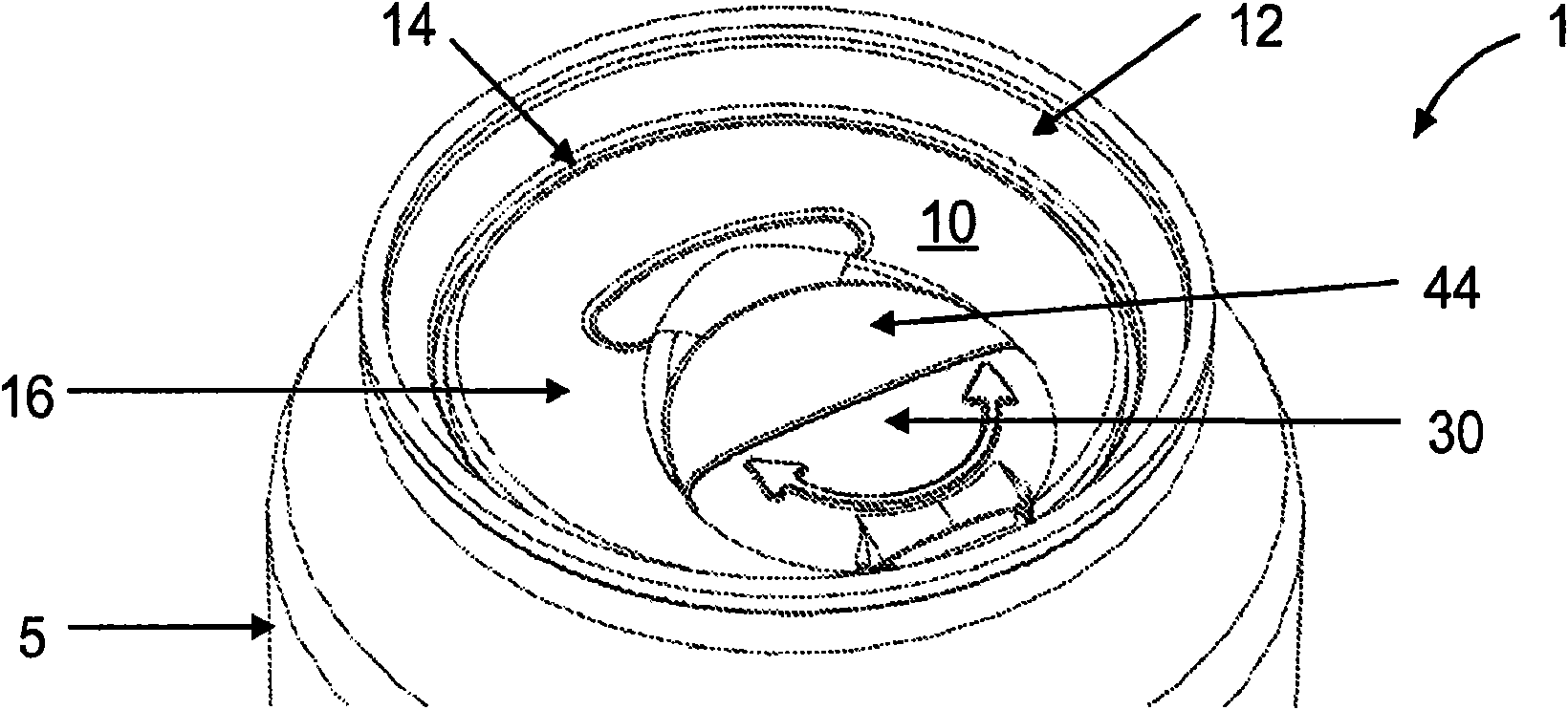

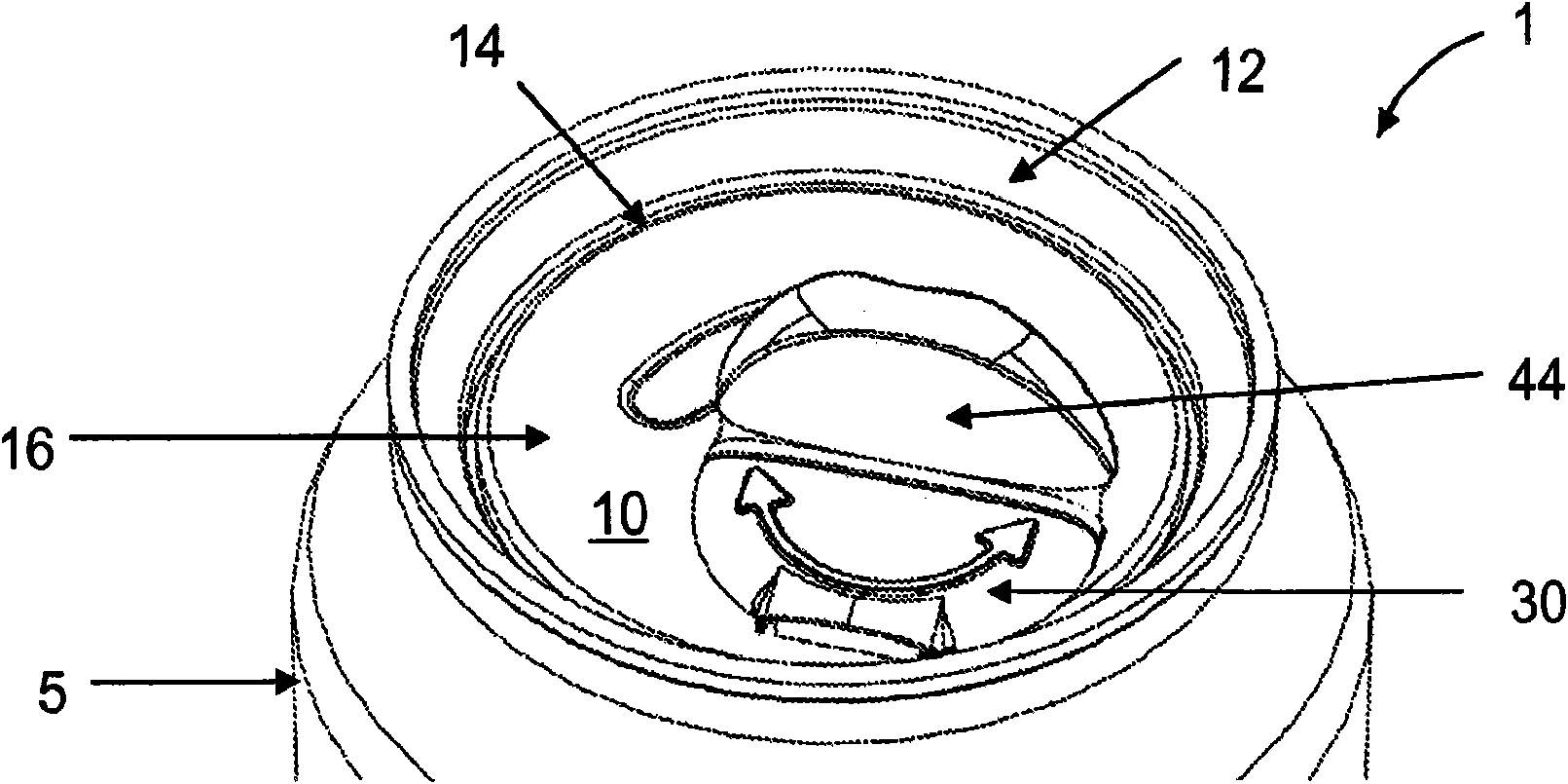

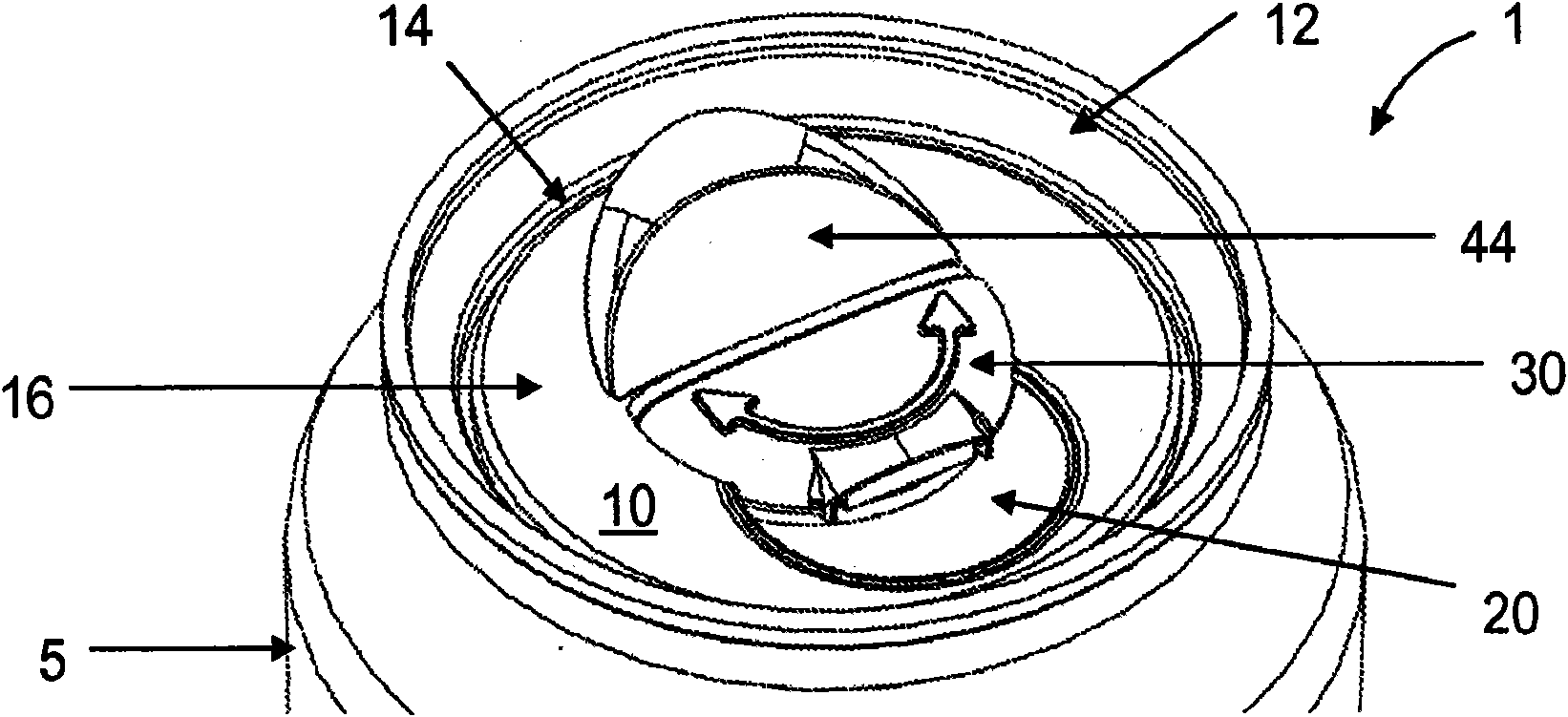

[0063] refer to Figure 1A to Figure 1C , a resealable beverage can 1 includes a conventional hollow body 5 and a resealable end 10 . The reclosable can end 10 includes a peripheral wall 12 , a countersink 14 at the base of the wall 12 , a central panel 16 and a closure 30 . The invention includes an unjoined can end and a can end joined to the beverage can body. So for example in Figure 2A In , can end 10 is shown shaped to form a double seam 18, which may be conventional. Preferably, the can end 10 is made from conventional can end stock material of conventional thickness.

[0064] Such as Figure 1C As shown in , the can end 10 also includes an aperture 20 formed in the central panel 16 . The edge forming the hole 20 is preferably formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com